TRU-TRAC IDLERS, FRAMES & STRUCTURES

Transcript of TRU-TRAC IDLERS, FRAMES & STRUCTURES

INDEXAbout Us

Steel Idler

Anti Roll Back Idler

HDPE Conveyor Idler

Rubber Impact Idler

Mining Frames

Underground Structures

Product Information

Tru-Trac Products

3

4

5

6

7

8

9

10

11

ABOUT USTru-Trac is a world leading manufacturer and supplier of conveyor belt solutions to the mining and bulk material handling industries worldwide. Located in Centurion, South Africa, Tru-Trac has a well-established sales and service presence throughout Southern Africa and most major mining regions on the African continent. Tru-Trac has today grown into a major intentional supplier of specialist conveyor components with an international sales and distribution network spanning 80 countries.

Conveyors are the lifeline of efficient operations and for over 25 years, Tru-Trac has helped the world’s biggest mining houses process minerals more efficiently, reliably and safely. We’ve built a repository of industry knowledge, technical expertise and the necessary operational scale, that gives us the ability to solve any conveyor problem you might face.

The problems we solve

Our service starts with understanding the root cause of your conveyor challenges, as well as their impact on your mining operation.

With this knowledge as a foundation, we’re able to offer a full range of solutions for the following common conveyor problems:

• Belt Misalignment • Belt Cleaning • Impact, dust & spillage solutions • Belt fasteners • Safety Hazards• Component damage or failure Once the scope of your conveyor requirements are clear, we work with you to select the right product and ensure optimal positioning within your conveyor system.

Installation of your conveyor components is handled by trained professionals.

4

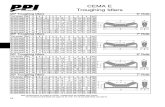

SPECIFICATIONS:

• Steel Tube Conveyor ST33 SANS 657-3 (Grade 355MH, Comply with EN 10219)• Mild Steel Shaft Round Drawn-QD Bright SAE/AISI C1018 (BMS)• Roller End Caps: Hot rolled deep drawn supra form pickle and oil HRSF190

Specification BS 1449. The roller end caps tolerances for fitting the bearings are as recommended by the bearing manufacturers.

• Bearings: C3 Clearance, rubber-Sealed TN9. Bearings life rating as per L10 calculating method.

• Labyrinth the type sealing arrangement.•

STEEL IDLER

FEATURES:

• We are able to supply the steel idlers in various roll diameters (101Ø, 127Ø, 152Ø etc)

• We are able to supply the steel idlers in various shaft diameters (25Ø, 30Ø, 35Ø, 40Ø etc)

• We are able to supply the steel idlers in various shaft end configurations (Open end, closed end, Jeffry type, garland type and series 2000)

SECTION VIEW

5

ANTI ROLL BACK IDLER

This one directional invention is a standard idler that is equipped with a brake system that prevents the idler from rolling back. Normally installed on long or steep inclines.

FUNCTIONS:

• The inner race turns in the forward direction, for normal operation without adding friction.

• Should anything happen, that the roller wants to turn back, the inner race wedges itself against the shaft and the narrow part of the outer race profile, will stop the idler.

ADVANTAGES:

• There will be no roll back, should the belt stop under load.• Belt will only run down a couple of meters should the belt snap.• Less down time to pull the belts back in.• No danger to workers when belt drops to the ground.• No damage to structure and equipment when belt drops

6

HDPE CONVEYOR IDLER

SPECIFICATIONS:

• Virgin Material-HDPE (high density polyethylene)• Wall thickness 15mm• 15x high-multi support inner cage 5mm thick• High impact nylon bearing housing with standard bearing and sealing

arrangement• Available in 127mm OD and 152mm OD

TECHNOLOGY WELL AHEAD OF ITS TIME

FEATURES:

• Corrosion resistant• Ultra light 60% lighter than steel• Wear / abrasive resistant 7x higher than steel• Ultra low noise• Stronger and higher impact resistance than steel• Non flammable AWOPS (Optional)

7

RUBBER IMPACT IDLER

SPECIFICATIONS:

• Steel Tube conveyor ST33 SANS657/3 PT3 (Grade 355MH, Comply with EN 10219)• Mild Steel Shaft Round Drawn-QD Bright SAE / AISI C1018 (BMS)• Roller End Caps: Hot rolled deep drawn supra form pickle and oil HRSF190

Specification BS 1449. The roller end caps tolerances for fitting the bearings are as recommended by the bearing manufacturers.

