Transformer Vault

-

Upload

mia-monica-fojas-loyola -

Category

Documents

-

view

120 -

download

1

description

Transcript of Transformer Vault

-

REQUIREMENTS FOR INDOOR INSTALLATION OF PADMOUNTED TRANSFORMERS Introduction An applicant applying for permanent electric service who opts to have the padmounted transformers installed inside his building shall be required to provide and construct a transformer vault conforming to the standards of Meralco. In view of the difficulties likely to be encountered by the building owner in providing the required location for the transformer vault inside the building once construction has started, he or his authorized representative should consult Meralco regarding this requirement during the initial design stage of the building. Transformer Vault All padmounted transformers to be installed inside customer-owned buildings shall be contained inside a PEC-approved transformer vault to be provided by the customer/building owner and to be used exclusively for the Meralco equipment. The walls and roof shall be constructed using reinforced concrete (buhos) not less than 150 mm thick. The floor shall have adequate strength for the load imposed on it and shall be not less than 100 mm thick reinforced concrete when in direct contact with earth or not less than 150 mm thick when located above another storey. Floor finish shall be trowelled smooth and painted with one coat of polyurethane sealer and two coats of epoxy dustproof coating. There shall be a maximum of two (2) padmounted tranformer units in a vault. Generally, the minimum required dimension for the vault shall be 5 m (width) X 4 m (depth) for one (1) three-phase padmounted transformer or 8 m (width) X 4 m (depth) for two (2) three-phase padmounted transformers units. This assumes that a 3-m clear space in front of the equipment for switching operations can be attained when the transformer access door is open. For 2nd floor and 1st basement installations where this is not possible, a 6-m minimum depth for the vault shall be required. [Exception: For 2nd floor transformer vault where a hatchway is used, the depth required is 8 m.] There shall be no openings, e.g., doors, vents, etc., from the transformer vault to any part of the building interior. All openings of the transformer vault shall only lead to the outside of the building. The customer shall be required to provide a concrete pad for the padmounted transformer, 75-mm height. A 150-mm high door sill shall be provided by the customer as part of the transformer vault liquid confinement area. Adequate and permanent ventilation to the outside air in the form of louvered vents shall be required to be provided by the customer as part of the transformer vault design. The vents shall have a combined net area of opening (less the area occupied by the louvers) of not less than 20 sqcm. per kVA of the transformer bank capacity installed. For adequate natural air circulation, the intake and exhaust vents shall be located on opposite sides of the padmounted transformer with half of the total area of openings situated near the floor (intake vent) and the other half near the ceiling (exhaust vent). Where the location of the transformer vault will not allow adequate natural circulation of air, or where the minimum required area of ventilation opening cannot be attained, the customer shall be required to provide an exhaust fan per transformer bank installed. In addition, G.I. sheet exhaust

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

AHJHighlight

-

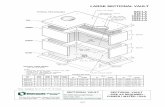

duct shall be installed on top of the transformer tank to the exhaust fan. To avoid unnecessary operation, the fan shall be temperature-controlled with switching ON setting of 40-deg. C (104-deg. F). A by-pass switch (test switch) shall be provided in the vault so that Meralco maintenance crew can, from time to time, check the operation of the exhaust fan. Power consumption and maintenance of the fan shall be assumed by the customer. Typical transformer vault layout for one padmounted transformer installed at the ground floor is shown below. For typical transformer vault layout for two padmounted transformers installed at the ground floor, please contact your nearest Meralcos Sales Office. Typical transformer vault layouts for one and two padmounted transformer(s) installed on the 2nd floor and 1st basement are also available.

