Two-Dimensional Nanocomposites Based on Chemically Modified Graphene

Two dimensional Transition metal dichalcogenides and graphene … · 2015-03-23 · Two dimensional...

Transcript of Two dimensional Transition metal dichalcogenides and graphene … · 2015-03-23 · Two dimensional...

Chalcogenide Advanced Manufacturing

Partnership Open Day

Two dimensional Transition metal dichalcogenides and graphene via CVD for optoelectronic applications Nikos Aspiiotis and Kevin C.C. Huang

Optoelectronics Research Centre – University of Southampton, Southampton, SO17-1BJ, UK

ChAMP Open Day is hosted by:

Optoelectronics Research Centre

Event administration by Xmark Media.

Research Sponsored by EPSRC, the

Engineering & Physical Sciences Research

Council

Grant Reference: EP/H02607X/1 - EPSRC Cen-

Graphene monolayer on copper, Raman

Transferred mono layer and myltilayer graphene to various sub-

Graphene deposited on copper

Raman measurements of transferred graphene

CVD system for MoS2 deposition.

Substrate of choice is inserted into a quartz

tube. Candidate substrates must have sim-

ilar crystal lattice contacts as MoS2. Then

at low pressure argon is introduced as a

carrier of MoCl5 . The reactive gas H2S is

being introduced in the system promoting

MoS3 deposition. After CVD a two step an-

nealing process is used to remove Cl at-

oms and to convert MoS3 to MoS2

Single layer graphene (SLG) deposited on 10cm x 10cm copper foil and it’s Raman

spectrum. The interpretation of Raman gives a through quality analysis . The de-

picted graphene sample is a high quality monolayer with minimum graphene de-

Transferred graphene from copper catalyst to various substrates. Copper - gra-

phene is spin coated with a thin film of sacrificial polymer. Then the copper - gra-

phene - polymer sandwich is placed in an Ammonium Persulfate bath (1M) re-

sulting to copper etching. Then graphene on polymer is transferred on the desired

substrate and the polymer is removed by the appropriate solvent. The final step is

the annealing of graphene—substrate to remove possible polymer residue.

CVD system for graphene deposition.

The copper substrate - catalyst is insert-

ed into a quartz tube . Then at low

pressure the forming gasses are intro-

duced using high temperature to pro-

mote uniform single layer or multi-

layer graphene sheets, as chosen.

Raman measurements of MoS2 deposited on different

substrates a) SiO2 / Si b)ZnO c)Sapphire MoS2 deposited on SiO2 / Si

Graphene transferred on Sapphire (0001) . Subsequent MoS2 CVD deposition

forming SLG - MoS2 heterojunction on sapphire

MoS2 Field effect transis-

tors

MoS2 deposited on Sapphire substrate was transferred to hihly doped SiO2 / Si. An

array of predefineD regions was fabricated using standard lithographic techniques

and sputtering deposition was employed for Au / Cr deposition. Each pair of Au / Cr

act as source and drain while the highly doped substrate acts as a gate. Furthermore

the transistors can be interconnected to form logic gates.

Schematic of the MoS2

FET

Multiple MoS2 FETs on SiO2 / Si

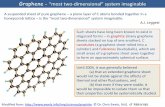

GRAPHENE TMDC MoS2

![Two‐Dimensional Metal Oxide Nanomaterials for Next ...download.xuebalib.com/xuebalib.com.33495.pdf · oxides,[9] transition-metal dichalcogenides (TMDs),[10–12] layered double](https://static.fdocuments.in/doc/165x107/6061bb8e1b6ca92a3150bd60/twoadimensional-metal-oxide-nanomaterials-for-next-oxides9-transition-metal.jpg)