Subsea Produksjon Og Broenner

-

Upload

jihwan-lee -

Category

Documents

-

view

37 -

download

2

description

Transcript of Subsea Produksjon Og Broenner

2

SUBSEA or SURFACE ?SUBSEA or SURFACE ?SUBSEA or SURFACE ?

Floating Production Storage & Floating Production Storage & Offloading VesselsOffloading Vessels

Turret Mooring Systems

Tension Leg Platforms

Light Well Intervention

Guidelineless Deepwater Trees

Subsea ManifoldSmart Well

Control Systems Subsea TemplateSystems

Standard Subsea Trees

Metering & Control Systems

Surface Well Systems

ROV Tie-In Systems

Subsea Processing

Subsea Drilling Systems

Time (days)

Depth

TD

RKB

7” Production Liner

30” - 36” Conductor

20” Surface Casing

13 3/8” Intermediate Casing

30” - 36” Hole

26” Hole

16” Hole

12 1/4” Hole

8 1/2” Hole

WELL CONSTRUCTION

TVD MD

Gas

Oil

HORISONTALHORISONTALXX--MAS TREEMAS TREE

No valves in the vertical boreAll valves on the sides / horizontal planeTubing Hanger orients, land and lock inside HXTWell head

VERTICAL XVERTICAL X--MAS TREEMAS TREE

Production Master and Swab Valves in the vertical boreTubing Hanger installed in WHWell Head

WELL HEADWELL HEADConnect well to XConnect well to X--MAS treeMAS tree

18 3/4” UWD-15 Wellhead HousingMetal-to-Metal Annulus Seal Assembly7” Casing Hanger10 3/4” Casing Hanger

30” Conductor Housing

13 3/8” Casing Hanger

Permanent Guide Base

CASING STRINGCASING STRING

Casing run after each section of drilled hole to:Prevent caving of unstable formationsProtect weak formationsIsolate abnormal pressure zonesSeal off lost circulation zonesComplete and produce the well efficiencyStructural support for BOPs and wellheads

Multi-position GLV

FLX4 - AVLDM ASV

Seal Stem to PBR

Completion packer

PBR

TRSCSSV

P/T Gauge Hanger

7" Production Tubing

M-Pas open hole packer

6 5/8" Stand alone screen

Bull nose

Shale

Sand

Sand

ICD

OCRE FBIV

Stand alone screens w/ICD,Zone control and

Annulus flow prevention

Upper and Lower completion installed

10 3/4" Casing Shoe

7" Liner

Sand

Sand

ShaleShale

10 3/4" x 7" Screen Hanger w/PBR

Sand

SandSand

Sand

Shale

Shale

Swell packer

WELL COMPLETION

DOWNHOLE TOOLSDOWNHOLE TOOLS

Flow Control SystemSub-Surface Safety SystemPacker SystemSand ControlLiner HangersInstrumentationChemical Injection

H-40 Used for large diameter casing only.J-55 Normally used if adequate (some normalize)K-55 Casing onlyN-80* N&T, C-Mg steel. HRC >24L-80 Q&T, Cr-Moly steel. HRC <23C-90 Q&T Type 1. HRC <25.4C-95* C-Mg steel. HRC >25T-95 Q&T Type 1. HRC <25.4P-110* Replaced P-105. HRC 35Q-125* High strength steelV-150* Extra high strength steel

* Not H2S SSC resistant unless temp high

API TUBULAR GRADESAPI TUBULAR GRADES

Consists of base pipe with drilled holes, wire wrapped screen jacket, consolidated prepack material, outer shroud with punched holes

Jacket and outer shroud are welded or mechanically attached to base pipe

Prepack material thickness ranges from .34” to .41”depending on size

SAND SCREENSAND SCREEN

DOWN HOLEDOWN HOLEMaterial ChallengesMaterial Challenges

Hydrocarbon mixtureCO2, H2S, salts, …

High temperatureHigh pressureSolids/sandDifferent well intervention fluids

Completion and packer brine fluidsMud acids (HCl - hydrochloric acid, HF – hydrofluoric acid)Stimulation fluidsScale inhibitorsChemicals to dissolve scaleMethanol

Local flow condition due to narrow gapsDifficult to monitor and inspect without retrieving the tubing

DOWN HOLEDOWN HOLEMaterial Challenges, cont.Material Challenges, cont.

