Triaxial Shear Testing of Polished Slick en Sided Surfaces

Transcript of Triaxial Shear Testing of Polished Slick en Sided Surfaces

LandslidesDOI 10.1007/s10346-011-0263-yReceived: 18 January 2011Accepted: 29 March 2011© Springer-Verlag 2011

Christopher L. Meehan I Binod Tiwari I Thomas L. Brandon I J. Michael Duncan

Triaxial shear testing of polished slickensided surfaces

Abstract A series of consolidated-drained triaxial tests wereperformed on precut and polished clay specimens to measuretheir drained residual strength. Two soils were tested during thisresearch program: Rancho Solano Clay and San Francisco BayMud. Specimens were tested using a specially modified triaxialcompression device which was developed to minimize the effectsof end-platen restraint on the measured strengths. Specialattention was paid to the influence of changing specimen areaand membrane effects during the test. Triaxial test results werecompared with baseline measurements of drained residual shearstrength that were made for each of the clay soils using Bromheadring shear tests and polished-specimen direct shear tests. Residualstrength values measured in the triaxial device were higher thanthe drained residual strengths measured in the Bromhead ringshear apparatus and the direct shear device, indicating that thistest approach is more challenging than the use of direct sheartests conducted on polished slickensided surfaces. Comparison ofsingle stage and multistage triaxial test data indicates thatmultistage triaxial testing may work well for specimens that failalong a well-defined plane, provided that careful attention is givento the effects of end platen restraint, membrane restraint, andchanges in specimen area during shear.

Keywords Triaxial tests . Clays . Overconsolidated soils .

Residual strength . Shear strength . Laboratory tests .

Compression tests

IntroductionSlickensides are surfaces of weakness formed in stiff clays as aresult of large shear displacements—on the order of 100 to500 mm—concentrated on a discrete surface of sliding (Skempton1964, 1985; Duncan and Wright 2005). As the clay soil is sheared,platy clay particles become aligned parallel to the direction ofshearing, resulting in the formation of a smooth surface that has ashear strength that is much lower than the strength of the adjacentclay through which the slickensided surface forms. The minimumshear resistance that can be mobilized along a smooth, slickensidedsurface is the residual shear strength (Skempton 1964). Evaluation ofthe residual shear strength is critical for slope stabilization ofpreexisting landslides in clayey soils. The magnitude of residualshear strength for a clay depends on the proportion of clay particlesthat are present in the soil matrix, the mineralogical composition ofthe clay particles, and the chemical state of the pore fluid (e.g.,Kenney 1977; Lupini et al. 1981; Tiwari and Marui 2005).

The drained residual shear strength of a soil specimen can bestbe accurately measured using a torsional ring shear device (e.g.,Bishop et al. 1971; Bromhead 1979). The primary advantage of thetorsional ring shear device over direct shear or triaxial test devices isthat it can apply unlimited shear displacement without changing thecontact area along the shear plane or reversing the direction of shear.However, due to the relatively high cost and the single-purposenature of the ring shear apparatus, these devices are not a commonfixture in production geotechnical testing laboratories. Efforts have

been made in the past to measure residual shear strength usingmultiple reversal direct shear tests (e.g., Skempton 1964) or triaxialtests (e.g., Chandler 1966; Bishop et al. 1971). The former has beenfrequently used in the past and is still in use (USACE 1986), whereasthe latter has mainly been a focus of research as opposed toproduction testing.

The use of the triaxial apparatus to measure residual shearstrengths has a significant appeal since it is common in mostproduction geotechnical testing laboratories. Bishop and Henkel(1962) were the first to suggest that triaxial compression testsconducted on precut specimens could be used to measure thedrained residual shear strength of a clayey soil. Later, Chandler(1966) measured the residual shear strength of Keuper Marl usingthe same methods proposed by Bishop and Henkel (1962). Triaxialtest data for precut test specimens presented by Bishop et al. (1971)for Brown London Clay shows that residual friction angles measuredin the triaxial device can be up to 30% higher than residual frictionangles measured in the Imperial College-type ring shear device.Lupini et al. (1981) also reported that triaxial compression tests cansometimes give residual shear strength values that are significantlyhigher than those measured in the ring shear device.

Bishop et al. (1971) precut their triaxial specimens with a wiresaw and reassembled the two halves for testing. No special emphasiswas placed on orienting the clay particles along the failure plane. Atthe onset of this research program, it was believed that previouslyemployed techniques for precutting test specimens without polish-ing, as well as the additional effects caused by end platen restraint athigher strains in the triaxial test, may explain the higher residualstrengths that have historically been measured in triaxial testapparatuses.

