UNLOCKING SMARTER ROUTES FOR HEAVY CARGO · The MTC 15 can quickly and simply turn any quay into a...

-

Upload

phungkhanh -

Category

Documents

-

view

212 -

download

0

Transcript of UNLOCKING SMARTER ROUTES FOR HEAVY CARGO · The MTC 15 can quickly and simply turn any quay into a...

UNLOCKINGSMARTERROUTES FORHEAVY CARGO

MAMMOET TERMINALCRANE, MTC 15

The MTC 15 can quickly and simply turn any quay into a heavylift terminal providing a new way for the transfer of heavycomponents at waterside locations. This may give any port aleading edge in an increasingly demanding market.

The MTC 15 offers the following advantages:• Low ground bearing pressure• Ease of operation• Containerized mobilization and demobilization• Simple and fast assembly and disassembly• Lifting capacity up to 600 t

MAMMOET THE BIGGEST THING WE MOVE IS TIME

2

Heavy industries are crossing new frontiers every day to satisfythe demand for more energy, materials and infrastructure acrossthe planet. Opening up opportunities in new markets and raisingquality of life mean more remote locations need to be accessed.This adds to the logistical challenges when constructing newpower plants, mining facilities and developing oil and gasfacilities. These can be particularly difficult in places where theinfrastructure for mobilizing heavy loads and materials may belimited or non-existent.

For many construction and turnaround projects the mostsuitable way to deliver heavy components is to transport themby water. However, often those ports or watersides that arelogistically optimal are not suited for heavy lifting activities,leading to longer and more expensive delivery routes. Mammoethas used its expertise in the logistics of oversized and heavyobjects to develop a new type of crane that overcomes thisbottleneck: the Mammoet Terminal Crane, MTC 15.

The Mammoet Terminal Crane, MTC 15, quickly and simply turns any quay into a heavy lift

terminal, unlocking faster and more efficient routes for heavy cargo. Easily mobilized,

assembled and disassembled, it provides a simple yet effective way to lift heavy loads in

remote locations without the need for ground reinforcement works.

THE MTC 15

The MTC 15 can quickly andsimply turn any quay into aheavy lifting terminal. ASSEMBLY IS SWIFTLY CARRIED OUT WITH ONE 80 TON CRANE

UNLOCKING FASTER ROUTESWorking in places only accessible via ‘the path less travelled’,throws up many challenges for transporting heavy cargo andMammoet loves a challenge. With the MTC 15, we havecreated a unique piece of heavy lifting equipment which canopen up better routes for moving heavy loads.

In addition to its maximum lifting capacity of 600 tons, it has amaximum load moment of 15,000 ton meter, comparable to a1,250 ton crawler crane. No other heavy lifting device on themarket combines the MTC 15 features with such high liftingcapacity. It also provides quick lifting and boom movements,with a lifting speed of up to 1.6 m/min delivered by four 22ton winches.

The specially designed combination of features makes it idealfor small quays and other waterside locations where

traditional heavy lifting equipment cannot operate. It has alow ground-bearing pressure of 10 ton per meter2 whichcan be further reduced with additional load spreaders.Loading and offloading heavy project cargo becomespossible without the need to reinforce the quay.

Easily shipped to any port capable of receiving containers,then assembled and erected in just seven days, the MTC 15is ideal for temporary use. There is no need for complicatedtransport solutions and assembly requires only one 80 toncrane. It is also possible to place the crane on a skid systemto enable either movement or relocation. Once it is in place,cargo can be offloaded quickly without a requirement forlarge crawler cranes or a heavy-lift ship. This makes thelogistics simpler, safer and more sustainable, saving clients’time and money.

Easily shipped to any port

capable of receiving

containers, then assembled

and erected in just seven

days, the MTC 15 is ideal

for temporary use.

