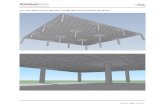

Two-Way Floor Slab

-

Upload

tyler-edgington -

Category

Documents

-

view

311 -

download

3

Transcript of Two-Way Floor Slab

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

82

Roof Design Two Way Slab. Cl 13.8 Slab Systems As elastic Frames

1) Criteria For Equivalent Frame Method CSA S23.3a) Within a panel , the ratio of longer to shorter span, center to center of supports, is not

greater than 2.0

b) Slab systems with beams between supports the relative effective stiffness of beams inthe two directions is not less than 0.2 or greater than 5.0.

Not Applicable as the roof slab is a flat slab without beams.c) Column offsets are not greater than 20% of the span (indirection of offset) from either

axis between centerlines of successive columns.No offset column in the building.

d) The Reinforcement is placed in an orthogonal grid.Reinforcement will be placed in an orthogonal grid.

2) Slab Thickness With Out Drop Spans Cl 13.2.3

ln= clear span between columns. Will use the actual span length to be conservative and preventredesign of roof with changing column sizes.

.:. ln=5m 5000mm

Increase the minimum thickness by 10% due to the discontinuous edges. Cl13.2.3

3) Factored Design Loads.

Loading Based upon Roof Loads Cases and Computed In S frame model.

Center Span L=10m Edge Span L=5mDeadLoad:

4.00 kPa 40.0 kN/m 20.0 kN/m

Live Load: 1.00 kPa 10.0 kN/m 5.00 kN/m

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

83

SnowLoad:

2.72 kPa 27.2 kN/m 13.6 kN/m

Wind Load 0.68 kPa 6.80 kN/m 3.40 kN/m

Considered Patterned Loading Cl 13.8.4.2

Slab BeamMoment of Inertia

Central Span Beam Edge Span Beam

Column Moment of Inertia

Column Effective Moment of Inertia Cl13.8.3.3No beams therefore =0 and l2/l1=1 as a result =0.3

Summary Of Worst Load CaseCritical Design Case is 1.25D+1.5S+0.5LMf bottom = 460kNm Decrease Moment

Mf top = 272kNmVf= 297kN(Edge) and 475kN (Central)

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

84

4) Shear Design One Way Cl 11.1 11.3

=0.21 as hs=190mm<350mm Cl 11.3.6.2

c=0.65 =1 normal Density fc’=25MPa bw=10,000mm dv

dv=136.8mm Greater of 0.72*hs=0.72*190=136.8mm

0.9*d=0.9*135=121.5mm

bw=10,000mm as Vf based upon 10m Span Beam

.:. One way shear is ok. No reinforcement required for one way shear.

5) Two Way Shear

Shear Force

Central Column

Edge Column

A B C

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

85

Central Column

Shear Strain

Confirm fc’^0.5 is less than 8MPa Cl 13.3.4

Shear Resistance

Central(13 5) (13 6) (13 7)

=1.50MPa =1.63 MPa =1.24 MPa

Edge(13 5) (13 6) (13 7)

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

86

=1.50MPa =1.73 MPa =1.24 MPa

Corner(13 5) (13 6) (13 7)

=1.50MPa =1.81 MPa =1.24 MPa

Vf is greater than Vc therefore shear reinforcement required.

Check the max allowable shear for Stud Reinforcement.

The vmax < vf therefore shear reinforcement cannot be designed for this section of slab. Theissue is the length of span creates a large shear stress. Options to resolve this are largercolumns, more columns to decrease tributary area, drop panels, or increase the depth.

The column and beams have already been sized and spaced; to prevent redesign of thesemembers the roof slab will be depended. The choice to deepen the entire slab opposed tolocality with drop panels is that all columns require deepening.

Solve for a new depth using

. One Way shear will still be adequate.

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

87

Recalculate Shear Reinforcement.

Confirm fc’^0.5 is less than 8MPa Cl 13.3.4

Shear Resistance

Central vf=1.86 MPa

(13 5) (13 6) (13 7)

=1.64MPa =3.09 MPa =1.35 MPa

Edge vf=1.35 MPa(13 5) (13 6) (13 7)

=1.64MPa =3.33 MPa =1.35 MPa

Corner vf=1.10 MPa(13 5) (13 6) (13 7)

=1.64MPa =2.86 MPa =1.35 MPa

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

88

Design Reinforcement.

