(TP0A008) Truck Unloading Metering Systems

-

Upload

roberto-carlos-teixeira -

Category

Documents

-

view

229 -

download

0

Transcript of (TP0A008) Truck Unloading Metering Systems

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

1/7

l#lfMiti Z,If, fi'ilmltJ,tJ

lntroductlon

Paul D. FloydLeonard P. Samowski

The purpose of this paper is to discuss a method ofmetering the liquid hydrocarbon fuels o r chemical prod. ucts delivered by typical tank trucks. Also included willbe receiving methods, assentia considerations required, the receiving equipment required, such aspumps, meters, air eliminator tanks, strainers, contraivaives, and aiarm devices. A section wiH aiso be devotedto the performance of these systems in terms of accuracy and efficiency.Recent marketing studies have revealed an estimated20,000 facilities in the U.S.A., such as manufacturing orprocess piants, electr ic tilities, hospitais, instittions,etc., buy more than $37,813,381,000 (see Reference 1worth offuel oi I each year, much ofwhich is unmetered.Also, although this paper is about truck unloading, thereare about 850,000 rail car loads of petroleum products(not nc ud ng petrochem ca s) that are un oaded w th out accurate accountability. The considerations forunloading rail cars are very similar to truck unloading.

r==i' L

i I il.Irlililili

gure - Typical Tank Truck

Truck UnloadingiVietering SystemsT A r h n i r ~ l P ~ n A r ~I'- ' ' 1 1 1 1 ' ' - - ' & 1 . . . . . t - 1 I'

Bulletin TPOA008Truck Types and Manlfolds Typlcally UseclThe tank trucks typically used would be represented bythe diagram shown in Figure 1. The typical tank truckhas four compartments, each containing 2,000 gallons,thus totaling 8,000 gallons for the entire load.A n. ' a i n ' n in n n r n11tlat rn : lni fnlrt :ur :lnno.rngnt r-n1 dri, t./PIVILAI . . , 1 . . . , . , , ~ VI VULIVL 1 1 1 ' - 4 1 1 1 1 \ J ~ U \ , o l l l ' - ' l o i i ~ V I I I V I I VV\.oiiUbe for individual discharge outlets or manifolded together as shown by Figure 2. The piping connectionsshown are aiso used for bottom ioading the tank truck.Receiving Posiiions and Typeslt is cstomry to receive liquid hydrocarbon fuels ymeans o either gravity flow to lower than grade storagetanks, or by pumping product into above grade storagetanks. The gravity f low systems are rather simple, andthe most common example is the typical system used atgasolina stations where the truck connects its bottomoutlets with a flexible hose to the tank inlets at theground levei.A typical system for pressure applications is shown inFigure 3. The main elements of this system are the air

Individual Compartment Loading Lcading Unes ~ l l a n i f o d e dto One Coupling Combination

( I I I )S ~ i ?

( I I I )l I . . I J

L -'

I I I I \\ I I I Jy y

' - - ' '--'

Ftgure Truck Manifolds1602 Wagner Avenue P.O. Box 10428 Erie, PA 16514-0428 Telephone: 814/898-5000 Telex: 19-9902 Fax: 814/899-8927

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

2/7

eliminator tank with its ai r sensing float switch system,the ai r vent system around the meter, the positive displacement meter, and the flow control valve which willbe discussed later. The pump for this system can beeither on the de ivering truck or permanent y groundmounted as part of this system. Other features of thissystem can include water detectors, which shut downthe system i water is detected, o r remote overfii I protection devices, which can also shut down the flow controlvalve if the maximum tank fluid levei is achieved.Essential design considerations are: Safety Accuracy Accountability Re iabi ity SecuritySfetySafety is maintained by careful selection of the propermateriais. flanae ratinas. flow ratinas. electrical annrovals pres5ure nd t e m ~ p r a t u r e - l i m l t s - ~ d - - ~ ~ ~ ~ ; ~ t f l ~ ; .capabilities.

ccuracyAccuracy is spelled "MONEY" and is documented byNBS (National Bureau of Standards) metering rules andguidelines. Basically, a meter should be used with ademonstrated capabi ity of 0.1o accuracy or better.This is verified by proving and calibration operations,which should be performed at least two times a year.

