Subsea 101 SUBSEA 101 · 2018-11-27 · the BOP. • DHXT – The completion is normally run on a...

Transcript of Subsea 101 SUBSEA 101 · 2018-11-27 · the BOP. • DHXT – The completion is normally run on a...

-

SUBSEA 101The purpose of this document is to help define some of the rationale behind the selection of a subsea tree configuration in a theoretical field for a project we are calling Project X. This section provides an example of the approach that our teams use to tailor our recommendations to the unique requirements of every project. The criteria in this document are specific to the deepwater high current environment in the UK North Sea. For other basins in the world, some of these criteria may or may not be valid.

Find more Subsea 101 case studies onlineSimilar papers cover equipment selection criteria in different geographies, water depths and customer challenges.

www.bhge.com/subsea-101

Subsea 101

-

ApproachOption IdentificationThe water depth on Project X, circa 3,280 ft (1,000 m), requires the use of BHGE’s deepwater tree family – our established DHXT deepwater horizontal tree, DVXT deepwater vertical tree, or our Aptara™ Lightweight Compact Tree, the newest variant of the vertical configuration, which has also been assessed due to its 10,000 ft (3,048 m) water depth rating.

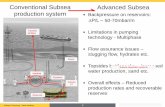

Subsea production trees can be segmented into two main types: horizontal and vertical. Horizontal trees are so called because the primary valves are arranged in a horizontal configuration (allowing easier access to the wellbore), and conversely Vertical Trees have the primary valves arranged in a vertical configuration (above the wellbore). Refer to the figures below.

The original designs of subsea vertical trees and tubing hangers were of a dual bore configuration. Prior to removal of the blowout preventer (BOP), it was necessary to set plugs in both the production and annulus bores using complex dual bore risers. The current BHGE DVXT systems provide access to the “A” annulus through the tree design. This access to the “A” annulus is controlled by gate valves for vertical tree (VXT) on Tubing Head Spool (THS) and annulus isolation devices for VXT on Wellhead, rather than plugs. This enables operations with a monobore, less complex riser, or landing string with BOP on tree, delivering significant advantages in deepwater.

3,280 ft3,280ft (1,000m) water depth for Project X

Subsea 101

-

BHGE’s latest tree design, the Aptara™ Lightweight Compact Tree is a vertical tree (VXT) configuration but with a new innovative flow path that reduces the effective height of the tree while providing footprint and weight benefits as well as improving life of field functionality and affording the same installation benefits of a traditional vertical tree. Refer to page 28 in section 2.

Deepwater Vertical Trees (DVXT)The DVXT or Aptara™ systems can be provided in two configurations: tree on Wellhead or tree on THS:

• Aptara™ & DVXT on THS. The THS is landed on the wellhead prior to running the completion and TH into the well. “A” – Annulus isolation is achieved by a valve in the THS. The TH is passively orientated by the THS. The THS permits the flowline connection to be moved off the tree onto the THS.

• Aptara™ & DVXT on Wellhead. The completion and TH can be installed after drilling the well, with the TH landing in the upper casing hanger. “A” – Annulus isolation is achieved by a hydraulically operated Annulus Isolation Device (AID) in the TH. TH orientation is actively achieved with a hydraulically actuated BOP pin that engages with a helix and slot in the Tubing Hanger Running and Orientation Tool (THROT) within the landing string.

Deepwater Horizontal Trees (DHXT)• The DHXT is installed on the wellhead prior

to running the completion and TH into the well. TH lands in the DHXT internal profile. “A” – Annulus isolation is achieved by a valve in the DHXT. The TH is passively orientated by the DHXT.

Drill-through DHXT has not been considered as existing infrastructure prevents its deployment, and Casing hanger arrangement is required to land the Production casing string through the tree head and into the wellhead. This system would not be compatible with the existing Appraisal Wellhead System.

