TrailerGUARD System Overview - WABCOinform.wabco-auto.com/intl/pdf/815/01/79/8150101793.pdf ·...

Transcript of TrailerGUARD System Overview - WABCOinform.wabco-auto.com/intl/pdf/815/01/79/8150101793.pdf ·...

TrailerGUARD

System Overview

TrailerGUARD System Overview

Edition 2

This publication is not subject to any update service.

You will find the current version under

http://www.wabco.info/8150101793

© 2012

The right of amendment is reserved.

Version 1/08.2012(en)

815 010 179 3

TrailerGUARD

4

Abbreviations

ABS Anti-Lock Braking System

API Application Programming Interface

BVA Brake pad wear indicator

CAN Controller Area Network; asynchronous, serial bus system for networking control devices in vehicles

DIAGN Diagnostic connection

DTC Diagnostic Trouble Code

EBS Electronic Braking System

ERP Enterprise-Resource-Planning

GIO Generic Input/Output

GMT Greenwich Mean Time; mean solar time at the prime meridian

GPS Global Positioning System; global navigation satellite system for determining position and time measurement

IVTM Integrated Vehicle Tire Pressure Monitoring System for commercial vehicles

LIN Local Interconnect Network; specification for a serial communication system, also LIN bus, sensor port/interface

ODR Operating Data Recorder

RSS Roll Stability Support; vehicle stability control

RxD Receive Data, data line: Received

TEBS Electronic Braking System for Trailers

TIM Trailer Info Module (Knorr)

TTU Trailer Telematic Unit

TxD Transmit Data, data line: Send

Table of Contents

TrailerGUARD

1 Disclaimer ............................................................................................................................... 6

2 System..................................................................................................................................... 7 2.1 Introduction................................................................................................................... 7 2.2 Structure....................................................................................................................... 8 2.3 Components ................................................................................................................. 9 2.4 Configuration / Power supply ..................................................................................... 11 2.4.1 Trailer EBS / ABS....................................................................................................... 11 2.4.2 TTU battery ................................................................................................................ 12 2.4.3 Refrigerator battery .................................................................................................... 12 2.4.4 Vehicle electrical system............................................................................................ 12

3 Components.......................................................................................................................... 13 3.1 Trailer Telematic Unit (TTU)....................................................................................... 13 3.1.1 Cable clip.................................................................................................................... 16 3.1.2 Filler plug.................................................................................................................... 16 3.1.3 TTU battery ................................................................................................................ 17 3.2 Sensors ...................................................................................................................... 18 3.2.1 Door sensor................................................................................................................ 18 3.2.2 Coupling sensor ......................................................................................................... 19 3.3 Temperature logger, cooling device........................................................................... 21 3.3.1 Temperature logger.................................................................................................... 21 3.3.2 Cooling unit ................................................................................................................ 22 3.3.3 Refrigerator battery .................................................................................................... 23 3.4 Cable .......................................................................................................................... 24

4 Communication and the Telematics Portal........................................................................ 26 4.1 Communication .......................................................................................................... 26 4.2 Telematics Portal........................................................................................................ 27 4.3 API interface............................................................................................................... 28

5

1 TrailerGUARD

Disclaimer

6

1 Disclaimer

We assume no liability for the correctness, completeness or actuality of the infor-mation in this document. All technical information, descriptions and images are ap-plicable at the time that this document or respective supplements were printed. We retain the right to make changes as a result of continuous further development.

The content of this document provides no guarantees nor warranted characteristics nor can it be construed as such. Liability for damages is strictly excluded, as long as there has been no respective intention or gross negligence on our part or any forced legal provisions in opposition.

Text and graphics are subject to our utilisation rights, and copying or distribution in any form require our approval.

Any brand markings, even if not indicated as such, are subject to the rules of the labelling rights. If legal disputes arise from the utilisation of the information in this document, these are exclusively to be handled under the regulations of national law.

In so far as components or individual formulations of this applicable legal status documentation are no longer or not fully relevant, the remaining parts of the docu-mentation remain unaffected thereby in their content and validity.

TrailerGUARD 2System

2 System

2.1 Introduction

The term "Telematics" is a combination of the words "Telecommunication" and "In-formatics". Telematics indicates the possibility of processing information and trans-porting it over a distance at the same time.

