TRAY-RATED CABLE ÖLFLEX · Tray-Rated Cable 800-774-3539 • • • 47 TRAY-RATED CABLE Quick...

Transcript of TRAY-RATED CABLE ÖLFLEX · Tray-Rated Cable 800-774-3539 • • • 47 TRAY-RATED CABLE Quick...

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 47

TRAY-RATED CABLE

Quick Select Chart 48

ÖLFLEX® TC 600/TC 600 S 50Flexible Tray Cable with TC-ER for Easier Installations; Unshielded & Shielded ÖLFLEX® TRAY II/TRAY II CY 52Extremely Oil-Resistant & Flexible Tray Cable with UL & CSA; Unshielded & Shielded ÖLFLEX® AUTO-I 54Heavy Duty, Flexible Tray Cable with Colored Conductors for DC or AC Control Wiring

ÖLFLEX® FORTIS 55Highly Flexible and Extremely Oil-Resistant Tray Cable; -40°C Flexible/-55°C Stationary

I 304 57300 V PLTC ITC Instrumentation Cable with Individually Shielded Pairs/Triads; Overall Shield

Tray-Rated Cable in Other Catalog Sections

ÖLFLEX® CONTROL TM/TM CY 30

ÖLFLEX® POWER MULTI 36

ÖLFLEX® FD AUTO-X 75

ÖLFLEX® VFD SLIM 96

ÖLFLEX® VFD XL 97

ÖLFLEX® VFD with Signal 98

V 2000 99

ÖLFLEX® FD VFD 100

ÖLFLEX® SDP TC 101

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com48

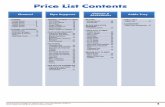

Product AWG Range Conductor Counts* Stranding Shield Jacket Low Temp High Temp Wet Rating Oil Flame Mechanical Page

ÖLFLEX® TC 600 18 - 6 AWG 2, 3, 4, 5, 7, 9, 12, 16, 19, 25 Class B stranded wire NoSpecially

formulated PVC-40°C 90°C 75°C 50

ÖLFLEX® TC 600 S 18 - 10 AWG 2, 3, 4, 5, 7, 9, 12, 16, 19, 25 Class B stranded wire YesSpecially

formulated PVC-40°C 90°C 75°C 50

ÖLFLEX® TRAY II18 AWG -

500 KCMIL2, 3, 4, 5, 7, 8, 9, 12, 16, 18, 25, 41, 50, 61 Class 5 / Class K fine wire No

Specially formulated

thermoplastic polymer

-40°C 90°C 75°C 52

ÖLFLEX® TRAY II CY18 AWG -

2 AWG2, 3, 4, 5, 7, 12,18, 25 Class 5 / Class K fine wire Yes

Specially formulated

thermoplastic polymer

-40°C 90°C 75°C 52

ÖLFLEX® AUTO-I 18 - 16 AWG 3, 5, 7, 11, 12, 19, 25, 33, 42, 49, 65 Class K fine wire No

Specially formulated

thermoplastic polymer

-25°C 90°C 75°C 54

ÖLFLEX® FORTIS 18 - 2 AWG 3, 4, 5, 7, 9, 12, 16, 18, 25 Class 5 / Class K fine wire NoSpecially

formulated PVC-55°C 105°C 75°C 55

I 304 20 - 16 AWGPairs: 1, 2, 3, 4, 6, 8, 12, 16, 24

Triads: 1, 2, 4, 6, 8, 12Class B stranded wire Yes PVC -30°C 105°C — 57

ÖLFLEX® CONTROL TM 18 - 10 AWG 3, 4, 5, 6, 7, 9, 10, 12, 15, 19, 20, 25 Class 5 fine wire No PVC -40°C 90°C 75°C 30

ÖLFLEX® CONTROL TM CY 18 - 10 AWG 3, 4, 5, 6, 7, 9, 10, 12, 15, 19, 20, 25 Class 5 fine wire Yes PVC -40°C 90°C 75°C 30

ÖLFLEX® POWER MULTI 18 - 8 AWG 3, 4, 5, 7, 12, 18, 25 Class 5 fine wire No Elastomeric alloy -40°C 90°C 75°C 36

UNITRONIC® 300/300 S 28 - 16 AWG 2, 3, 4, 6, 8, 10, 15, 20, 25, 30, 40, 50 Class 5 fine wire Yes & No PVC -25°C 90°C 75°C 208

ÖLFLEX® FD AUTO-X 18 - 16 AWG 3, 5, 7, 11, 12, 19, 25, 33, 42, 49, 55 Class M stranding No TPE -25°C 90°C 75°C 75

ÖLFLEX® VFD SLIM 18 - 2 AWG 4 Class 5 fine wire Yes PVC -25°C 90°C 75°C 96

ÖLFLEX® VFD XL 16 - 2 AWG 4 Class 5 / Class K fine wire Yes PVC -25°C 90°C 90°C 97

ÖLFLEX® VFD with Signal 16 - 4 AWG 4 conductors + 1 pair Class 5 fine wire Yes TPE -25°C 105°C 75°C 98

V 20001 AWG -

500 KCMIL3 conductors + 3 symmetrical grounds Class B stranded wire Yes PVC -25°C 90°C 90°C 99

ÖLFLEX® VFD FD 14 - 10 AWG 4 Class 6 super fine wire Yes TPE -25°C 105°C 75°C 100

ÖLFLEX® SDP TC 14 - 2 AWG 4 Class 5 fine wire No TPE -40°C 105°C 75°C 101

Quick Select Chart

* Other conductor counts are available upon request.