Tree Selection

DHXT• Passive TH orientation• Most mature solution• Requires multiple BOP trips• Crown plug barriers• Least flexible weather window installation• Must pull completion to pull XT• Average weight• Maximizes WH fatigue• Lowest CAPEX potentially higher OPEX

DVXT• Active/passive TH orientation• Mast maturity solution• Can minimize BOP trips• Gate valve barriers• Flexible weather window installation• Can pull XT without touching completion• Average weight• Maximizes WH fatigue

On THS• Higher stack-up so worse for

wellhead fatigue• Passive TH alignment• 1 more BOP trip• Reduced installation flexibility as THS

on critical path• Highest CAPEX, lower OPEX

On Wellhead• Lower stack-up so better for

wellhead fatigue• Active TH alignment (BOP Mod required)• One less BOP trip• Greater installation flexibility (if all ball

valves used) as THS not on critical path• Medium CAPEX, lower OPEX, lowest

TOTEX

VXT (dual bore) on wellhead HXT on wellhead

Production Master Valve (PMV)

Production Master Valve (PMV) Production

Wing Valve (PWV)

Production Wing Valve (PWV)

LP WellheadLP Wellhead

HP Wellhead

HP Wellhead

Casing HangersCasing Hangers

ConnectorConnector

Tubing Hanger

Tubing Hanger

Crown Plugs

Master Valve Block (MVB)Master Valve

Block (MVB)

Subsea 101

-

Lifecycle Stage Functional Criteria Commercial Criteria

Design and Manufacture Wellhead Fatigue CAPEXLead Time

Installation Equipment RequiredFlexibility/Options AffordedBarrier PhilosophySequencing and Durations

Operation Reliability OPEXDownhole FunctionsPressure and Temperature SensingAnnulus Access

Intervention Light InterventionHeavy WorkoverTree RepairWell Kill

Decommissioning Tree Retrieval

Evaluation CriteriaA range of criteria has been identified that covers the tree performance from its initial design, through installation, operation, intervention, and finally decommissioning. Assessments made against these criteria are predominantly qualitative in nature but where possible initial quantitative assessments of likely economic impact have been captured in the commercial section.

The criteria are shown in the table opposite.

For each functional criterion a brief discussion is provided on the relative merits or limitations of the tree configuration options available, followed by a ranking assessment.

For the commercial criteria, assessments are made against scenarios associated with the likely activities. Where information is not known, the assumptions made are clearly stated.

A new innovative flow path reduces the footprint and weight of the tree. It also allows for improved life of field functionality through the life of field cap.

Subsea 101

-

Functional assessmentsDesign and ManufactureWellhead Fatigue ImpactDue to the harsh environmental conditions in the UK North Sea, the potential for wellhead fatigue is high and, where practicable, the selected subsea solutions should minimize this risk. Fatigue damage accumulated in the well will be cumulative across all BOP operations conducted upon it. Therefore, fatigue damage accumulated during drilling and completion detracts from the available fatigue capacity for future workovers and plug and abandonment operations. This is a key driver for other operators to move away from HXTs in the UK North Sea to VXTs on wellhead.

Having the BOP connected directly onto the wellhead (rather than onto either a DHXT or THS located between the wellhead and BOP) ensures that the lowest possible bending moment is applied to the wellhead, reducing the level of applied fatigue damage. Having a tree or THS between the wellhead and BOP can typically reduce the fatigue life of a wellhead system by as much as 25%.

Verdict – Wellhead Fatigue

HXT VXT (WH) VXT (THS) Aptara™ (WH)

3rd 1st 2nd 1st

VXT (WH) scores the highest by having the BOP connected directly to the wellhead.

Drilling and Completion Schedule AlignmentThe intent of the project is to run the completions within eight months and for the first tree to be installed in 18 months, with subsequent trees delivered monthly thereafter.

Both the HXT and THS need to be installed on the wellhead prior to running the upper completion and TH putting the THS or HXT on the critical path. The VXT on Wellhead option facilitates the installation of the upper completion and TH in the wellhead, thereby decoupling the XT or THS delivery from offshore completion schedules and de-risking the overall project schedule.

Verdict – Drilling Schedule Alignment (lead time)

HXT VXT (WH) VXT (THS) Aptara™ (WH)

3rd 1st 2nd 1st

VXT (WH) scores the highest as neither the tree or THS is required prior to offshore installation of the completion.

InstallationEquipment RequiredBoth DHXT and DVXT systems require the use of a specific suite of rental tooling. The DVXT tooling package requires more tooling than the HXT system and is therefore slightly more expensive. Both systems use a casing or “landing string” to run the completion through the BOP.