Telematics, as an application in the commercial vehicle industry, makes it possible to transfer data and information that is sensed in the trailer to a computer via a wireless connection for further processing. Normally, the access to the information occurs via an Internet portal.

Utilisation of this information is complex and depends on the business processes of the user.

Areas of use

The range of applications for a Trailer Telematics system can be:

• Location-detection for the trailer

• Documentation for the condition of goods, such as e.g. the temperature in the trailer

• Monitoring of the technical characteristics of the trailer, e.g. the tire pressures

The Trailer Telematics System is designed for geographical Europe (including Tur-key). Operation of TrailerGUARD is only possible in areas with GPS- and mobile reception.

The area of application for the Trailer Telematics system is mainly dependent on

the technical boundary conditions, e.g. the GSM coverage in the respective coun-tries.

7

2 TrailerGUARD

System

8

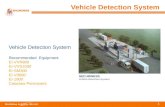

2.2 Structure

A Telematics system essentially consists of the following components:

Legend

1 GPS data 2 Hardware in the vehicle 3 Data transmission 4 Data management 5 Telematics Portal

The data transfer and data management are components that work in the back-ground and are not visible to the user.

GPS data

Data definition via satellite.

Hardware in the vehicle

The hardware installed in the vehicle connects various sensors and collects data.

Data transmission

The transfer of data enables the bidirectional communication between the vehicle and the communication centre (Telematics Portal).

Data management

The data management is an IT architecture for the collection, evaluation and man-agement of received telematics data.

Telematics Portal

The end user retrieves information and communicates with the vehicle by means of a web-based user interface.

TrailerGUARD 2System

2.3 Components

The components installed in the vehicle determine which information can be trans-ferred from the Trailer Telematic Unit (TTU).

# Component Information Description

Item Current GPS position Distance and direction to the nearest town

Speed Current speed (determined from GPS signal)

Odometer Status Driven kilometres (determined from GPS signal)

Date, time Date and time (GMT) relating to the different items of information

1 Trailer Telematic Unit (TTU)

Park- and drive-trip Start / Target position, distance Start / Target time, driving time Standstill time

2 TTU battery Battery voltage Charge status Capacity

Voltage Charge status Available capacity

3 Door sensor Door status open/closed Number of times doors were opened / closed during a trip Door status at the end of a trip

4 Coupling sensor Connect status Trailer hitched/unhitched

Speed Current speed Maximum and average speed during a trip

Odometer Status Distance driven in kilometres

Aggregate load Maximum and average aggregate load during a trip

Trips without EBS Trips without connected Trailer EBS plug (24N supply)

Ignition on/off Towing vehicle's ignition status with hitched trailer

5 Trailer EBS

Other EBS data3)

Yellow/Red warning indicator RSS interventions level 2

9

2 TrailerGUARD

System

10

# Component Information Description

ODR data2) Operating data from the internal operating data memory of the WABCO Trailer EBS modulator

6 IVTM1) Tyre pressure Up to 6 pressures measured on the wheels

7 BVA3) Display of brake lining wear

Brake lining ok / not ok

8 Temperature logger Temperature Current temperature Minimum, maximum and average temperature during a trip

Operating status on/off

Messages Status of the cooling device

Operating hours Operating hours of the cooling unit according to operating mode (electric motor or combustion engine)

Set Point Set Point (nominal temperature value) Minimum and maximum Set Point during a trip

9 Cooling unit

Defrost cycle on/off

10 Cooling device battery Battery voltage Voltage

Only possible in combination with: 1) WABCO Trailer EBS as of generation D1 Premium 2) WABCO Trailer EBS as of generation E0 3) WABCO Trailer EBS as of generation D1 Premium / Haldex EBS with CAN / Knorr EBS with CAN

TrailerGUARD 2System

2.4 Configuration / Power supply

2.4.1 Trailer EBS / ABS

The power supply via terminal 15/30 through the Trailer EBS is implemented by the POWER / EBS slot on the TTU. This slot is also used to transfer the CAN data to the Trailer EBS.