• Bearings: C3 Clearance, rubber - Sealed TN9. Bearing life rating as per L10 calculating method.

• Labyrinth the type sealing arrangement.• The rubber impact disc has a shore hardness of ±70

FEATURES:

• We are able to supply the steel idlers in various roll diameters (133Ø, 152Ø, 159Ø, etc.)

• We are able to supply the steel idlers in various shaft diameters (25Ø and 30Ø)

• We are able to supply the steel idlers in various shaft end configurations (Open end, closed end, Jeffry type, garland type and series 2000)

• Fire resistance and Antistatic

8

Tru-Trac frames are manufactured from graded material and jig manufactured. This means that the frames are manufactured symmetrical which allows for the idlers to be seated identically throughout the span of the conveyor system. This allows the conveyor belt to run seamlessly over the idlers without causing the idlers to bounce or vibrate.

All welding procedures are certified (AWS D.1.1) and all welders qualified to the procedure.

Receipt inspection takes place on all components to ensure that it conforms to the correct client specifications. The tubes are CNC bent to ensure every pipe is identical.

Tru-Trac mining frames uses a three-stage jig process:The first stage is manufactured according to the approved client drawing and uses toggle clamps, clamps to ensure that the parts for each frame remains fixed in set positions. Mounting pins on the jig ensures that the hole and fixing centres are placed correctly.

The second stage jig is utilised when welding up of the frames to ensure that no movement takes place during the final welding process. The third jig is used when the frames have had corrosion protection applied, whereby a final fitment takes place to ensure that prior to dispatch every frame is to specification.

Corrosion protection: Standard manufacturing tolerance in accordance with SANS 121.

TRU-TRAC MINING FRAME5 Roll Retractable Impact Frame 5 Roll Tubular Troughing Frame 3 Roll Tubular Troughing Frame

2 Roll Tubular Vee Return Frame 3 Roll Adjustable Transition Frame 3 Roll Underslung Frame

9

UNDERGROUND STRUCTURES

Tru-Trac are able to supply floor standing or hanging structures in any configuration as illustrated. We are able to supply the stringers, stools, inner legs, frames or idlers individually. The components of the structure are laser cut, this ensures that the structure is of the highest quality and correctly aligned.

Thus preventing the belt from running out which prevents spillage problems and prevents damage to the belt, idlers, frames and structure. We are able to provide galvanized and painted structures.

10

PRODUCT INFORMATION

3 Roll Troughing

Belt Width Roll Face Roll Gauge

300 130 140

400 170 180

450 190 200

500 200 210

600 240 250

750 290 300

900 340 350

1050 390 400

1200 450 460

1350 500 510

1500 560 570

1650 610 620

1800 660 670

2100 765 775

2400 870 880

1 Roll Flat Return

Belt Width Roll Face Roll Gauge

400 484 494

450 536 546

500 586 596

600 688 698

750 840 850

900 994 1004

1050 1146 1156

1200 1298 1308

1350 1450 1460

1500 1602 1612

1650 1754 1764

1800 1908 1918

2100 2212 2222

2400 2518 2528

5 Roll Troughing

Belt Width Roll Face Roll Gauge

1050 240 250

1200 270 280

1350 300 310

1500 340 350

1650 370 380

1800 400 410

2100 475 485

2400 536 546

1 Roll Flat Return

Belt Width Roll Face Roll Gauge

600 300 310

750 400 410

900 475 485

1050 560 570

1200 635 645

1350 720 730

1500 800 810

1650 885 895

1800 965 975

2100 1146 1156

2400 1298 1308

11

TRU-TRAC PRODUCTSTru-Trac offers solutions for the following common conveyor problems:

• Belt Trackers• Belt Scrapers• Load Zone Impact Control• Dust Control & Skirting

TRU-TRAC SERVICESTru-Trac offers integrated solutions and support services to help drive optimisation of production plants on a sustainable basis. Our broad skill set and expertise allows us to empower industries to continuously improve production. Our product offering is supplemented with the provision of the highest level of technical support and service.

Field Service Maintenance Conveyor Training

Conveyor Surveys Mobile Showroom

• Fasteners• Conveyor Idlers & Frames• Safety Products• Belting, Pulleys & Lagging

Return Trackers Trough Trackers Scrapers

Impact Beds Dust Skirting Fasteners

+27 12 661 9531

www.tru-trac.com

590 Barolong Street, Sunderland Ridge, Centurion, 0157