3

MAMMOET THE BIGGEST THING WE MOVE IS TIME

WATERSIDE FLEXIBILITYThe containerization of the MTC 15 means it can be easilydelivered to both sea ports and up river locations. Thiseliminates many problems, such as the need for reinforcedroads or bridges, encountered when delivering other heavylifting equipment, e.g. a crawler crane, to a remote site.

The MTC 15’s clever design solves another potential logisticsproblem; there is no need for the costly transport of ballast tothe site. Using water as ballast, readily available at the type ofsite where it will be deployed, up to twenty containers can befilled to provide 520 tons of ballast material. The containers arefilled with bags, just like those used to ship wine in bulk. Theseare filled with water at the site and use a simple counterweightsystem to signal if ballast levels need to be checked.

The MTC 15 is also very easy to operate; its control console isoperated remotely, allowing the operator to maneuver the cranefrom the best possible viewing position. Once assembled, thecrane requires only one operator.

MTC 15 KEY FEATURESThe MTC 15 offers the following features:• 600 metric tons off-loading capacity at 25 m radius• Load moment of 15,000 tm• Lifting speed of up to 1.6 m/min with four 22 twinches

• Radius up to 41 m• Low ground-bearing pressure of 10 t/m2

• Swiftly and easily put in place, in just seven days using80 t mobile crane

• Only one MTC 15 operator needed when assembled• A temporary solution for occasional or one-offactivities

• Available in two configurations with different back mastlengths (shown on data sheet)

4

The containerization of the MTC 15 means it can be

easily delivered to both sea ports and up river locations.

environmental risks. Our expertise enables us to identifyopportunities at the planning, preparation and executionstages of each project to reduce waste, use less energy andmanage risks safely.

Using the MTC 15 limits the environmental impacts of aproject by reducing transport and using materials on site.The MTC 15 has also been constructed by reusing steel fromprevious cranes, reducing its environmental footprint. Usingsand or water on-site for ballast reduces environmentalimpacts further.

All the vehicles in Mammoet’s fleet meet stringentinternational safety standards and are subject to strictmaintenance programs for maximum safety and reliability.The MTC features typical crane control systems such asangle sensors, boom stops and a ballast indication systemall of which contribute to a safety system which warns theoperator if there are problems detected and will stop theoperation if safe limits are exceeded.

KEEPING SAFE, HELPING THE ENVIRONMENTWorking with Mammoet guarantees high levels of quality andsafety. Both by working with clients to optimize their logisticschains and by providing the highest quality equipment andprofessionals, Mammoet can help improve safety and reduce

THE EASY TO USE CONTROL CONSOLE IS REMOTELY OPERATED

5

MAMMOET THE BIGGEST THING WE MOVE IS TIME

6

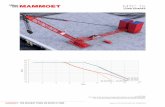

SPECIFICATIONS

MTC 15 MTC 15 MTC 15–2 MTC 15–2 40–28–600 46–38–600 45–29–600 45–39–600Max. lifting capacity 600 t 600 t 600 t 600 t

Radius (R) 6.3–36 m 7.1–41.1 m 6.8–41 m 6.8–41 m

Back mast length (LBM) 27.8 m 38.6 m 28.6 m 39.4 m

Main boom length (LMB) 40.5 m 46.2 m 45.2 m 45.2 m

Main boom angle (�) 27.1–82.5 ° 27–82.5 ° 26.1–82.6 ° 26.1–82.6 °

Max. hoisting height (HH)

@ minimum radius 34.5 m 40 m 41.5 m 41.5 m

@ maximum radius 12.5 m 15 m 16 m 16 m

Max. hoisting depth (HD)