Cl 13.3.8.2

Stud Reinforcement:

Concrete Shear Stress is Stud Region Cl 13.3.8.3

Stud Spacing Cl 13.3.8.6

Stud Area Cl 13.3.8.5

Use 3/8” studs (9.5mm) area of Stud As=71mm2

in each direction

Layout of Stud rail “g”:

Spacing between rails:

Minimum length of stud rail: Cl 13.3.7.4

/and extend to where shear force is/

Length of rails based upon two rails per face with 7 studs

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

89

bo with rails

.

Final Stud Shear Resistance

Notes: the d/2 calculations for critical shear area were not revised upon deepening of the slab.As a result the “bo” values were not revised. As a result the shear stress for the two way shearwas designed with a larger value. The actual revised shear stress for the central column wouldbe:

RailLength

d/2=147.5mm

Column250x350

250mm

(11062+11062)0.5=1564mm

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

90

Shear Slab

Column Central Edge Cornerwf (kPa) 9.58d mm 135TA (m) 10x10 5x5 5x10Column (m) 0.350x0.250Shear Vf (kN) 956.2 477.5 238.2Shear stress vf (MPa) 1.86 1.35 1.10Concrete Resist vc(MPa)

1.00 1.35 1.35

Shear Steel vs (MPa) 1.16Use 30MPa ConcreteSlab Thickness: 350mmShear Studs at center column: Two Rails each face with 7 3/8” studs @ 145mm.End Distance to Stud 118mm

6) Design of Slab using Elastic Frames Cl 13.8

Criteria for Equivalent Frame Method

a) Within a panel , the ratio of longer to shorter span, center to center of supports, is notgreater than 2.0

b) Slab systems with beams between supports the relative effective stiffness of beams inthe two directions is not less than 0.2 or greater than 5.0.

Not Applicable as the roof slab is a flat slab without beams.c) Column offsets are not greater than 20% of the span (indirection of offset) from either

axis between centerlines of successive columns.No offset column in the building.

d) The Reinforcement is placed in an orthogonal grid.Reinforcement will be placed in an orthogonal grid.

Design Info:

Fy = 400 MPa f’c = 30 MPa hs = 350mm d = 295mm

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

91

7) Factored Design Loads.

Loading Based upon Roof Loads Cases and Computed In S frame model.

Center Span L=10m Edge Span L=5mDeadLoad:

4.00 kPa 40.0 kN/m 20.0 kN/m

Live Load: 1.00 kPa 10.0 kN/m 5.00 kN/mSnowLoad:

2.72 kPa 27.2 kN/m 13.6 kN/m

Wind Load 0.68 kPa 6.80 kN/m 3.40 kN/m

Consider Pattern Loading Cl 13.8.4.2

Slab BeamMoment of Inertia

Central Span Beam Edge Span Beam

Column Moment of Inertia

Column Effective Moment of Inertia Cl13.8.3.3No beams therefore =0 and l2/l1=1 as a result =0.3

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

92

Critical Design Case is 1.25D+1.5S+0.5L

Mf bottom = 460kNm Decrease Moment

Mf top = 272kNm

Vf= 297kN and 475kN

8) Treat the Frame System as a continuous Beam. This ignores the stiffness provided by the

Min Area of Steel Cl 7.8.1

Area of steel Required By Direct Procedure

A B C

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

93

Bottom Reinforcement Spacing for 15M rebar

Check against Spacing Limitations Cl 13.10.4

Outside of Band Width bb (1400mm)

Lesser of:

Within Band Width bb (1400mm)

Lesser of:

Band Width

Beam Strip

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

94

Exterior Midspan Interior Column

Steel Location Top Bottom TopMf (kNm) 12 272 400Column Strip Width (mm) 5000 5000 5000Within Band Width bbBand Width bb (mm) 1400 1400Moment 12 †1 400/3=133Reinforcement Required As (mm2) 118 1360Spacing Required (mm) 2350 200Max Spacing (mm) 250 250Bars 6 15M@250

for 10007 15M@200

†2Asmin (mm2) 980 980†3 Column WidthStrip Width 10000Moment 272Reinforcement Required As (mm2) 2690Spacing Required (mm) 744Max Spacing (mm) 500Bars 15M@ 400 †4

† 1 Cl 13.11.2.7 Interior Columns to support 1/3 of design moment

† 2 Cl 7.8.1 Min Area: Sample Calc. on previous Page

† 3 No Middle Strip as length and width of the spans are equal.

