Two Way Slab New

-

Upload

abdul-hamid-bhatti -

Category

Documents

-

view

13 -

download

2

description

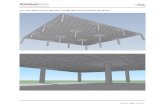

Transcript of Two Way Slab New

Sheet1Two Way Slab1- Minimum Thicknessla16ftlb16ftP64ft2(la+lb)Thickness4.267in(12 x P/180)h5in2- Dead Load CalculationR.C.C Unit Weight150CftD.L (Slab)62.5Psf(h/12 x 150)3- Roofing (Mud + Tiles)Assumed Thickness0inUnit Weight130CftD.L (Roofing)0Psf(6/12 x 130)4- Factored D.LF.D.L87.5Psf1.4 (D.L (slab) + D.L (Roofing))5- Live LoadLive Load140Psf(From Code)Factored Live Load238Psf(1.7 x 100)6- Wu Wu325.5Psf(F.D.L + F.L.L)7- Determination of Moment Co-efficientm (la/lb)1.00From end ConditionCase Type3DiscontinuousContinuousCa, neg0.05Cb, neg0.050Ca, dl, pos0.027Cb, dl, pos0.027Ca, ll, pos0.032Cb, ll, pos0.0328- Positive Moments at Mid SpanMa, pos4916.352ft-lb(Ca,dl,Pos x Wu x La2) + (Ca,ll,Pos x Wu x La2)58.996K-inMb, Pos4916.352ft-lb(Cb,dl,Pos x Wu x Lb2) + (Cb,ll,Pos x Wu x Lb2)58.996K-in9- Negative Moments at Continuous EdgeMa, neg4166.4ft-lbCa,neg x Wu x La249.9968K-inMb, neg4166.4ft-lbCb,neg x Wu x Lb249.997K-in10- Negative Moment at discontinous edgeMa, neg, discontinuous19.646K-in(0.333 x Ma, Pos)Mb, neg, discontinuous19.646K-in(0.333 x Mb, Pos)11- Check designM12.546K-inEnter the required value of Momentsf3Ksify60Ksii0.90(0.85-0.05(f - 4))i should be more than 0.650.9and less than 0.9Rhomax0.75RhobRhomax0.75 x [0.85 x i x f/fy x (87/87+fy)]fy in KsiRhomax0.017From above formula0.9dreq1.292ind = SQRT((M)/(i*fy(1-0.59)*Rhomax *fy/f)hreq2.292ind+1"(1" cover)Check hreq2.292inAs compared to hdesign5inOK12- Rho-Calculationfy60Ksif3Ksib12inh5ind4inMa, neg49.9968K-inMb, neg49.997K-inMa, pos58.996K-inMb, pos58.996K-inRho0.85 x f/fy x (1-SQRT(1-2.61 M (k-in) / (f x b x d2)))Rho a, neg0.005123Rho b, neg0.005123Rhomax0.017Rho a, pos0.006122Rho b, pos0.006122Rhomin0.003333333313- Steel Area CalculationMaximum Spacing should not be more than 2h i.e10inaRho a, neg0.0035As a, neg0.21in2Enter Rho value manually Provide # 3 @ 4" c/c with As a, neg0.25in2(As = (Rho a, neg x b x h))bRho b, neg0.0035As b, neg0.21in2 Provide # 3 @ 4" c/c with As b, neg0.25in2cRho a, pos0.0035As a, pos0.21in2 Provide # 3 @ 4" c/c with As a, pos0.25in2dRho b, pos0.0035As b, pos0.21in2 Provide # 3 @ 4" c/c with As b, pos0.25in214- Determination of failure modefy60Ksif3Ksii0.9As0.25in2Enter manuallyb12ind4a0.490in(Asfy)/(0.85f*b)c0.545ina/ic/dShould not be greater than 0.6. If so thensteel will yield before Concrete crushing.15- If c/d is less than 0.375 i.e in tension controlled region then tension failure will control and = 0.9 to be used in the formula M = Mn , Mn = Asfy(d-a/2)

Sheet2

Sheet3