@ minimum radius 0 m 4.5 m 0 m 0 m

@ maximum radius –23 m –20 m –26 m –26 m

Max. ground bearing pressure1

@ counterweight arrangement 8 t/m2 8 t/m2 13 t/m2 13 t/m2

@ base frame arrangement 17 t/m2 17 t/m2 18 t/m2 18 t/m2

No. of ballast containers 20 20 20 20

Max. weight of the ballast containers 520 t 520 t 502 t 502 t

Ballast material Water or sand Water or sand Water or sand Water or sand

Operational wind ≤ 12 m/s ≤ 12 m/s ≤ 12 m/s ≤ 12 m/s

Auxiliary crane 80 t mobile crane 80 t mobile crane 80 t mobile crane 80 t mobile crane

6000

LBM R

α

8000

L MB

HH

HD

1500

0

1250

011

700

Dimensions are in millimeters

t

m

Radius305 10 15 20 25 35 40 45

100

150

200

250

300

350

400

450

500

550

600

650

Cap

acity

40-28-600

46-38-600

45-29-60045-39-600

MTC 15SPECIFICATIONS

1 Ground bearing pressure can be reduced with more load spreaders. t = metric tons

The content in this document is mentioned for reference use only. Values may differ from current data. Always contact Mammoet for current project calculations.

Mammoet helps clients improve construction efficiency andoptimize the uptime of plants and installations. We lift,transport, install and decommission large and heavystructures.

We believe our business is about time: uptime, turnaroundtime and time to market. To our customers, time is thecurrency that matters most. That’s why we strive to bringtheir deadlines forward.

It’s an integrated, daily effort shared by everyone atMammoet, in every aspect of our services: creativeengineering, careful planning and safe delivery. Over twohundred years of operational experience, from jobs in a widevariety of circumstances, ensures that Mammoet can comeup with effective approaches for challenging situations.

Our services are focused on the petrochemical and miningindustries, civil engineering, power generation and offshoreprojects. The logistic challenges in these industries aregrowing daily. Factors such as remote locations, harshclimates and a strong emphasis on the environment areconstantly driving us towards smarter and safer solutions.

Mammoet’s services in Engineered Heavy Lifting andTransport comprise:• Heavy Lifting Services• Heavy Transport Services• Plant Turnaround / Shutdown Management• Site-wide Construction Services• Modular Construction• Factory-to-Foundation / Logistics• Emergency response & Wreck removal• Decommissioning of onshore and offshore installations• Trading in new and used equipment worldwide

We have the largest and most modern fleet of equipmentavailable in the world. The unique capability of ourequipment, combined with our experience, enables us toget the best results from our services and unlock moreefficient ways of working. Strict maintenance programsensure maximum safety and reliability. After all, when ourcustomers choose Mammoet, we want them to be sure ofone thing: that Mammoet professionals and theirequipment get the job done well, safely and on time.

Discover more on mammoet.com

1 MAMMOET CANADA WESTOffice: Edmonton, CanadaTel.: +1 780 449 0552E-mail: [email protected]

2 MAMMOET CANADA EASTOffice: Guelph, CanadaTel.: +1 519 740 0550E-mail: [email protected]

3 MAMMOET EUROPEOffice: Schiedam, the NetherlandsTel.: +31 10 204 2740E-mail: [email protected]

4 MAMMOET RUSSIAOffice: Moscow, RussiaTel: +7 495 956 08 38E-mail: [email protected]

5 MAMMOET USAOffice: Rosharon, USATel.: +1 281 369 2200E-mail: [email protected]

6 MAMMOET MIDDLE-EASTOffice: Dubai, United Arab EmiratesTel.: +97 14 812 8000E-mail: [email protected]

7 MAMMOET ASIA-PACIFICOffice: SingaporeTel.: +65 6861 1638E-mail: [email protected]

8 MAMMOET LATIN-AMERICAOffice: São Paulo, BrazilTel.: +55 11 4440 0333E-mail: [email protected]

9 MAMMOET SOUTH-AFRICAOffice: Johannesburg, South-AfricaTel.: +27 11 882 4499E-mail: [email protected]

2

5

8

34

6

9

7

1

Would you like to get in touch? Please find your nearest Mammoet regional head office here.