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 49

Product AWG Range Conductor Counts* Stranding Shield Jacket Low Temp High Temp Wet Rating Oil Flame Mechanical Page

ÖLFLEX® TC 600 18 - 6 AWG 2, 3, 4, 5, 7, 9, 12, 16, 19, 25 Class B stranded wire NoSpecially

formulated PVC-40°C 90°C 75°C 50

ÖLFLEX® TC 600 S 18 - 10 AWG 2, 3, 4, 5, 7, 9, 12, 16, 19, 25 Class B stranded wire YesSpecially

formulated PVC-40°C 90°C 75°C 50

ÖLFLEX® TRAY II18 AWG -

500 KCMIL2, 3, 4, 5, 7, 8, 9, 12, 16, 18, 25, 41, 50, 61 Class 5 / Class K fine wire No

Specially formulated

thermoplastic polymer

-40°C 90°C 75°C 52

ÖLFLEX® TRAY II CY18 AWG -

2 AWG2, 3, 4, 5, 7, 12,18, 25 Class 5 / Class K fine wire Yes

Specially formulated

thermoplastic polymer

-40°C 90°C 75°C 52

ÖLFLEX® AUTO-I 18 - 16 AWG 3, 5, 7, 11, 12, 19, 25, 33, 42, 49, 65 Class K fine wire No

Specially formulated

thermoplastic polymer

-25°C 90°C 75°C 54

ÖLFLEX® FORTIS 18 - 2 AWG 3, 4, 5, 7, 9, 12, 16, 18, 25 Class 5 / Class K fine wire NoSpecially

formulated PVC-55°C 105°C 75°C 55

I 304 20 - 16 AWGPairs: 1, 2, 3, 4, 6, 8, 12, 16, 24

Triads: 1, 2, 4, 6, 8, 12Class B stranded wire Yes PVC -30°C 105°C — 57

ÖLFLEX® CONTROL TM 18 - 10 AWG 3, 4, 5, 6, 7, 9, 10, 12, 15, 19, 20, 25 Class 5 fine wire No PVC -40°C 90°C 75°C 30

ÖLFLEX® CONTROL TM CY 18 - 10 AWG 3, 4, 5, 6, 7, 9, 10, 12, 15, 19, 20, 25 Class 5 fine wire Yes PVC -40°C 90°C 75°C 30

ÖLFLEX® POWER MULTI 18 - 8 AWG 3, 4, 5, 7, 12, 18, 25 Class 5 fine wire No Elastomeric alloy -40°C 90°C 75°C 36

UNITRONIC® 300/300 S 28 - 16 AWG 2, 3, 4, 6, 8, 10, 15, 20, 25, 30, 40, 50 Class 5 fine wire Yes & No PVC -25°C 90°C 75°C 208

ÖLFLEX® FD AUTO-X 18 - 16 AWG 3, 5, 7, 11, 12, 19, 25, 33, 42, 49, 55 Class M stranding No TPE -25°C 90°C 75°C 75

ÖLFLEX® VFD SLIM 18 - 2 AWG 4 Class 5 fine wire Yes PVC -25°C 90°C 75°C 96

ÖLFLEX® VFD XL 16 - 2 AWG 4 Class 5 / Class K fine wire Yes PVC -25°C 90°C 90°C 97

ÖLFLEX® VFD with Signal 16 - 4 AWG 4 conductors + 1 pair Class 5 fine wire Yes TPE -25°C 105°C 75°C 98

V 20001 AWG -

500 KCMIL3 conductors + 3 symmetrical grounds Class B stranded wire Yes PVC -25°C 90°C 90°C 99

ÖLFLEX® VFD FD 14 - 10 AWG 4 Class 6 super fine wire Yes TPE -25°C 105°C 75°C 100

ÖLFLEX® SDP TC 14 - 2 AWG 4 Class 5 fine wire No TPE -40°C 105°C 75°C 101

Cable Attributes, see page 659

Rating Oil Resistance

Flame Resistance

Mechanical Properties

Ultimate OR-05 FR-05 MP-05Excellent OR-04 FR-04 MP-04Superior OR-03 FR-03 MP-03

Above Average OR-02 FR-02 MP-02Average OR-01 FR-01 MP-01

ÖLFLEX®

Flexible Control Cable Sub Header

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com50

Tray-Rated Cable

Unshielded Construction

Shielded Construction

Complete the Installation Similar Cables

Application Advantage

Approvals

Recommended Applications

SKINTOP®

Strain Relief:page 502

EPIC®

Connectors:page 278

Technical Data Minimum Bend Radius:

- for installation: 4 x cable diameter - shielded: 6 x cable diameter

Temperature Range: - UL TC/CSA CIC: -40°C to +90°C - for flexible use: -5°C to +90°C - for stationary use: -40°C to +105°C

