Sustainability of Liquids with Inkjet Technology Daniel J. Fry February 25, 2008.

-

Upload

kelli-brailsford -

Category

Documents

-

view

221 -

download

0

Transcript of Sustainability of Liquids with Inkjet Technology Daniel J. Fry February 25, 2008.

Sustainability of Liquids with Inkjet TechnologyDaniel J. FryFebruary 25, 2008

Definition of Sustainability

• According to Webster– of, relating to, or being a method of harvesting or using a resource so

that the resource is not depleted or permanently damaged

• According to Wikipedia– is a characteristic of a process or state that can be maintained at a

certain level indefinitely.

Concerns of the Trade Shop

• Film image setters are becoming harder to find and more difficult to maintain and repair

• Silver film is getting expensive, the longer term viability is unknown

• Lost margins from converting liquid plate production to digital sheet production

Options Available to the Trade Shop

• Remain on Silver Films– Acquire backup processor or processor parts

– Secure long term supply agreements with the film suppliers

• Go Digital– High cost of entry

– Higher raw material costs

• Identify alternative options for film supply

Silver Film Alternatives

Thermal films

• Slow, low quality, film does not store well

Ablative film

• A digital image setter is required

Ink jet film systems

• Proven technology in the Screen Printing market since 1996

• Cost neutral position to silver film

• No processor effluent or silver recovery issues

Aspect Quadra Systems

• Introduced in 1996 to the Screen-print market and currently there are over 600 systems installed

• Aspect Quadra is a Proven reliable and inexpensive “all-format” turnkey system

• Printer, film, hardware, and ink are designed for best results of a commercial user

• Established regional technical support system already in place

Aspect Thermal System 1996

Aspect Quadra Advantages - Flexo Customers

• Proven high quality commercial grade printer

• Film & ink cost are comparible to silver film

• In house control of production schedules

• Interactive layouts for job “nesting”

• Scalable system, ability up to 4 printers to the RIP for increased productivity

• Waterproof, durable instant dry film

• Color Halftone Simulation Proofs option

Aspect Quadra System Details

• Roland Pro-II commercial printers

• Film widths 16” to 65.75” on 100 ft. rolls

• High density Quadra-K water-based dye ink

• Wasatch RIP Software for quality process color screening

• Custom-built Windows XP workstation and 17” LCD monitor

Roland Pro-II Printers

Roland Pro-II FJ-540

54” width, Piezo printheads

Film take-up reel (optional)

Roland Pro-II SJ-645

64” width, Piezo print heads

Film take-up reel (optional)

Wasatch RIP Software

• Wasatch SoftRIP is used for all Quadrasystems - partner since 1995

• Wasatch version provides vital features– Monochrome drivers for film output

– Ink volume/droplet control

– Special precision rosette screening

– Layout features for film savings• Auto-nesting• Manual nesting• Cropping/rotation• Distortion scaling

– Pre Linearized configurations to 85 line

– Color Halftone Proofing profiles to 85 line• Ability to print on boards up to 4mm thick (e-flute)

Quadra-K Ink

• Dye black, water-based ink provides– Maximum film penetration

– Excellent halftone dot formation

– Bulk ink options, available in cartridges, liters, gallons

• Color ink available– Cyan

– Yellow

– Magenta

– Light Cyan

– Light Magenta

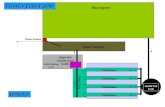

Quadra Inkjet Film

- 7

- 6

- 5- 4

- 3

- 2- 1

• 1 - Anti-static back coating and traction enhancer

• 2 - Primer coat

• 3 - Polyester base material

• 4 - Primer coat

• 5 - Blocking layer and seal to prevent spreading

• 6 - Absorption layer and micro-encapsulation

• 7 - Topcoat-receiving layer with matte particles

Quadra micro encapsulation film - cross section

Quadra film attributes

• Quadra film is designed for quality line and dot images

• High density = 3.5 to 4.0+ U.V.

• Instant dry via total encapsulation (dye ink)

• Totally waterproof (submersible)

• Anti static traction back coat, eliminates droplet deflection

• 100 foot rolls maintain register accuracy

• Dimensionally stabilized for excellent registration properties

Finished Film

• 75 lpi, round dot– Output on a Roland FJ540

using 1440dpi output

• Compatible with typical film cleaners

10% dot

70% dot

System Productivity

• Quadra Output Speeds

• As with all output devicesslower = higher quality/resolution faster = more throughput for less critical jobs

• Quadra speed is adjustable to meet requirements

Customer Output Times

• Times listed below are to produce a 40” x 40” film

Output Setting (dpi)

Time (minutes)

720 7 min 20 sec

1080 10

1440 15

Aspect Quadra Specifications

• Registration – start to finish accuracy and fit between films

– 0 .014” over 8 feet

Factors that affect registration• Film loading - tensioning

• Weight of roll (100 foot rolls)

• Cleanliness of printer media deck and pinch rollers

• Skew - the ability to produce geometrically square output

– 0.039” or less over 4 feet - grid test

Factors that affect skew• Film loading and initial

calibration

• Mechanical accuracy of printer• Tension in media 120” 5 color job

Summary

• Aspect Quadra System offers the Trade Shop the following benefits:

• Proven commercial technology

• Durable, archivable film in widths up to 65.75”

• Cost effective replacement to silver films

• A means to keep Liquid plate manufacturing sustainable