Previous work by the authors using a series of direct shear testshas indicated that it is possible, for some soils, to artificially createpolished slickensided surfaces in the laboratory (Meehan et al. 2010).Measurement of the drained residual strength along these interfacesin the direct shear device can yield results that are in excellentagreement with Bromhead ring shear tests (Meehan et al. 2010). Thelogical extension of this work is the measurement of shear strengthsalong polished slickensided surfaces in the triaxial device. Thisapproach to testing is extremely desirable as it would provide ameans for testing specimens containing preformed slickensidedfailure surfaces under undrained or cyclic loading conditions,allowing for measurement of dynamic strengths that can be usedin seismic analyses of slopes that contain slickensided surfaces(Meehan 2006; Meehan et al. 2008).

The research program discussed in this paper focuses onmeasuring the drained residual shear strength of two clay soilsusing the triaxial apparatus; this work is an extension of the directshear test approach utilized in Meehan et al. (2010). This paperpresents the results from a series of consolidated-drained triaxialcompression tests that were performed on precut and polishedcylindrical clay specimens to measure the drained residual strength.Two soils were tested during this research program: Rancho SolanoClay and San Francisco Bay Mud. Specimens were tested using a

Landslides

Original Paper

specially modified triaxial compression device which was developedto minimize the effects of end-platen restraint on the measuredstrengths. The triaxial test results are compared with measurementsof drained residual shear strengthmade using a Bromhead ring shearapparatus and a direct shear apparatus (Meehan et al. 2007, 2010).

The goal of this research was to revisit some of the historicalconclusions that had been drawn by early researchers that examinedthe use of the triaxial device for measurement of residual strengths.What makes this research different (and a new and significantcontribution) is the use of specially developed triaxial testingtechniques (free-platens, specimen polishing techniques, etc.), whichcan be used in conjunction with fully automated triaxial testequipment. Also of interest are the results from multistage triaxialtests.

Properties of test soilsThe ring shear and triaxial tests described in this paper wereperformed on two natural fine-grained soils. The first soil wasobtained from the Rancho Solano residential development inFairfield, California. The second soil was San Francisco Bay Mud,which was obtained from Hamilton Air Force Base in California.The soils were batch mixed at water contents ranging from 1.0 to1.2 times their liquid limits to ensure uniformity. The thick clayslurries were then pushed through a #40 sieve to remove largersoil particles that could interfere with the preparation of thepreformed slickensided failure plane. Index tests on the processedsoil were conducted in accordance with the appropriate ASTMprocedures, and yielded the soil properties given in Table 1. Grainsize curves for these soils are given in Fig. 1.

Preparation of triaxial test specimensThe thick clay slurries were consolidated in a 125 mm diameterbatch consolidometer to reduce the water content for creation oftest specimens with sufficient strength to trim. The test specimenswere consolidated incrementally to a final vertical effective stressof 350 kPa to obtain a cylindrical clay specimen of 125 mmdiameter and 100 mm height. Four 35 mm diameter, 75 mm tallcylindrical triaxial specimens were trimmed from each batchconsolidometer specimen.

In order to prevent significant disturbance to a triaxial testspecimen during slickenside preparation, it was necessary toconstruct a mold that could be used to hold the specimen as itwas being wire-cut and polished to form slickensides. Figure 2shows an aluminum mold that was fabricated for this purpose.The orientation of the failure plane in the slickenside preparationmold is 55° from the horizontal. This angle was selected using theformula 45� þ f0r=2, following the approach used by Chandler(1966). The residual friction angle that was used in this equation

(20°) was selected as an approximately representative residualfriction angle for both Rancho Solano Clay and San Francisco BayMud. Similar secant residual friction angles were observed forspecimens tested in the same range of confining pressures in theBromhead ring shear device: for Rancho Solano Clay, 17.9° and17.1° at normal stresses of 52 and 100 kPa, respectively, and for SanFrancisco Bay Mud, 20.0° and 18.5° at normal stresses of 52 and100 kPa, respectively (Meehan et al. 2010). Selection of apreformed plane angle of 55° should not significantly affect thedrained shear strengths that are measured in the triaxial devicesince triaxial test results are not sensitive to small variations inthe orientation of the preformed failure plane (Chandler 1966).