Nominal Voltage: - UL TC/CSA CIC: 600V - UL WTTC: 1000V

Test Voltage: 2000V

Conductor Stranding: Class B stranded wire

Color Code: Black with white numbers and color name per color chart ICEA-NEMA (K-2): Chart 10, page 698, plus green/yellow ground

Approvals: UL: TC-ER per UL 1277 MTW per UL 1063 (14 AWG and larger) WTTC per UL 2277 B us Drop Cable

(14 AWG and larger, 3c & 4c) AWM 20886 Attributes: 75°C Wet; 90°C Dry Sunlight Resistant Direct Burial NFPA 79 2015 Bus Drop Approval NEC: Class 1 Division 2 per NEC Article 501 Canada: c(UL) CIC FT4 cRU AWM I/II A/B FT4 Additional: CE & RoHS

• ÖLFLEX® TRAY II/TRAY II CY• ÖLFLEX® CONTROL TM/

CONTROL TM CY

Cable Attributes, see page 659

OR-01 FR-03 FL-01 MP-03

OIL FLAME MOTION MECHANICAL

• Easier to pull than standard tray cable• UL TC-ER approval to reduce material costs; no

conduit is needed• Black numbered conductors with printed color code

for easy identification• UV-resistant and direct burial• UL wet rating 75°C

Plant expansion; contractor markets; A&E firm plant designs; tray wiring; anywhere VNTC® cables are used

ÖLFLEX® TC 600 is a multi-conductor cable approved for use in cable trays. It is UL TC-ER & CSA CIC approved, making it perfect for new plant installations and factory expansions. ÖLFLEX® TC 600 S has an overall foil tape and drain wire for EMI & RFI protection.

Conductors: Finely stranded bare copper

Insulation: Specially blended PVC/nylon

Shielding: Foil tape (100% coverage); drain wire

Jacket: Specially formulated PVC; black

LAPP KABEL ÖLFLEX® TC 600 S

Conductors: Finely stranded bare copper

Insulation: Specially blended PVC/nylon

Jacket: Specially formulated PVC; black

LAPP KABEL ÖLFLEX® TC 600

Flexible Tray Cable with TC-ER for Easier Installations; Unshielded & ShieldedÖLFLEX® TC 600/600 S

VNTC® is a registered trademark of General Cable.

Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 51

Recommended SKINTOP® assumes minimal OD variance. Additional configurations are available, please see our SKINTOP® Section. Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

ÖLFLEX® TC 600 S

ÖLFLEX® TC 600

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (7 strand)211802* 2 0.273 6.9 13 42 S2109211803 3 0.287 7.3 16 55 S2111211804 4 0.310 7.9 22 64 S2111211805 5 0.335 8.5 27 75 S2111211807 7 0.361 9.2 38 97 S2111211809 9 0.416 10.6 48 108 S2113211812 12 0.462 11.7 64 165 S2116211819 19 0.569 14.5 101 262 S2121211825 25 0.648 16.5 133 311 S2121

16 AWG (7 strand)211602* 2 0.295 7.5 18 51 S2111211603 3 0.311 7.9 26 66 S2111211604 4 0.337 8.6 35 79 S2111211605 5 0.364 9.2 43 95 S2111211607 7 0.394 10.0 60 123 S2113211609 9 0.455 11.6 77 165 S2113211612 12 0.508 12.9 103 214 S2116211615 15 0.594 15.1 128 235 S2121211616 16 0.594 15.1 137 246 S2121211619 19 0.624 15.8 162 287 S2121211625 25 0.718 18.2 213 311 S2129211637 37 0.822 20.9 300 514 S2129

14 AWG (19 strand)211402* 2 0.325 8.3 27 64 S2111211403** 3 0.343 8.7 41 84 S2111211404** 4 0.373 9.5 54 104 S2111211405 5 0.405 10.3 68 123 S2113211407 7 0.439 11.2 94 163 S2113211412 12 0.602 15.3 162 298 S2121211419 19 0.699 17.8 255 450 S2129211425 25 0.807 20.5 336 569 S2129

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

12 AWG (19 strand)211202* 2 0.363 9.2 43 86 S2111211203** 3 0.384 9.8 64 110 S2113211204** 4 0.419 10.6 86 148 S2113211205 5 0.456 11.6 107 181 S2113211207 7 0.496 12.6 150 324 S2116211209 9 0.610 15.5 192 359 S2121211212 12 0.681 17.3 256 432 S2129211216 16 0.754 19.2 341 1190 S2129211219 19 0.794 20.2 405 683 S2129211225 25 0.960 24.4 533 899 S2129

10 AWG (19 strand)211002* 2 0.439 11.2 74 326 S2113211003** 3 0.466 11.8 103 194 S2116211004** 4 0.511 13.0 138 256 S2116211005 5 0.591 15.0 172 306 S2121211007 7 0.642 16.3 241 430 S2121