• DHXT – The completion is normally run on a Subsea Test Tree (SSTT) within the marine riser and the tubing hanger is landed within the horizontal tree. Once the TH is landed in the tree, and the completion set, tested and the well cleaned up, wireline deployed crown plugs are located and tested in the TH.

• DVXT – Well clean up, well testing and removal of wireline deployed barriers on a well that is intended for a vertical tree has traditionally only been carried out after the well has been suspended, the BOP removed, and the tree installed. Well access is achieved via a dedicated test package and open water riser. This test system comprises two main assemblies, the Well Control Package (WCP)

and the Emergency Disconnect Package (EDP). In a similar fashion to the subsea test tree, this system enables the drilling rig or vessel to safely disconnect from the well in the event of an emergency. WCP/EDP packages and associated open water riser systems represent considerable capital investments, typically in the order of tens of millions of dollars. By comparison, SSTT can be rented on the open market on a per day or per well basis. As a result, they have a much lower capital impact, and this was one of the key drivers for developing a similar approach for monobore VXT systems to eliminate the need for the costly dedicated test package and open water riser.

Using hydraulically actuated suspension barrier ball valves that can be closed and tested during the completion installation, and then opened after VXT installation, eliminates the need for the LRP/EDP packages, as wireline intervention is not required to remove these

barriers. This is particularly advantageous for the VXT on Wellhead, as actuation of the barrier valves is faster than the deployment of wireline plugs (reducing online rig time) and this also permits the rig to depart the well after the completion installation. All the XT installation activities can therefore be conducted off-line from the rig scopes of work by a lower cost installation vessel.

Verdict – Installation – equipment required

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

VXT (WH) and (THS) score the highest as the use of actuated completion barrier valves reduce the amount of wireline activities and reduce on-line rig time required offshore.

Key

1st Product ranked first

2nd Product ranked second

3rd Product ranked third

Subsea 101

-

Reducing rig time at each well will also help to ‘clear the field’ and create longer SURF installation windows.

FlexibilityOperational weather windows for rig and SURF installation activities are very short in harsh environments. Therefore, a key driver for subsea system selection is to minimize or remove scopes of work carried out on the rig. Reducing rig time at each well will also help to ‘clear the field’ and create longer SURF installation windows. This will maximize value at the rig by making it available earlier for other scopes of work, and allowing dynamic re-prioritization and planning to maintain the overall schedule.

Also, de-coupling major SPS hardware deliveries (tree and/or THS) from the rig activities minimizes the risk of potential hardware delays affecting the rig schedule.

• DHXT – requires the tree to be installed on the wellhead between drilling the well and prior to completion installation. This increases the time spent on the well by the rig.

• VXT – on THS requires the THS to be installed on the wellhead between drilling the well and prior to completion installation. This increases the time spent on the well by the rig.

• VXT – on wellhead – the full completion can be installed in the wellhead without the tree. This reduces the time spent on the well by the rig.

Reducing the amount of time that the rig is on each well allows plans to be re-prioritized (e.g. fast track drilling and completion activities can be scheduled or a change in the order of activities with short notice can be made to capitalize on opportunities). DHXT and DVXT on THS make this very difficult, whereas DVXT on WH allows a higher flexibility in the rig operations.

Verdict – Installation – flexibility

HXT VXT (WH) VXT (THS) Aptara™ (WH)

3rd 1st 2nd 1st

VXT (WH) scores the highest by minimizing the rig time spent on the well.

Subsea 101

-

Project X completion

Well status (prior to XT installation)Primary barrier elements

Element Qualification Monitoring

Upper completion – Orbit barrier valve above safety valve (ball valve, control line operated)

Pressure tested from above

Periodic ROV monitoring

TRSCSSV Inflow tested Active barrier: inflow tests/function tests are required

Gas lift mandrel Inflow test of check valves during completion

A-annulus pressure

CIV w/ injection line/valve Inflow test of check valves during completion

A-annulus pressure

Production packer Pressure tested from above and below

A-annulus pressure

Casing cement Job performance, cement bod log and FIT

Not accessible

Secondary barrier elements

Element Qualification Monitoring

Tubing hanger annulus isolation device

Pressure tested from above

Periodic ROV monitoring

Lower completion – CBV barrier valve (ball valve, hyd opened)

Pressure tested from above

Not accessible

Wellhead Pressure tested Not accessibleCasing hanger Pressure tested Not accessibleCasing Pressure tested Not accessibleCasing cement Job performance,

cement bod log and FITNot accessible

Note: All pressures to be defined during well design. SPS hardware rated to 10ksi.