ccountabilityAccountabilitv is maintained bv the utilization of areceiving ticket which provides numerical r e ~ o r d ofthe amount of product received. In order to avoidexpansion and contaction eiOiS it is possible to obtaina volume record that shows the amount of fuel corrected to a 60 F temperatura. Thus, the record of fuel onhand can always reter to one standard temperatura. Theincoming fuel ticket can also be obtained with thetemperature corrected mount as we . The productdispensed from the storage tanks can also be meteredand controlled if desired. This provides a complete "invs. out" record.ReliabilltyReliability is obtained by procuring the metering systemequipment from a reputable source who has a provenrecord of supplying reliable equipment to the petroleumindustry. A nationwide sales, spare parts, and serviceorganization helps considerably when requests aremade for additional equipment, or should replacementparts be required, or if the assistance of a field serviceperson is needed.SecurltySecurity steps must be taken to minimize the possibiii ties of product pilferage. Such pilferage can be theresult of tampering with the metering equipment byunauthorized personnel. -

Air EliminatorTank

qulpment

P.D. Meter Flow ControlVai

Equipment normally required to perform the truck unloadingmetering inciudes the foiiowing: Pumps Ai r E iminator Tanks Meters and Accessories Flow Control Valves Water Detectors Backflow Prevention Overfill Alarms

PumpsPumps are required if the storage tanks are ata high ielevation than the tank trucks, or if the flow rateachieved during gravity flow is not acceptable. Severaltypes of pumps are used, including centrifugai and positive displacement types. A typical system to handle an8.00Q-aallon truck to unload aooroximatelv 20 minuteswouldrequire a flow rate capbili ty 4oogpin 9 i ~ ~ tthe flow resistance (head loss) created by the receivingeqipment the lines to the tanks, and the height fproduct in the tank itself.ir Eiiminaior TanksThe elimination of gas and vapors from liquid productmetering systems is essential to metering accuracy. Thepresence of entrained and/or slug air has long beenrecognized as a potential threat to optimum accuracy,and there are various methods utiiized to eiiminate theentrapped air before it can pass through the meteringelement.The most efficient meansof eliminating ai r before i t canpass through the system meter is the utilization of asetiiing tank. The principie by which a settiing tankexpels entrapped a r is a simpleon the product to bemetered is allowed to accumulate in a larae tank orbasin creating a zero velocity situation, durlng whichtime the ai r being lighter than the liquid, rises to the top

TPO OOB

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

3/7

of the accumulated liquid and escapes to atmosphere.The levei of efficiency of this method is a direct functionof the product viscosity and the duration of the "settling"period.Because a significant amount of time is required toseparate ali of the entrained ai r from a volume of liquid,the settling tank method may not always be a practicaone. In addition, the capital investment required andspace limitations of an installation might also prohibitthe settling tank appmach. A common aiternative is theinstallation of an in-line ai r eliminator tank upstream ofthe system meter. The method of operation of an aireliminator is similar to that of a settling tank. Since theai r eliminator tank body diameter is significantly largerthan the adjoining system piping, the ve ocity of theproduct passing through the tank is reduced, allowingairtrapped wi thin the liquid time to rise and accumulateat the top of the vessei. However, since the fiow condition through the air eliminator is not a zero velocitycondition, it is likely that the bulk of "slug ai r," and only aportion of the entrained ai r, will be separated from theliquid dueto a lack of sufficient "rise time." To enhancethe removal of the entrained air, series of "scn..;bberplates" can be incorporated into the ai r eliminator tank.As the product passes through the tank, the entrainedor smaiier "bubbies" of air coiiect aiong the scrubber