8 AWG (19 strand)210804** 4 0.650 16.5 233 335 S2121

6 AWG (19 strand)210604** 4 0.746 18.9 346 580 S2129

4 AWG (19 strand)210404** 4 1.009 25.6 521 924 S2136

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (7 strand)211802S* 2 0.276 7.0 17 44 S2111211803S 3 0.290 7.4 22 57 S2111211804S 4 0.313 8.0 27 66 S2111211805S 5 0.338 8.6 32 77 S2111211807S 7 0.364 9.2 43 99 S2111211809S 9 0.419 10.6 49 112 S2113211812S 12 0.465 11.8 69 170 S2116211819S 19 0.572 14.5 106 271 S2121211825S 25 0.651 16.5 138 322 S2121

16 AWG (7 strand)211602S* 2 0.298 7.6 18 119 S2111211603S 3 0.314 8.0 35 68 S2111211604S 4 0.340 8.6 43 84 S2111211605S 5 0.367 9.3 52 97 S2111211607S 7 0.397 10.1 69 126 S2113211609S 9 0.458 11.6 83 170 S2113211612S 12 0.511 13.0 111 220 S2116211619S 19 0.627 15.9 159 295 S2121211620S 20 0.658 16.7 161 311 S2121211625S 25 0.721 18.3 222 322 S2129

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

14 AWG (19 strand)211402S* 2 0.328 8.3 30 148 S2111211403S** 3 0.346 8.8 47 86 S2111211404S** 4 0.376 9.6 68 108 S2113211405S 5 0.408 10.4 81 128 S2113211407S 7 0.442 11.2 108 170 S2113211409S 9 0.513 13.0 122 224 S2116211412S 12 0.605 15.4 175 306 S2121211419S 19 0.702 17.8 262 463 S2129211425S 25 0.810 20.6 349 586 S2129

12 AWG (19 strand)211202S* 2 0.366 9.3 50 196 S2111211203S** 3 0.387 9.8 73 115 S2113211204S** 4 0.422 10.7 95 152 S2113211205S 5 0.459 11.7 106 185 S2113211207S 7 0.499 12.7 158 333 S2116211209S 9 0.613 15.6 190 370 S2121211212S 12 0.684 17.4 264 445 S2129211219S 19 0.797 20.2 409 705 S2129211225S 25 0.963 24.5 539 926 S2129

10 AWG (19 strand)211002S* 2 0.422 10.7 74 339 S2113211003S** 3 0.469 11.9 100 198 S2116211004S** 4 0.514 13.1 145 264 S2116211005S 5 0.594 15.1 179 317 S2121211007S 7 0.645 16.4 232 443 S2121

* 2c cable does not include ER and green/yellow ground** UL Bus Drop Approval

* 2c cable does not include ER and green/yellow ground** UL Bus Drop Approval

ÖLFLEX®

Flexible Control Cable Sub Header

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com52

Tray-Rated Cable

Unshielded Construction

Shielded Construction

Approvals

Application Advantage Recommended Applications

Similar Cables Complete the InstallationSKINTOP®

Strain Relief:page 502

EPIC®

Connectors:page 278

Technical Data Color Code: Black with white numbers,

plus green/yellow ground

Approvals: UL: TC-ER per UL 1277 MTW per UL 1063 WTTC per UL 2277 Submersible Pump (14 AWG & larger) PLTC-ER per UL 13 (18 - 12 AWG) ITC-ER per UL 2250 (18 - 12 AWG) DP-1 per UL 1690 AWM 20886 Attributes: UL Oil Res I/II 75°C Wet; 90°C Dry Sunlight Resistant Direct Burial NFPA 79 2015 NEC: Class 1 Division 2 per NEC Article 501 Canada: c(UL) CIC/TC FT4 CSA AWM I/II A/B FT4 Additional: T orsion Rated for Wind Market

(± 90°/m) & (± 150°/m) CE & RoHS MSHA-P07-KA050016-MSHA (shielded only)

Minimum Bend Radius: - for installation: - < 1 AWG: 4 x cable diameter -≥1AWG: 6xcablediameter - shielded: 6 x cable diameter

Temperature Range: - UL/CSA TC: -25°C to +90°C - for stationary use: -40°C to +105°C -forflexibleuse: -25°Cto+105°C

Nominal Voltage: - UL/CSA TC: 600V - UL WTTC/CSA AWM: 1000V

Test Voltage: 2000V

Conductor Stranding: -18-6AWG: Class5finewire* -4-2AWG: ClassKfinewire - 1 AWG - 500 KCMIL: Stranded wire

• ÖLFLEX® CONTROL TM/CONTROL TM CY

• ÖLFLEX® TC 600/600 S

Cable Attributes, see page 659

OR-03 FR-03 WT-02 MP-03

OIL FLAME MOTION MECHANICAL

Industrial plant expansions; automotive plants; tray wiring; anywhere VNTC® cables are used

• Oil-resistant pressure-extruded jacket for improved flexibility

• Easier to pull than standard tray cables, minimizing labor costs

• UL TC-ER approval to reduce material costs; no conduit is needed

•Blacknumberedconductorsforeasyidentification•Improvedshieldingeffectiveness

Conductors: Finely stranded bare copper

Insulation: Specially blended PVC/nylon

Shielding: Double laminated foil tape; tinned copper braid (70% coverage)

Jacket: Specially formulated thermoplastic polymer; black

ÖLFLEX® TRAY II is an industrial grade tray cable with superior oil performanceforlongcablelife.Ithasapressure-extrudedjacketandfinecopperstrandingforexcellentflexibility,makingitmucheasiertopullthrough tray. With UL TC-ER approval, no conduit is needed so you can reduce material costs along with saving on labor. ÖLFLEX® TRAY II CY has Lapp’s new double laminated foil tape and tinned copper braid shield for improvedeffectiveness.

