Lesson 14 Idlers and Pulleys

-

Upload

superior-industries -

Category

Documents

-

view

226 -

download

1

Transcript of Lesson 14 Idlers and Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

1/53

Lesson 14: Components

Idlers and Pulleys

In this lesson you will learn:

How to select idler class. How to determine thedesired drive pulley RPM. The effect of belt wrapon belt tension and pulley selection. How to selectproper pulley diameter.

-

8/3/2019 Lesson 14 Idlers and Pulleys

2/53

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

3/53

Types - Carry or Trough Return

Purpose -

Shape load Support the belt

Idlers

http://www.superior-ind.com/si_detview.aspx?id=prdd&pid=632732637869759232 -

8/3/2019 Lesson 14 Idlers and Pulleys

4/53

Return Idlers

Troughing or CarryIdlers

TransitionIdlers

Impact Idlers

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

5/53

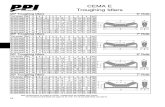

CEMA Classifications

B

C

D

E

F

typicalaggregate sizes

Idlers

http://www.superior-ind.com/si_detview.aspx?id=prdd&pid=632732637869759232 -

8/3/2019 Lesson 14 Idlers and Pulleys

6/53

CEMA Idler Classification

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

7/53

Common idler roll diameters -

4

5 6

7

8

typicalaggregate sizes

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

8/53

Carry Idlers

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

9/53

Trough Angle -

20 degree

35 degree most widely used

45 degree

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

10/53

Return Idlers - different profiles

Flat

Rubber disc

V

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

11/53

Trough Training Idlers

Helps train the belt

Typically spaced every 100 -150

Training idlers - approximately taller thanstandard idler to help create aligning effect

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

12/53

Return Training Idlers

Helps train the belt onreturn side

Typically spaced every 100 -150

Good contact with belt is critical

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

13/53

Off-center loading cannot be corrected

by training idlers

Training idlers work more effectively atlow belt tensions

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

14/53

Training idlers are especially effective in lowtension reversible conveyors

Belts greater than 48 wide are not generally

effected by training idlers belt weight providesgreater training force

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

15/53

Rule of thumb

the greater the belt tension,

the less effective training idlers are!

Idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

16/53

Idler selection

CEMA has a nice idler selection guide

Step-by-step method to select idlers

-

8/3/2019 Lesson 14 Idlers and Pulleys

17/53

Step 1: Troughing Idler series selection

Calculated Idler load (CIL):

Idler selection

IMLSKWWCIL imb 1Where:

Wb = Belt Weight (lb/ft)

Wm = Material Weight (lb/ft)

Si = Idler spacing (ft)

K1 = Lump adjustment factor (see table on next slide)

IML = Idler misalignment load (lbs) (see slide after next)

-

8/3/2019 Lesson 14 Idlers and Pulleys

18/53

Idler selection

K1 Lump adjustment factor

Maximum Lump size (in)

Material Weight (lb/ft3)

50 75 100 125 150 175 200

4 1 1 1 1 1.1 1.1 1.1

6 1 1 1 1.1 1.1 1.1 1.1

8 1 1 1.1 1.1 1.2 1.2 1.2

10 1 1.1 1.1 1.1 1.2 1.2 1.2

12 1 1.1 1.1 1.2 1.2 1.2 1.3

14 1.1 1.1 1.1 1.2 1.2 1.3 1.3

16 1.1 1.1 1.2 1.2 1.3 1.3 1.3

18 1.1 1.1 1.2 1.2 1.3 1.3 1.4

-

8/3/2019 Lesson 14 Idlers and Pulleys

19/53

Idler selection

Idler Misalignment Load (IML)

iS

TDIML

6

Where:

D = Misalignment (in)

T = Belt Tension (lbs)

Si = Idler spacing (ft)

-

8/3/2019 Lesson 14 Idlers and Pulleys

20/53

Troughing series idler selection

Use CIL to select the idler series from the load ratingtables in the idler catalog

Idler selection

-

8/3/2019 Lesson 14 Idlers and Pulleys

21/53

Step 2: Return idler series selection

Pick a return idler series based on the load rating

tables in the idler catalog

Idler selection

IMLSWCIL iBR

-

8/3/2019 Lesson 14 Idlers and Pulleys

22/53

Steps 3-7: Impact idler selection and L10 calculations

Read CEMA Idler standards for an overview

Will not be covered in this class

Rules of thumb for diameter More than 500RPM decreases L10 life

Try to stay below 500RPM, but 4 is really going away 4dia @500RPM = 524FPM **only use 4 in economy situations

5dia @500RPM = 654FPM

6dia @500RPM = 785FPM

Etc.

