The Triangle Shirtwaist Factory Fire - Lina Saenz.ppt

19

The Triangle Shirtwaist The Triangle Shirtwaist Factory Fire Factory Fire 1 Lina Saenz Noval Mary Kay O’ Connor Process Safety Center http://www.ilr.cornell.edu/Trianglefire/ http://www.ilr.cornell.edu/Trianglefire/

Transcript of The Triangle Shirtwaist Factory Fire - Lina Saenz.ppt

Microsoft PowerPoint - The Triangle Shirtwaist Factory Fire -

Lina_Saenz.ppt [Compatibility Mode]Factory FireFactory Fire

Process Safety Center http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

In 1906, The Triangle Shirtwaist Company opened a factory in the ASCH Building in New

York. Most of the employees were young women who worked additional hours under

unsanitary conditions for a piece of apple pie. The owners did not have any programs to

promote safety as evidenced by the lack of precautions to prevent fires and the inadequate

fire escape facilities in the building.

The Triangle Shirtwaist FireThe Triangle Shirtwaist Fire

2

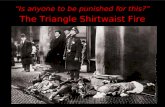

On March 25, 1911, a fire broke out on the 8th floor. The fire claimed 146 victims in less

than 30 minutes. Like most workers at that time, the Triangle victims and their families

received little help from the law, either guaranteeing their safety or compensating them for

their injuries.

Their deaths led to numerous changes in occupational safety standards and still remains

one of the most vivid tragedies.

The Triangle Shirtwaist FactoryThe Triangle Shirtwaist Factory

The largest manufacturer of women’s shirtwaists in US.

Shirtwaist was a high necked blouse usually made of crisp, light, translucent cotton or sheer line.

It occupied the top three floors of the ten-story Asch building in New York City at the intersection of Greene Street and Washington Place.

Approximately 500 employees, mostly young Italian, Yiddish and German immigrant women.

3

Owners: Isaac Harris and Max Blank.

Well-known outside the garment industry due to the continuous strikes by the International Ladies’ Garment Workers’ Union (ILGWU).

It was a good example of “ A Sweatshop ” because of

Lack of additional pay for overtime,

Low Wages,

Unsanitary conditions,

Also, talking and singing were forbidden, there were fines for errors, and the workers had to buy their own needles, thread, and other supplies.

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

http://www.failuremag.com/arch_history_triangle_fire.htmlhttp://www.failuremag.com/arch_history_triangle_fire.html

Saturday March 25Saturday March 25thth ,1911,1911 At 4:45 pm, 15 minutes before the end of the work day, a fire

began on the eighth floor because of a lit cigarette butt in a bin of scrap fabric.

The workers on the tenth floor were alerted quickly and headed to the roof. Most on 8th and 10th floor were able to evacuate.

When the word of the fire reached the 9th floor, the workers could not escape because

One of the two doors on this floor had been locked and

4

One of the two doors on this floor had been locked and the other was inaccessible because of smoke and flames,

The fire escape collapsed under the weight of the people trying to escape,

And the elevator stopped working.

Each of the four elevators held 10 people and made approximately 15 to 20 trips each.

The women leaped out the factory windows or jumped down the elevator shaft.

The fire was extinguished a half hour later.

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/triangleimages.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/triangleimages.html

19 bodies against the locked door,

25 bodies in the cloakroom,

30 bodies in the elevator shafts,

Approximately 70 died by falling or jumping out of the building

The steel frames and concrete structures were undamaged.

5

undamaged.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

Contributing Factors: Building ConstructionContributing Factors: Building Construction

The Asch Building was a “fire proof building” less than 150 ft high. The building itself would emerge nearly undamaged but everything inside would burn completely.

The danger in these fire proof buildings resulted from the use of wood for the floors, doors, and trim.

The fire escape was inadequate for the number of

6

The fire escape was inadequate for the number of people employed in the building because

It ended at a second floor skylight.

It was dangerously loose at the upper floors.

Its doors opened outward so as to block the catwalks that connected the flights.

The doors only opened inwards.

The spiral stairways were narrow which restricted the number of people on it.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

It had been declared as a Fire Trap by the New York City Fire Commissioner some three months earlier.

The workers were packed closely together on each floor with high ceilings in the building as the Labor Code mandated a minimum of 250 cubic feet of air per worker.

The location of the stairs or exterior fire escape was unknown for the employees.