Conductors: Finely stranded bare copper

Insulation: Specially blended PVC/nylon

Jacket: Specially formulated thermoplastic polymer; black

LAPP KABEL ÖLFLEX® TRAY II CY

LAPP KABEL ÖLFLEX® TRAY II

Extremely Oil-Resistant & Flexible Tray Cable with UL & CSA; Unshielded & ShieldedÖLFLEX® TRAY II/TRAY II CY

*18AWGmeetsonlytheClass5crosssectionandDCresistance

VNTC® is a registered trademark of General Cable. Photographs are not to scale and are not true representations of the products in question. Forcurrentinformationgotoourwebsite.Ifnototherwisespecified,allvaluesrelatingtotheproductarenominalvalues.

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 53

Recommended SKINTOP® assumes minimal OD variance. Additional configurations are available, please see our SKINTOP® Section. Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

ÖLFLEX® TRAY II CY

ÖLFLEX® TRAY II

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (1.00 mm2)221803 3 0.297 7.5 20 57 S2111221804 4 0.320 8.1 26 66 S2111221805 5 0.346 8.8 33 77 S2111221807 7 0.373 9.5 46 99 S2111221809 9 0.429 10.9 59 112 S2113221812 12 0.477 12.1 79 172 S2116221818 18 0.587 14.9 118 245 S2121221825 25 0.664 16.9 164 322 S2121221850 50 0.939 23.9 303 646 S2129

16 AWG (1.50 mm2)221603 3 0.325 8.3 29 68 S2111221604 4 0.351 8.9 39 84 S2111221605 5 0.381 9.7 49 99 S2113221607 7 0.412 10.5 68 128 S2113221608 8 0.444 11.3 78 137 S2113221609 9 0.476 12.1 88 172 S2116221612 12 0.565 14.4 117 220 S2121221616 16 0.621 15.8 155 271 S2121221618 18 0.652 16.6 175 289 S2121221625 25 0.741 18.8 242 397 S2129221634 34 0.904 23.0 296 540 S2129221641 41 0.986 25.0 357 626 S2136221650 50 1.048 26.6 436 760 S2136221661 61 1.085 27.6 533 771 S2136

14 AWG (2.50 mm2)221403 3 0.362 9.2 49 88 S2111221404 4 0.392 10.0 65 106 S2113221405 5 0.427 10.8 81 128 S2113221407 7 0.463 11.8 113 170 S2116221409 9 0.571 14.5 146 225 S2121221412 12 0.636 16.2 194 309 S2121221418 18 0.737 18.7 290 439 S2129221425 25 0.886 22.5 404 586 S2129

12 AWG (4 mm2)221203 3 0.423 10.7 78 126 S2113221204 4 0.460 11.7 104 152 S2113221205 5 0.503 12.8 129 187 S2116221207 7 0.581 14.8 181 258 S2121

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

10 AWG (6 mm2)221003 3 0.498 12.6 117 218 S2116221004 4 0.578 14.7 155 264 S2121221005 5 0.631 16.0 194 317 S2121221007 7 0.686 17.4 271 445 S2129

8 AWG (10 mm2)220804 4 0.703 17.9 258 384 S2129220805 5 0.772 19.6 323 518 S2129

6 AWG (16 mm2)220603 3 0.776 19.7 310 454 S2129220604 4 0.899 22.8 413 580 S2129220605 5 0.982 24.9 517 725 S2136

4 AWG (21 mm2)220403 3 0.999 25.3 386 919 S2136220404 4 1.094 27.8 544 952 S2136

2 AWG (33.7 mm2)220203 3 1.155 29.3 658 1085 S2136220204 4 1.272 32.3 859 1320 S2248

1 AWG (42.3 mm2)220104 4 1.400 35.6 1065 1563 S2142

1/0 AWG (52.9 mm2)221104 4 1.466 37.2 1302 1920 S2142

2/0 AWG (67.3 mm2)222204 4 1.674 42.5 1720 2369 S2148

3/0 AWG (84.8 mm2)223304 4 1.695 43.1 2185 3020 S2148

4/0 AWG (106.7 mm2)224404 4 2.059 52.3 2695 3597 53112080*

250 KCMIL (128.4 mm2)222504 4 2.167 55.0 3211 4221 531112511*

350 KCMIL (181.9 mm2)223504 4 2.501 63.5 4542 6004 53112510*

500 KCMIL (257.6 mm2)225004 4 2.902 73.7 6410 8233 53112512*

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

MS-SCPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (1.00 mm2)2218030 3 0.322 8.2 29 79 531122202218040 4 0.346 8.8 38 93 531122202218050 5 0.371 9.4 45 99 531122302218070 7 0.398 10.1 59 130 531122302218120 12 0.508 12.9 101 223 531122402218180 18 0.618 15.7 145 295 531122502218250 25 0.695 17.7 238 386 53112260