Experience: In most of the oil companies Well & Well completion are treated by a special group of people.These people are working separate from the material-and corrosion group in the company.This is a challenges due to transfer of experience and knowledge

MATERIALS SELECTION FOR WELLSMATERIALS SELECTION FOR WELLS

NORSOK M-001

ISO/CD 21457

DOWN HOLEDOWN HOLEUsed materialsUsed materials

Casings made from carbon steelTubings made from

CS 13CrHigher alloyed SS for aggressive hydrocarbon mixtures

Downhole completion equipmentDifferent types of materials both CS, SS and Ni-alloys

Challenge for new high pressure, high temperature sour wells

Sour service requirement to be fullfilled for the actual CRA (Corrosion Resistant Alloy)Probability of hydrogen embrittlement (HE)

Reference article:P.R.Rhodes et.al.: Pushing the limits of metals in corrosive oil and gas well environments. CORROSION – Vol. 63, No. 1 2007

SUBSEA PRODUCTION SYSTEMS, SUBSEA PRODUCTION SYSTEMS, PIPELINES AND RISERSPIPELINES AND RISERS

27

MANIFOLDMANIFOLD

Ormen Lange Ormen Lange –– Mating of manifold and Mating of manifold and foundation structurefoundation structure

Example of piping manifold (Example of piping manifold (OsebergOseberg J) during J) during fabricationfabrication

FLEXIBLE PIPE FLEXIBLE PIPE DesignDesign

1. Stainless steel carcass2. Thermoplastic liner3. Carbon steel pressure

armour4. Carbon steel tensil

armour, two centra-wound layers

5. Thermoplastic outersheath

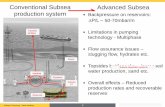

SUBSEA PROCESSINGSUBSEA PROCESSING

Definition:Subsea Processing is any active handling and treatment of produced fluids at or below the seabed.

To date, the following have been given most attention:

Boosting / pumpingSeparation processesWetgas boosting / compression

SUBSEA PROSESSINGSUBSEA PROSESSINGWhy?Why?

Tieback to platforms enable use of existing infra structureEnable longer tiebacksBulk separation and re-injection of produced waterBoost flowing well head pressureGas compression

Re-injectionExport

Raw seawater injectionHydrate suppression

Remove water from well stream

SUBSEA PROCESSINGSUBSEA PROCESSINGNeeded equipmentNeeded equipment

SolidsSeparator

Water Injection Pump

Compressor

LiquidPump

ControlValve

HVTransformer

UltrasonicLevel

Indicator

SeparatorTank

ControlModule

Cooler

SUBSEA PRODUCTIONSUBSEA PRODUCTIONChallengesChallenges

Water depths between 100 m and 3000 mReservoir pressures up to 15.000 psi (1035 bar)Temperatures;

-200 C to + 1500 C normally( -500 C to + 2000 C in extreme cases)

Design life of 20 years + (up to 50 years)

SUBSEA PRODUCTIONSUBSEA PRODUCTIONChallengesChallenges

Material technology and fluid compatibilityFlow assurance & insulationLong distances to topsideProcess equipment subsea

Increased complexityEnvironment protection

Zero emissionFishingDecommissioning

TYPICAL SUBSEA EQUIPMENTTYPICAL SUBSEA EQUIPMENT

Wellheads & X-mas trees for well control

Piping manifolds (large-bore piping for hydrocarbons and water injection, small-bore piping for hydraulics and chemicalinjection.)

Pipe spools, flowlines (pipelines)

Connectors

Structures

Riser, workover equipment, tools

Control system (hydraulic, electrical)

In future, more and more ”complex” equipment, such as separators and gas compressors will be located subsea.

SUBSEA APPLICATIONSUBSEA APPLICATIONRequirementsRequirements

All subsea applications have very high quality requirements, since possibilities for inspection and maintenance are verylimited, and replacement costs for non-conforming equipmentare very high.

Limited possibilities for monitoring and replacements

Seals and other non-metallic materials must be designed and qualified for full lifetime of field (typically 10-50 years)

Metallic materials must in general be resistant to internalcorrosion for the full lifetime of the field (pipelines with simple and predictable flow conditions may be in carbon steel withcorrosion allowance combined with corrosion inhibitors.)

