SUBSEA PIPELINE TECHNOLOGY - Atlantic Canada · PDF fileSUBSEA PIPELINE TECHNOLOGY ......

Transcript of SUBSEA PIPELINE TECHNOLOGY - Atlantic Canada · PDF fileSUBSEA PIPELINE TECHNOLOGY ......

One Source... Diversi�ed Solutions.

SUBSEA PIPELINE TECHNOLOGY

World-Class Deepwater Pipeline Repair SolutionsROV or Diver Operable, Full Structural Pipeline Repair Clamp

World’s largest clamp helps to mitigate risk

Oil States Industries Houston has designed and is currently manufacturing two unique application HydroClamps also known as Pipeline Repair Clamps for the Nord Stream Pipeline. While Oil States has been a pioneer in HydroClamp design for over 40 years, this specialized unit takes subsea engineering design to a new level of expertise.

The clamps are approximately 30 feet long with a sealing surface of almost 10 feet and a gross weight just over 106 tons making it the largest full structural clamp in the world. The clamps are in the testing phase with delivery expected in 2016. Once completed, the clamps will be stored as stand-by equipment for use in the event there is pipeline damage (dent or small leak). Should this occur, a clamp can be installed over the affected area to re-establish full structural and pressure integrity to the pipeline with only minor disruption. The most unique aspect of the clamp is the internal seals can be changed to accommodate four varying sizes of pipe.

The Nord Stream Pipeline is a twin 48” diameter pipeline system that runs from Portovaya Bay near Vyborg, Russia to the coast of Lubmin, Germany to Portovaya Bay near Vyborg, Russia. It spans 1,224 kilometers across the Baltic Sea and connects the vast natural gas fields of Russia to the European Union gas system. Each line of the twin system has the capacity to supply 27.5 bcm (billion cubic meters) per year for a total of 55 bcm. In the 2013 World Energy Outlook report, the International Energy Agency projected the EU-27 will see a 116 bcm supply shortfall of natural gas by 2030. The pipeline is a major step in helping to ease that supply deficit.

The pipeline was built in three separate sections that have varying pipe wall thicknesses due to pressure rating drops over the length of the pipeline. This was done to save money on the cost of the pipe. The section tie-ins were completed utilizing a special hyperbaric welding chamber at a depth of 80 meters off the coast of Sweden and Finland.

Nord Stream is a long-term, private investment consortium of Russian, German, French and Dutch energy companies helping the EU to achieve its goals of energy supply, security and climate protection. The system has been online since 2011 and has the capacity to supply natural gas to some 26 million households throughout Germany, Denmark, the UK, the Netherlands, Belgium, France, the Czech Republic and other countries. Due to the global nature of this project, which has set a new benchmark for offshore pipeline infrastructure, companies from all over the world were meticulously chosen to supply the safest and most technologically advanced products to assure its success. Oil States is proud to be part of such a historic project.

www.oilstates.com

OIL STATES HOUSTON

Sales, Engineering & Manufacturing6120 E. Orem DriveHouston, Texas 77048 USAPh +1 (713) 445 2210Fx +1 (713) 445 [email protected]

WORLDWIDE SALES OFFICES:

Oil States Industries, Inc.1155 Dairy Ashford, Ste. 700Houston, Texas 77079 USAPh +1 (713) 510 2200Fx +1 (713) 510 2307

Oil States Industries,(UK) Ltd.Blackness RoadAltens Industrial EstateAberdeen AB12 3LHScotland, UKPh +44 (0)1224 896190Fx +44 (0)1224 896199

Oil States Industries, Inc.5 Allee des Mesanges13012 Marseille, FrancePh +33 491 95 60 51Fx +33 491 95 60 51

Oil States Industries MENAJumeirah Lakes Towers, Cluster F HDS Tower, unit 2209Dubai, United Arab EmiratesPh +971 4 4528482Fx +971 4 3688403

Oil States Industries,(Nigeria) Ltd.No. 50C Glover RoadIkoyi, Lagos, NigeriaPh +234 1 2718363Fx +234 1 2718364

Oil States Industries, Inc.102 Bis/M Le Lai StreetDistrict 1Ho Chi Minh City, VietnamPh +84 8 3925 3545Fx +84 8 3925 0123

Oil States Industries, Inc.Suite 5, 1 F Amirov StreetAZ1000 Baku, AzerbaijanPh +994 12 5 981 125Fx +994 12 4 379 125

O I L S TAT E S I N D U S T R I E S , I N C .

©2016 Oil States Industries, Inc.SS0209 2m

Diverless or Diver-Assist HydroClampOne Clamp Accommodates Four Pipe Sizes

Function testing demonstrating closure of the clamp around the pipe, bolts fully tensioned, saddles properly adjusted on the pipe and annulus test to ensure seal integrity.

The clamp has hydraulically activated saddles at each end. These help position the clamp properly on the pipe during installation.

Weight: 212,220 lbs Pipe wall thickness: 41.0, 34.6, 30.9 and 26.8 mm Length Overall: 30 feet Seal Length: 10 feet Tension Studs: 84Design/Operating Pressure: 220 barNACE Compliant for external sour service

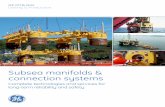

The image shows the original concept graphic of how the clamp would be used in conjunction with lift frames, diver assist or ROV assist. The inset map details the Nord Stream Pipeline path and areas served.