A slickensided failure plane was created in each triaxialspecimen by placing a trimmed intact specimen into the polishingmold as shown in Fig. 2a. The test specimen was precut along theshear plane using a piano wire leaving the two halves as shown inFig. 2b. Each specimen half was polished by shearing it along thesurface of a 0.3 m long wet frosted glass plate to align the clayparticles along the precut shear plane in the direction of shear, asshown in Fig. 2c. Six passes along the frosted glass plate wereperformed for each half of the test specimen, corresponding to atotal shear displacement of 1.8 m. This displacement was judged

Table 1 Rancho Solano Clay and San Francisco Bay Mud index properties and mineralogy

Clay USCSclassification

LL PI Clayfractiona

Specificgravity

Activity Major minerals

Rancho Solano Clay Fat clay (CH) 61 36 53 2.65 0.68 Quartz, Smectite, Feldspar,Kaolinite

San Francisco BayMud (SFBM)

Elastic silt (MH) 85 47 47 2.70 1 Quartz, Smectite, Feldspar,Kaolinite, Pyrite

a Clay fraction determined as the percentage of grains smaller than 0.002 mm

Fig. 1 Particle size distribution of Rancho Solano Clay and San Francisco Bay Mud

Original Paper

Landslides

to be sufficient to achieve the clay particle orientation that isassociated with residual strength. Figure 2d shows the finalappearance of the slickensided failure plane after wet polishing.After polishing, the two halves of the triaxial specimen werereassembled, the specimen was trimmed at each end so that itsheight was approximately 75 mm, and the specimen was placed inthe triaxial cell for testing.

Triaxial testing with “free platens”A number of researchers have noted the significant effect thatend-platen restraint can have on shear strengths measured in thetriaxial device (Bishop and Henkel 1962; Barden and McDermott1965; Chandler 1966; Skempton and Petley 1967). Bishop andHenkel (1962) discuss specifications for a “free top platen” toconduct triaxial compression tests for specimens that fail via a“single plane shearing” mechanism. Skempton and Petley (1967)and Chandler (1966) used this type of platen for their research.Barden and McDermott (1965) also describe a “free-endapproach” for triaxial testing, which consisted of a greasedmembrane that allowed radial expansion at the specimen ends,as well as a small amount of lateral movement of the specimenduring shear.

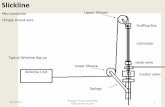

To minimize the effect of lateral platen restraint as aspecimen was sheared along a single shear plane, a “both ends-free” platen approach was developed for use in this study. Usingthis approach, specially constructed base and top platens wereused to allow unrestrained lateral movement of a test specimen asit is sheared. Ball bearings placed in a thin layer of vacuum greaseare used to allow free lateral movement of each of the platens; 70–3.2 mm diameter steel ball bearings were used on both the upperand lower platen. Figure 3 shows a schematic of the “both-endsfree” triaxial test device that was used for testing. Figure 4 shows atriaxial specimen setup for testing in this device.

The approach shown in Figs. 3 and 4 is similar in concept tothat employed by Bishop and Henkel (1962). Critical design

elements include the use of ball bearings instead of rollers (sincethe ball bearings allow for unrestrained movement in anyhorizontal direction), and the addition of a “free” base. Havingboth the top and the bottom of the specimen able to freely movein any lateral direction helps keep the triaxial specimen centeredbeneath the loading piston, and helps to prevent the developmentof additional undesirable force couples due to eccentric loading.

Fig. 2 Forming slickensided surfacesin triaxial test specimens; a placing thespecimen in the mold, b two halves ofeach specimen after wire cutting, cpolishing the wire-cut plane on frostedglass to form slickensides, and d theslickensided failure plane

Fig. 3 Schematic of “both-ends free” triaxial test device. a Specimen assemblybefore shearing, and b free movement of top and bottom platens allowsunrestrained shear on a well-defined shear plane

Landslides

Triaxial compression test procedureConsolidated-drained triaxial compression tests were performedusing displacement-controlled loading in an automated triaxialsystem manufactured by the GeoComp Corporation. The testswere conducted in general accordance with the triaxial testmethods outlined in Bishop and Henkel (1962) and Head (1986).

To begin each test, an assembled cylindrical test specimenwas placed on the lower platen, and two test membranes wererolled upwards around the cylinder. Considerable care wasrequired to prevent the top and bottom halves of the specimenfrom shifting position relative to each other while the specimenwas setup in the cell.

Each triaxial test was begun by back-pressure saturating thetest specimen until a minimum B value of 0.95 had been attained.The test specimen was then consolidated to the desired effectivestress for shearing.

Upon completion of consolidation, the triaxial test specimenswere sheared using displacement-controlled loading. The strainrate that was used for testing was determined from the measuredconsolidation data following the approach described by Head(1986), which is shown in Eq. 1. The time to reach 100% primary

consolidation (t100) was calculated for each final consolidationstep using Casagrande’s “Log of Time” method.

