SPRINGER - TÍTULOS 2007 (eng) OPENURLspringer - tÍtulos 2007 (eng) openurl

Transflex Eng

-

Upload

mickijevic -

Category

Documents

-

view

227 -

download

0

Transcript of Transflex Eng

-

8/10/2019 Transflex Eng

1/6

ENGINEERED SYSTEMS

ENGINEERED SYSTEMS

TRANSFLEX EXPANSION JOINTS FOR BRIDGES

WE ARE EXPERTS IN RUBBER

Trelleborg have over a hundred years' experience in the manufacture of rubber products. We

mak e major inv estm ents in R+D . Ou r sales representat ives, chemists and engin eers are strivi ng to

fin d b etter soluti ons for our custom ers throu gh t he on going d evelopm ent of n ew comp oun ds,

ma terials, designs and production m ethods. T he Trelleborg Group has more than 22 .00 0

employees and is established in over 40 coun tries.

A comprehensive programme for construction :Structural Bearings, Deck Joints for Bridges (Transflex), PipingCompensators (Teguflex), Special Hoses, Rubber-Metal Mouldings.

Trelleborg IESA, s.a.C/ San Vicente, 25E 01440 Izarra (lava) - SpainTel.: + 34 945 437 090Fax: + 34 945 437 [email protected] www.trelleborg.com/iesa

Divi sin Expandite:C/ Ro Manzanares, 20-22P. Ind. JosLuisVelascoE 28500 Argandadel Rey (Madrid) - SpainTel.: +34 918 701 700Fax: +34 918 703 [email protected]

Trelleborg IESA, s.a.

-

8/10/2019 Transflex Eng

2/6

In 1964 theAmerican rubber manufacturer General Tiredeveloped a system of expansion jointsfor br idgescalledTRANSFLEX. It registered thepatent of invention andthetrademark worldwide.In 1971 theExpandite Division carried out thefirstinstallation in Spain with TRANSFLEX material (Bailen-Ferraz flyover in Madrid). In 1997 theTrelleborg Groupintegrated theExpandite Division into its organisation.At thepresent timeTrelleborg IESA, a company within theTRELLEBORG Group, hasthe rightsof ownership of thetrademark, manufactureand distribution, which arecarriedout through itsExpanditeDivision.

Brief description of the product

TheTRANSFLEX system consistsof rubber mouldedmodulesreinforced with steel.TRANSFLEX issupplied in modulesof a specified lengthand areanchored to both sidesof thestructural joint. .Thereisa widerangeof modulesthat absorb movementsupto 330 mm in length, including thoseproduced by skew joints. Their main functionsareto absorb thesemovements,ensurequiet traffic and provideeffective sealing of thejointon theroad surface.

Characteristics

The joint absorbsmovementsup to 330 mm in lengthModulesare rubber coated to protect the reinforcementsThey ensure comfortable travel over the jointExtraordinary durabili ty.

Possibil it y of absorbing skew movements.Easy, fast assembly when replacing old jointsThe impact loadsare fully absorbed by the system.

Our installationsat Izarra, wheretheTRANSFLEX joint ismanufactured.

ENG 2006 09

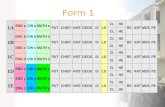

TRANSFLEX 1 50-300 expansion joint(Manufactured under ISO-9002, Certif icate No. 57596 )

TRANSFLEX 4 00-130 0 expansion joint(Manufactured under ISO-9002, Certifi cate No. 57596)

Epoxy adhesiveSelf-locking nutSealer

Drainage Sealer Sealer WaterproofingResin

(max. opening at averagetemp.)No. of anchors

Agglomerate

2t W

C

D

M b t

ConcreteDeck

Mortar bed TR-M-150Transition mortar TR-MR-300

Length L(mm) (mm ) (mm ) (mm ) (mm ) (mm ) (mm ) (uds)

W t c b M D( )t rans nModel

Transflex 400 102 M1 6

M2 0

M2 4

M2 727 0

618 12

12

8

12

1080

787

49 8170

20 0

22 0

38 1

273

20 3

15 2

12 7

93

75

54

1207

89 0

72 4

59 0

1830

1830

1220

1830

33 0

23 0

16 5Transflex 650

Transflex 900

Transflex 1300

Length L(mm) (mm ) (mm ) (mm ) (mm ) (mm ) (mm ) (uns)W t c b M D(trans) nModel

Transflex 150 38 M1 2

M1 4

M1 4

M1 6170

220 12

12

12

14

34 2

279

19 015 0

15 0

15 0

88

67

51

39

54

46

40

35

43 2

35 6

274

24 0

1830

1830

1830

1750

80

65

50Transflex 200

Transflex 200

Transflex 300

Epoxy adhesiveSelf-locking nut Sealer

Sealer SealerDrainage WaterproofingResin

(max. opening at averagetemp.)No. of anchors

Agglomerate

2t W

c

D

M b t

ConcreteDeck

Mortar bed TR-M-150Transition mortar T R-MR-300

-

8/10/2019 Transflex Eng

3/6

Epoxy adhesiveMortar bed TR-M-150

Transition mortarTR-MR-300

Self-locking nut

Anchorhousing

AnchorhousingElastomer Elastomer

Steel plateSteel plate

Steelangle

Steelangle

Sealer SealerResin

Waterproofing

Sealer

Deck Concrete

DrainageAgglomerate

2.- Detail of installed joint

1.- Composition

M odels 150, 200, 250 and 300 M odels 400 , 650 , 900 and 1300

150200250300400650900

1300

1750 mm1830 mm1830 mm1830 mm1830 mm1830 mm1830 mm1220 mm

35 mm40 mm46 mm54 mm54 mm75 mm93 mm

127 mm

12 mm14 mm14 mm16 mm16 mm20 mm24 mm27 mm

240 mm274 mm356 mm432 mm590 mm724 mm890 mm

1207 mm

28 Kg45 Kg62 Kg88 Kg

150 Kg260 Kg375 Kg438 Kg

38 mm (+-19)50 mm (+-25)65 mm (+-33)80 mm (+-40)