Manufacturer Power source / Modulator 5 V CAN interface (data from TEBS)

Trailer EBS E X

Trailer EBS D Premium X

Trailer EBS D Standard –

WABCO

Vario Compact ABS (VCS II) –

TEBS G2 / 2.1 X*

TEBS G1 without 5 V CAN –

Knorr

TEBS G1 with 5 V CAN X

Haldex EB+ Gen2 (as of software version C499) X*

Corresponding modulator parameters generally need to be defined for the correct

power supply of the TTU, siehe publication „TrailerGUARD – System Descrip-tion“ => chapter „Installation of the TTU“.

In this regard, always observe the documentation of the respective manufacturer for the modulator and strictly follow the specifications and instructions!

WABCO Trailer EBS

The WABCO Trailer EBS as of generation D1 Premium supplies the TTU with in-formation on the trailer EBS as well as the voltage. The trailer EBS also transfers data from the tyre pressure monitoring system IVTM and the brake lining wear in-dicator BVA to the TTU via the second CAN bus (5 V).

Modulators of the Trailer EBS of generation D0 (production date up to 09/2003,

serial number up to 75000) do not support the power supply of the TTU can there-fore cannot be used for connecting a TTU.

Please refer to the TEBS E documents for a detailed description of the TEBS E

system.

WABCO Vario Compact ABS (VCS II)

The WABCO Vario Compact ABS "VCS II" allows operation of the TTU without a 5 V CAN interface. However, no CAN data (e.g. loading and brake lining wear) is transferred from the VCS II modulator to the TTU.

The vehicle speed and the odometer reading are determined by the TTU on the basis of the received GPS data.

11

2 TrailerGUARD

System

2.4.2 TTU battery

The TTU battery supplies the TTU with power, if the trailer is disconnected and the TTU is not supplied via terminal 15/30. The TTU battery is charged through the TTU when the power supply is connected.

2.4.3 Refrigerator battery

In addition to or instead of the TTU battery, the battery for the refrigerator can also be used to supply the TTU with power when the ignition is switched off.

The refrigerator battery is not charged by the TTU. This causes the danger of run-

ning down the battery if the refrigerator is not run for longer periods of time.

To prevent this discharge, the telematics system is equipped with a preset under-voltage limit for the refrigerator battery. When the value drops below this limit and the TTU is also equipped with a TTU battery, the TTU disables the refrigerator bat-tery as a power source and supply is continued from the TTU battery. Only when there is sufficient voltage available again is the battery used as a power source for the TTU again.

2.4.4 Vehicle electrical system

The vehicle electrical system (12 V or 24 V) can be used as another power source, connected to the POWER/EBS slot on the TTU.

The TTU can also be connected directly to the vehicle electrical system of a vehi-cle such as e.g. delivery vehicle or passenger vehicle. Prerequisite for this is a constant supply voltage via terminal 30 (even with ignition OFF). There is no re-quirement for using a TTU battery this way.

This configuration is not suitable for a trailer vehicle however, since the constant power supply via terminal 30 is not assured when the trailer vehicle is not con-nected.

If the vehicle electrical system is used as a power source, no CAN data is available

on the trailer EBS.

Connecting the TTU directly to the power supply of the ISO 7638 plug connection (ABS/EBS connector) is not permitted according to applicable regulations.

12

TrailerGUARD 3Components

3 Components

WABCO part number Description

446 290 110 0 446 290 150 0 446 290 120 0 884 008 791 4

TTU set (TTU, cable clip, filler plug) TTU battery set (battery, fastening screw) TTU Mounting Set (cable clip, filler plug) TTU mounting plate

446 290 231 0 441 044 110 0

Connect sensor, converter Connect sensor, pressure sensor

446 290 261 0 446 290 25. 0

Magnet Door sensors, see chapter 3.2.1 "Door sensor", page 18

449 ... ... 0 894 ... ... 0

Cable, see chapter 3.4 "Cable", page 24

3.1 Trailer Telematic Unit (TTU)

Purpose

The TTU is the central component for Telematics in trailers. It handles the following tasks:

• Collecting and temporarily storing the data from the individual system compo-nents and sensors

• Managing the individual tasks for reading, temporarily storing and transferring the data.

• Bidirectional communication between the Telematics Portal and the vehicle.

• Determining the position using a GPS signal. Coordinating the operating modes and the power supply of the LIN sensors.