16 AWG (1.50 mm2)2216030 3 0.350 8.9 41 97 531122202216040 4 0.376 9.6 51 117 531122302216050 5 0.406 10.3 63 128 531122302216070 7 0.443 11.3 88 165 531122402216120 12 0.596 15.1 144 287 531122502216180 18 0.683 17.3 210 346 531122602216250 25 0.772 19.6 280 430 53112260

14 AWG (2.50 mm2)2214030 3 0.387 9.8 62 121 531122302214040 4 0.423 10.7 85 150 531122302214050 5 0.458 11.6 101 181 531122402214070 7 0.494 12.5 136 220 531122402214120 12 0.667 16.9 225 399 531122502214180 18 0.768 19.5 328 527 531122602214250 25 0.917 23.3 461 705 53112260

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

MS-SCPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

12 AWG (4 mm2)2212040 4 0.491 12.5 126 212 531122402212050 5 0.568 14.4 157 260 531122502212070 7 0.612 15.5 209 335 53112250

10 AWG (6 mm2)2210040 4 0.609 15.5 183 370 531122502210050 5 0.662 16.8 224 412 531122502210070 7 0.717 18.2 308 575 53112260

8 AWG (10 mm2)2208040 4 0.737 18.7 295 575 53112260

6 AWG (16 mm2)2206040 4 0.918 23.3 470 811 53112260

4 AWG (21 mm2)2204040 4 1.127 28.6 579 1331 53112270

2 AWG (33.7 mm2)2202040 4 1.309 33.2 950 1951 53112670†

* SKINTOP® MS-M: nickel-plated brass with metric thread.

† SKINTOP® MS-SC with metric thread.

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com54

Complete the Installation

Recommended SKINTOP® assumes minimal OD variance. Additional configurations are available, please see our SKINTOP® Section. Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

Recommended Applications

Approvals

Application Advantage

Construction

Similar CablesEPIC®

Connectors:page 278

SKINTOP® Strain Relief:

page 502

Technical Data

ÖLFLEX® AUTO-IHeavy Duty, Flexible Tray Cable with Colored Conductors for DC or AC Control Wiring

LAPP KABEL ÖLFLEX® AUTO-IConductors: Finely stranded bare copper

Insulation: Specially formulated PVC/nylon

Jacket: Specially formulated thermoplastic elastomer (TPE); gray

ÖLFLEX® AUTO-I is a UV-resistant, multi-conductor cable designed for use on machine tool equipment and other industrial machinery conforming to NFPA 79 2015 wiring norms. ÖLFLEX® AUTO-I is color-coded with either blue, red, yellow, orange, or black conductors for DC, AC, and other control wiring.

Machine tool machinery; food & beverage; processing equipment; automotive and machine wiring for conformance to NFPA 79 2015

• UL TC-ER & CSA CIC/TC approval• Number coded for easy wiring with either blue, red,

orange, black, or yellow conductors

• ÖLFLEX® TRAY II• ÖLFLEX® CONTROL TM

Cable Attributes, see page 659

OR-03 FR-03 FL-02 MP-03

OIL FLAME MOTION MECHANICAL

Minimum Bend Radius: 4 x cable diameter

Temperature Range: - UL/CSA TC: -25°C to +90°C -forflexibleuse: -25°Cto+105°C - for stationary use: -40°C to +105°C

Nominal Voltage: - UL/CSA TC: 600V - UL WTTC: 1000V

Test Voltage: 2000V

Color Code: - up to 7c: Colored with black numbers,

plus green/yellow ground (Black conductor has white numbers)

Conductor Stranding: ClassKfinewire

Color Code: - more than 7c (blue): No. 2 conductor is white/blue stripe - more than 7c: No. 2 conductor is white

(red, yellow, or orange)

Approvals: UL: TC-ER per UL 1277 WTTC per UL 2277 Attributes: UL Oil Res I 75°C Wet; 90°C Dry Sunlight Resistant Direct Burial NFPA 79 2015 NEC: Class 1 Division 2 per NEC Article 501 Canada: c(UL) CIC/TC FT4 CSA AWM I/II A/B FT4 Additional: CE & RoHS

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (1.00 mm2)251803IB 3 0.297 7.5 20 57 S1111251805IB 5 0.346 8.7 33 77 S1111251807IB 7 0.373 9.4 46 99 S1111251811IB 11 0.463 11.8 71 156 S1116251812IB 12 0.477 12.1 78 172 S1116251819IB 19 0.583 14.8 123 253 S1121251825IB 25 0.677 17.2 162 322 S1121251833IB 33 0.736 18.7 200 397 S1129251842IB 42 0.818 20.7 254 509 S1129251849IB 49 0.908 23.0 317 617 S1129251865IB 65 1.011 25.6 420 688 S1136

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

16 AWG (1.50 mm2)251603IB 3 0.323 8.2 26 66 S1111251607IB 7 0.409 10.4 60 126 S1113251611IB 11 0.541 13.7 94 203 S1121251612IB 12 0.557 14.1 103 218 S1121251617IB 17 0.638 16.1 145 256 S1121251619IB 19 0.643 16.3 162 284 S1121251625IB 25 0.737 18.7 213 397 S1129251633IB 33 0.816 20.7 270 489 S1129251642IB 42 0.950 24.1 343 628 S1129251649IB 49 1.005 25.5 401 760 S1136251665IB 65 1.123 28.5 531 1005 S1136

Part numbers shown are for blue conductors. For other colors, replace the ‘B’ with an ‘R’ for red, ‘Y’ for yellow, ‘O’ for orange, or ‘BK’ for black conductors.