Strain rate ¼ "f � Ltf

ð1Þ

Where:

εf Axial strain at failureL Initial height of triaxial test specimentf Time to failure, which is assumed to be equal to 8.5×t100t100 Time for 100% primary consolidation

The challenge in implementing Eq. 1 for triaxial testsconducted on specimens that contain preformed slickensidedsurfaces is selecting the expected axial strain at failure prior to thetest. Triaxial tests on specimens that contain preformed slick-ensided failure surfaces are expected to reach failure at smallerstrains than tests conducted on intact triaxial specimens. Thisselection process is further complicated by the fact that earlier

Fig. 4 Triaxial setup allowing “freeplaten” movement at the top andbottom of the test specimen; a steelball bearings held in place with a thinlayer of vacuum grease, b theconnection of the load piston with thetop platen, c the connection of thespecimen base with the base of thetriaxial cell, and d a triaxial specimenready for “free-platen” testing

Table 2 Calculated strain rates for triaxial tests on Rancho Solano Clay specimens

Effective confiningpressure (kPa)

Measuredt100 (min)

Assumedεf (%)

Calculated strainrate (%/min)

Observedεf (%)

Strain rate usedfor testing (%/min)

35 180 1 0.0007 0.5 0.0001

70 470 1 0.0003 0.8 0.0001

84 529 1 0.0002 1.2 0.0001

105 670 1 0.0002 1.5 0.0001

Original Paper

Landslides

researchers (Bishop and Henkel 1962; Chandler 1966; Blight 1967)have all used different methods for determining the failure strainand strain rates for “single plane shearing” CD triaxial tests. Basedon data from various researchers, Head (1986) recommended that afailure strain of 1–5% be used for brittle clays. Chandler’s test resultsshowed approximately 2% axial strain at failure for preformedshearing plane tests conducted on Keuper Marl specimens.

Data used to determine the maximum allowable strain rate (toensure “drained” behavior) for triaxial tests conducted on RanchoSolano Clay and San Francisco Bay Mud specimens are given inTables 2 and 3, respectively. A failure strain of 1.0% was initiallyassumed, which was less than the lowest failure strain presented byChandler (1966). Based on the calculated maximum strain rates, aconservative strain rate of 0.0001%/min was selected for all tests.After testing, the observed strains at failure were all in theneighborhood of 1%, which means that the conservative strain ratethat was used was slow enough to ensure adequate pore pressuredissipation during shear. The tests that were conducted can thereforebe considered “drained.” Selection of a consistent strain rate for eachof the tests was also beneficial for negating any differences in themeasured strength values that might occur due to shear rate effects.

Once the residual strength had been reached, it was expectedthat application of additional axial strain would cause the testspecimens to deform by shearing along the preformed slickensidedplane. It should be noted that the term “strain” does not have apractical meaning for triaxial specimens that deform along a well-defined failure plane, since the shear occurs along a discontinuity,similar to what is observed in a direct shear test. The term“displacement” is probably more appropriate for specimens thatdeform by this mechanism.

Four consolidated-drained triaxial compression tests wereperformed on polished Rancho Solano Clay specimens, and threewere performed on polished San Francisco Bay Mud specimens.Rancho Solano Clay specimens were tested at effective confiningpressures of 35, 70, 84, and 105 kPa. San Francisco Bay Mudspecimens were tested at effective confining pressures of 35, 70, and105 kPa. For each triaxial compression test, test specimens weresheared until the deviator stress vs. strain curve showed that aconstant minimum shear stress had been reached.

Analysis of triaxial compression test dataIn order to determine accurate residual strength results from thetriaxial tests, it is essential to correctly account for the effect ofarea change and membrane restraint. For the case of specimensthat fail along a single shear plane, this procedure is moreinvolved than normal triaxial corrections. For this type of failuremechanism, strains develop throughout the entire specimen untilthe residual shear strength along the failure plane is fullymobilized (Head 1986); during this phase of the test, the specimendeforms by “barreling,” as shown in Fig. 5. This barrelingmechanism causes the area along the shear plane to increase,leading to an increase in membrane confinement around thespecimen due to the lateral constraint applied by the membrane.Once the strength along the shear plane has been reached, thespecimen begins to shear along the preformed plane. As thisoccurs, the area along the shear plane decreases, as the two halvesof the specimen are displaced past one another (Fig. 5). Thiscauses the membrane confinement to increase at an even moredramatic rate, as the membrane is then restraining two relativelyrigid objects that are being pushed past one another.