Customer to Supply120 Vac, 1 AMP

plates, which are inclined in parallel, and then rise to thetop of the vesse .Both horizontal and vertical body styles are used in thedesign of air eliminators. In the "horizontal" mode, thetank body is typically installed in parallel with the system piping, with the in let and outlet flanges on the samecenter ine as the piping. This arrangement aUows forthe use of the aforementioned scrubber plates, as wellas a perforated baffle plate, which is typically installedinternaiiy nearthe iniet side ofthe tank. The baffle platefurther enhances the separation of ai r from the liquid byequally distr ibuting the flow through the vessel. In addition, the horizontal design lends itself to a multiple ai rrelease head arrangement which is advantageous inhigh flov.t capacity systems.In "vertical" tank designs, the body is upright, perpendicular to the system piping, the inlet flange locatednear the top of the tank and the outlet flange close to thebottom. When the inlet and outlet nozzles are installedtangentiafly to the tnk body, air removal is enhancedby centrifugai forces caused by the "swir l" of the product along the tank wall as it passes through the vessel.Both horizontal and vertical air eliminators are with anai r release portor "head." The a r release head providesan escape path for the CCmlated ai r venting the ai r

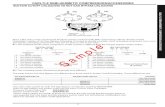

Schematic Diagram -Float Switch andI I Conduit- Customerl Flow Control ValveI I to Con nectI I

----------L L-------,.- - - - - - - - - - J - - - - - - l I

Operation

\I li \..._ Explosion Proof Junction Box I :~ ~ ~ ~ ~ with lntrinsic Safe Barrier Relay : II I li Plug N c _ '---I g Needle Solenoid 1...-.J

~ i ~ ~ ~ \1 I ii i ~ l T V a i ~ V a l v e ~ o n t r o ltQ -&I I

I ~LeveiBI

FlgureTPOA008 3

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

4/7

to atmosphere or to a point upstream or downstream asdictated by the system design. The most basic airrelease head is the poppetfioat arrangement where afloat, connected by a rod to the head poppet assembly,is suspended from the top of the tank. When the tank issumped or full of liquid, the float is buoyed near the topof the tank blocking the air vent path. As ai r accumu-

~ t ~ ~ t h c f ina+ h . o n i n ~ +n r t r n n 1"'\n.o.ni ....- f.h,., _____ . . - ~ ' I.IIW IIVU.I. . n ; ; ; ~ l l l ~ LU U I V tJ 1 V t J ' V I I I I I ~ LII'C I J UtJ 1J t : :L1allowing the ai r to vent from the tank.Another float style of a mechanical air release headcommonly used- is the "rocker'' or "roll band" design.This arrangement features a float connected to a steel

n ~ n f l \Aihif""h \ A i r " : l l r ' \ ~ : l l r ' l " ' \ l l n r l 1"'\1" l a u ~ 1"'\u_.,"" hl - " " ' l . , f .h.,_o ,.,..""'...,._, ,..,. t ' I J I 1 Y'IJ 1 U I VUIIU VI lO. V V 'O' Q U I \ . ~ r\. Llll U U : J I Iwhich the vent port is drilled. As the float drops, theband peels off the vent port allowing the accumulatedai r to be reieased.A more sophisticated approach to ai r elimination is onein whi l"h a n a i r Q . O . n ~ i n , rl.o.ui,....t ''t. in+o..f....,_ _ " .... . .., a . . . - ~ ~111 n- u 1 1 U l l . ; ; ~ ~ ~ t i W I I I I ~ U VY I\ , t : ; IIIL'O'IIQ\.IC' .o;) YYILII 0 UIV\. . ir\valve installed downstream of the system meter. Bythismethod, when a significant amount of air is detected,the biock vaive cioses quickly, stopping flow until the ai ris expelled from the ai r eliminator tank. This simulatesthe zero velocitv condition realized when a settlina tankis in use. The vlve reopens when li o f - t h ~ s e ~ - s e d ~ i ~eliminated.One method of sensing ai r utilizes a device for monitoring the capacitance of the fluid. When the capacitanceof the fluid chanaes due to the increased oresence ofair, an electricaliY controlled system ~ a l v e i ; c l ~ ~ e d :preventing the resumption of product flow until the airisl".t"'t.l.o....,roo.,.,I 'V" I 'VQ; ; ) t ; : ;U.

