Ultra Efficient Light Duty Powertrain with Gasoline Low ...

Transcript of Ultra Efficient Light Duty Powertrain with Gasoline Low ...

Ultra Efficient Light Duty Powertrain with Gasoline Low Temperature Combustion

This presentation does not contain any proprietary, confidential, or otherwise restricted information

Project ID: ACE094DE-EE0006839

Keith Confer – Principal InvestigatorDelphi Advanced Powertrain

2015 DOE Vehicle Technologies ReviewJune 11th, 2015

ACE094 Project Overview

Timeline

• Project start: 10/1/2014

• Project end: 9/01/2018

• Percent complete: 18%

• VT Programmatic Barrier• Improve the efficiency of light-duty engines for

passenger vehicles through advanced combustion and minimization of thermal and parasitic losses.

• Project primarily addresses VT Program Barriers:

• A: Advanced engine combustion regimes• B: Emission controls• D: Effective engine controls

Budget• Total project funding share

• DOE : $9,812,865 (40%)• Contractor: $14,719297 (60%)

• Budget Period Funding• BP1 2014-2015 : $2,935,672• BP2 2015-2016 : $3,442,329• BP3 2016-2017 : $2,158,100• BP4 2017-2018 : $1,276,763

Partners• Delphi - Project Lead• HATCI (Hyundai America Technical Center Inc.)• University of Wisconsin - Madison• Oak Ridge National Lab• Umicore

Relevance and Project Objectives• Relevance:

The Advanced Combustion Engine R&D (ACE R&D) subprogram supports the mission of the Vehicle Technologies Program to develop more energy-efficient and environmentally friendly technologies for highway transportation vehicles.

This project directly addresses two of the three primary ACE R&D directions:

• Improve the efficiency of light-duty engines for passenger vehicles and heavy-duty engines for commercial vehicles through advanced combustion research and minimization of thermal and parasitic losses;

• Develop aftertreatment technologies integrated with combustion strategies for emissions compliance and minimization of efficiency penalty

• Project Goal The project will develop, implement and demonstrate a low temperature

combustion scheme called Gasoline Direct-injection Compression Ignition (GDCI). The project will demonstrate a 35% fuel economy improvement over the baseline vehicle while meeting Tier 3 emissions levels.

This Project supports the Vehicle Technologies Program’s goal to improve the efficiency of light-duty engines for passenger vehicles through

advanced combustion and minimization of thermal and parasitic losses.

Relevance and Project Objectives• Project Objective: Demonstrate the fuel consumption reduction capability of

GDCI combustion at a vehicle level. The primary project focus is on a number of technical risks which must be overcome for a production-viable technology:

• Development of an aftertreatment system that is effective in dealing with the low-temperature challenges of a highly efficient engine.

• Further refinement of the GDCI combustion system to achieve near-ideal air/fuel mixture preparation for high efficiency and low HC and CO emissions

• Demonstration of transient control with high EGR levels during real-world transient driving maneuvers and over a broader range of ambient conditions

• Objectives (October 2014 – March 2015)

• Finalize and kick-off project teams • Evaluate and document GDCI baseline performance (Fuel Economy, Power and

Emissions) • Complete first samples of Gen2 GDCI engine hardware and debug

This Project supports the Vehicle Technologies Program’s goal to develop aftertreatment technologies integrated with combustion strategies for

emissions compliance and minimization of efficiency penalty

Approach / Strategy• The project will employ a unique low temperature combustion scheme called Gasoline Direct-

injection Compression Ignition (GDCI) to achieve the targeted fuel economy improvements. High compression ratio with multiple late injections (similar to diesel) Gasoline which vaporizes & mixes easily at low injection pressure Low-temperature combustion process for Partially-Premixed Compression Ignition

• The project will develop an aftertreatment system approach that works with the low-temperature challenges of a highly efficient engine. Address: system content, system architecture, combustion strategies and catalysts materials Collaboration with Oak Ridge National Lab and Umicore Autocat USA

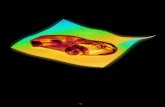

GDI Homogeneous HCCI - GasolineStratified Lean SI GDCI Diesel CI

Fuel-AirMixture

Air-Residuals-EGRMixture

Fuel-AirMixture

High Compression Ratio CI EnginesMedium Compression Ratio SI Engines

Air-Residuals-EGRMixture

Air-Residuals-EGRMixture

Approach / Strategy

Is the concept viable?

How to design an engine around the concept?

How to control the engine?

How to make a vehicle drivable?

How to meet FE and emissions targets?

How to have the vehicle function under all operating conditions?

How to meet all regulatory requirements?

How to have a production-level of performance?

2010

2014

2018

Engine design upgrades?

