Superior Quality Sand Screens · 2020. 6. 15. · screens for use as downhole sand exclusion...

Transcript of Superior Quality Sand Screens · 2020. 6. 15. · screens for use as downhole sand exclusion...

-

superiorcompletionservices.com

Superior Quality Sand ScreensPortfolio

-

2 ©2020 Superior Energy. All Rights Reserved.

Business ObjectivesRemain focused and deliver on our Shared Core Values:

Integrity We conduct ourselves and our business affairs with honesty and integrity and do not tolerate illegal or fraudulent activities.

Respect We treat our employees with fairness, dignity, and respect and do not tolerate any forms of discrimination.

Safety We protect the safety and health of ourselves, our fellow employees, and everyone that we work with and stop unsafe actions.

Fair Play We deal fairly with customers, suppliers, and other business relationships and always act in the best interests of the Company.

Citizenship We conduct ourselves as good citizens in the communities where we operate, and we respect the environment.

Deliver superior screen products on a global basis:• Expand footprint in the international market place

• Partnering with screen manufacturers in strategic locations

• Continue to meet and/or exceed our domestic US client base expectations

• Invest in R&D for development, qualification, and commercialization of innovative screen and AICD products

• Continuously explore and work closely with suppliers to fill gaps in the portfolio when and where it makes sense

Who We AreSuperior Energy Completion Services has been manufacturing screens for use as downhole sand exclusion products since 2004. From its inception, Superior’s mission has been to produce and deliver the highest quality and most innovative Sand Control Well Screens and Passive/Autonomous Inflow Control Devices to our customers.

This is achieved through many avenues:• Perpetual training of our personnel

• Engagement with our quality team throughout the entire production cycle - from securing raw material through our approved vendors to the finished goods being prepared for shipping

• Ongoing performance monitoring through our Continuous Improvement Process (CIP)

• Machine operators working closely with the maintenance team to ensure routine and preventative maintenance on all manufacturing equipment is current and accounted for

-

©2020 Superior Energy. All Rights Reserved. 3

Portfolio Bench StrengthsWhether your requirements are for conventional* or unconventional* screen types, Superior’s portfolio of sand control products are designed, manufactured and equipped to handle your well’s specific exclusion issues.

CONVENTIONAL SCREENS• ProWeld™

• SlimFlo™

• ProWeld™ TOP

• ProWeld™ Precision TOP

• EconoWeld™

• EconoWeld™ TOP

• DynaFlo™ DB

• CoilFlo™ DB

• EconoFlo™

• DynaFlo™ FM

• SureFlo™

• SureFlo™ CT

• DynaFlo™ Interceptor

UNCONVENTIONAL SCREENS• MST™ Screens

• MST™ Screens with Shunt Tube

• SelectFlo™

• UniFlo™

- Radial Orifice ICD (ROI)

- Autonomous Flow controller Device ( AFD)

- AFD Select

*Conventional Screens: A conventional screen has perforations in the base pipe for fluid flow from the filter media to inside the base pipe for production and just the opposite for injection.

*Unconventional Screens: Communication of filtered fluid flow from the reservoir to inside the base pipe is not achieved through perforations in the base pipe. It is achieved by any one or combination of the following components in a screen assembly: sliding sleeve, screen communication system (SCS), and/or an ICD AICD.

-

4 ©2020 Superior Energy. All Rights Reserved.

Historical MilestonesSuperior’s commitment to constantly designing and developing high-quality technology has benefited our clients and has also derived a variety of evolutionary* and proven designs. The generations are evident in our portfolio and have also resulted in revolutionary* and unique products within the Superior Sand Screen portfolio throughout the years.

2004ProWeldSlimFlo

2005ProWeld TOP

2007MST ScreensDynaFlo DBCoilFlo DB

2013EconoFlo

2014UniFlo ROI

2015ProWeld Precision TOP

-

©2020 Superior Energy. All Rights Reserved. 5

2016EconoWeldEconoWeld TOPDynaFlo FMSureFloSureFlo CT

2017SelectFlo

2018MST Screen w/Shunt Tube

2019DynaFlo Interceptor SureFlo SCS

2020UniFlo AFD Select

Legend:*Revolution = totally new/disruptive/game changer

*Evolution = next generation/gradual/adaptive changeSilver Gold

Platinum

-

6 ©2020 Superior Energy. All Rights Reserved.