MATERIAL SELECTIONMATERIAL SELECTIONPrinciplesPrinciples

Materials must be selected based on:

Strength (yield, tensile) and hardnessDuctilityFracture toughness (Normally Charpy-V, sometimes fracture mechanics testing)PriceAvailability (Small quantities, global fabrication)Fabrication methods (welding, induction bending, cold bending etc.), industry experienceDecision on solid material or low alloy steel with CRA cladding where corrosion resistance is required

ENVIRONMENTAL EFFECTENVIRONMENTAL EFFECT

External corrosionSeawater

Internal corrosionHydrocarbon systemInjection water

De-oxygenated seawaterRaw-seawaterProduced water

Internal erosionDue to solids (sand) in the fluid

WearDue to relative motion between components

Hydrogen Induced Stress cracking (HISC) or Hydrogen embrittlement (HE)

HYDRROGEN EMBRITTLEMENTHYDRROGEN EMBRITTLEMENT

H2S corrosion ”sour service” in oil & gas systems, controllede.g. by hardness (max 22HRC for carbon steels). Guideline for material selection given in ISO15156/ NACE MR0175. (This is the same effect whether the equipment is subsea or topside.)

For submerged equipment, cathodic protection reactions mayin addition give atomic hydrogen on steel surface. Criticalfor carbon/ low alloy steels with a hardness aboveapproximately 35HRC or SMYS above appr. 700 MPa, or for duplex steels if highly stressed.

GISLE RGISLE RØØRVIK, STATOILHYDRORVIK, STATOILHYDROPresentation at NTNU, October 2008Presentation at NTNU, October 2008

HISCHISCWhat is important?What is important?

Access to hydrogenWelding and CP (plus internal corrosion (H2S))

Certain strain/stress level (global and local)Load and geometry

MicrostructureSelected material

HYDROGEN STRESS/STRAIN

MATERIAL

All these are needed at the same time!

A PHONE CALL FROM A SUPPLIERA PHONE CALL FROM A SUPPLIER

I’m going to supply a subsea clamp to an oil company and am aware of the HE problem. My clamp is made from

a polymer material – probably GRP. This clamp is attached to the subsea unit by use of bolts made

from 25% Cr SDSS. Which bolt tension (stress) can I accept and still avoid HE to damage the bolts?

STRESS/STRAIN

MATERIAL

HYDROGEN No HE

HOW CAN WE PREVENT HE?HOW CAN WE PREVENT HE?

Hydrogen Hydrogen EmbritlementEmbritlement of of 25% Cr SDSS25% Cr SDSS

DESIGNDESIGN

Design with acceptable local stress / strainSTRESS/STRAIN

For duplex stainless steel

ACCESS OF HYDROGENACCESS OF HYDROGEN

Reduced protection potentialWelding with low hydrogen inputAlways “bake” bolts or other components with HDG or electrolyttic zinc coating (2500C / 4 hours)Use coating that prevent hydrogen to penetrate into the metal

HYDROGEN

HOW BIG IS THE HE PROBLEM SUBSEA?HOW BIG IS THE HE PROBLEM SUBSEA?

STATOIL:From early 1990’s

Several subsea fields developedwith 22% Cr DSS and 25% CrSDSS in

Piping, Manifolds, ValvesInstruments……

25% Cr SDSS standard for umbilical tubes

Today275 wells + 50 subsea templates> 1000 km small bore umbilicaltubing

Subsea template with SDSS pipingSource: Ø.Strandmyr, Duplex 2007, Grado Italy

NORSOK MNORSOK M--001001SubseaSubsea

External protectionChapter 4.3.4, 4.3.5, 4.3.6

Weld overlay (e.g. flange surfaces)Chapter 4.4

PipelinesChapter 4.3 (Corrosion evaluation), 4.5, 4.6, 5.6.1 (Bolting materials), 5.7, 5.8

Chains and mooring systemsChapter 5.9

Structural materialsChapter 6.2

ISO/CD 21457ISO/CD 21457SubseaSubsea

External protectionChapter 4.5.1, 4.5.4

Weld overlay (e.g. flange surfaces)6.11

PipelinesChapter 4.3 (Corrosion evaluation), 4.5.4, 4.6, 5.5, 6.2, 6.3, 6.4, 6.5.1, 6.8.1, 6.8.2, 6.9, 6.10, 6.13

MATERIAL SELECTION FOR XMATERIAL SELECTION FOR X--MAS MAS TREETREE

Composite valve block (CVB):Low alloy steel w/ Inconel 625 overlay on all wetted parts or F6NM (13Cr 4Ni) martensitticstainless steel w/ 625 overlay in seal areas.

Production wing blockAs for CVB or solid 25Cr superduplex stainless steel.

Annulus valve block and X-overflowloop:Carbon/ low alloy steel w/ 625 overlay in seal areas.

Metal gaskets:Inconel 625, Incoloy 825 or other CRA.

MATERIAL SELECTION FOR XMATERIAL SELECTION FOR X--MAS MAS TREETREE, cont., cont.

Valve internal parts:Variuos types of nickel alloysand stainless steels.