2008

SC

E

Gen

1 G

DC

I

Gen

1 G

DC

I

Gen

2 G

DC

I

Gen

3 G

DC

I

DOE ATP1

DOE ATP2

Gen

2

Gen

3

Develop, implement and demonstrate the fuel consumption reduction capability of GDCI at a vehicle level.

Engine control upgrades?

Approach / Strategy:Milestones• Milestones and go/no-go’s for FY 2014 and FY 2015

(note that project started in FY2015)

Project Decision PointsRecipient: DelphiProject: Ultra Efficient Light Duty Powertrain with Gasoline Low Temperature Combustion

Task Title Milestone Type

Milestone Description Anticipated Quarter

Status

Build Gen2 engines Milestone Gen2 GDCI engine assemblies built and ready for debug

Q1 2015 Complete

Engine and Vehicle Simulation

Milestone GT Drive engine simulation completed for the Gen2 in the ATP1 vehicle

Q2 2015 Complete

ORNL characterize Gen 2 GDCI LTC emissions

Go/No-GoGen2 engine built and characterized - Go/No-Go for Gen2 vehicle build activities

Q3 2015 On Target

Develop and build aftertreatment for Gen2 GDCI

MilestoneHigh performance low temperature exhaust aftertreatment system designed and built for use on the Gen2 GDCI development vehicle.

Q3 2015 On Target

Discussed later in this presentation

GT Drive simulation complete and Gen1 GDCI engine run for

true peak torque values

Gen2 engine running on

dynamometer. ORNL and Delphi

successfully characterized Gen1 vehicle using same tools required for

this task.Characterization of the vehicle

emissions, with cold FTP, forms the basis for the projects exhaust

aftertreatment work (key cornerstone of development work).

Technical Accomplishments and Progress:Background: Ultra Fuel Efficient Project EE0003258• Delphi and HATCI along with WERC demonstrated the potential of Gasoline Direct-injection

Compression Ignition (GDCI) with the UFEV project which concluded in September 2014

• Project culminated in a vehicle level demonstration of 39% combined City+Highway fuel economy improvement with a warmed-up engine relative to a 2009 port fuel injected baseline vehicle (also run warm).

• While fuel economy targets were exceeded, the emissions performance target (Tier 2, Bin 2) was not met.

Gen1 GDCI engine

GDCI vehicle running FTP at Delphi

This work was supported by the US Department of Energy, Office of Vehicle Technology Thank you to the DOE

Technical Accomplishments and Progress:Overview

• This project highly leverages the previous project’s hardware allowing early progress

• Project management activities and establishment of new team required significant effort in these early stages of the project

• Primary areas of technical accomplishments since the start of the project in October 2014 include: Controls development progress and testing using vehicle and engine

from UFEV project. Characterization of vehicle level emissions on FTP cycle High load dynamometer testing of Gen1 GDCI engine from UFEV project Build and debug of Gen2 GDCI single cylinder engine Build and debug of Gen2 GDCI multi-cylinder engines

Technical Accomplishments and Progress:Vehicle Level Progress

• ORNL & Delphi fully characterize emissions Teams from Delphi and ORNL tested the Delphi

Gen 1 GDCI vehicle under a variety of transient and steady-state conditions and made measurements of emissions. The objective of the testing was to characterize the vehicle-level engine–out transient emissions.

• Delphi EMS controls progress using vehicle from UFEV project FTP cycle run successfully from room

temperature Algorithms have been developed which

automate the cold start and warm-up transition to closed loop control.

Technical Accomplishments and Progress:Vehicle Level Progress• Vehicle-level Engine–out Transient Emissions Characterization with ORNL

• Catalyst replaced with an inert brick so that tailpipe and post-dilution-tunnelmeasurements are common with engine-out emissions

• Combustion efficiency as well as aftertreatment will be used to address emissions

Baseline emissions studies form the foundation for the projects aftertreatment development

Technical Accomplishments and Progress:Vehicle Level Progress• Vehicle emissions –

Emission data show transients as high contributors to emissions Several new algorithms have been developed that improve transient control Calibration of these algorithms is underway

Transient control of this new combustion process is one key to emissions reduction

• Build of Gen2 MCE engines Gen2 GDCI engine was designed by Delphi and HATCI outside of

Department of Energy funded projects. First Gen2 engine was completed for the project. Updates include:

• Increased Compression Ratio (15.5 vs 15.0 for Gen1)• New fuel system • New valvetrain • New thermal management system • New aftertreatment system • New piston and ring packs• Improved lubrication system • Reduced motoring and firing friction• Updated engine sensors and actuators

Technical Accomplishments and Progress:Hardware Build

Technical Accomplishments and Progress:Dynamometer Testing• Gen 1 GDCI Multi-cylinder Engine

The Gen 1 GDCI engine was run at high load to characterize the full-load performance of that design phase.