Table 3 Calculated strain rates for triaxial tests on San Francisco Bay Mud specimens

Effective confiningpressure (kPa)

Measuredt100 (min)

Assumedεf (%)

Calculated strainrate (%/min)

Observedεf (%)

Strain rate usedfor testing (%/min)

35 313 1 0.0004 1.8 0.0001

70 650 1 0.0002 1.8 0.0001

105 1,120 1 0.0001 2.1 0.0001

Fig. 5 Specimen deformation by “barreling” and “single plane shearing”(modified from Head 1986)

Fig. 6 “Single plane shearing” membrane corrections; data from tests on Lucitespecimens

Landslides

Area correctionThe transition from a “barreling” to a “single plane shearing”mode of failure can occur at relatively low strain levels. The pointat which this transition occurs is dependent on the ratio of intactspecimen strength to the strength along the predefined failureplane (e.g., a more heavily overconsolidated specimen will beginshearing along the plane at smaller deviatoric strains). As thistransition point can be very subtle, it is nearly impossible toidentify the specific strain at which this transition happens fromvisual observation. In order to identify the amount of shearingthat has occurred along the failure plane during a test, Bishop andHenkel (1962), Chandler (1966), and Head (1986) suggest that thetotal final displacement along the shear plane be measured afterthe test has been completed. This displacement can then be usedto back-calculate the corresponding strain at which the transitionfrom “barreling” to “single plane shearing” occurred. During thisstudy, it was observed that this approach is much more difficult toapply than first expected due to fact that the leading edges of eachspecimen half are deformed from the stresses applied by themembrane.

In this study, the point of inflection in the deviator stress—axial strain curve was used as an indicator of the initiation of“single plane shearing.” This inflection point coincided with aconsiderable reduction in the volumetric strain, a phenomenonnoted by Head (1986) to be a reasonable indicator of thecommencement of single-plane shearing.

Separate area and membrane corrections were applied in thisstudy, corresponding to the current deformation mechanism thatwas occurring during the triaxial test. Prior to the commencementof single plane shearing, the “barreling” correction given in Eq. 2was used. After the initiation of “single plane shearing,” Eq. 3 wasused, as proposed by Head (1986).

The following equation was used to correct the specimenarea while the specimen was deforming by the barrelingmechanism:

A ¼ Ac1� "v1� "a

ð2Þ

Where:

A Corrected area while the specimen is deforming by barrelingAc Area of the specimen after consolidation, prior to applica-

tion of deviator stressεv Volumetric strainεa Axial strain

The following equation was used to correct the specimen areaafter the point of failure, while the specimen was deforming bythe “single plane shearing” mechanism:

As ¼ A � 2p

� �: b � sin b: cos bð Þ ð3Þ

Where:

As Corrected area after the point of failure (while “single planeshearing” is occurring)

A Specimen area right before “single plane shearing” begins,corrected for the effect of barreling

β cos�1 "sLD tan �

� �εs Strain at which single plane shearing initiatedL Height of the specimen right before the “single plane shea-

ring” begins

Fig. 7 Typical “deviator stress-axial strain” and “volumetric strain-axial strain”plots for triaxial tests on polished Rancho Solano Clay specimens

Fig. 8 Typical “deviator stress-axial strain” and “volumetric strain-axial strain”plots for triaxial tests on polished San Francisco Bay Mud specimens

Fig. 9 Mohr’s circles for single-stage triaxial tests on polished Rancho Solano Clayspecimens

Original Paper

Landslides

D Diameter of the specimen right before “single plane shearing”begins

θ Angle of inclination of the shearing plane from the vertical axis.

Membrane correctionPrior to the commencement of “single plane shear,” use of amembrane correction corresponding to a “barreling” shear mecha-nism is appropriate. The correction recommended by Bishop andHenkel (1962), based on the extension modulus of the triaxialmembranes, was used in this study. The correction in deviator stresswas calculated using Eq. 4:

�r ¼ p � D �M � "a � 1� "að ÞAo

¼ 4 �M � "a � 1� "að ÞD

ð4Þ

Where:

Ao Initial cross-sectional area of the membraneσr Correction in deviator stressD Initial diameter of the specimenεa Axial strainM Compression modulus of the rubber membrane, per unit

width (assumed approximately equal to the measured exte-nsion modulus)

Two latex membranes were used to confine the triaxialspecimens during each test. Each membrane was approximately

0.07 mm thick, for a combined latex thickness of 0.14 mm.Membranes were tested using an Instron tension testing machine,and the value of Young’s Modulus of Elasticity (E) and extensionmodulus of the membrane were 1.39 MPa and 0.2 N/mm,respectively.