Function

Operating modes

The TTU can switch operating modes for extending the standby time with discon-nected trailers. The TTU chooses the respective operating mode automatically, however, many components may not be available depending on the mode of op-eration.

Interfaces

The TTU has three interfaces for connecting components and sensors:

Interface Slot Description

CAN 1, OPTIONS 3, POWER/EBS

Interface to the Trailer EBS or other CAN-capable modulators (slot 1) and for diagnosing via CAN (slot 3). Downstream from the trailer EBS are diagnostic port, IVTM and BVA.

LIN 2, BATTERY 4, LIN

Interface to battery, door- and coupling sensor and the LIN-based sensors. The individual sen-sors are connected with Y-distributors.

RS232 1, OPTIONS Interface to refrigeration system and to diagnostics. The information of the cooling device is transferred directly via the temperature logger.

The TTU housing is not to be opened.

13

3 TrailerGUARD

Components

Components

Component Part number

Trailer Telematic Unit (TTU) Technical data of the TTU Protection class: IP6k9k Operating voltage: DC 12 V ... 24 V Current consumption at 24 V: min. 5 mA; max. 1,350 mA Operating temperature (full function): -30 °C ... +75 °C No power supply via the TTU battery, limited GSM communication: -40 °C ... -30 °C +75 °C ... +85 °C

446 290 100 0

Trailer Telematic Unit (TTU) Set

Components: TTU, cable clip, filler plug

446 290 110 0

14

TrailerGUARD 3Components

Pin assignments

Slot Pin Assignments

1 RS232 #2 TxD

2 reserved

3 External power supply

4 External PWR ground

5 reserved

6 not connected

7 RS232 #2 RxD

8 reserved

9 reserved

10 CAN-Low

11 Relay driver (150 mA)

12 reserved

13 RS232 #2 GND

14 reserved

15 reserved

16 CAN-High

17 Relay driver

OPTIONS

18 reserved

1 Power supply, battery

2 Ground

3 Data line (LIN)

BATTERY

4 not connected

1 Power supply, ignition (terminal 15)

2 Power supply (terminal 30)

3 Ground

4 CAN-High

5 CAN-Low

POWER / EBS

6 reserved

1 Power supply, 12 V

2 Data line (LIN)

LIN

3 Ground

15

3 TrailerGUARD

Components

16

3.1.1 Cable clip

Purpose

The cable clip is used for fastening and relieving strain on the cable, and to protect the plug connection against direct water and dirt.

Components

Component Part number

Cable clip (consist-ing of cover and bottom section)

TTU with opened cable clip, inserted power- and LIN-cables and filler plugs for slot OPTION; right

The cable clip is part of the TTU set 446 290 110 0, see chapter 3.1 "Trailer Telematic Unit (TTU)", page 13.

Connection

– Attach the cable clip to the TTU.

The installation and operation of the TTU without a cable bracket is not permitted.

3.1.2 Filler plug

Purpose

Filler plugs close off the unused slots of the TTU.

CAUTION

Damage to the TTU due to the ingress of moisture – Seal unused slots with a filler plug.

Moisture can enter the TTU through an unsealed slot and cause damage.

Components

Component Part number

Filler plug; OPTIONS slot

Filler plug; BATTERY slot

Filler plug; LIN slot

Available in the TTU assembly set 446 290 120 0

TrailerGUARD 3Components

3.1.3 TTU battery

Purpose

The TTU battery supplies the TTU with power if the TTU is not supplied via termi-nal 15/30.

Function

The TTU battery is charged through the TTU when the power supply is connected.

In exclusive battery operation, the TTU can be supplied with voltage for approxi-mately 8 weeks. The duration depends on the application conditions and the in-stalled components and can greatly deviate from this value.

Notes for battery operation

The TTU battery has logic that protects it from deep discharge. As soon as the voltage drops below a defined value, the battery switches off automatically. It is ac-tivated again by the power supply of the TTU through terminal 15 / 30.

If the TTU has switched off for self-preservation, the TTU cannot record, save or

send any data via terminal 15 / 30 if no power is supplied.

CAUTION

Damage to the battery cells due to lack of charging – Completely charge the TTU battery even when not used (e.g. putting the trailer

out of service for a longer period) no later than after three months.