M_Fioat_Assembly n

Another method of combining an air sensing devicewith a block valve is one which utilizes a dual floatswitch assembiy suspended from the air release headwhich is electrically connected to a valve installeddownstream of the meter. (See Figure 4).When the fluid levei stays ator near Levei "A," the floatcontro l valve is allowed to remain open, permitting flow,untii the trapped air causes the liquid levei to drop belowLevei "B." When the lower float drops, a switch is trippedand solenoid electrical power is interrupted by theintrinsically safe relay, thereby closing the flow controlvalve and stopping product flow. This same switchingaction also cases the vent solenoid valve to open torelease the trapped air out of the vent port. As thetrapped air is vented and replaced by rising liquid, thefloat control valve remains closed until the liquid rises tothe high float or Levei "A." This raises the upper floatand trips a second switch. This ogic de-energizes thevent solenoid to close it and cease the venting actionwhile simultaneously energizing the solenoid on theflow Ontrol vaive, permitting it to open siowiy to resumeflow.As was mentioned previous y, a major factor affectingthe separation of liquid andairis the product viscosity.The remova I of entrained airfrom a viscous product hasalways been onsidere virtuaiiy impossibie uniess thesettling tank approach were used. The dual floatswitch/block valve method of air elimination is adaptable tohigh viscosity product applications and provides a substantial improvement over poppet or roll band systems.

T h ~ ~ m i t h Putnrlol n ~ _ ? fnr a v ~ r n n l . o 'hlni,...ol": ,ll\1 IIC'O.t" lo,o'""""""' ' ' '"' ' , . . , . ,_ _ - '-- -I lVI l l l i iAUIIItJ11i;;; 1 L J I - ' 1 \ . I Q I I J

u D E ~ 2 H o dL ~ can be connected to sump inlieu of downstream.

Figure Smlth Model DE 2 wlth 202 Bare alve

4 TPOA 8

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

5/7

with a block valve that is void of the pilot loop arrangement which is vulnerable to the performance problemscaused by viscous fiuids (see Figure 5j. The E-2incorporates ali of the features described in the dualfloat switch svstem described above. However, whenthe fluid levei falls low enough to permit the lower floatto drop, a three-way solenoid is also actuated, allowingthe pressure of the accumulated air to pressurize thecover chamber of the block valve, causing the valve toclose, thereby stopping product flow. Once the accumulated air has been vented through the two-way solenoid, the fluid levei again rises, with the valve remainingclosed until the upper float rises. This action deenergizes both solenoids, blocking the air vent paththrough the two-way solenoid and simultaneously permitting the pressure in the valve wver chamber to bevented downstream of the meter, thus allowing theblock valve to reopen.Meters andAccessoriesPositive Disp acement (P.D.) ~ . ~ e t e r s are most appropriate for offloading applications because of the systems'inherent operating conditions. P.D. Meters are ruggedlyconstructed and are adaptabie to changes in operatingparameters, such as product viscosity and flow rate.lnaddition, they are best suited to perform accuratelyduring the stp/start sequences caused by the closingand opening of a system block valve linked to an airroo.oru .in- A.o. i,...n.;:)I 1.;: 11 UVY I . IV.Available meter accessories include various types ofcalibrators. temoerature comoensators, counters, ticketprinters, and pulse transmitters, ali of which can bearranged in numerous combinations suited to satisfyunique system requirements.Row Control ValvesThey provide control functions, such as flow rate limiting, on/off permissive, over temperature emergencyshutdown, and pressure regu ation. t may a so shutdown the flow if the proper signaling is provided.

Bacldlow PreventlonBackflow prevention from above ground tanks is essential because of the possibility of having the tank headflow backward out of the receiving system. A simplecheck va ve between the out et of the receiving systemand the tank satisfies this requirement.Row liidicatoii Water Detectors Ala;;;; Der1cesThese devices can be utilized to cover special situationswhen circumstances warrant them. Flow rate indicators~ n b e p ~ o v i e give operators a manual indicationthat the system is flowing smoothly. Water detectorscan be installed to shui down the receiving position ifthe percentage of water content is greater than thepermissible amount. Overfill protection devices andalarms are available to protect the receiving customerfrom the dangers and hazards of overfilling the receiving tank.PerformancePerformance for petroieum product metering systems,including ai r remova efficiency, is defined per NationalBureau of Standards Handbook 44 - Specifications,Tolerances, and Other Technical Requirements forWeighing and Measuring Devices. This handbook covers a multitude of measuring and weighing devices fromtaximeters to berry boxes, including liquid-measuringdevices and vehicle tank meter combinations, such as ahome heating oi I fuel delivery truckThe standard states in Section 3.30, Table 2, that theoverregistration or underregistration errar is limited to25 cubic inches for 50 gallons, plus one-quarter cubicinch for each gallon over 50 gallons. This cal cu atesoutto be .00216 or roughly 0.2%, and this is (+) or -)for 50gallons. lf the delivered volume becomes 10,000 gallons, then the accuracy limit is now 2,512.5 cubic inchesor .00109 or roughly 0.1%. A typical meter accuracycurveis shown in Figure 6.

