Value proposition in Welding industry through the IoT qualification ... register functionalities...

Transcript of Value proposition in Welding industry through the IoT qualification ... register functionalities...

Agenda

• Kemppi Oy

• Welding industry – Trends and phenomena's

• Processes around the welding and possible value potential areas

• Kemppi Welding Management software

• Requirements for effective IT system

6.6.2016 Value proposition in Welding industry through the IoT2

CEO

Anssi Rantasalo

Kemppi Oy

• Founded in 1949 by Martti Kemppi

• Private family-owned company with the

third generation in charge

– Mrs. Teresa Kemppi-Vasama

Executive Chairman of the Board,

Kemppi Oy

– Mr. Antti Kemppi

Executive Chairman of the Board,

Kemppi Group Oy

• Over 600 employees in 16 countries

Global revenue

111M €

(2015)

16 subsidiaries

Headquarters

in Lahti,

Finland

Welding industry – Trends and phenomena'sProcesses around the welding and value areasKemppi Welding Management softwareRequirements for effective IT system

Norms and regulations

Date Value proposition in Welding industry through the IoT5

IEC

/ EN

60974-2 EN 3834-2

EM

C

EM

F

EN 1090-2

IEC

/ EN

60974-3

IEC

/ E

N

60974-5

IEC / EN 60974-7

IEC / EN 60974-10ISO

EN

50504

IEC 61000-3-12

CISPR 11: Class A.

IEC / EN 60974-11

ASME IX

AWS

AS/NZS 1554.1 CE

Requirements for documentation are increasing

Value proposition in Welding industry through the IoT9

How much do we really know about quality of welding?

Value proposition in Welding industry through the IoT10

Need for more transparent welding production

Value proposition in Welding industry through the IoT11

Welding industry – Trends and phenomena's

Processes around the welding and value areasKemppi Welding Management softwareRequirements for effective IT system

Processes around the welding

Value proposition in Welding industry through the IoT13

WeldingWelding

preparationPainting

Final Assembly

and testingDeliveryInspection

Product

Planning

Project

planning and

configuration

Production

adjustment

Receiving

goods

Production management – Production structure, internal logistics

Resource

planning &

management

Financial and

accounting

Documentation

Standardization

and

requirements

Supplier and

partner

management

Procedures and

qualification

management

Customer and

shareholder

management

Sourcing

Warranty

management

Inventory management and

consumables

Maintenance

Project, risk and issue management

Logistics

Safety at work

ICT and technology operations

Asset

management

Possible value potential areas – Our perspective

Value proposition in Welding industry through the IoT14

Welding monitoring and WPS

compliance control

Improved repair-rate

through the transparency

Improved Information

management for Inspectors

Improved safety

in production

Improved stakeholder

and customer

relationship

Automatized

documentation

processes

Improved WPS

management and

prolongation

processes

Transparency to sub-

contractors welding

processes

Up-to date

inventory levels

Improved production

planning and

management through

the more efficient

reporting

Preventive fleet

management

Possible value potential areas – Our perspective

Value proposition in Welding industry through the IoT15

Welding industry – Trends and phenomena'sProcesses around the welding and value areas

Kemppi Welding Management softwareRequirements for effective IT system

Date Presentation name / Author17

WeldEye is a solution to manage

welding, quality control and documentation

WeldEye

WeldEye modules – Basic solution

Value proposition in Welding industry through the IoT18

Managing welding procedure

specifications (WPS) according

the most important standards

Welding Procedures

Includes all personnel's and

welder qualification

certificates and their renewal

processes

Personnel and

qualifications

Includes welding quality

management functionalities

welding procedure

specification and

qualification compliance

control functions

Quality management,

Welding procedure

and qualification

control

Includes welding- and project

management, welding

inspection and document

register functionalities

Welding project

management

Establish value from customer operations

Value proposition in Welding industry through the IoT20

Idea: Find value from customer operations

• Establish new capabilities and tools to support more effective

welding management processes

• Recognize our selves as a value partner instead of machine supplier

Supportive phenomena's

• Industrial trends, standardization and tightening requirements for

documentation and transparency

• Lean methodology

• Digitalization

Requirements

• Suitable and effective solution for welding management

• Consultancy and IT-service capabilities in sales, delivery and

operational services

• Understanding of customer structure, environment, processes,

value-chain and requirements

Targets

• Commit customer to develop their own manufacturing processes

• Commit customer to machine supplier

• Establish value from customers processes. Get profit from welding

management solutions and related services

Background

• Welding is important part in manufacturing industry

• Industry is old fashioned with traditional culture

• Main drivers are standardization, quality and effectiveness

• Documentation process in welding requires a lot of manual work

• Production management operations and performance indicators

varies

• Economically shipyards and manufacturers are struggling

• Labor union is in strong position

Example 1. Improved and automatized welding documentation management

Value proposition in welding industry / Tuomas Kivisaari21

• Offshore sub-contractor used 7 persons for 2

weeks for gathering welding documentation in

single project

• Each person used 2 hours in day for gathering

documentation

• Company holds 60 projects in year

• With better documentation management and

company reduced documentation time for 67%

Man hours in documentation in year

Value potential through the documentation process

Example 2. Improved repair-rate through the welding monitoring and WPS compliance control

Value proposition in welding industry / Tuomas Kivisaari22

• Manufacturing company take new WPS

management and compliance control system in

use

• Because of more transparent control the repair

rate in welding improved over 40% from 3,9 %

to 2,3 %

• Savings realized through the reduced repairing

costs and time saving for valuable work

Improved repair rate through the WPS compliance control

Value potential through the improved repair rate

Welding industry – Trends and phenomena'sProcesses around the welding and value areasKemppi Welding Management software

Requirements for effective IT system

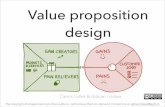

Successful IT-management system in welding – Requirement areas

Value proposition in Welding industry through the IoT25

External factors

External requirements

Customer operations

Internal Capabilities

Operating model

Effective

IT system

Standards

Regulations

Qualifications

Customer request’s

Expectations

Service levels and tools

Customers

Functionality,

Maintainability

Usability

Performance

Cyber security

Availability

Roles KPI’s

Suppliers

OperationsDecision

rights

Service levels and tools

Structures Rules