STUDY ON THE EXPANSION OF RAIL TRANSPORT ......Feasibility Study for Promotion of International...

Transcript of STUDY ON THE EXPANSION OF RAIL TRANSPORT ......Feasibility Study for Promotion of International...

Feasibility Study for Promotion of International Infrastructure Projects

in FY2011

STUDY ON THE EXPANSION OF RAIL TRANSPORT

CAPACITY FOR ROCK PHOSPHATE,

THE KINGDOM OF MOROCCO

FINAL REPORT

【SUMMARY】

November 2012

Prepared for:

The Ministry of Economy, Trade and Industry

Prepared by:

PACIFIC CONSULTANTS CO., LTD.

HITACHI, LTD.

TOSHIBA CORPORATION

1. Background and Necessity of the Project

In the output of phosphorus (phosphate rock), which is one of the three major ingredients of fertilizers,

Morocco is world number 3 (26.6 million tons) after China and the United States. As the United States

and China have a large population and therefore have export restriction, Morocco leaves the two

countries far behind international distribution. OCP (royal Moroccan phosphates company), a

monopolistic firm in the phosphate rock industry, has approved a mid and long term plan to increase its

phosphate rock production capacity from the current 28 million tons to 5.5 million tons, anticipating the

rise in the international market. Currently, OCP depends on ONCF for almost 100% of the

transportation from three mines, out of the four developed by OCP, to the ports of embarkation.

ONCF has allocated 39 electric locomotives to the phosphate rock transportation and secured around 30

million tons of annual transportation capacity. However, it is required to establish a plan to increase its

transportation capacity to respond to OCP’s plan to increase its production to 5.5 million tons.

Out of the total of 39 electric locomotives for phosphate rock transportation, 30 locomotives were

produced and delivered jointly by Hitachi and Toshiba through a yen loan. Although it has been over

30 years since the delivery, they are still highly reliable and the quality is highly valued.

The purpose of the project is to propose the best portfolio of locomotives owned by ONCF (optimal

assets of locomotives with a combination of new electric locomotives and existing Japanese ones with

repair and life-prolonging measures through examination of proposals for repair and life-prolonging

measures of the existing cars and procurement of new ones both from technical and cost points of view,

after investigating the details of OCP’s phosphate rock production and ore transportation plans for the

increase of ONCF’s phosphate rock transportation capacity.

2. Basic Policy to determine the Project Scope of

Work To determine the contents of the project, the study is conducted with following basic policies.

Analyze future outlook of phosphate rock production in Morocco.

Sort out requirements for railway freight transportation based on the result of the transportation

demand forecast.

Examine measures to increase transportation capacity of electric locomotives of Japanese make.

Selection of the best portfolio with a combination of new electric locomotives and existing

Japanese ones with repair and life-prolonging measures.

3. Project Overview

3.1 Actual Conditions and Future Prospects of Railway

Transportation of Phosphate Rock

3.1.1 Vehicle Ownership

Out of the 89 electric locomotives owned by ONCF, 39 locomotives are operated mainly for the

transportation of phosphate rock. 30 of them were made in Japan and delivered between 1977 and

1987.

While the Japanese locomotives take an important role in the transportation of phosphate rock, one of the

most important export items for Morocco, the average age of the locomotives is about to reach 30 years

old, which is generally considered as the end of the life. Therefore, there have recently been cases

where the service of these locomotives is suspended due to breakdown and measures are required.

Table 3-1 List of Electric Locomotives Owned by ONCF (delivered in 1977 and later)

Model Year of

delivery

No. of

cars Power Max speed Use Manufacturer

E1100 1977 22 2,850 kW 100 km/h Phosphate rock Hitachi

Toshiba (truck etc.)

E1200 1982 8 2,850 kW 100 km/h Phosphate rock Hitachi

Toshiba (truck etc.)