Well suspension diagram with vertical TH in wellhead and ball valve barriers in completion

Barrier PhilosophyTwo types of well barrier for suspension are available depending upon the tree system selected:

VXT systemsAfter the well has been drilled to TD (prior to VXT installation) the lower completion can be run, and formation isolated using a tubing deployed downhole barrier valve – CBV Barrier Valve (ball valve, hydraulically opened by applying tubing pressure cycles).

The upper completion is installed with an Orbit Valve (Hydraulically operated, Bi-directional downhole barrier ball valve). It is operated by two hydraulic lines through the TH, installation tooling and DVXT.

This permits the BOP to be removed after completing the well with two tested barriers in place that can then be opened after VXT installation and eliminates the need for wireline recovery of these barriers via an open water WCP/EDP system.

TH Suspension Cap

TRSCSSV

AID

Orbit Barrier Valve

CBV Barrier Valve

Subsea 101

-

A typical well suspension diagram with a DHXT and Crown Plugs.

Typical subsea production well with horizontal production tree

Primary barrier elements

Well barrier elements Comments

Production packer 7Completion string 25 Production tubing between

production packer and SCSSVSCSSV 8 SCSSV 1 or SCSSV 2Secondary barrier elements

Well barrier elements

Casing cement 22Casing 2Wellhead 5 Including casing hangerTubing hanger 10Tubing hanger plug 11Subsea production tree 31 w/AMV and PMV

DVXT systemsThe BOP will be installed on the DHXT prior to running the completion. The Tubing Hanger and completion will be landed, suspended, locked and sealed within the HXT internal profile. Main barriers to the well bore are by wireline installed Crown Plugs. The Crown Plugs are landed, locked and sealed in profiles in the TH bore.

Verdict – Barrier Philosophy

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

VXT (WH) and (THS) score the highest by using remotely operated ball valve barriers in the completion, thereby eliminating the requirement to run and recover wireline plugs.

Subsea 101

-

Sequencing and DurationsThe high-level operational activities and a review of the additional number of BOP trips required for each system are as follows:

DHXT System or VXT with THS SystemThe following sequence would be typically required for the initial drilling and completion of each well, for a non-drill through DHXT or DVXT with THS:

1. 36-inch Conductor Housing and extension installed by vessel.

2. Top hole activities drilled by the selected Dynamic Positioning (DP) rig. 18-3/4-inch HP Wellhead Housing c/w 20-inch extension and 13-3/8-inch casing string run open water and installed in the well and landed, locked and cemented.

3. BOP installed on the wellhead.

4. Well drilled and 10-3/4-inch Casing Hanger c/w 10-3/4-inch – 9-5/8-inch casing string run through the marine riser and BOP. Installed in the wellhead and landed, locked, cemented and pressure tested.

5. Well suspended.

6. BOP unlatched from the wellhead – best case, it is ‘bunny hopped’” onto another wellhead.

7. DHXT or THS landed, locked and tested on the wellhead.

8. BOP landed, locked on the DHXT and tested on the well.

9. Well suspension plugs/barriers drilled/removed from well.

10. Well drilled to TD.

11. Lower completion installed and tested.

12. Upper Completion with TH installed, landed, locked in DHXT, packer set and completion (including TH) pressure tested.

13. Wireline crown plugs run, landed and locked in TH.

14. BOP unlatched and recovered to surface.

15. External tree cap installed on DHXT mandrel profile, or suspension cap installed on THS.

This sequence (assuming vessel and HXT or THS availability) has the following number of BOP trips (with the associated on-line rig time):

• 1 BOP trip and 1 BOP unlatch/relatch/pressure test: 4.5 days to run and test the BOP, 3.0 days to recover the BOP, 1.75 days to hop the BOP, 1.5 days to drill cement plugs. Total = 10.75 days.

VXT on WellheadThe following sequence would be typically required for the drilling and completion of each well:

1. 36-inch Conductor Housing and extension installed by vessel.