ÖLFLEX®

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 55

Recommended SKINTOP® assumes minimal OD variance. Additional configurations are available, please see our SKINTOP® Section. Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

Tray-Rated Cable

Approvals

Recommended Applications Application Advantage

EPIC®

Connectors:page 278

Complete the InstallationSKINTOP®

Strain Relief:page 502

Similar Cables

Technical Data

LAPP KABEL ÖLFLEX® FORTIS

• ÖLFLEX® TRAY II• ÖLFLEX® CONTROL TM

Minimum Bend Radius: 4 x cable diameter

Temperature Range: - UL/CSA TC: -25°C to +90°C - for flexible use: -40°C to +105°C - for stationary use: -55°C to +105°C

Nominal Voltage: - UL/CSA TC: 600V - UL WTTC: 1000V

Test Voltage: 2000V

Conductor Stranding: - 18 - 6 AWG: Class 5 fine wire* - 4 - 2 AWG: Class K fine wire

Color Code: Black with white numbers, plus green/yellow ground

Approvals: UL: TC-ER per UL 1277 MTW per UL 1063 WTTC per UL 2277 Attributes: UL Oil Res I/II 75°C Wet; 90°C Dry Sunlight Resistant NFPA 79 2015 NEC: Class 1 Division 2 per NEC Article 501 Canada: c(UL) CIC/TC FT4 CSA AWM I/II A/B FT4 Additional: T orsion Rated for Wind Market

(± 90°/m) & (± 150°/m) CE & RoHS

Cable Attributes, see page 659

OR-03 FR-03 WT-03 MP-04

OIL FLAME MOTION MECHANICAL

Wind energy; machine tools; forestry equipment; oil & petrochem equipment; cold temperature storage & packaging facilities

• Arctic-grade jacket passes UL -40°C cold impact test• Passes Oil Res I/II requirements• Meets all tray cable (UL 1277) requirements• Outstanding mechanical toughness: TC-ER rated• Meets all Wind Turbine Tray Cable (UL 2277)

requirements• Meets torsion requirements for wind turbine

applications• Copper core is dual-rated for North American and

European standards: 18 AWG (1 mm2) to 6 AWG (16 mm2)

Conductors: Finely stranded bare copper

Insulation: Specially blended PVC/nylon

Jacket: Specially formulated PVC; blackÖLFLEX® FORTIS is named after the Latin word meaning “strength”. It offers outstanding mechanical performance, particularly at low temperatures. The specially formulated elastomeric jacket passes UL’s -40°C cold impact and -55°C cold bend tests. ÖLFLEX® FORTIS also offers outstanding oil resistance (UL Oil Res I/II) and meets all tray cable (UL 1277) and Wind Turbine Tray Cable (UL 2277) requirements.

Highly Flexible and Extremely Oil-Resistant Tray Cable: -40°C Flexible/-55°C StationaryÖLFLEX® FORTIS

Construction

* 18 AWG meets only the Class 5 cross section and DC resistance

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com56

Recommended SKINTOP® assumes minimal OD variance. Additional configurations are available, please see our SKINTOP® Section. Photographs are not to scale and are not true representations of the products in question. For current information go to our website. If not otherwise specified, all values relating to the product are nominal values.

ÖLFLEX® FORTIS

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG (1.00 mm2)331803 3 0.297 7.5 20 57 S2111331804 4 0.320 8.1 26 66 S2111331805 5 0.346 8.8 33 77 S2111331807 7 0.373 9.5 46 99 S2111331809 9 0.429 10.9 59 112 S2113331812 12 0.477 12.1 79 172 S2116331818 18 0.587 14.9 118 245 S2121331825 25 0.664 16.9 164 322 S2121

16 AWG (1.50 mm2)331603 3 0.325 8.3 29 68 S2111331604 4 0.351 8.9 39 84 S2111331605 5 0.381 9.7 48 99 S2113331607 7 0.412 10.5 68 128 S2113331609 9 0.476 12.1 88 172 S2116331612 12 0.565 14.4 117 220 S2121331616 16 0.621 15.8 155 271 S2121331618 18 0.652 16.6 175 289 S2121331625 25 0.741 18.8 242 390 S2129

14 AWG (2.50 mm2)331403 3 0.362 9.2 49 88 S2111331404 4 0.392 10.0 65 106 S2113331405 5 0.427 10.8 81 128 S2113331407 7 0.463 11.8 113 170 S2116331409 9 0.571 14.5 146 225 S2121331412 12 0.636 16.2 194 309 S2121331418 18 0.737 18.7 290 439 S2129331425 25 0.886 22.5 404 586 S2129