M e te rMo d e . :S =erial No.Manifest No.MeterTnr11Clearances Af l l??Curve Ptotted by t,t7: L Date I ? 101~ ~ s ~ : S ~ i ~ ~ d @ S O F ~ : } ~ Gravrty@60 F .. _t to rCommentsTPOA008

. . ., ' I 1 1 1 1 1 1 1 li 111 li li li li . .1.0020100101000

9990

+.2+.1

-.1~ . 2I I I 111i11111 111111LIII111

Flow Rate- U.S. GPMRgure 6 - P D Meter Accuracy Curve Curve No.: G-18713

5

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

6/7

onclusionSeveral factors contribute to a successful truck unloading metering system. However, the ultimate goal is asystem that can be economicaiiy justified. Because ofthe monetary value of the product being transferredfrom the custody of one party to another. it is imoerativethat measurement problem s be anticipated nd thatsteps are taken to minimize or eliminate the effects ofthese prob ems. Critica fa.ctors, such as the pesence ofair, for example, have to be addressed if optimum system accuracy is to be maintained.This paper was presented y the author at the 60thlnternational School of Hydrocarbon Measurement inNorman Oklahoma April 1985

ReferencesBasic Petroleum Data Book, Vol. IV, No. 3 September1984, American Petroleum lnstitute, Washington, D.C.National Petroleum News - 1984 Fact Book.National Bureau of Standards Handbook 44-1982, U.S.epartment of Commerce, Washington, D.C.Streeter, Victor L., Handbook of Fluid Dynamics,

c G r a w - H i , f .Je\V York, 1961.Streeter, Victor L., Fiuid Mechanics, McGraw-Hi ll, NewYork, 1958.

TPOA008

-

8/12/2019 (TP0A008) Truck Unloading Metering Systems

7/7

Visit our website at www.smithmeter.com

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications arecurrently in effect. Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

Headquarters:6677 North Gessner Road, Suite 315, Houston, TX 77040 USA, Phone: 713/510-6970, Fax: 713/510-6972

Printed in U.S.A. 4/85 FMC Measurement Solutions. All rights reserved. TP0A008 Issue/Rev. 0.0 (4/85)

Locations:Erie, PA USAPhone 814/898-5000, Fax 814/899-8927Corpus Christi, TX USAPhone 361/289-3400, Fax 361/289-1115Stephenville, TX USAPhone 254/968-2181, Fax 254/977-1627Longmont, CO USA Phone303/702-7400, Fax 303/702-1608Los Angeles, CA USAPhone 661/296-7711, Fax 661/296-5166Eunice, LA USAPhone 337/550-7133, Fax 337/550-7134Thetford, England Phone (44) 1842-82-2900, Fax (44) 1842-76-5402Slough, England Phone (44) 1753-57-1515, Fax (44) 1753-52-9966

Ellerbek, Germany Phone (49) 4101-3040, Fax (49) 4101-304133Kongsberg, NorwayPhone (47) 32/286-700, Fax (47) 32/289-590Barcelona, SpainPhone (34) 93/201-0989, Fax (34) 93/201-0576Moscow, RussiaPhone (7) 095/564-8705, Fax (7) 095/926-5066SingaporePhone (65) 869-0605, Fax (65) 861-2401Beijing, China Phone (86) 10/6500-2251, Fax (86) 10/6512-6857Chennai, India Phone (91) 44/496-0455, Fax (91) 44/496-0114San Juan, Puerto Rico Phone 787/274-3760, Fax 787/274-1020