ProWeld ◌ ProWeld TOP ◌ ProWeld Precision TOP

Conventional Wire Wrap Jacket Screens

ProWeld™ProWeld was introduced in 2004 as one of the first screen products manufactured by Superior Completion Services. A combination of rib wire for support, and a wrap wire with a micron sized gap, keeps solids at bay in a downhole sand control completion.

ProWeld™ TOPDeveloped in 2005, ProWeld TOP (PWT) was a revolutionary wire wrap jacket concept. Adding base pipe as part of the fabrication process delivers a wire wrap jacket product with higher mechanical strengths than the predecessor. An interference fit increases the collapse values to the collapse of the base pipe. Burst values are some of the highest in the industry with the actual jacket push off exceeding 40 tons per foot of jacket length.

ProWeld™ Precision TOPIn 2015, Superior Completion Services commercialized an evolutionary version of the original ProWeld TOP. With additional capabilities to the manufacturing process and the use of an optical camera to verify the final wrapped gauge, resulted in two distinct benefits: 1) alleviated any possibility of necking and delivery of the same size gap across the rib equal to the gap between the ribs; and 2) reduced any unnecessary cold working of the wrap wire which hardens the material during the wrapping process.

-

©2020 Superior Energy. All Rights Reserved. 7

EconoWeld ◌ EconoWeld TOP ◌ SlimFloEconoWeld™In 2016, after a dramatic downturn in the oil and gas industry, lower-cost solutions were required for the silver and brownfield markets. To deliver on this need, Superior recognized through reduced manufacturing cost of an existing screen design, ProWeld, it would meet the client’s expectations. By removing the shrink rings on the ProWeld design and welding the wire wrap jacket directly to the base pipe, an equivalent evolutionary product was born at a more economical price point.

EconoWeld™ TOPAnother 2016 product change brought about a direct wrap screen similar to ProWeld™ TOP with the only difference being the removal of the shrink ring used for attaching the jacket to the base pipe. The actual jacket is welded directly to the base pipe just like EconoWeld. This product enables the same performance as a ProWeld TOP but at a price point less than PWT.

SlimFlo™Introduced in 2004, SlimFlo is a pre-packed screen designed to add a level of assurance in a gravel packed sand control application. Voids between an inner and outer wire wrap jacket are filled with a proppant. This feature prolongs production and decreases a premature screen failure or “hot-spotting”, which is a localized high velocity of solid laden fluid passing through the wire wrap jacket.

Conventional Wire Wrap Jacket Screens

-

8 ©2020 Superior Energy. All Rights Reserved.

MST ScreensMST™ Screens2007 was the year Superior Completion Services commercially launched a patented Multizone Single-Trip (MST) gravel/frac pack system in the Gulf of Mexico. This revolutionary screen design does:• Provide a closed system for all zones of interest

• Deliver access to each zone by mechanically manipulating a sliding sleeve

• Provide fluid leak-off during pumping services

• Offer fluid loss control by closing each sliding sleeve of every zone during retrieval of the service tool upon completion of the pumping operations

Unconventional Wire Wrap Jacket Screens

-

©2020 Superior Energy. All Rights Reserved. 9

DynaFlo DB ◌ CoilFlo DB ◌ DynaFlo FMDynaFlo™ DB2007 introduced the first, revolutionary premium metal mesh screen into the Superior portfolio. DynaFlo DB is a four-layer stacked plain square weave (PSW) where each of the four layers has the actual filter layer located as the third layer from the direction of fluid flow into the media. DynaFlo DB is a Platinum Product offering when performance and quality are the key drivers. Its unrestricted flow path reduced erosion potential caused by a change in direction of fluid flow, permits a direct line of sight flow through its unique array of stacked layers. This product covers base pipe sizes from 2-3/8-in. to 7-in. in outside diameter.

CoilFlo™ DBCoilFlo is a sibling to DynaFlo DB, and also designed in 2007. It covers the smaller 1-in. to 2-1/16-in. thru-tubing sizes for all remediation sand control applications. CoilFlo DB can be installed in a live well deployment as standalone screens or gravel packed with thru-tubing gravel pack systems.