A narrow passageway between tables and the only exit on the

Contributing Factors : Building Design Contributing Factors : Building Design

7

A narrow passageway between tables and the only exit on the Greene Street side and not enough space in the room: 8 tables and 240 sewing machines on the ninth floor.

The stairways:

The Greene St stairway was used to check the workers for stolen goods.

The Washington stairway was locked to prevent an alternate route.

The location of the stairways and exterior fire-escapes was obstructed by machinery, wooden partitions, and piled-up merchandise.

Spiral stairway in the Triangle Shirtwaist FactorySpiral stairway in the Triangle Shirtwaist Factory

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The 9The 9thth floor of the Asch Buildingfloor of the Asch Building

8 Tables

ElevatorsFire Escape

Washington St G

machinesmachines

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

The owners neglected to install fire safety technology. They refused to sign the collective bargaining agreement to improve the factory conditions.

The only measures available for the workers were 27 buckets of water and a fire escape.

Contributing Factors : Lack of Safety MeasuresContributing Factors : Lack of Safety Measures

9

No sprinkler system because they were not required in New York city buildings, in1911.

No fire extinguishers.

The fire hose was rotten and broken.

The valve of the pipe that carried water to the building was rusted which prevented access to water .

http://lawprofessors.typepad.com/laborprof_blog/commentary/index.htmlhttp://lawprofessors.typepad.com/laborprof_blog/commentary/index.html

Employees and employers smoked during business hours and at meal time.

Illumination was provided by gas lighting but they were unprotected by globes and were placed near flammable material.

Contributing Factors : Lack of safety measures (cont.)Contributing Factors : Lack of safety measures (cont.)

10

No regular effort was made to clear the oil and grease soaked floors and the rubbish heaps.

No fireproof receptacles were provided for the accumulated waste.

The last time an accumulation of cutaways was picked up from the factory was on January 15, 1911.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

Inadequate inspectionsInadequate inspections

The Triangle Shirtwaist Factory passed a routine fire inspection on October 15, 1910.

Primarily trivial violations were identified during the inspection on February 27, 1911:

- The shafting under the machine tables was not guarded. - The factory had no dressing rooms for the girls.

- The lights in the halls were inadequate.

11

- The lights in the halls were inadequate.

The inspector failed to identify major violations, such as: • Violation of the child labor law because the

employees hid the kids in cases for the shirts. • Smoking even though he saw some cigarette butts

in the factory. • Adequate distances between the exits and the

machines and tables. • Locked doors because they were unlocked before

the inspection. No corrective measures were taken after several warnings

to improve the safety measures in the Factory.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The manager tried to put the fire out himself; he did not call the Fire Department immediately.

Fire ladders could reach no higher than the 6th

floor.

12

floor.

The firefighters tried to enter as the workers streamed out in the narrow stairway.

The firefighters focused on stopping the fire on the 8th floor instead of trying to rescue workers.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

After The FireAfter The Fire

On June 30, 1911, a Factory Investigation Commission was established that resulted in:

36 new safety laws in factories were enacted.

The New York Fire Department was reorganized.

The number of Inspectors was doubled.

13

Some of the defects in the building were corrected almost immediately after the fire. These were:

Making the Washington Place stairs a place accessible to the roof.

Adding a new fire escape

Constructing two large water tanks on the roof.

Installing a sprinkler system.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The owners were indicted for manslaughter but the jury acquitted them on December 27,1911 when it was concluded by one juror that the workers had caused their own deaths:

“ I can’t see that any one was responsible… it must have been an act of God. I think the factory was well managed, and was as good or better than many others. I think that the girls, who undoubtedly have not as much intelligence as others might have

in other walks of life, were inclined to fly into a panic.”

Consequences for the OwnersConsequences for the Owners

14

"The Triangle Shirtwaist Fire of 1911: Social Change, Industrial Accidents, and the Evolution of Common-Sense Causality," Law & Social Inquiry, 20 (1995): 637.

In 1914, the owners had to pay damages in the amount of $75 to each of the families of 23 victims who had sued.

The Triangle Factory set up shop in another location a week after the fire in a building with the same design and the same faults.

The owners recovered insurance payments of $445 per worker killed.

This incident among others led to numerous changes in Occupational Safety Standards.

All the doors must open outwards.

No doors are to be locked during working hours.

Sprinkler systems must be installed in all factory buildings over seven stories or 90 ft in height in which wooden floors or wooden trim are used, and more than 200 people are employed above the seventh floor.