† 4 Spacing Reduced from 500mm to 400mm to provided additional strength allowing forconstruction Errors.

9) Slab Integrity Reinforcement Cl 13.10.6.1

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

95

10) Deflection Calculations

Deflection Calculations can be waived according to Cl 13.2.2 as the slab thickness (350mm) islarger than the minimum thickness (183mm) specified in Cl 13.2.3.

11) Development Length

Mid Span Bars

Tension Development Length is satisfactory for the mid span (bottom) bars as they run theentire 10m of slab. Compression Development is also satisfactory at the ends as the top steel isdesigned to take the entire moment load.

Center Column Cl 12.2.3

Table 12.1 is valid as

Point of inflection is 1.2m from column

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

96

Embedment length beyond inflection point Cl 12.12.2

Check the Maximum allowable Development Length Cl 12.11.3

The Length of Steel to either side of the central Column Center Line Must be

Edge Bars Hook Bars 90o

Note the Development Length a straight bar is the same as above 400mm

Use hook bars as there is insufficient bar length for full development Cl 12.5.2

Cover=40mm (outside)+10m(10M Column

Ties)=50mm

250

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

97

Point of inflection is 0.04m from edge.

Hook Length N12.5.2

Embedment length beyond inflection pointCl 12.12.2

Check the Maximum allowable Development Length Cl 12.11.3

Straight Length

Hook Design

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

126

Two Way Shear Cl 13.3.3.4.1

Determine the pressure on footing

Left=

Right= = Q Force= +Q Moment =

Slope

Shear Stress Cl 13.3.4.1

Where bo is the Critical Shear Failure around the Column

Continue with

70mm is the minimum Depth for equation (c ) as mentioned earlier the minimum Depth is 150.

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

127

Check Equations (a) and (b) of Cl 13.3.4.1 to determine if the resistance is greater than equation(c) Greater resistance means that the equation would not govern, if theresistance is lesser with a revised depth of 150mm.

Using d=150mm

Where

Note Equation (b) actually governed as without the increased in depth the resistance is lessthan 1.235MPa.

Actual Height of Footing

The actual height will be Depth, cover, and one layer of 25M

Oneway Shear Cl 11.3.4

Critical Shear Force Occurs at the a distance dv from pedestal.

180mm Governs

Distance is

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

128

Shear Resistance of Concrete

where

The concrete is adequate to carry shear load no Shear reinforcement required

Flexure Design

Treat the load as uniform form 0.35m to the end, this will over estimate the result.

Determine Area of Steel Required for Mr

Check Required Steel

Steel Bars

Spacing is the Length –End Spacing *2, divided by the number of spaces

Min Spacing Same as Pedestal, as a result it is adequate.

Max Spacing Cl 7.4.1.2 and Cl 13.10.4

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

129

500mm Spacing Governs. and 260mm is less .:. ok.

Bearing Between Footing and Pedestal Cl 10.8.1

Footing

Pedestal

Bearing Strength of Concrete is Adequate on Bearing Reinforcement Required.

Minimun Reinforcement Across Interface Cl 1.5.9.2.1

Four Bars

Bottom Hook

Note Hooks are not effective in compression (Cl 12.5.5) The hook Length is to provide length totie the bar to the Footings Flexural Steel

Development Length Cl 12.3

Final Report on the Design of aFire Testing & Research Facility

Lakehead University, Thunder Bay, Ontario

130

Development Length of Dowels is greater than footing Depth .:. Increase footing Height

SummaryDimensions 1.2mx1.2m Flexural Reinforcing 5 25M@ 260mm

Height 570mm

Dowels

4 25M 880mm lengthNo Shear Steel 300mm Hook

Cover 75mm All Faces Spliced to columnStarter Bars