By charging the battery you avoid irreparable damage to the battery cells.

The maximum storage duration of the TTU battery is 1 year from the production date. WABCO provides no guarantee for the TTU battery after the storage time elapses.

Component Technical data Part number

TTU battery

Type: Lithium Ion Mangan Protection class: IP6k9k Operating voltage: 7.2 V Capacity: 4,350 ... 4,500 mA Operating temperature: Voltage drop -30 °C ... +75 °C charging + 0 °C ... +65 °C

Within a temperature range of -30 °C … 0 °C the battery is heated by an integrated heater to > 0 °C to allow charging. Below -30 °C, the heater is switched off and charging the battery is no longer possible.

446 290 150 0

Assembly

– Insert the TTU battery into the battery compartment of the TTU. – Use a fastening screw to fasten the TTU battery to the TTU. – Connect the TTU battery plug to the 2 BATTERY slot on the TTU. The TTU battery indicates the battery voltage, charge status and capacity of

the TTU via the LIN interface.

Disposal

Batteries are hazardous waste. Dispose of the battery according to environmental specifications based on the national / regional regulations or send the battery back to WABCO.

17

3 TrailerGUARD

Components

18

3.2 Sensors

The sensors are connected with the TTU via a LIN bus (Slot 4 LIN). A maximum of 4 door sensors and one connect sensor can be connected to the TTU. Starting with the first cable (449 745 005 0), all other sensors are introduced in a Y distributor (894 600 024 0) in the layout.

Connecting the sensors to the TTU

Legend

1 TTU 2 Cable for sensor 449 745 005 0

3 Y distributor 894 600 024 0

4 Coupling sensor (Pressure sensor with converter)

5 Door sensors

3.2.1 Door sensor

Purpose

The door sensor detects by means of the magnet whether the door is open or closed.

The door sensor can also be used to sense the tailgate on a dumping body or a box with fittings.

Function

The door sensor is a non-contact switch, consisting of a hall sensor and a magnet. Up to 4 door sensors can be connected to the TTU. The door sensor detects whether the door is open or closed by means of the magnets and sends the door status and a change of the door status to the TTU. In the Telematics Portal, the status "Door open" is indicated as soon as one of the doors has been opened

Each door sensor is recognised via its own ID in the LIN bus. Therefore, when us-ing multiple door sensors, different item numbers have to be used. The door sen-sors must be used in combination with magnet 446 290 261 0.

TrailerGUARD 3Components

Components

Component Technical data Cable length

ID Part number

Magnet

- - 446 290 261 0

1 446 290 251 0

2 446 290 252 0

3 446 290 253 0

0,5 m

4 446 290 254 0

1 446 290 255 0

2 446 290 256 0

3 446 290 257 0

6 m

4 446 290 258 0

1 446 290 259 0

2 446 290 260 0

3 446 290 262 0

Sensor

Figure: Sensor with magnet

Protection class: IP6k9k Operating temperature: -40 °C ... +85 °C Switch limit: 21 ±2 mm Protection class: IP5K4K, IP 6K9K (with mating connector plugged in) Operating temperature: -40 °C … +85 °C Pin assignments: A : Plus 12 V; B: Data; C: GND Two M6 cheese head screws with hexagon socket ISO 4762 are used to fasten the magnet and door sensor to the housing Tightening torque: 4 ... 5 Nm Switching range: 21 +5/-2 mm

18 m

4 446 290 263 0

Angle bracket

Outline drawing, see publication „TrailerGUARD – System Description“ (815 010 181 3) => chapter „ Angle bracket“

- - 446 290 350 4

3.2.2 Coupling sensor

Purpose

The connect sensor recognises, by means of the pressure in the supply line (red coupling head), whether the trailer vehicle is connected to a towing vehicle.

Function

If pressure is applied, the system recognises that the trailer is connected with a towing vehicle. The coupling sensor consists of two components – the pressure sensor (441 044 110 0), which senses the pressure, and a converter (446 290 231 0) that converts this pressure signal into a LIN bus signal.