• Evaluated Injection strategies, boost systems, thermal system, fuel injection system, and valvetrain system modifications during testing

• Achieved torque needed for successful down-speeding & boost strategy

While additional full load development is needed, results for the first generation GDCI multi-cylinder engine met project expectations.

Gen1 GDCI engine on Dynamometer at Delphi

Original Calibration MapNew Full Load Map

Technical Accomplishments and Progress:Dynamometer Testing• Gen 2 GDCI Multi-cylinder Engine

The first Gen 2.0 GDCI engine was installed on the dynamometer & debugged

Includes a vehicle ready thermal management system, sensors, and actuators

Pre “break-in” motoring friction significantly reduced relative to Gen I engine

-140

-120

-100

-80

-60

-40

-20

00 500 1000 1500 2000 2500 3000 3500 4000

FMEP

(kPa

)

Engine Speed (RPM)

FMEP MCE-1

FMEP MCE-4

FMEP MCE-4R

Gen 2.0

Gen 1 – MCE1Gen 1 – MCE4Gen 1 – MCE4 RGen 2 dyno engine

Friction Mean Effective Pressure (FMEP) of Gen 2 GDCI engine versus previous Gen 1 GDCI builds

Collaboration and Coordination with Other Institutions

Oak Ridge National Laboratory - National LabAnalyze exhaust emissions samples after sample collection at the Delphi facility. (Collect, Analyze, Consult)

Hyundai America Technical Center, Inc. (HATCI), OEMEngineering design and analysis as well as prototype fabrication and testing at component, engine and vehicle levels. (Support, Resources)

University of Wisconsin Madison - UniversityCharacterization testing of gasoline fuel injectors. (Test)

Umicore Autocat USA – Tier 1 SupplierPrepare and test low temperature exhaust aftertreatment samples. (Analyze, Design, Formulate, Build, Consult)

Superior Township, MI

Oak Ridge, TN

Madison, WI

Auburn Hills, MI

Remaining Challenges and Barriers• Development of an aftertreatment system that is effective in dealing with

the low-temperature challenges of a highly efficient engine.

• Further refinement of the GDCI combustion system to achieve near-ideal air/fuel mixture preparation for high efficiency and low HC and CO emissions

• Demonstration of transient control with high EGR levels during real-world transient driving maneuvers and over a broader range of ambient conditions

Proposed Future WorkNext Steps• Characterize and map the Gen2 GDCI multi-cylinder dynamometer

engine. Refine combustion system to achieve near-ideal air/fuel mixture preparation and low

engine out emissions Optimize engine out temperature profiles for exhaust aftertreatment

• Develop low temperature exhaust aftertreatment system based on emissions data from ORNL and on the Gen2 temperature profiles Delphi and ORNL working closely with Umicore

• Further develop and refine controls and calibration of GDCI for improved fuel economy and emissions with an emphasis on vehicle transient operation.

Summary• Leveraging the previous projects hardware allowed early progress

• Project management activities and establishment of new team required significant effort in early stages of the project

• Primary areas of technical accomplishments since the start of the project in October 2014 include: Controls development progress using vehicle and engine from UFEV project. Characterization of vehicle level emissions on FTP cycle with ORNL High load dynamometer testing of Gen1 GDCI engine Build and debug of Gen2 GDCI single cylinder engine and multi-cylinder engine complete

• All Milestones were met on time

• Future Work for Calendar Year 2015 / 2016 Characterize Gen2 GDCI engine on dynamometer Develop low temperature exhaust aftertreatment system based on emissions results from

Gen1 vehicle and on Gen2 temperature profiles from dynamometer Refine controls and calibration of GDCI for improved fuel economy and emissions with an

emphasis on vehicle transient operation.

Thank you to the Department of Energy for supporting this project.

Responses to Previous Year Reviewers’ Comments

• This project was not reviewed last year but we look forward to your feedback this year.

Technical Back-Up Slides

Technical Back-Up Slide: Previous project results (UFEV Project EE0003258)• On a warm-start, combined FTP cycle, the GDCI vehicle achieved 39% improvement in fuel

economy relative to a baseline PFI vehicle, exceeding the DOE ATP target of 25%improvement and the project target of 35% improvement.

• While fuel economy targets were exceeded the emissions performance target (Tier 2, Bin2) was not met.

Delphi GDCI Vehicle Fuel Economy (mpg)

Cycle Run 1 Run 2 Run 3 Avg.City - EPAIII (Warm, uncorrected E10 fuel) 38.19 38.47 38.44 38.37Hwy (uncorrected E10 fuel) 57.04 57.86 59.54 58.15CAFE method Combined FE (Warm, corrected to E0) 46.21 46.66 47.11 46.66Percent Improvement over BaselineCombined FE comparison (Warm, corrected to E0) 38.0% 39.3% 40.7% 39.3%