102 mm (+-51)165 mm(+-83)

230 mm (+-115)330 mm (+-165)

Models Length ofmovement

Lengthof the

module

Heightof the

module

Widthof the

module

Weightof the

module

Diameterof thebolt

Models 150, 200, 250 and 300

Models 400, 650, 900 and 1300

NOTE: Model 1300 hasfour (8) anchorsper module

Drainingrelief

Drainingrelief

Tongued and grooved

Tongued and grooved

CL

CL

C

C

45 Nm100 Nm100 Nm175 Nm175 Nm190 Nm275 Nm300 Nm

58 mm76 mm98 mm

126 mm152 mm203 mm273 mm381 mm

250 mm305 mm305 mm305 mm305 mm305 mm305 mm305 mm

70 mm80 mm92 mm

108 mm108 mm150 mm180 mm260 mm

39 mm51 mm67 mm88 mm

102 mm121 mm158 mm216 mm

190 mm220 mm279 mm342 mm498 mm618 mm787 mm

1080 mm

27 mm32 mm40 mm42 mm42 mm51 mm60 mm70 mm

150 mm150 mm150 mm170 mm170 mm200 mm220 mm270 mm

Max. heightof the bolt

on thefloor

Tighteningtorque

Lengthof thebolt

Max. widthof the jo in tat average

temp.

Max.widthof the joint

Anchortransition

width

Distance betweenanchors

(transv.) C

Distance betweenanchors

(longit.) CL

-

8/10/2019 Transflex Eng

4/6

Examples:

Special parts.

Theformation of special partsfor kerbs, pavementsor other reliefsisoffered for all theTransflex modelsto ensurecontinuity of thesealing.

To order themanufactureof thesepartsit isessential to specify all thedimensions.

Changein levelof pavements

SkewcaseTransflex, modules 150, 200 , 250 and 30 0

Transflex, modules 400, 650 , 900 and 13 00

-

8/10/2019 Transflex Eng

5/6

Graph of maximum movements absorbed by the different m odules according to the angle formed by the joint wit h the longitudinal axis of the floor.

COMPONENT PARALLEL WITH THE JOINT

400

350

0

MODEL 150MODEL 200MODEL 250MODEL 300

MODEL 400

MODEL 650

MODEL 900

MOD EL 1300

100 200 300mm

mm

300

250

200

150

100

50

0

C O M P O N E N T P E R P E N D I C U L A R T O

T H E J O

I N T

010

20

30

40

50

60

70

80

90

90

80

70

60

50

40

30

20

10

0

Load/ deformation curves for Transflex, per module

160

3 T

2 T

2 T

1 T

1 T

160140 140120 120100 10080 8060 604040

40 40

TRANSFLEX 1300

TRANSFLEX 900TRANSFLEX 650

TRANSFLEX 400

TRANSFLEX 150TRANSFLEX 200TRANSFLEX 250TRANSFLEX 300

COMPRESSIONin m/m

COMPRESSIONin m/m

EXTENSIONin m/m

EXTENSIONin m/m

20

30 3020 2010 10

200

0

-

8/10/2019 Transflex Eng

6/6

Maximum temperaturespecified

249 mm 274 mm 299 mm

Averagetemperaturespecified(moduleat rest)

T e m p e r a t u r a

d e l

t a b l e r o

C

Minimum temperaturespecified

Guide to adjustment according to t emperature.

Example based on Transflex 200

(Remanent irreversible movements are not included).

TECHNICAL DATA

ELASTOM ER Value Unit s Test method

Indentation hardness 605 ShoreA ASTM D2240

Rupture load >150 Kgs/cm ASTM D412/NFT46002

Elongation at rupture >425 % ASTM D 412/NFT46002

Rubber-steel adhesion >11,8 N /mm ASTM D429 Method B

Low temperature resistance -30 C ASTM D1329

Ozoneresistance Without ASTMD1149 Method B cracks 25ppcm (48 hours at 38C)

Remanent deformation 35 % maxim. def. ASTM D395 Method B(24 hoursat 70C)

Thermal aging 5 ShoreA ASTM D573-15 % Inc. Load by hot air-25 % Inc. Elongati on (70 hours at 70C)

STEEL

Componentsmanufactured to: ASTM TypeA36DI N 17-100 TypeST 37-2

NOTE:All reasonablecarehasbeen t aken to providethe correcttechnical dataon our products. All r ecommendationsorsuggestions regardin g their usearemadein good faith and arebased on our experience. However, it i st her esponsibil it y of theuser or designer to ensurethat each product is suitablef or t hepurposefor which it isintended and that theconditionsof useareappropriate.