-

LEGEND: EXHAUST FAN: FOR FORCED AIR VENTILATION; TEMPERATURE-CONTROLLED; DIRECT DRIVEN BY TOTALLY ENCLOSED MOTOR WITH GRAVITY TYPE DAMPERS. THE FAN SHALL BE RATED HP, 71 CU.M/MIN (2500 CFM) @ 3.2MM (1/8 IN) STATIC PRESSURE. EXHAUST DUCT: MADE OF G.I. SHEET, GAGE 20. DOORWAY: FOR PERSONNEL ACCESS FROM THE OUTSIDE OF THE BUILDING, 0.8M WIDE X 2.0M HIGH X 3.2 MM THICK STEEL DOOR, OUTWARD SWING WITH 150MM HIGH DOOR SILL. THE DOOR SHALL BE FITTED WITH A LATCH DEVICE FOR MERALCO PADLOCK. IT SHALL BE PROVIDED WITH A PANIC BAR DESIGNED TO OPEN THE DOOR OUTWARD UNDER SIMPLE PRESSURE DURING EMERGENCY. TRANSFORMER ACCESS DOOR: 3.0M WIDE X 2.5M HIGH X 3.2 MM THICK, STEEL DOORS; DOUBLE OUTWARD SWING WITH 150MM HIGH DOOR SILL FOR EQUIPMENT IN AND OUT ACCESS. THE DOORS SHALL BE LOUVERED AT THE LOWER HALF AND SHALL BE FITTED WITH A LATCH DEVICE FOR MERALCO PADLOCK. DANGER SIGN: TO BE PAINTED AND/OR POSTED AT THE STEEL DOOR. TRANSFORMER: PADMOUNTED, COMPARTMENTAL TYPE, DEAD FRONT, 3-PH., 60 HZ. LESS-FLAMMABLE LIQUID-FILLED; EQUIPPED WITH PRESSURE-RELIEF DEVICE, EXPULSION FUSES AND CURRENT LIMITING FUSES; BUILT IN ACCORDANCE WITH ANSI C57.12.26, LATEST REVISION. GROUND ROD: GALVANIZED STEEL ROD, SIZE 25MM X 3 M LONG, OR EQUIVALENT. GROUND LEAD: SIZE 100MM (AWG #4/0) BARE, STRANDED, SOFT-DRAWN COPPER, FROM GROUND ROD TO GROUNDING SYSTEM INSIDE THE TRANSFORMER VAULT. GROUND WIRE: SIZE 100MM (AWG #4/0) BARE, STRANDED, SOFT-ANNEALED COPPER, CONNECTING THE TRANSFORMER NEUTRAL TO THE GROUND LEAD INSIDE THE TRANSFORMER VAULT. FLOOR DRAIN: FOR DRAINAGE OF ANY ACCUMULATION OF WATER IN THE TRANSFORMER VAULT; 200 SQUARE X 100 MM DEEP TRAPPED DRAIN WITH STRAINER AND 50MM DRAIN PIPE CONNECTED TO A POSITIVE DRAINAGE SYSTEM OR SUMP FACILITIES. THE FLOOR DRAIN SHALL BE LOCATED WHERE IT SHALL BE VISIBLE AND SAFELY ACCESSIBLE FROM THE DOORWAY. THE DOOR SHALL BE PITCHED TOWARD THE DRAIN. BOLT-EYE: GALVANIZED STEEL, ATLEAST 10,000KG STRENGTH; ANCHORED ON THE WALL 1000MM HIGH. CONCRETE PAD: 75MM HIGH.

EF

FD

BE

GW

GL

GR

T

DS

TA

DW

ED

CP

-

Location of Transformer Vault The required location for the transformer vault shall be at the ground floor of the building where it can easily be accessed from the outside. This is to ensure ease of installation and future replacement/retirement of the padmounted transformer.