Seal surfaces: Overlay welded with Inconel625.

Components not exposed to well fluid:Normally carbon or low alloysteel.

TYPICAL MATERIALS USEDTYPICAL MATERIALS USEDSubseaSubsea

Piping systems (oil/ gas/ water injection):Carbon steel or low alloy steel (typically ASTM A350 Grade LF2, AISI 8630 or ASTM A182 Grade F22) with UNS N06625 overlayweld on components like hubs and valves.

For smaller dimensions, use of solid stainless steel forgings may be more economical. HIP (Hot Isostatic Pressing) may be an alternative to forged material.

Martensittic stainless steel type F6NM (13%Cr 4%Ni) may be used where high strength is required. Has limited corrosion resistance, normally overlay welding with Inconel 625 is required on all sealsurfaces.

22Cr/ 25Cr duplex stainless steels may also be used.

TYPICAL MATERIALS USEDTYPICAL MATERIALS USEDSubseaSubsea

Smallbore piping systems (hydraulics and chemical injection), typically 3/8” to ¾”:

AISI 316 where low strength is acceptable. (Alternatively colddrawn AISI 316 where higher strength is required, and if weldingis not required).

22Cr Duplex or 25Cr Superduplex where extra strength is required. This has been ”standard” material selection for more than10 years.

Cold bending (min. bending radius 2,5xD, max hardness 360 HV) used in fabrication, and has never caused problems with hydrogen embrittlement.

MATERIALS FOR SEAWATER MATERIALS FOR SEAWATER

Seawater resistant materials are used for piping systems for ”rawseawater” (i.e. seawater with high oxygen content) and for components where cathodic protection (CP) cannot be ensured or where CP have to be avoided (e.g. due to problems with calcareousdeposits).

25Cr superduplex (Note: With PRE-value and other properties accordingto Norsok M-630.)

6MoUNS N06625 (Inconel 625)TitaniumFibre Reinforced Epoxy

MATERIAL SELECTION MATERIAL SELECTION TO AVOID HISCTO AVOID HISC

In later years, we have seen an increased focus on risk for HISC (Hydrogen Induced Stress Cracking) from several oil companies. This has resulted in additional requirements on several projects, such as:

Restrictions on use of HISC-sensitive materials, such as 22Cr- or 25Cr-duplex. Alternatives are C-steel with internal overlay weld (typicallyUNS N06625/ Inconel 625) or alternatively austenittic stainlesssteels. Austenittic stainless steels are often impractical due to lowstrength.

Detailed design requirements with restrictions on local stresses and strains, smooth cross sectional changes, restrictions on cold bending ofpipes etc. (Ref. e.g DNV (Draft) RP-F112 and Norsok WA-01.)

Special coating on all duplex piping, such as vulcanized polychloroprenerubber, to prevent hydrogen formation on the steel surface.

CAN SOMETHING GO WRONG?CAN SOMETHING GO WRONG?

Use of wrong material – not according to specificationNo Cathodic Protection applied – not electrical contact between sacrificial anodes and structureHISC due to a combination between stress, hydrogen and susceptible materialSolids in the fluid – causing catastrophic metal loss followed by a leakComposition of process fluid out of control causing severe corrosionCorrosion inhibitor not supplied or mal-functioning causing severe corrosion

CAN SOMETHING GO WRONG?CAN SOMETHING GO WRONG?continuecontinue

Fatigue due to system vibration (including free span of pipelines)Fatigue in wellhead/casing due to overload during work-over operationNo or “wrong” inspection program implemented……….

EXAMPLEEXAMPLEElectricalElectrical penetratorpenetrator

25% Cr Duplex materialSubsea without CP30 - 35 % sigma phase due to incorrect heat treatmentSevere corrosion attack due to the sigma phase

(In this case, the correct material had been selected, but due to

incorrect heat treatment, material had not got the

required properties.)

CORROSION PROTECTION IS IMPORTANT CORROSION PROTECTION IS IMPORTANT TO SECURE STRUCTURAL INTEGRITY!TO SECURE STRUCTURAL INTEGRITY!

USE OF ELASTOMERS OFFSHOREUSE OF ELASTOMERS OFFSHORE

Thermal insulation SealsCable and flowlineprotectionBearing systemsFendering and buoyancyHoses++

ALEXANDER KIELLAND ULYKKENALEXANDER KIELLAND ULYKKEN27. mars 1980 27. mars 1980 –– 123 123 menneskermennesker omkomomkom

EN SLIK ULYKKE VIL VI IKKE HA IGJEN!