Once a specimen begins to shear along a preformed failureplane, it becomes necessary to use a different membranecorrection than what was used when the specimen wasdeforming by a “barreling” shear mechanism; a “single planeshear” membrane correction is more appropriate at this point.The appropriate membrane correction for “single plane shear-ing” has been examined by Chandler (1966), Blight (1967), LaRochelle (1967), Symons (1967), Symons and Cross (1968), andBalkir and Marsh (1974). The general approach employed bythese researchers was to perform tests on dummy samples ofPlasticine, Lucite, or Perspex having preformed shearing planesthat were well-lubricated or fitted with ball bearings. Ingeneral, the results obtained by these researchers were notconsistent, although all have observed that the resistanceprovided by the membrane is proportional to triaxial cellpressure.

To evaluate the membrane correction that should beused for these tests, a cylindrical Lucite “specimen” havinga diameter of 35 mm and height of 85 mm was fabricatedand cut at an angle of 55° from the horizontal. The precutplane was lubricated with vacuum grease applied to a thinplastic sheet. The pieces were then reassembled, placed in atriaxial compression device, and sheared at a strain rate of1%/min. The resulting membrane corrections for differentcell pressures obtained from this experiment (for “freeplatens” on both ends) are presented in Fig. 6. Anempirical equation was developed for the data shown inFig. 6 and the membrane correction (σm) was calculatedusing Eq. 5.

�m ¼ "a � 0:8þ 0:0048 � �30ð Þ ð5Þ

Where,

σm Membrane correction in kPaσ3' Effective cell pressure in kPaεa Axial strain

Fig. 11 Residual strength failure envelopes measured in single-stage CD triaxial tests, Bromhead ring shear tests, and polished-specimen direct shear tests on RanchoSolano Clay specimens

Fig. 10 Mohr’s circles for single-stage triaxial tests on polished San Francisco BayMud specimens

Landslides

Triaxial compression test resultsTypical deviator stress and volumetric strain measurements fortriaxial tests conducted on Rancho Solano Clay and San FranciscoBay Mud specimens are shown in Figs. 7 and 8, respectively. Thedata presented are for tests conducted at an effective confiningpressure of 70 kPa. Mohr’s circles and the corresponding Mohr–Coulomb failure envelopes for the CD triaxial tests on polishedRancho Solano Clay and San Francisco Bay Mud specimens aregiven in Figs. 9 and 10. Linear regression analysis resulted in thedrained residual shear strength parameters shown below:

Rancho Solano Clay c0 ¼ 0 kPa; and fr0 ¼ 24:5�

San Francisco Bay Mud c0 ¼ 18:6 kPa and fr0 ¼ 21:3�:

Figures 11 and 12 show the residual strength envelopes thatwere measured in the triaxial tests that were conducted, and theaverage results from Bromhead ring shear tests and polished-specimen direct shear tests conducted on Rancho Solano Clay andSan Francisco Bay Mud specimens (Meehan et al. 2007, 2010). Ascan be seen, the residual strength failure envelopes measuredusing triaxial tests on wire cut and polished specimens are higherthan the residual strength failure envelopes obtained from thedrained ring shear tests. For the tests on Rancho Solano Clayspecimens, this is a particularly unexpected result, because testson polished direct shear specimens gave drained residual shearstrengths that were in excellent agreement with those measured inring shear tests (Meehan et al. 2010).

The lack of agreement between triaxial test data and ring sheartest data for San Francisco Bay Mud specimens is consistent withwhat was observed in direct shear tests on polished SFBM testspecimens (Meehan et al. 2010). The greater discrepancy betweentriaxial test results and ring shear test results for San Francisco BayMud (illustrated by the large difference in measured cohesion) mayhave been caused by the SFBM specimen polishing process. For thissoil, it was much more difficult to obtain a “shiny” polished surface.The reason for this difference in behavior is not clear; it is thoughtthat perhaps the polishing process was affected by the high organiccontent of the San Francisco Bay Mud.

For comparison purposes, the shear rate for the ring shear testswas 0.018 mm/min, and the shear rate for the direct shear tests was0.003 mm/min. For triaxial tests conducted at an axial strain rate of0.0001%/min, for an approximately 75 mm tall specimen with afailure plane oriented at 55° from the horizontal, the resulting shear

displacement rate along the failure plane would be approximately0.00009 mm/min. From these numbers, it can be clearly seen thattest specimens with an increasingly longer drainage path length (ringshear, direct shear, and then triaxial, in that order) require slowerand slower shear rates to ensure adequate pore pressure dissipationduring drained testing. As noted previously, the largest strengthswere measured for the triaxial tests, which were conducted at theslowest rate. As faster shear tests are generally associated with highershear strengths (the strain-rate effect), the different strengths thatwere measured in the different test devices cannot be attributed torate-of-loading effects alone.