19

3 TrailerGUARD

Components

Components

Component Technical data Part number

Coupling sensor (consisting of pressure sensor and converter)

Protection class: IP6k9k Operating temperature: -40 °C ... +85 °C Cable length: Pressure switch - Converter: 0.5 m; converter - coupling point: 0.5 m Pin assignments: A : Positive 12 V; B: Data; C: GND Switch limits: connected: 2.2 bar (1.3 V); uncoupled: 1,0 bar (0.9 V)

Pressure sensor: 441 044 110 0

Converter: 446 290 231 0

Assembly

– Connect the coupling sensor to the LIN slot on the TTU.

20

TrailerGUARD 3Components

3.3 Temperature logger, cooling device

The temperature logger, the cooling device and the refrigerator battery are not

components of the WABCO product range.

Notes and information on these components are found in the documentation of the manufacturer.

The data of the refrigeration system are normally provided by the temperature log-ger.

Layout of the refrigeration interface

Legend

1 TTU 2 Refrigerator battery 3 Temperature logger

4 Refrigerator 5 Options/Refrigeration technology cable

3.3.1 Temperature logger

Purpose

The temperature logger is a certified device for recording the temperatures in a re-frigeration vehicle.

Function

This data is read from a temperature logger by the TTU, since it cannot be ac-cessed directly from the temperature sensors.

Up to 4 different temperatures can be processed and transferred.

Components

Temperature logger supported by the TTU:

Manufacturer Refrigerator Temperature logger

Interface Comment

Thermo King SLX series SL 400e SL 100 SL 200 SL 300 Spectrum

Smart Reefer 2

Technical Data: Protection class: IP-65 Operating voltage: 10 V ... 6 V Operating temperature: -30 °C ... +65 °C

i-Box (incl. cable harness) 884 014 852 0 (Thermo King PN: 40-870)

The "i-Box" interface is used to connect the "SmartReefer 2" temperature logger to the TTU. Software version: >B003

21

3 TrailerGUARD

Components

22

Manufacturer Refrigerator Temperature logger

Interface Comment

Data Cold 500 Software version: <2.17

- Protocol name for the TTU configuration: Carrier Datacold 500

Carrier Vector 1850 E/T Maxima 1000/1300 R/S/T

Data Cold 500 Software version: ≥2.17

- Protocol name for the TTU configuration: Carrier Datacold 5002

Euroscan - Euroscan TX1 - Version A (29/2000)

- Transscan 2/4 - UDN-1623-A (23.04.2002) ColdChain

- Transscan-XL - -

Thermo King "SmartReefer 2"

The i-Box supplies the temperature data of the SmartReefer 2 from up to 4 sensors and the corresponding Set Point values (may. three) to the TTU. In addition, the re-frigerator status, information on the defrost cycle, refrigerator service messages and the diesel engine's operating hours are transmitted to the TTU and displayed in the Telematics Portal.

If the refrigerator is switched off, the i-Box does not send any data of the refrigera-

tor to the TTU. The message Temperature monitoring not possible appears in the Telematics Portal in this case.

Carrier "Data Cold 500"

The "Carrier Data Cold 500" temperature logger can be used for temperature moni-toring in combination with the TTU.

Data Cold 500 supplies temperature data from up to 4 sensors and the corre-sponding Set Point values (max. three). In addition, the refrigerator status, informa-tion on the defrost cycle and the electric motor's and the diesel engine's operating hours are transmitted to the TTU and displayed in the Telematics Portal.

Data Cold 500 uses a special algorithm for data processing that, when there are

great temperature fluctuations, can result in deviations between the temperatures indicated in the display of the Data Cold 500 and those in the Telematics Portal or the diagnosis.

Connection

– Connect the temperature logger to the OPTIONS slot on the TTU.

3.3.2 Cooling unit

In addition to the data from the temperature logger, cooling device data (e.g. Set Points or messages) can also be sent to the TTU. This is only possible however if the temperature logger supports this option and a data line is installed between the cooling device and the temperature logger.

Up to 3 Set Points can be processed and transferred by the TTU. The temperature loggers listed in the table below support the transmission of data from the cooling unit. The scope of data is different however and depends on the system used.