In cases where the source of power is coming from networks or underground facilities, 1st basement or 2nd floor installation may be allowed provided that direct access from the outside of the building for equipment and Meralco personnel can be provided at all times. [Note: Basement location for the transformer vault, i.e., where the building has only one basement, will not be allowed in order to safeguard Meralcos facilities against possible flooding.] For flood-prone areas, padmounted transformer shall only be allowed to be installed on the 2nd floor. A transformer access doorway shall be provided to be used when conveying the padmounted transformer into the vault. For vaults located on the 2nd floor or 1st basement, a hatchway maybe employed. Transformer access doorways and hatchways shall be readily accessible from the outside of the building at all times. A separate personnel access doorway shall be provided for use exclusively by Meralco crew/contractors conducting regular inspection, vault cleaning, operational switching and maintenance of the padmounted transformer. For vaults located on the 2nd floor and 1st basement, an independent staircase leading to the personnel access doorway shall be provided. The personnel access doorway shall be readily accessible from the outside of the building either directly or by way of the staircase. It shall be provided with a panic bar or a pressure plate or other means that is normally latched but will open the door outward under simple pressure during emergencies. A clear and permanent vehicle access road leading to the transformer vault entrance shall be provided by the customer and available at all times for use of Meralco vehicles. The basic requirement is that during installation or replacement/retirement of the padmounted transformer, the Meralco truck and crane can maneuver and position effectively to load/unload the equipment right outside the transformer vault entrance. A minimum of 6.5-meter road width shall be required. The access road shall meet a minimum 20-ton construction.

-

Hoisting Facility

Where the transformer vault is located on the 2nd floor or 1st basement, customers/building owners shall be required to provide and maintain a hoisting facility consisting of an I-beam and chain block with roller with a combined capability of not less than 10 tons.

Where the transformer vault is located on the 2nd floor and provided with a transformer access doorway, the hoisting facility shall be installed inside the vault. The I-beam shall extend 1.5 meters outside the doorway.

Where the transformer vault is located on the 2nd floor or 1st basement and provided with a hatchway, the hoisting facility shall be installed directly above the hatchway.

A clear headroom of 4.0 meters from the bottom of the I-beam shall be required when hoisting facility is provided. This is in order to maintain the desired sling angle of lift of 30 degrees from the vertical when lifting the padmounted transformer at its standard four lifting hooks on top of the tank. A lower headroom will result in a sling angle more than the required which would compress the upper portion of the tank with a force that could compromise the tanks structural integrity.

The customer shall submit to Meralco a certification, signed and sealed by a registered structural engineer attesting to the designed lifting capability of the hoisting facility provided.

Where the transformer vault is located at the ground floor, customers/building owners shall not be required to provide a hoisting facility inside the vault. Therefore, a 3.0-meter minimum headroom is already adequate for this type of installation. The padmounted transformer shall be rolled to cover the short distance from the vault entrance to the concrete pad using approved type of rollers (i.e., pagong). Use of any other means for rolling such as steel rods or pipes placed underneath the padmounted transformer is not acceptable.

Secondary Main Circuit Breaker

The customer shall be required to install a secondary main circuit breaker at the service connection point. This means that direct connection of secondary cables from the transformer to multiple circuit breakers or panel boards of the customer shall not be allowed. In order to limit the length of unprotected secondary cables, the customer shall be required to install his secondary main circuit breaker immediately outside the transformer vault, i.e., in the adjoining room, mounted on the opposite side of the common wall with the transformer vault. Primary and Service Cables

Primary cables shall be installed in concrete-encased ducts, 110 mm in diameter, thick-walled, red orange color, made of unplasticized polyvinyl chloride (uPVC) in accordance with PNS 14. The thickness of the concrete envelope from the surface of the duct shall be 75 mm. The primary cables shall be supplied, installed and terminated at the primary terminals of the padmounted transformer by Meralco. The service cables shall likewise be installed in concrete-encased ducts, 110 mm in diameter, thick-walled, red orange color, made of unplasticized polyvinyl chloride (uPVC) in accordance with PNS 14.

-

Meralco shall supply and install the service cables from the secondary compartment of the padmounted transformer up to the customers main circuit breaker. The customers electrical contractor shall be the first to terminate the service cables to their circuit breaker using their own terminal lugs. Meralco shall then terminate the service cables to the secondary terminals of the padmounted transformer.