In general, despite the lack of agreement between thetriaxial data and the ring shear and direct shear data, the useof free-platens was found to be extremely beneficial for triaxialspecimens that fail along a well-defined plane. Comparison ofthe test results presented here with the results from testsconducted using traditional fixed platens on the same soilsshows that platen restraint had an extremely significant effecton the measured strengths. Also, the precutting and polishingprocedure significantly lowered the measured residual strengthvalues from those that were measured in intact specimentesting, for tests conducted using both fixed and free platens.These triaxial testing techniques may prove beneficial for othertriaxial test research projects and experimental studies.

Fig. 13 Comparison of deviator stresses measured in single stage and multistagetriaxial tests on Rancho Solano Clay specimens

Fig. 12 Residual strength failure envelopes measured in single-stage CD triaxial tests, Bromhead ring shear tests, and polished-specimen direct shear tests on SanFrancisco Bay Mud specimens

Original Paper

Landslides

“Multistage” CD triaxial testingDuring the course of this research, it was found that it was ratherdifficult and time-consuming to set up each specimen, to prepareconsistently similar specimens for the individual tests, and tomaintain similar conditions for tests conducted at differenteffective confining pressures. In addition, the slow strain ratesused required lengthy testing times. Therefore, to reduce testingtime and to simplify the testing process for future consolidated-drained triaxial tests of this type, the utility of “multistage”triaxial tests was explored. For each multistage test, a single claytriaxial specimen was consolidated using an effective cell pressureof 105 kPa, and unloaded to an effective cell pressure of 35 kPa.The specimen was then sheared until a constant minimumresidual strength value had been measured. Rancho Solano Clayspecimens were then reconsolidated and sheared at highereffective cell pressures of 70, 84, and 105 kPa; and San FranciscoBay Mud specimens were reconsolidated and sheared at highereffective cell pressures of 70 and 105 kPa. The deviator stressmeasurements that were made in single stage and multistagetriaxial tests conducted on Rancho Solano Clay specimens areshown in Fig. 13.

As shown in Fig. 13, there was close agreement between theresidual strengths measured in single stage and multistagetriaxial tests for Rancho Solano Clay. Similar agreement wasobserved for triaxial tests conducted on San Francisco BayMud specimens; for brevity, this data has been omitted. Thistest data supports the use of multistage testing for consoli-dated-drained triaxial tests, provided that careful attention isgiven to the effects of end platen restraint, membrane restraint,and change in specimen area during shear. It is believed that awell-defined failure plane was beneficial for achieving theagreement that is shown above.

Summary and conclusionsConsolidated-drained triaxial tests were performed to measurethe drained residual strength of two natural fine grained soils,Rancho Solano Clay and San Francisco Bay Mud. To prepare thetriaxial specimens for residual strength testing, specimens wereprecut at an angle of 55° from the horizontal and polished againsta frosted glass plate for a cumulative displacement of approx-imately 1.8 m. Custom end platens were used for the triaxialtesting, allowing for unrestrained horizontal movement of bothends of the test specimen. Care was taken to obtain the propertiesof the membrane, and to apply the appropriate membranecorrection factors and area correction factors for specimens thatfail along a well-defined plane.

The resulting drained residual shear strengths measured forthe precut and polished specimens were found to be higher thanthe drained residual strengths measured for these soils in theBromhead ring shear device, and were also higher than thosemeasured in tests on polished direct shear specimens (Meehan etal. 2010). This difference occurred despite thorough attempts toaddress triaxial testing details such as the effect of end platenrestraint and selection of the appropriate membrane correctionfor specimens that fail along a well-defined shear plane. Thesefindings are different than those presented in Meehan et al. (2010)for direct shear tests conducted on polished slickensided surfaces.It is consequently clear that triaxial testing of polished slick-ensided surfaces is significantly more challenging than the use of

direct shear tests for this purpose. However, triaxial tests areneeded for cyclic (seismic) testing, so future research in this areais warranted. In any case, it is hoped that the techniquespresented in this paper can be of use to other researchers thatare conducting work in this area, eventually leading to amethodology that can be used for the seismic testing ofslickensided surfaces.

Although the triaxial tests presented herein did not agreeclosely with the Bromhead ring shear data, there was excellentagreement between the residual strengths measured in singleand multistage triaxial tests. This data supports the use ofmultistage testing for triaxial specimens that fail along a welldefined plane. If a multistage triaxial test approach is going tobe used, careful attention needs to be given to the effects oflateral end platen restraint, membrane restraint, and changesin specimen area during shear. A “both-ends free” platenapproach is recommended for minimizing the effect of endplaten restraint, particularly for specimens that fail along awell-defined failure plane.

