Thermal Stress Analysis of Dovetail Clad

Transcript of Thermal Stress Analysis of Dovetail Clad

■ Copper – Aluminum Dovetail Clad

■ Thermal Stress Analysis

■

TM

Copper and Aluminum have different coefficients of thermal expansion. As a

result, in a multi-layer composite material with Aluminum and Copper layers, a

change in temperature will cause the different layers to expand in different

amounts.

However, the Cu and Al layers are firmly bonded together. Therefore, the

dimensions of those layers are constrained to be the same; even after a

temperature change. This dimensional constraint drives stresses to develop

within each layer. Since Aluminum expands more than Copper, Al will generate

a compressive stress as it is constrained, and Cu will see a tensile stress.

Though stresses develop in each layer, a force balance must be maintained

over the entire part. Since Aluminum and Copper are present in equal amounts,

this force balance means the stresses generated in the Cu and Al layers are

equal, but of opposite signs (Compress vs. Tensile).

Using these two conditions of (1) Maintaining Equal Lengths and (2) Force

Balance, we can calculate the rate of stress generation with temperature. This

is about 0.075ksi per degree C.

Thermal Stress Analysis

3

Laminate Plate Assumptions

( ) TEE

CuAl

Al

Al

Cu

Cu ∆−=

−+

−⊥ αα

ννσ

11

αAl = 24 x 10-6 °C-1

αCu= 16 x 10-6 °C-1

Differential Thermal Expansion drives differential strain generation

In-Plane Dimension of Cu and Al must remain the same.

Using this boundary condition:

Calculated Biaxial Thermal Stress Rate Is 50 MPa/100°C

Thermal Stress Analysis

4

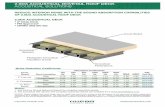

Compare to Aluminum Inlay for Wire Bonding

50 MPa/ 100°C

Cu

50 µm

0.6 mm

Dovetail

30 years Field Experience: High Performance Copper/Aluminum Leadframes, with no failures.

Al Inlay 75 MPa/ 100°C

Thermal fatigue life will be much longer in Dovetail.

Thermal Stress Analysis