2. Top hole activities drilled by the selected Dynamic Positioning (DP) rig. 18-3/4-inch HP Wellhead Housing c/w 20-inch extension and 13-3/8-inch casing string run open water and installed in the well and landed, locked and cemented.

3. BOP installed on the wellhead.

4. Well drilled and 10-3/4-inch Casing Hanger c/w 10-3/4-inch – 9-5/8-inch casing string run through the marine riser and BOP. Installed in the wellhead and landed, locked, cemented and pressure tested.

5. Well drilled to TD.

6. Lower completion installed and tested. Lower completion CBV barrier closed and tested.

7. Upper Completion with TH installed, landed, locked in wellhead, packer set and completion (including TH) pressure tested.

8. Upper completion Orbit barrier valve closed and tested.

9. BOP unlatched and recovered to surface.

10. Suspension cap installed on TH and wellhead.

This sequence has the following number of BOP trips (with the associated on-line rig time):

• 1 BOP trip and 1 BOP unlatch/relatch/pressure test: 4.5 days to run and test the BOP, 3 days to recover the BOP. Total = 7.5 days

Verdict – Sequencing & Durations

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 2nd 1st

VXT (WH) scores the highest by reducing the number of BOP trips/hops on the well.

Subsea 101

-

OperationReliabilityThe proposed systems all use the same basic components (e.g. valves, actuators and forgings) but arranged slightly differently. Control system and tie connection configurations will be the same for all systems. As such, all systems will have similar reliability assessments.

Verdict – Reliability

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 1st 1st 1st

Downhole FunctionsThe following maximum number of downhole functions through the tree and tubing hanger systems are as follows:

• VXT (WH): 7 hydraulic and 2 electrical

• DVXT (THS): 10 hydraulic and 2 electrical

• DHXT: 8 hydraulic and 2 electrical

The total number of downhole functions is limited by the available real estate in the tubing hanger assemblies between the production bore and tubing hanger bodies.

Verdict – Downhole functions

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 2nd 1st 2nd

HXT and VXT (THS) scores the highest due to their capability to have one extra downhole hydraulic line. However, it should be noted that each of the tree systems’ downhole function capability exceeds the minimum requirements for the Project X wells.

“A” Annulus AccessThe proposed systems all provide access to the “A” annulus, between the production tubing and the production casing. This is required for a number of functions, including pressure monitoring and gas lift. Any pressure build-up in the “A” annulus can be bled to the production flowline via a crossover loop on the tree. Access to the “A” annulus is incorporated into the tree design and controlled by gate valves.

Verdict – “A” Annulus Access

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 1st 1st 1st

All the tree solutions provide a similar method of control and annular access via a crossover spool connecting the annulus to the production and controlled via a hydraulically actuated gate valve.

Subsea 101

-

InterventionLight Well Intervention (LWI)Each of the tree systems are configured to permit access via Light Well Intervention packages. Riserless Light Well Intervention provides safe access to a subsea well using a specialist LWI Vessel. The vessel has a well control stack that is deployed on wire to depth and latched onto the tree. However, a specific LWI adapter is required for the tree system to suit the LWI system provider.

After installation of the LWI stack well on the VXT, well access is achieved by opening gate valves in the production bore of the VXT. On the DHXT well access can only be achieved once the Upper and Lower Crown Plugs have been recovered from the TH internal profile. Each Crown Plug retrieval and replacement requires separate trips of the open water lubricator wireline package before and after carrying out any in-well scopes of work.

Typical scopes performed by LWI are Production Logging Trip (PLTs), well zonal isolation, cementing, scale squeeze and re-perforations.

Verdict – Light Well Intervention

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

VXT (WH) and (THS) score the highest as well access is simplified by the opening of gate valves rather than having to recover Crown Plugs.

Heavy WorkoverHeavy Workovers (i.e. full recovery of the completion by rig) is marginally easier with an HXT as the completion can be recovered without having to recover the HXT. However, as the planned completions are not complex, and the base case for the Project X development does not include the requirement for planned heavy workovers, the ease of completion recovery without removal of the tree has not been a driver in selection of the respective system.

Verdict – Heavy Workover

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 2nd 2nd 2nd

HXT scores the highest as the design lends itself to the requirement for heavy workovers.

Tree RepairAlthough it is unlikely that the trees will require repair, the VXTs can be recovered without the need for a heavy workover, whereas a full heavy workover and completion recovery will be required for a DHXT.