AcknowledgmentsFunding for this research was provided by the NationalScience Foundation under Award nos. CMS-0321789 andCMS-0324499.

References

Balkir T, Marsh AD (1974) Triaxial tests on soils: corrections for effects of membranesand filter drain. TRRL Supplementary Report 90 UC, Transportation and RoadResearch Laboratory, Crowthorne

Barden L, McDermott RJW (1965) Use of free ends in triaxial testing of clays. J SoilMech Found Div, ASCE 91(6):1–23

Bishop AW, Henkel DJ (1962) The measurement of soil properties. Edward ArnoldPublishers Ltd, London

Bishop AW, Green GE, Garga VK, Andresen A, Brown JD (1971) A new ring shearapparatus and its application to the measurement of residual strength. Geotechnique21(4):273–328

Blight GE (1967) Observations on the shear testing of indurated fissured clays. ProcGeotech Conference, Oslo 1:97–102

Bromhead EN (1979) A simple ring shear apparatus. Ground Eng 12(5):40–44Chandler RJ (1966) The measurement of residual strength in triaxial compression.

Geotechnique 16(3):181–186Duncan JM, Wright SG (2005) Soil strength and slope stability. Wiley, HobokenHead KH (1986) Manual of soil laboratory testing. Vol. 3 (effective stress tests), for ELE

International Ltd. Wiley, NYKenney TC (1977) Residual shear strength of mineral mixtures. Ninth Int Conf Soil Mech

Found Eng Jpn 1:155–160La Rochelle P (1967) Membrane, drain, and area correction in triaxial tests on soil

samples failing along a single shear plane. Proc. 3rd Pan-American conference onsoil mechanics and foundation engineering, Caracas, Venezuela, 1, 273–292

Lupini JF, Skinner AE, Vaughan PR (1981) The drained residual strength of cohesivesoils. Geotechnique 31(2):181–213

Meehan CL (2006) An experimental study of the dynamic behavior of slickensided slipsurfaces. Virginia Tech Ph.D. Dissertation, Advisor: J. Michael Duncan (Dissertationsubmitted to the faculty of the Virginia Polytechnic Institute and State University in partialfulfillment of the requirements for the degree of Doctor of Philosophy in Civil Engineering.Available from: http://scholar.lib.vt.edu/theses/available/etd-01302006-101603/)

Meehan CL, Brandon TL, Duncan JM (2007) Measuring drained residual strengths in theBromhead ring shear. Geotech Test J ASTM 30(6):466–473

Meehan CL, Boulanger RW, Duncan JM (2008) Dynamic centrifuge testing ofslickensided shear surfaces. J Geotech Geoenviron Eng, ASCE 134(8):1086–1096

Meehan CL, Brandon TL, Duncan JM, Tiwari B (2010) Direct shear testing of polishedslickensided surfaces. Landslides, Journal of the International Consortium onLandslides, Springer, 7(2), 157–167

Landslides

Skempton AW (1964) Long-term stability of clay slopes. Geotechnique 14(2):75–102Skempton AW (1985) Residual strength of clays in landslides, folded strata, and the

laboratory. Geotechnique 35(1):3–18Skempton AW, Petley DJ (1967) The strength along structural discontinuities in stiff

clays. Geotech Conference, Oslo, 29–46Symons IF (1967) Discussion. Proc Geotechnical Conference, Oslo 2:175–177Symons IF, Cross MR (1968) The determination of the shear-strength parameters along

natural slip surfaces encountered during sevenoaks by-pass investigations. Report LR139. Transportation and Road Research Laboratory, Crowthorne, Berks

Tiwari B, Marui H (2005) A new method for the correlation of residual shear strength ofthe soil with mineralogical composition. J Geotech Geoenviron Eng, ASCE 131(9):1139–1150

USACE (1986) Laboratory soils testing—engineer manual 1110-2-1906. United StatesArmy Corps of Engineers, Washington, D.C

C. L. Meehan ())Department of Civil and Environmental Engineering,University of Delaware,301 DuPont Hall, Newark, DE 19716, USAe-mail: [email protected]

B. TiwariDepartment of Civil and Environmental Engineering,California State University,Fullerton, 800 N. State College Blvd. E-419, Fullerton, CA 92834, USA

T. L. Brandon : J. M. DuncanDepartment of Civil and Environmental Engineering,Virginia Tech,200 Patton Hall, Blacksburg, VA 24061, USA

Original Paper

Landslides