Fire drills are mandatory if a company employs more than 25 people

Improved Safety Requirements Improved Safety Requirements

15

Fire drills are mandatory if a company employs more than 25 people above the ground floor. They must be conducted at least once every three months under the supervision of the Local Fire Department.

Multiple fire exits.

Training for employees about safety in the workplace are required.

Emergency evacuation plans.

Fireproof receptacles are needed to place all flammable material, cuttings and rubbish, to throw out the accumulation.

Smoking must be prohibited in the factories.

The building is now known as The building is now known as

the Brown Building of the Brown Building of Science and it is listed as a Science and it is listed as a National Historic Landmark.National Historic Landmark.

16

http://www.ustrek.org/odyssey/semester2/011701/011701stephfire.htmlhttp://www.ustrek.org/odyssey/semester2/011701/011701stephfire.html

The International Women’s Day The International Women’s Day is celebrated on March 8 as a is celebrated on March 8 as a commemoration to that day.commemoration to that day.

In September 1991, a very similar incident in Hamlet, North Carolina, at The Imperial Food Products Company required about one hour to extinguish and resulted in the deaths of 25 people and injured another 56.

Many similar factors were identified:

No sprinkler system,

17

No marked fire exits and no regular fire drills,

Fire inspectors had not visited the factory since it had been operating.

The state found a total of 83 violations of state and federal regulations, 54 of them willful.

This time, there were sanctions against the plant and its owner.

http://www.ilr.cornell.edu/Trianglefire/

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

www.nyc.gov/html/records/pdf/govpub/2826staloysius.final.pdf

http://www.failuremag.com/arch_history_triangle_fire.html

http://en.wikipedia.org/wiki/Triangle_Shirtwaist_Factory_fire

ReferencesReferences

18

http://en.wikipedia.org/wiki/Triangle_Shirtwaist_Factory_fire

www.historybuff.com/library/refshirtwaist.html

www.trianglememorial.com/mainframe.htm

"The Triangle Shirtwaist Fire of 1911: Social Change, Industrial Accidents, and the Evolution of Common-Sense Causality," Law & Social Inquiry, 20 (1995): 621-651

BooksBooks

The Triangle Shirtwaist Factory Fire: Landmark Events In American History by Adam R. Shaefer.

Triangle Shirtwaist Factory Fire of 1911 by Janell Broyles.

Triangle: The Fire that changed America by David Von Drehle.

More informationMore information

Fire at the Triangle Factory by Holly Littlefield.

The Triangle Shirtwaist Factory Fire by Elaine Landau.

Triangle by Katherine Weber.

Process Safety Center http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

In 1906, The Triangle Shirtwaist Company opened a factory in the ASCH Building in New

York. Most of the employees were young women who worked additional hours under

unsanitary conditions for a piece of apple pie. The owners did not have any programs to

promote safety as evidenced by the lack of precautions to prevent fires and the inadequate

fire escape facilities in the building.

The Triangle Shirtwaist FireThe Triangle Shirtwaist Fire

2

On March 25, 1911, a fire broke out on the 8th floor. The fire claimed 146 victims in less

than 30 minutes. Like most workers at that time, the Triangle victims and their families

received little help from the law, either guaranteeing their safety or compensating them for

their injuries.

Their deaths led to numerous changes in occupational safety standards and still remains

one of the most vivid tragedies.

The Triangle Shirtwaist FactoryThe Triangle Shirtwaist Factory

The largest manufacturer of women’s shirtwaists in US.

Shirtwaist was a high necked blouse usually made of crisp, light, translucent cotton or sheer line.

It occupied the top three floors of the ten-story Asch building in New York City at the intersection of Greene Street and Washington Place.

Approximately 500 employees, mostly young Italian, Yiddish and German immigrant women.

3

Owners: Isaac Harris and Max Blank.

Well-known outside the garment industry due to the continuous strikes by the International Ladies’ Garment Workers’ Union (ILGWU).

It was a good example of “ A Sweatshop ” because of

Lack of additional pay for overtime,

Low Wages,

Unsanitary conditions,

Also, talking and singing were forbidden, there were fines for errors, and the workers had to buy their own needles, thread, and other supplies.

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

http://www.failuremag.com/arch_history_triangle_fire.htmlhttp://www.failuremag.com/arch_history_triangle_fire.html

Saturday March 25Saturday March 25thth ,1911,1911 At 4:45 pm, 15 minutes before the end of the work day, a fire

began on the eighth floor because of a lit cigarette butt in a bin of scrap fabric.