Verdict – Tree Repair

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

VXT (WH) and (THS) scores the highest as these trees can be recovered without disturbing the completions.

Subsea 101

-

Well KillIn the event of a requirement to kill the well, this would involve the use of a drilling rig.

• The BOP would be landed, locked and tested on the upper profile of the tree or BOP adapter.

• A landing string with Subsea Test Tree (SSTT) and Tubing Hanger Running Tool (THRT) would be run through the marine riser and BOP.

• THRT would be landed, orientated and latch onto the DHXT TH or DVXT BOP adapter.

• Surface Well Test Spread would be hooked up and surface wireline BOPs installed above the Surface Flow Tree on the rig floor.

– DHXTs – Wireline tooling can then be deployed to recover the Crown Plugs. After the Crown Plugs are recovered the well can be killed.

– VXTs – gate valves in the production bore can be functioned open. After the gate valves are opened the well can be killed.

Verdict – Well Kill

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

VXT (WH) and (THS) score the highest as the well can be accessed and killed after opening the actuated gate valves rather than having to recover Crown Plugs on wireline.

Installation DHXT DVXT (THS) DVXT (WH)

Activity VesselAssumed

duration (days)Corresponding

costAssumed

duration (days)Corresponding

costAssumed

duration (days)Corresponding

cost

BOP Trip MODU 7.5 $1,687,500 7.5 $1.687,500 7.5 $1.687,500BOP Hop MODU 1.75 $393,750 1.75 $393,750 0 –Drill Cement Plugs MODU 1.5 $337,500 1.5 $337,500 0 –THS Installation LCV – Cat 2 0 – 0.5 $57,500 0 –Tree Installation LCV – Cat 2 0.5 $57,500 0.5 $57,500 0.5 $57,500Total Per Well 11.25 $2,276,250 11.75 $2,533,750 8 $1,745,000Total for 9 Wells 101.25 $22,286,250 105.75 $22,803,750 72 $15,705,000

DecommissioningTree RetrievalAll BHGE tree systems are designed to be easily retrieved at the end of life and the field decommissioning, recovery methodology for each system is similar.

Verdict – Tree Retrieval

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 1st 1st 1st

Commercial assessmentsIn this section we make initial quantitative assessments of the potential impact of tree selection on initial equipment purchase and installation (CAPEX) and subsequent life of field activities (OPEX). The numbers show directional trends to aid decision making and illustrate major differences rather than build up detailed numbers across common aspects.

CAPEXEquipmentComparing vertical and horizontal tree solutions, in line with industry expectations, the horizontal tree is a lower CAPEX solution than traditional vertical trees. This is especially clear when the functionality of the THS is included in the vertical solution. Aptara™, BHGE’s new tree configuration, reduces the number of components, as well as the footprint and weight, removing cost from the entire manufacturing cycle. The result is a low CAPEX solution that is comparable to or more cost effective than a horizontal tree.

Verdict – CAPEX – Equipment

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 2nd 3rd 1st

Installation For installation and subsequent intervention assessments, the following working assumptions on vessel rates have been used.

Vessel

Example Rates to demonstrate evaluation

MODU Rate (USD) 225,000 $/DayCat 2 Installation vessel (USD)

115,000 $/Day

Lightwell Intervention Vessel (USD)

175,000 $/Day

Timings are aligned to the major differences with additional detail sub-tasks provided where appropriate. The table below summarizes the anticipated differences in installation costs between the tree options assessed.

The table below shows that the removal of the BOP hop for the VXT (WH) option saves approximately $730,000 per well in rig time over the DHXT or DVXT (THS) alternatives, which amounts to circa $6.5 million across the nine wells. The magnitude of these savings may be even higher if the BOP has to be pulled before running the HXT or THS from the rig, and then re-deploying the BOP.

Verdict – CAPEX – Installation

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 2nd 1st

Subsea 101

-

CAPEX summary Combining estimates of tree equipment and installation shows the following likely impact over the baseline nine-well development for Project X (again noting that the values shown are focused on key differences rather than providing total budget values).

Verdict – CAPEX – Summary

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 2nd 3rd 1st

From a CAPEX perspective, the Aptara™ on Wellhead solution is likely to offer best value for this specific application.

