Trolley Winch Design

Click here to load reader

-

Upload

utaya-kumar-veelmurugan -

Category

Documents

-

view

13 -

download

3

description

Transcript of Trolley Winch Design

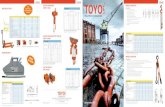

5m beamPROJECT TITLE:Proposed Additions & Alterations for New Membrane Plants to Existing Bio-Reactors at Liquids Module 1 Changi

SECTION REFERENCE:TROLLEY SUSPENSION WINCHDate:3/13/15Time:7:36 PM

DESIGN OF AXIALLY LOADED (COMPRESSIVE) UNIVERSAL BEAM/COLUMN WITH APPLIED MOMENTS TO BS 5950: PART 1: 2000

DESIGN SUMMARY

Universal Beam/Column Section Selected:203 x 203 x 100 kg/mDesign Steel Grade:S275Steel Section Selected is Class 2, Compact

a.Steel Section Properties (Universal Beam / Column Secion)Reference

Design Steel Grade of SectionS=275Depth of SectionD=228.6mmWidth of SectionB=210.3mmWeb Thicknesst=14.5mmFlange ThicknessT=23.8mmDimensionsCorner Radiusr=10.2mmDepth of the Webd=160.7mmArea of SectionAg=127.0cmRadius of Gyration about Major Axisrx=9.4cmRadius of Gyration about Minor Axisry=5.4cmRolled SectionElastic Modulus about Major AxisZx=990.0cmA=123.40Elastic Modulus about Minor AxisZy=351.0cmIxx =14164.25Plastic Modulus of about Major AxisSx=1,150cmIyy =7665.45Plastic Modulus of about Minor AxisSy=536cmx =10.52Plastic Modulus of Shear Area about Major AxisSVX=189.4cmSVX=tD/4Cl. 4.2.5.3y =11.43Plastic Modulus of Shear Area about Minor AxisSVY=12.0cmSVY=tD/4Cl. 4.2.5.3Sx =1239.22Buckling Parameteru=1.0Conservative ApproximationsCl. 4.3.6.8Sy =729.00Torsional Indexx=9.6x=D/TCl. 4.3.6.8Design Strength of SteelPy=265N/mmT=23.8mmTable 9Section Classification Constant=1.0=(275/Py)Table 11, Note bRatio of Local Buckling of Flangeb/T=4.4Rolled Sectionb/T10.0Ratio of Local Buckling of Webd/t=11.1Section is Compactd/t 80Table 11

b.Ultimate Limit State Loading Conditions

Maximum Ultimate Axial Compression LoadFc=0kNF.O.S.=1.5Maximum Ultimate Applied Moment about x-x AxisMx=16.67kNmMaximum Ultimate Applied Moment about y-y AxisMy=0kNmMaximum Ultimate Shear ForceFv=15kN

c.Structural Design of Steel Section

(i) Shear Buckling Check

Ratio Limit for Shear Buckling Webd/t70 O.K.No Check Needed, d/t 70 Cl. 4.2.3

(ii) Shear Capacity CheckCl. 4.2.3

Intermediate Stifferner Spacinga=0.0mma/d=0Annex H.IShear Area of SectionAv=3314.7mmAv=tDCl. 4.2.3(a), (b)Shear Capacity of SectionPv=527.0kNPv=0.6 x Py x AvCl. 4.2.3>FvO.K.Classification of Shear Load0.6Pv=316.2kNFv0.6 PvLow Shear LoadCl.4.2.5.2/3Moment Capacity Reduction Factor=0.00=[2 x Fv/Pv -1], if Fv>0.6PvCl.4.2.5.3

(iii) Cross-Section Capacity CheckCl.4.8.3.2

Moment Capacity of Section about x-x axisMcx=305kNmMcx=Py x SxCl.4.2.5.2Moment Capacity of Section about y-y axisMcy=112kNmMcy=1.2 x Py x ZyCl.4.2.5.2Applied Axial Load to Compression Resistance RatioFc/(AgPy)=0.000Cl.4.8.3.2(a)Applied Moment to Moment Capacity Ratio (x-x)Mx/Mcx=0.055Applied Moment to Moment Capacity Ratio (y-y)My/Mcy=0.000Interaction ExpressionFc/(AgPy) + Mx/Mcx + My/Mcy=0.0551.00O.K.Cl. 4.8.3.2(a)