The workers on the tenth floor were alerted quickly and headed to the roof. Most on 8th and 10th floor were able to evacuate.

When the word of the fire reached the 9th floor, the workers could not escape because

One of the two doors on this floor had been locked and

4

One of the two doors on this floor had been locked and the other was inaccessible because of smoke and flames,

The fire escape collapsed under the weight of the people trying to escape,

And the elevator stopped working.

Each of the four elevators held 10 people and made approximately 15 to 20 trips each.

The women leaped out the factory windows or jumped down the elevator shaft.

The fire was extinguished a half hour later.

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/triangleimages.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/triangleimages.html

19 bodies against the locked door,

25 bodies in the cloakroom,

30 bodies in the elevator shafts,

Approximately 70 died by falling or jumping out of the building

The steel frames and concrete structures were undamaged.

5

undamaged.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

Contributing Factors: Building ConstructionContributing Factors: Building Construction

The Asch Building was a “fire proof building” less than 150 ft high. The building itself would emerge nearly undamaged but everything inside would burn completely.

The danger in these fire proof buildings resulted from the use of wood for the floors, doors, and trim.

The fire escape was inadequate for the number of

6

The fire escape was inadequate for the number of people employed in the building because

It ended at a second floor skylight.

It was dangerously loose at the upper floors.

Its doors opened outward so as to block the catwalks that connected the flights.

The doors only opened inwards.

The spiral stairways were narrow which restricted the number of people on it.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

It had been declared as a Fire Trap by the New York City Fire Commissioner some three months earlier.

The workers were packed closely together on each floor with high ceilings in the building as the Labor Code mandated a minimum of 250 cubic feet of air per worker.

The location of the stairs or exterior fire escape was unknown for the employees.

A narrow passageway between tables and the only exit on the

Contributing Factors : Building Design Contributing Factors : Building Design

7

A narrow passageway between tables and the only exit on the Greene Street side and not enough space in the room: 8 tables and 240 sewing machines on the ninth floor.

The stairways:

The Greene St stairway was used to check the workers for stolen goods.

The Washington stairway was locked to prevent an alternate route.

The location of the stairways and exterior fire-escapes was obstructed by machinery, wooden partitions, and piled-up merchandise.

Spiral stairway in the Triangle Shirtwaist FactorySpiral stairway in the Triangle Shirtwaist Factory

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The 9The 9thth floor of the Asch Buildingfloor of the Asch Building

8 Tables

ElevatorsFire Escape

Washington St G

machinesmachines

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.htmlhttp://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

The owners neglected to install fire safety technology. They refused to sign the collective bargaining agreement to improve the factory conditions.

The only measures available for the workers were 27 buckets of water and a fire escape.

Contributing Factors : Lack of Safety MeasuresContributing Factors : Lack of Safety Measures

9

No sprinkler system because they were not required in New York city buildings, in1911.

No fire extinguishers.

The fire hose was rotten and broken.

The valve of the pipe that carried water to the building was rusted which prevented access to water .

http://lawprofessors.typepad.com/laborprof_blog/commentary/index.htmlhttp://lawprofessors.typepad.com/laborprof_blog/commentary/index.html

Employees and employers smoked during business hours and at meal time.

Illumination was provided by gas lighting but they were unprotected by globes and were placed near flammable material.

Contributing Factors : Lack of safety measures (cont.)Contributing Factors : Lack of safety measures (cont.)

10

No regular effort was made to clear the oil and grease soaked floors and the rubbish heaps.

No fireproof receptacles were provided for the accumulated waste.

The last time an accumulation of cutaways was picked up from the factory was on January 15, 1911.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

Inadequate inspectionsInadequate inspections

The Triangle Shirtwaist Factory passed a routine fire inspection on October 15, 1910.

Primarily trivial violations were identified during the inspection on February 27, 1911:

- The shafting under the machine tables was not guarded. - The factory had no dressing rooms for the girls.

- The lights in the halls were inadequate.

11

- The lights in the halls were inadequate.

The inspector failed to identify major violations, such as: • Violation of the child labor law because the

employees hid the kids in cases for the shirts. • Smoking even though he saw some cigarette butts

in the factory. • Adequate distances between the exits and the

machines and tables. • Locked doors because they were unlocked before

the inspection. No corrective measures were taken after several warnings

to improve the safety measures in the Factory.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The manager tried to put the fire out himself; he did not call the Fire Department immediately.

Fire ladders could reach no higher than the 6th

floor.

12

floor.

The firefighters tried to enter as the workers streamed out in the narrow stairway.