OPEXTree RepairAlthough tree failures are rare and hence unlikely on Project X, the potential shouldn’t be ignored. VXTs can be recovered by vessel, while leaving the full completion in place. However, DHXTs will require a heavy workover with a drilling rig prior to recovering the tree. After the tree replacement, a full completion re-installation will be required. Therefore, the cost of a DHXT replacement will be significantly higher than that for a DVXT.

Verdict – OPEX – Tree Repair

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

Light Well InterventionCosts for LWI access will be heavily dependent upon the scope and extent of the activities planned. Prior to the commencement of these activities, well access with a VXT is achieved by opening gate valve in the production bore of the VXT. However, well access through a DHXT can only be achieved once the Upper and Lower Crown Plugs have been recovered from the TH internal profile. Every additional wireline trip will incur vessel time and associated costs, increasing the cost of LWI for DHXTs.

Verdict – OPEX – Light Well Intervention

HXT VXT (WH) VXT (THS) Aptara™ (WH)

2nd 1st 1st 1st

Heavy Well WorkoverWhile heavy workovers of the completion are relatively rare for non-ESP developments, they do occur. Crucially however, in the case of requiring a heavy workover, the cost and disruption to operations is already likely to be very high, so the additional act of first removing the VXT has limited additional impact.

While the cost of retrieving a tree for maintenance would be more than 22 times for an HXT than a corresponding VXT, the cost of working over the well by pulling the VXT prior to the completion only represents around a 5% increase in costs over the equivalent HXT.

Verdict – OPEX – Heavy Well Workover

HXT VXT (WH) VXT (THS) Aptara™ (WH)

1st 2nd 2nd 2nd

OPEX summary It is difficult to assess the likely impact of tree selection through the life of the field without first understanding the anticipated frequency of operations. However, to provide guidance the following assumptions have been made (across the nine-well development for its life of field):

• 1 tree recovery in total

• 2 heavy workovers in total

• 2 light well interventions per well

This results in the HXT incurring an additional estimated $13 million in OPEX costs across the life of the field. Removing the tree recovery from the assessment reduces this value to circa $5 million but the costs of HXTs will likely increase for each light intervention over a VXT and reduce for each heavy intervention. The magnitudes of these differences are broadly comparable, but light interventions are more likely on Project X, so it is anticipated that the VXT options will represent better value from an OPEX perspective as well as CAPEX.

The Aptara™ vertical tree shows a clear TOTEX advantage.

Subsea 101

-

Conclusions and recommendationsSummary of FindingsSummary of all findings linked to each of the assessment criteria is shown below. The collated verdict tables confirm that Aptara™ on Wellhead is the recommended tree option for use on Project X, with the highest number of top ratings from each category.

Aptara™ (WH) – 16 top ratings

DVXT (WH) – 15 top ratings

DVXT (THS) – 11 top ratings

DHXT – 7 top ratings

Verdict DHXT DVXT (WH) DVXT (THS) Aptara™ (WH)

Wellhead Fatigue 3rd 1st 2nd 1st

Lead Time 3rd 1st 2nd 1st

Installation – Equipment Required 2nd 1st 1st 1st

Installation – Flexibility 3rd 1st 2nd 1st

Barrier Philosophy 2nd 1st 1st 1st

Sequencing and Durations 2nd 1st 2nd 1st

Reliability 1st 1st 1st 1st

Downhole Functions1st 2nd 1st 2nd

“A” Annulus Access1st 1st 1st 1st

Light Well Intervention 2nd 1st 1st 1st

Heavy Workover1st 2nd 2nd 2nd

Tree Repair 2nd 1st 1st 1st

Well Kill 2nd 1st 1st 1st

Tree Retrieval1st 1st 1st 1st

CAPEX – Equipment1st 2nd 3rd 1st

CAPEX – Installation 2nd 1st 2nd 1st

OPEX – Tree Repair 2nd 1st 1st 1st

OPEX – Light Well Intervention 2nd 1st 1st 1st

OPEX – Heavy Well Workover1st 2nd 2nd 2nd

Aptara™ lightweight compact tree.