Idler selection

-

8/3/2019 Lesson 14 Idlers and Pulleys

23/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

24/53

End Disc

Rim Shaft

Hub

Bushing

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

25/53

Types -

Drum

Wing

Purpose -

Transmit power to the belt

Change belt direction

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

26/53

Tail

Pulley

SnubPulley

Take-upPulley

Bend Pulley

Bend Pulley

Head or DrivePulley

Pulleys

http://../Pulleys/Chevron/chevron-7.jpghttp://../Pulleys/Chevron/chevron-7.jpghttp://../Pulleys/Chevron/chevron-7.jpg -

8/3/2019 Lesson 14 Idlers and Pulleys

27/53

CEMA DUTY -

Load, dimensions and crowndefined by ANSI B105.1

Used on fabric belt

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

28/53

MINE DUTY

Not governed by ANSI

Standard size drums and wings

Manufacture specified designs

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

29/53

ENGINEERED CLASS -

Designed to meet load requirements

at a specific location on a conveyor

Primary used on steel cord belts

Belt tensions and loads exceedCEMA B105.1 and 501.1 > 800 PIW

> 80,000 modulus PIW

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

30/53

Pulley Lagginga smooth or embossedcovering or coating applied to a pulley

Increases belt traction

Minimizes wear due to abrasion

Promotes cleaning action

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

31/53

Grooved laggingused on drive pulley toshed water & improve traction

Chevron - grooves meet at center

Herringbone - offset at center by spacing

** Apex should be in direction of belt travel

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

32/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

33/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

34/53

Ceramic

Increased coefficient of friction

Excellent abrasion resistance

High tension & HP applications

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

35/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

36/53

Wing Pulleys

- help protect the conveyor belt from the damaging effectsof fugitive material trappedbetween pulley and belt.

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

37/53

B t i

-

8/3/2019 Lesson 14 Idlers and Pulleys

38/53

Bent wings

-

8/3/2019 Lesson 14 Idlers and Pulleys

39/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

40/53

Pulleys

-

8/3/2019 Lesson 14 Idlers and Pulleys

41/53

-

8/3/2019 Lesson 14 Idlers and Pulleys

42/53

-

8/3/2019 Lesson 14 Idlers and Pulleys

43/53

-

8/3/2019 Lesson 14 Idlers and Pulleys

44/53

Pulley selection is based heavily on belt tensions

So to start were going to look at belt tensions at

locations where pulleys are commonly installed

Pulley Selection

-

8/3/2019 Lesson 14 Idlers and Pulleys

45/53

Belt Tensions

Te is calculated from the application

Te is used in an equation:

In order to find T1, we must first solve T2

21 TTTe

21 TTT e

-

8/3/2019 Lesson 14 Idlers and Pulleys

46/53

Belt Tensions

There are two equations that calculate T2 Whichever T2 is higher governs

T2based on 2% sag:

.long arduous equation I will spare youfrom.

T2based on drive slip:

we CTslipT 2

-

8/3/2019 Lesson 14 Idlers and Pulleys

47/53

Belt Tensions

Once we have T2, we can solve the equation:

..to find T1

21TTT e

-

8/3/2019 Lesson 14 Idlers and Pulleys

48/53

Belt Tensions

After T2, very little changes to belt tension downto TT.

Some change due to return roller friction

Some change due to non-drive pulley friction

-

8/3/2019 Lesson 14 Idlers and Pulleys

49/53

Example 100 conveyor

Head/drive tension (T1) = 6612.5lbs

Snub tension (T2) = 2527.9lbs

Bend pulley tensions (Ttakeup) = 2479.8lbs Takeup pulley tension (Ttakeup) = 2479.8lbs

Tail pulley tension (TT) = 2287.6lbs

Pulley Selection

-

8/3/2019 Lesson 14 Idlers and Pulleys

50/53

Turn tensions into PIW (pounds per inch of beltwidth)

36BW:

T1 = 6612.5lbs = 184PIW

T2

= 2527.9lbs = 70PIW

Ttakeup = 2479.8lbs = 69PIW

TT = 2287.6lbs = 64PIW

Pulley Selection

)(

)(

inBeltWidth

lbnBeltTensioPIW

-

8/3/2019 Lesson 14 Idlers and Pulleys

51/53

S

-

8/3/2019 Lesson 14 Idlers and Pulleys

52/53

Many programs can be used to select idlers andpulleys

Here is an example of how they work:

Idler & Pulley Selection

-

8/3/2019 Lesson 14 Idlers and Pulleys

53/53

Questions???