The firefighters focused on stopping the fire on the 8th floor instead of trying to rescue workers.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

After The FireAfter The Fire

On June 30, 1911, a Factory Investigation Commission was established that resulted in:

36 new safety laws in factories were enacted.

The New York Fire Department was reorganized.

The number of Inspectors was doubled.

13

Some of the defects in the building were corrected almost immediately after the fire. These were:

Making the Washington Place stairs a place accessible to the roof.

Adding a new fire escape

Constructing two large water tanks on the roof.

Installing a sprinkler system.

http://www.ilr.cornell.edu/Trianglefire/http://www.ilr.cornell.edu/Trianglefire/

The owners were indicted for manslaughter but the jury acquitted them on December 27,1911 when it was concluded by one juror that the workers had caused their own deaths:

“ I can’t see that any one was responsible… it must have been an act of God. I think the factory was well managed, and was as good or better than many others. I think that the girls, who undoubtedly have not as much intelligence as others might have

in other walks of life, were inclined to fly into a panic.”

Consequences for the OwnersConsequences for the Owners

14

"The Triangle Shirtwaist Fire of 1911: Social Change, Industrial Accidents, and the Evolution of Common-Sense Causality," Law & Social Inquiry, 20 (1995): 637.

In 1914, the owners had to pay damages in the amount of $75 to each of the families of 23 victims who had sued.

The Triangle Factory set up shop in another location a week after the fire in a building with the same design and the same faults.

The owners recovered insurance payments of $445 per worker killed.

This incident among others led to numerous changes in Occupational Safety Standards.

All the doors must open outwards.

No doors are to be locked during working hours.

Sprinkler systems must be installed in all factory buildings over seven stories or 90 ft in height in which wooden floors or wooden trim are used, and more than 200 people are employed above the seventh floor.

Fire drills are mandatory if a company employs more than 25 people

Improved Safety Requirements Improved Safety Requirements

15

Fire drills are mandatory if a company employs more than 25 people above the ground floor. They must be conducted at least once every three months under the supervision of the Local Fire Department.

Multiple fire exits.

Training for employees about safety in the workplace are required.

Emergency evacuation plans.

Fireproof receptacles are needed to place all flammable material, cuttings and rubbish, to throw out the accumulation.

Smoking must be prohibited in the factories.

The building is now known as The building is now known as

the Brown Building of the Brown Building of Science and it is listed as a Science and it is listed as a National Historic Landmark.National Historic Landmark.

16

http://www.ustrek.org/odyssey/semester2/011701/011701stephfire.htmlhttp://www.ustrek.org/odyssey/semester2/011701/011701stephfire.html

The International Women’s Day The International Women’s Day is celebrated on March 8 as a is celebrated on March 8 as a commemoration to that day.commemoration to that day.

In September 1991, a very similar incident in Hamlet, North Carolina, at The Imperial Food Products Company required about one hour to extinguish and resulted in the deaths of 25 people and injured another 56.

Many similar factors were identified:

No sprinkler system,

17

No marked fire exits and no regular fire drills,

Fire inspectors had not visited the factory since it had been operating.

The state found a total of 83 violations of state and federal regulations, 54 of them willful.

This time, there were sanctions against the plant and its owner.

http://www.ilr.cornell.edu/Trianglefire/

http://www.law.umkc.edu/faculty/projects/ftrials/triangle/trianglefire.html

www.nyc.gov/html/records/pdf/govpub/2826staloysius.final.pdf

http://www.failuremag.com/arch_history_triangle_fire.html

http://en.wikipedia.org/wiki/Triangle_Shirtwaist_Factory_fire

ReferencesReferences

18

http://en.wikipedia.org/wiki/Triangle_Shirtwaist_Factory_fire

www.historybuff.com/library/refshirtwaist.html

www.trianglememorial.com/mainframe.htm

"The Triangle Shirtwaist Fire of 1911: Social Change, Industrial Accidents, and the Evolution of Common-Sense Causality," Law & Social Inquiry, 20 (1995): 621-651

BooksBooks

The Triangle Shirtwaist Factory Fire: Landmark Events In American History by Adam R. Shaefer.

Triangle Shirtwaist Factory Fire of 1911 by Janell Broyles.

Triangle: The Fire that changed America by David Von Drehle.

More informationMore information

Fire at the Triangle Factory by Holly Littlefield.

The Triangle Shirtwaist Factory Fire by Elaine Landau.

Triangle by Katherine Weber.