Subsea 101

-

Conclusion – Tree Configuration for Project XBased on these assessments, a Vertical Tree on Wellhead configuration is recommended for the Project X development. The primary factors influencing this recommendation can be summarized as follows:

1. CAPEX – Although the DVXT on Wellhead is more expensive than the DHXT for equipment supply, this increase is offset by the significant saving on the system installation, as the completion can be landed in the wellhead system with no planned BOP disconnection. When BHGE’s Aptara™ tree is considered, the initial cost of the tree is comparable or favorable to a HXT, as well as having the installation cost advantages of a vertical tree.

2. OPEX – With no planned heavy workovers on Project X, the easier access to the wellbore for light well interventions afforded by a vertical tree is likely to outweigh the benefits of being able to pull the completion without first retrieving the tree for heavy workovers. Further, in the unlikely event that a tree fault develops, requiring retrieval for diagnosis or maintenance, the impact of achieving this with a VXT is lower than with an HXT by significant orders of magnitude.

3. Installation Flexibility – With the narrow working windows for both the rig and SURF installation scopes, reducing the time that the rig spends on the well provides increased operational windows for the SURF vessels. VXT on Wellhead offers the opportunity to reduce the rig time by just over three days per well. It also opens up the potential to re-plan or prioritize rig activities as circumstances change, where wells can be completed and suspended prior to tree delivery without the need to re-mobilize a rig at a later date.

4. Wellhead Fatigue – VXT on Wellhead ensures that the BOP will only be installed directly onto the wellhead. Introduction of a DHXT or THS between the wellhead and BOP increases the bending moment between the BOP wellhead, which increases the potential for accelerated use of the wellhead’s fatigue life. The VXT on Wellhead system minimizes that risk.

Subsea 101

-

Recommendation – Tree Type for Project XBy considering the project specific requirements against the tree configurations available from BHGE, the Aptara™ lightweight compact tree on wellhead configuration is recommended for the Project X development.

Historically, with the Project X field having greater than 2,460 ft (750 m) water depths, if a vertical tree was required, then only a traditional DVXT would be available. However, BHGE has recently introduced an optimized version of the DVXT designed specifically to take cost, weight and time out of subsea developments, while optimizing use through the life of the field. The system uses virtually all the same constituent parts as the DVXT but packages them in a more efficient manner to save approximately 50% of the size and weight. Central to this saving is a unique flow path that enables the choke (and, if required, the multi-phase flow meter) to be housed in an easily recoverable life-of-field cap. Not only does this make recovery easier, it also makes the tree simpler and lighter, as the equipment is positioned centrally through the axis of the body rather than being offset. Initial assessments of the anticipated cost of the comparable Aptara™ Lightweight Compact Vertical Tree on Wellhead across the nine-well development is 15% lower than the DVXT on Wellhead option (with installation and life-of-field costs being equivalent or lower).

Furthermore, by using a vertical tree, it is possible to decouple the tree delivery from the drilling program. This opens up the potential benefits of the Aptara™ system. The downward interface with the tubing hanger system and the upward interface with riser systems, as well as the running tools, are all designed to be identical between the Aptara™ tree and the existing DVXT.

An overview of the key benefits supporting the Aptara™ Lightweight Compact tree on Wellhead solution for Project X are summarized below:

• CAPEX equipment. Aptara™ total hardware price is 15% lower cost than the DVXT on Wellhead.

• Lighter. The Aptara™ is 50% lighter than a conventional VXT. This reduces the Aptara™ tree weight c/w cap to circa 40 tons against 75 tons for a DVXT. This reduction in weight may facilitate the use of lighter installation vessels and reduce installation costs.

• Easier use of life-of-field (LOF) cap vs flow control module. The LOF modular cap is more easily installed and recovered as it is located on the XT upper mandrel, clear of any adjacent hardware. The LOF cap is also configured to permit the introduction of other technologies in later field life, such as subsea pumping to increase overall field production.

• Flexibility. With Aptara™ you can have the same part number for the production and water injection trees to facilitate installation flexibility and potential future reconfiguration through long-term re-profiling of the reservoir.

• Simpler. There is the potential to eliminate the tree flow meter and use the distributed flow meter within the LWCT tree solution.

The Aptara™ vertical tree on wellhead has been recommended as it provides improved performance at the lowest cost over the life of field.

Aptara™ vertical tree on Wellhead has been recommended as it provides improved performance at the lowest cost over the life of field.

Subsea 101