DynaFlo™ FMIn 2016, a need for a metal mesh screen without any welds on the filter media was required to develop a very high burst and collapse rating required by a large National Oil Company (NOC). DynaFlo FM, or Fixed Mesh screen was designed to meet this revolutionary challenge. This product offers an integral filter cartridge that consists of an inner perforated shroud as a support and standoff layer, wrapped with a layer of large PSW, two layers of actual filter media, another drainage/separation weave, sandwiched together during the wrapping process with an outer perforated protective shroud.

Conventional Woven Metal Mesh Screens

-

10 ©2020 Superior Energy. All Rights Reserved.Conventional Woven Metal Mesh Screens

SureFlo ◌ SureFlo CT ◌ SureFlo SCS SureFlo™In 2016 the manufacturing process gained a revolutionary change eliminating all welding requirements of the filter media by bonding the actual filter media to the outer protective shroud providing an integral single laminated filter cartridge. This delivered a low profile filter cartridge/laminate without any welding on or near the actual filter media. This product covers base pipe sizes from 2-3/8-in. to 7-in. outside diameter.

SureFlo™ CTIn 2016, SureFlo CT was born as the smaller size version of SureFlo, 1-in. to 2-1/16-in. It is designed to address sand control failure remediation needs as a standalone screen or gravel packed in place with thru-tubing gravel pack assemblies.

SureFlo™ SCSAlso in 2019 the industry’s first-ever external screen communication system (SCS), a patented product was created using the SureFlo screen product as a basis for the design. The standard means of communicating fluid with an MST System has always been using fluid by-pass across the blank section of each screen joint via an internal micro-annulus created with the internal SCS. This external SCS, SureFlo SCS, delivers the following results:

-

©2020 Superior Energy. All Rights Reserved. 11 Conventional Woven Metal Mesh Screens

• 100% screen coverage across the payzone in cased and open hole applications

• Delivers the proppant to the annulus in a gravel/frac pack application. The fluid leaks off across the blank sections of screen joints where the SureFlo SCS is located, enabling deposition of the sand without any reliance on gravity or breaking of the gelled carrier fluids as used in frac packing operations.

• Offers 100% radial flow of fluid from the payzone directly underneath the screen jacket at every inch of the screen assembly via the external SureFlo SCS and whatever type of screen is provided for the application. The fluid then passes across each screen's connection, or blank section, until a point of entry into the base pipe is reached, typically a sliding sleeve. This eliminates the potential for convergence flow within the porous media and a mechanically induced skin effect.

DynaFlo InterceptorDynaFlo™ Interceptor™In 2019 Superior branded a suppliers product, Interceptor™, as the DynFlo™ Interceptor™. This product consists of an inner wire wrap jacket, slip-on or direct wrap (as the high strength version), a sheet of filter media wrapped around the inner jacket longitudinally the length of the filter media with the overlap aligned and tacked to the inner jacket via an end ring on both ends, followed by a stamped protective shroud and another end ring where all three segments are tacked in place on one end. The assembly then passes through a series of roller swages enabling the entire product to be swaged together in a series of smaller ID increments to prevent the cold working of the material. The final assembly is welded to the base pipe.

-

12 ©2020 Superior Energy. All Rights Reserved.Conventional Woven Metal Mesh Screens

EconoFloEconoFlo™EconoFlo is the first fully fabricated in-house premium metal mesh screen. In 2013, an International Oil Company (IOC) approached Superior requesting a premium-built metal mesh product with a price point similar to slotted liners. Historically, the IOC had been installing a slotted liner in their heavy oil fields for thermal producers and water interdiction wells around the world. The challenge was addressed by designing a resistance welding machine to attach the woven metal mesh filter media directly to the base pipe. The end product delivered the expected performance and price point results. All installations to date, since the first in January of 2014, are still producing at a constant rate without any measurable solids production for this IOC.

EconoFlo progressively became the product of choice in brownfield development around the world, as a premium performing product with an exceptional price point.