(iv) Member Buckling Resistance CheckReference

Length of Span for Compression LoadL=5000mmSway ModeTable 22Effective Length for Compression Member about x-x AxisLECX=5000mmLECX=2 LcTable 22Effective Length for Compression Member about y-y AxisLECY=5000mmLECY=2 LcCl. 4.7.2Slenderness for Compression Member about x-x Axiscx=53.0cx=LECX/rxyCl. 4.7.2Slenderness for Compression Member about y-y Axiscy=92.8cy=LECY/rwLength of Span for Lateral Torsional BucklingLb=5000mmCantilever BeamEffective Length for Lateral Torsional BucklingLEL=5000mmLEL=2 L (Normal Load)Table 14Slenderness for Lateral-Torsional BucklingL=92.8L=LEL/rwCl. 4.3.6.7Slenderness Factor=0.42=1/[1+0.05 (L/x]^Cl. 4.3.6.7Ratiow=1.00w=1Cl. 4.3.6.9Equivalent SlendernessLT=39.0LT=uLwCl. 4.3.6.7Limiting SlendernessLD=33.9LD=0.4 x (E/Pv)Table 17Bending Strength of SectionPb=248.2N/mmTable 17Buckling Ressistance Moment of Section about x-x AxisMb=285.4kNmMb=Pb x SxCl. 4.3.6.4 (c )Moment Capacity of Section about y-y AxisMcy=93.0kNmMcy=Py x ZyCl. 4.8.3.3.1Compression Resistance with Buckling about x-x AxisPcx=224.39N/mmTable 24 (b)Compression Resistance with Buckling about y-y AxisPcy=151.72N/mmTable 24 (d )Minimum Compression Resistance of ColumnPc=151.72N/mmPc=Minimum (Pcx, Pcy)Cl. 4.8.3.3.1Applied Axial Load to Minimum Compression Strength RatioFc/(AgPc)=0.00Applied Moment to Moment Capacity Ratio (x-x)mxMx/(PxZx)=0.06mx=1Table 26Applied Moment to Moment Capacity Ratio (y-y)myMy/(PyZy)=0.00my=1Table 26Interaction Expression 1Fc/(AgPc)+mxMx/(PxZx)+myMy/(PyZy)=0.061.00O.K.Simplified ApproachCl. 4.8.3.3.1Axial Load to Compression Strength with y-y Buckling RatioFc/(AgPcy)=0.00Applied Moment to Buckling Moment Ressistance Ratio (x-x)mLTMLT/Mb=0.06mLT=1Table 18Interaction Expression 2Fc/(AgPcy)+mLTMLT/Mb+myMy/(PyZy)=0.061.00O.K.Simplified ApproachCl. 4.8.3.3.1

column designProject:Proposed Additions & Alterations for New Membrane Plants to Existing Bio-Reactors at Liquids Module 1 ChangiSheet No:ofDate:3/13/15Ref:TROLLEY SUSPENSION WINCHDesigned by:SRHChecked by:JY

1.General Details

I-Beam Section Details:203x203x100kg/mkg/mDepth of SectionD:228.60mmWidth of SectionB:210.30mmDepth of the Webd:160.70mmArea of SectionA:127.00cmRadius of Gydration about Major Axisrx:9.44cmRadius of Gydration about Minor Axisry:5.39cmWeb Thicknesst:14.50mmFlange ThicknessT:23.80mmRatio of Local Buckling of Flangeb/T:4.43Ratio of Local Buckling of Webd/t:11.10Factored Axial Load:15kN15 kN

2.Design Strength

Py=265N/mm=275=1.021500mmPy

i) Flange. b/T :=4.4311.10Therefore, web is class 1.

:-Hence section can be classified as class 1.

3.Slenderness

a)Effective Length, Le=1500mm

lx=Lex=16rx

ly=Ley=28ry

Buckling about x-x:Table 24(b)Strut curve 'b', for lx=16 and py= 265N/mm2 , pcx = 264.6N/mm2

Buckling about y-y:Table 24(c)Strut curve 'c', for ly=28 and py= 265N/mm2 , pcy = 249.2N/mm2

Compressive strength about y-y governs, i.e., pc=pcy249.2N/mm2

4.Compression Resistance

* Basic requirement Fc [ Pc

Pc=Ag Pc=3164.84kN

Check Adequancy :

3165kN>15kNOK!

Therefore, the compression resistance is adequate.

5. Shear Bucklingd[70t11.08[71.31

* Therefore no further shear buckling check required.

SFD N BMDProject:Proposed Additions & Alterations for New Membrane Plants to Existing Bio-Reactors at Liquids Module 1 ChangiSheet No:ofDate:3/13/15Ref:TROLLEY SUSPENSION WINCHDesigned by:SRHChecked by:JY