TrailerGUARD 3Components

Manufacturer Interface / Temperature logger data transmitted

Thermo King i-Box Shutdown alarms, hours of operation, battery status, fuel level

Data Cold 500 Software version: <2.17

Alarms, refrigeration unit status, de-frost cycle status

Carrier

Data Cold 500 Software version: ≥2.17

Alarms, refrigeration unit status, de-frost cycle status, operating hours (electrical / diesel engine)

Information on the installation of the connection between the cooling device and the

temperature logger can be found in the manufacturer's documentation.

3.3.3 Refrigerator battery

Purpose

In addition to or instead of the TTU battery, the battery for the refrigerator can also be used to supply the TTU with power when the ignition is switched off.

The refrigerator battery is not charged by the TTU. This causes the danger of run-

ning down the battery if the refrigerator is not run for longer periods of time.

To prevent this discharge, the telematics system is equipped with a preset under-voltage limit for the refrigerator battery. When the value drops below this limit and the TTU is also equipped with a TTU battery, the TTU disables the refrigerator bat-tery as a power source and supply is continued from the TTU battery. Only when there is sufficient voltage available again is the battery used as a power source for the TTU again.

When connecting the refrigerator battery to the TTU, a 5 A fuse is to be installed in the + line

Technical data

Pin assignments A: brown / GND

B: blue / PWR

Connection

– Connect the refrigerator battery to the options slot on the TTU using the match-ing options cable, see chapter 3.4 "Cable", page 24.

23

3 TrailerGUARD

Components

24

3.4 Cable

Cable Part number Lengths Design of the cable ends

Power cable

Trailer EBS D

449 910 050 0 5.0 m POWER IN/OUT2

Trailer EBS E

449 917 025 0449 917 050 0

2.5 m 5.0 m

POWER SUBSYSTEM

Trailer EBS E

449 918 025 0449 918 050 0

2.5 m 5.0 m

POWER GIO5

Trailer EBS E

449 920 248 0 L1: 3.0 m L2: 6.0 m L3: 1.0 m

POWER SUBSYSTEM; IVTM/ SmartBoard

Haldex EB+ Gen. 2

449 922 060 0 6 m POWER DIAGN (green connector)

Knorr

449 923 127 0 L1 = 2.50 m L2 = 2.50 m

POWER DIAGN TIM

Vehicle electrical system (for inside use only)

449 919 050 0 5.0 m POWER open end 1: red / IGN 2: green / PWR 3: brown / GND 4: black / CAN-H 5: white / CAN-L 6: -

ELEX

449 907 010 0 1.0 m POWER SUBSYSTEM

Sensor cable (connect- and door-sensor)

Sensors

449 745 005 0 0.5 m LIN 3-pin socket connector

TrailerGUARD 3Components

25

Cable Part number Lengths Design of the cable ends

Y distributor

894 600 024 0 0.15 m 3-pin socket connector

3-pin plug-in connector

Extension (red marking)

449 747 060 0 6.0 m 3-pin socket connector

3-pin plug-in connector

Option- and refrigeration technology cable

Temperature logger (blue marking), refrigerator battery (yellow marking) and diagnosis

894 600 025 0 0.5 m 0.5 m 1.0 m

OPTION 3-pin socket connector 2-pin socket connector Diagnostic socket with yellow cap

Temperature logger (blue marking), refrigerator battery (yellow marking)

894 600 036 0 0.5 m 0.5 m

OPTION 3-pin socket connector 2-pin socket connector

Extension Temperature logger (blue marking)

449 746 150 0 15.0 m 3-pin socket connector

3-pin plug-in connector

Temperature logger

449 718 005 0449 718 020 0449 718 025 0449 718 050 0449 718 150 0449 718 160 0

0.5 m 2.0 m 2.5 m 5.0 m 15.0 m 16.0 m

3-pin plug-in connector

open end A: white / TxD B: red / RxD C: brown / GND

Refrigerator battery

449 748 180 0 18.0 m 2-pin plug-in connector

open end A: brown / GND B: blue / PWR

4 TrailerGUARD

Communication and the Telematics Portal

26

4 Communication and the Telematics Portal

Besides the components in the vehicle, the Telematics system also consists of the data transmission, the data management and the user interface. The data man-agement and user interface are combined in the Telematics Portal or the API inter-face. The data transmission occurs in the background and can only be influenced indirectly.