“EconoFlo outperformed the competition in the original

pilot project and has become our standalone screen design for thermal

production needs in this heavy oil field. EconoFlo has undertaken the most

aggressive cyclic steam qualification of any of its peers in this product

class that I have ever seen.” - IOC representative

-

SelectFloSelectFlo™In 2017 a brand name, SelectFlo, was assigned to a suite of screens, wire wrap and woven metal mesh, delivering a screen wrapped sliding sleeve to enable the following:• Filtered fluid flow from produced and injected fluids

• Mechanical and hydraulic independent zonal flow control, on or off, when run with an annular isolation barrier between zones in both open hole and cased hole applications, as a standalone screen, or gravel packed in place

• Installing a screen system as a closed solid liner for circulating capabilities

©2020 All Rights Reserved. Superior Energy Services. 13 Unconventional Screens

-

14 ©2020 Superior Energy. All Rights Reserved.

v

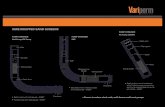

UniFlo ROI ◌ UniFlo AFD Select UniFlo™ ROIThe UniFlo™ brand for inflow control devices (ICDs) was established in 2010. In 2014 the UniFlo ROI was released to compete in the ICD commodity market. The ROI is a radial orifice ICD used for the production of oil in long open hole horizontal standalone screen applications. The UniFlo ICD/AICD brand can be equipped with any of the screens within the portfolio.

UniFlo™ AFD* (Autonomous Flow-controller Device) SelectIn 2020, Superior delivered the industry’s first-ever autonomous downhole flow regulator. It was designed to deliver a constant flow rate across the entire lateral section irrespective of the reservoir heterogeneities or the fluid properties. This self-regulating valve assembly design is equipped with a unique shaped flow path in the valve body. The piston is held in place inside the valve body by a high alloy rod spring. This high-strength material retains the elasticity of the spring over a 20-40 year well life. The maximum force applied to the rod-spring when the piston reaches the end of travel never exceeds 50% of its yield strength. The design is also qualified to API-19 ICD Standards.• The AFD will function at operating differential pressures across the unique shape of the valve body ranging from as low as 50 psi to as high as 600 psi for a single fluid type.

• The first commercial product, the UniFlo AFD Select, offers the autonomous flow control performance of the AFD, the filtering capabilities of any screen offerings in the portfolio, and a multi-position sliding sleeve with three positions. The positions are obtained through a mechanical/hydraulic shifting tool deployed on coiled tubing, spaghetti string, or with a well tractor for long horizontal sections.

• The three positions: 1) Closed, 2) AFD/Production mode, or 3) Frac mode are identifiable by a hard stop of the hydraulic shifting tool before moving to the next position or sleeve in the desired interval of interest. Each sliding sleeve is designed for multiple openings/closings and desired modes of operation as required.

Unconventional Screens

Clos

ed M

ode

Aci

d Fr

ac M

ode

Prod

uctio

n M

ode

* patent pending

-

©2020 Superior Energy. All Rights Reserved. 15 Unconventional Screens

MST Screens with Shunt TubeMST™ Screens with Shunt Tube Technology (STT)In 2018, Superior worked with a licensed supplier for STT to meet a NOC’s need to ensure a complete annular pack in a 60-degree hole angle for a cased and perforated application. The application called for fracturing and annular packing of a multiple-zone well, in a single-trip, with a high angle wellbore. With proper planning, teamwork across suppliers, good communication, and excellent execution, Superior along with its licensed supplier delivered the very first MST System with STT in the world.

“Superior performed flawlessly

from the conceptual design of the 9637 MST System shunt tube technology

(STT) screens all the way through execution during installation by the Superior Energy Services

completion team out of Balikpapan. The timing was critical for this project and Superior worked

diligently with their suppliers in making this a feasible opportunity in the time frame allotted. We are

pleased with the results and have plans to install other completions such as this in other wells,

which may include using Superior’s 7027 MST System with STT Screens.”

- NOC representative

-

superiorcompletionservices.com

SUPERIOR QUALITYAt Superior we constantly strive to produce the highest quality products our customers have grown to expect. As a customer-driven organization, we continue to pay very close attention to our clients’ needs and work collectively as a team within manufacturing, engineering, marketing, quality, and operations to meet and serve those needs.

Superior Manufacturing, Engineering, and Operations are fully qualified to the following standards:• ISO 9001:2015

Although our screen manufacturing is registered to ISO 9001, work is completed to the same procedures/processes as contained within API Q1

• The registrar for Screens is Quality System Registrar’s, Inc.

Contact your local sales representative to learn how our Superior Sand Screens can deliver the highest quality and most innovative sand exclusion products to meet your needs.