PartNumber

Number of Conductors

(incl. ground)

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

12 AWG (4 mm2)331203 3 0.425 10.8 78 126 S2113331204 4 0.460 11.7 104 152 S2113331205 5 0.503 12.8 129 187 S2116331207 7 0.581 14.8 181 258 S2121

10 AWG (6 mm2)331003 3 0.500 12.7 117 181 S2116331004 4 0.578 14.7 155 264 S2121331005 5 0.631 16.0 194 317 S2121331007 7 0.686 17.4 271 445 S2129

8 AWG (10 mm2)330804 4 0.703 17.9 258 414 S2129330805 5 0.772 19.6 323 518 S2129

6 AWG (16 mm 2)330604 4 0.899 22.8 413 580 S2129330605 5 0.982 24.9 517 725 S2136

4 AWG (21 mm 2)330404 4 1.094 27.8 515 952 S2136

2 AWG (33.7 mm 2)330204 4 1.272 32.3 875 1395 S2148330205 5 1.408 35.8 1095 1631 S2142

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com 57

Construction

Application Advantage Recommended Applications

Approvals

Similar Cables• UNITRONIC® 300 STP

Complete the InstallationSKINTOP®

Strain Relief:page 502

EPIC®

Connectors:page 278

Minimum Bend Radius: 8 x cable diameter

Temperature Range: - for stationary use: -30°C to +105°C - for flexible use: -10°C to +105°C

Nominal Voltage: 300V

Test Voltage: 1500V

Conductor Stranding: Class B stranded wire

Color Code: - Pairs: Black & white with printed numbers - Triads: Black, white, red with printed

numbers

Approvals: UL: CMG per UL 444 PLTC per UL 13 ITC per UL 2250 AWM 2464 Attributes: Sunlight Resistant Direct Burial NFPA 79 2015 Canada: CSA CMG FT4 CSA AWM I/II A/B FT4 CSA C22.2 No.214:

Communications Cable CSA C22.2 No. 210:

Appliance Wiring Material

Cable Attributes, see page 659

OR-01 FR-03 FL-01 MP-01

OIL FLAME MOTION MECHANICAL

Conductors: Bare copper

Insulation: PVC insulation (cabled pairs or triads); individually foil-shielded pairs or triads with a tinned copper drain wire; orange PVC communication wire*

Shield: Overall foil shield with a tinned copper drain wire (100% coverage)

Jacket: PVC; black

The Lapp Group’s new I 304 is an instrumentation cable rated for UL CMG, PLTC & ITC and CSA CMG. It is available with individually shielded pairs and triads and has an overall foil shield.

• UL/CSA rated 300 V• Passes UL & CSA Flame Test (70,000 BTU)• Sunlight & UV resistant, Direct Burial• Rated 105°C

Petrochem processing; machine control; oil & gas refining; low voltage control wiring

300V PLTC ITC Instrumentation Cable with Individually Shielded Pairs/Triads; Overall ShieldI 304

I 304

Technical Data

*Not required for single pair/triad construction

ÖLFLEX®

Tray-Rated Cable

800-774-3539 • www.lappusa.com • www.lappcanada.com • www.lappmexico.com58

I 304: Pairs

I 304: Triads

PartNumber

Number of Pairs

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

20 AWG2221312 1 0.213 5.4 10 25 S21072221313 2 0.327 8.3 24 54 S21112221314 8 0.514 13.1 79 141 S21162221315 12 0.637 16.2 116 207 S2121

18 AWG2221285 1 0.233 5.9 15 36 S21072221286 2 0.408 10.4 37 81 S21132221287 4 0.468 11.9 67 125 S21162221288 6 0.530 13.5 96 163 S21162221289 8 0.594 15.1 125 196 S21212221290 12 0.737 18.7 183 283 S21292221291 16 0.836 21.2 241 350 S2129

PartNumber

Number of Triads

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

18 AWG2221292 1 0.236 6.0 21 45 S21072221293 2 0.450 11.4 48 116 S21132221294 4 0.533 13.5 89 167 S21212221295 6 0.593 15.1 129 221 S21212221296 8 0.654 16.6 169 284 S2121

PartNumber

Number of Pairs

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

16 AWG2221297 1 0.257 6.5 22 46 S21092221298 2 0.450 11.4 53 114 S21132221299 3 0.481 12.2 78 138 S21162221300 4 0.512 13.0 96 164 S21162221301 6 0.600 15.2 139 218 S21212221302 8 0.687 17.4 181 281 S21292221303 12 0.822 20.9 267 386 S21292221304 16 0.936 23.8 352 507 S21292221305 24 1.149 29.2 523 714 S2136

PartNumber

Number of Triads

Nominal Outer Diameter

Copper Weight

Approx.Weight

SKINTOP®

Non-MetallicPG Thread(inches) (mm) (lbs/mft) (lbs/mft)

16 AWG2221306 1 0.271 6.9 30 59 S21092221307 2 0.506 12.9 67 150 S21162221308 4 0.569 14.5 127 224 S21212221309 6 0.666 16.9 186 316 S21212221310 8 0.704 17.9 244 389 S21292221311 12 1.000 25.4 361 563 S2136