4.1 Communication

Communication between vehicle, telematics data centre and user

Legend

1 Vehicle 2 Telematics data centre 3 Web portal

4 API interface 5 Telematics user 6 Data processing of the telematics user

The communication between the vehicle and the Telematics Portal occurs at fixed intervals and in the case of a message from the connected sensors or components (event-based) via the mobile phone network.

The communication between the Telematics Portal and the Telematics user takes place via the Internet. The notification for defined events is implemented via e-mail and SMS and can be freely configured in the Telematics Portal.

TrailerGUARD 4Communication and the Telematics Portal

4.2 Telematics Portal

The Telematics Portal is an internet-based application in which the data and infor-mation recorded in the vehicle can be displayed and processed.

Telematics Portal

Call up the following internet address: http://www.wabco-telematics.com

Log on with your user name and password.

Click OK.

The different functions of the Telematics Portal are also described here:

• Description of the Telematics Portal, see publication „TrailerGUARD – System Description“ (815 010 181 3) => chapter „Customer Service & Service“ => Sec-tion "More information"

• Telematics Portal online help

Service package

The functions that are available in the Telematics Portal depend on the service package and may vary:

• Basic: Optimises the capacity utilisation of your vehicle, supported by Track & Trace.

• Trailer: Optimises capacity and efficiency with Track & Trace and vehicle infor-mation.

• Cooler: Optimises your refrigerated transport through verification of temperature monitoring.

Options

The following options can be additionally selected for each service package:

• Map: Your vehicle is indicated on a digital map.

• ODR: You can request the Operating Data Recorder data at any time via the Telematics Portal.

• SMS: You also receive a notification via SMS of events that you have defined accordingly.

• DTC: You receive a diagnostic protocol with a list of all active and passive diag-nostic messages.

Prerequisites

Hardware

• Desktop PC or Notebook with Windows operating system as of Windows XP

• Screen resolution (at least 1024 x 768)

• Internet access with a band width of > 1 Mbit/s

Software

• Internet browser: Microsoft Internet Explorer (version 6.0 - 9.x)

Security setting: Activating "Scripting of Java-Applets".

Security setting: add http://www.wabco-telematics.com as trustworthy site

Always allow the download of files from http://www.wabco-telematics.com

• Adobe Acrobat Reader for displaying pdf reports

• Microsoft Excel for displaying Excel reports

Administration

Completely set up user access to http://www.wabco-telematics.com with user name and password, see publication “TrailerGUARD – System Description“ (815 010 181 3) => chapter „Registering & Administration“.

27

4 TrailerGUARD

Communication and the Telematics Portal

28

4.3 API interface

WABCO TrailerGUARD provides an interface for application programming, abbre-viated as. This interface allows use of online services to transfer telematics data to an ERP system or other software for direct further processing.

The API is included in all service packages so that telematics vehicle data can also be used separately from the web portal. A Pull-API (to retrieve telematics data when requested) and a Push-API (to obtain telematics data automatically) are sup-ported.

The implementation of a Pull-API client is described in the TrailerGUARD SOAP-API documentation, which can be obtained from WABCO Service [email protected] and also includes the configuration files "API.wsdl" and "API.zip".

A description of the implementation of a Push-API client, also including the configu-ration file "PushAPI.wsdl" is also available.

A Java client can be used to set up API and a data connection.

The following items relate to the API service and it is essential to take them into account:

• Java environment: http://java.sun.com/downloads/index.html

• ANT: http://ant.apache.org/bindownload.cgi

• AXIS: http://ws.apache.org/axis/

• WSDL file with definitions (<HTTP address>/api/API.wsdl)

• Javadoc for API (<HTTP-address>/api/doc/index.html)

• Login and password for using API (identical to the login for the web portal)

• IP address (name of the computer) and port for API users

WABCO Vehicle Control Systems (NYSE: WBC) is a leading supplier of safety and control systems for commer-cial vehicles. For over 140 years, WABCO has pioneered breakthrough electronic, mechanical and mechatronic technologies for braking, stability, and.

transmission automation systems sup-plied to the world’s leading commercial truck, trailer, and bus manufacturers WABCO is headquartered in Brussels, Belgium. For more information, visit http://www.wabco-auto.com

© 2

012

WA

BC

O

All

right

s re

serv

ed.

815

010

179

3/08

.201

2