E1250 1987 12 3,900 kW 160 km/h Passengers Hitachi

E1300 1991 18 4,000 kW 160 km/h Passengers Alstom

E1350 2000 9 4,500 kW 120 km/h Phosphate rock Alstom

E1400 2010 20 5,500 kW 160 km/h Passengers and

containers Alstom

Note) Rows with thick frames: Locomotives for phosphate rock transportation

Source: Study team

3.1.2 Actual Situation of Phosphate Rock Transportation

According to the interview with the person in charge of freight operation management at ONCF

Casablanca Engine Depot, the actual situation of phosphate rock transportation is as below.

23 trains on average, 25 at maximum, are in operation every day for phosphate rock transportation.

The breakdown of the phosphate rock trains are 15-16 trains between Khouribga and Casablanca

Port/Jorf Lasfar Port and 8-9 trains between Ben Guerir and Safi Port.

The weight of a train is 4,800t. The empty weight of a 60-car train is 960t and the phosphate rock

load capacity per train is 3,840t.

A locomotive is operated for 1.5 cycles (1 cycle = from start point, Youssoufia, to end point).

The schedule of phosphate rock transportation is 6-7 days for a locomotive to pull freight cars, 1 day

for the push-pull operation from around Khouribga Station to the branch lines to the mines and

another extra day for rescue etc.

According to the interviews with the Freight Transportation General Manager of the Freight and

Logistics Bureau of ONCF and the Ben Guerir Office of OCP, the load capacity of phosphate rock

freight on the South Axis (Ben Guerir/ Youssoufia to Safi) is 3,600t/train. Therefore, we will use

this number for the following calculations.

Figure 3-1 Routes for Railway Transportation of Phosphate Rock

Source: Study team

ONCF has a plan to increase the operation to 19 round trips on North Axis and 10 round trips on

South Axis.

If the plan presented by the general manager in charge of phosphate rock transportation is

achieved, the transportation volume (mining volume) is estimated as below.

Table 3-2 Estimated Volume When Transportation Capacity Is Increased as Stated by General Manager

in Charge of Phosphate Rock Transportation in the Interview

Route No. of Trains/d Transportation

volume per train

No. of

operating

days

Estimated

transportation volume

(Estimated mining

volume)

Khouribga 19 3,800t 365

26.353M t/y

Ben Guerir 10 3,600t 13.14M t/y

Total 29 - - 39.493M t/y

Source: Study team

3.2 Outline of the Project

In this project, regarding the procurement of the required number of locomotives to increase railway

transportation capacity to meet the plan of future increase of phosphate rock production, we will set the

following three cases, and, through comparison, consider the most appropriate option (best portfolio) for

the procurement of locomotives for phosphate rock transportation.

(Scenarios for consideration)

Combination of rehabilitated locomotives and newly-built locomotives (Case 1) :Procure

rehabilitated locomotives of existing operable locomotives and make up for the gap with new

locomotives to secure the number of locomotives required by the beginning of 2020.

Use of new locomotives (Case 2): Procure as many new locomotives as possible by the

beginning of 2020 and make up for the gap with rehabilitation of existing operable

locomotives to secure the number of locomotives required by the beginning of 2015.

Combination of newly-built locomotives and rehabilitation (Case 3): Secure about half of the

locomotives required by the beginning of 2020 through rehabilitation and procure new

locomotives for the remaining half.

3.3 Project Costs Overview

The project costs of this project at 2011 are shown in Table 3-3 - Table 3-5.

Table 3-3 Project Cost (Case 1)

Initial Construction Cost 2014~2019 216 million US$

Additional Construction Cost 2030~2034 245 million US$

2046 35 million US$

2059~2061 93 million US$

2064 105 million US$

2075~2079 245 million US$

Source: Study team

Table 3-4 Project Cost (Case 2)

Initial Construction Cost 2014~2018 321 million US$

Additional Construction Cost 2048 139 million US$

2059~2063 321 million US$

Source: Study team

Table 3-5 Project Cost (Case 3)

Initial Construction Cost 2014~2018 253 million US$

Additional Construction Cost 2030~2033 163 million US$

2047 72 million US$

2059~2062 175 million US$

2063 67 million US$

2075~2078 163 million US$

Source: Study team

3.4 Preliminary Economic and Financial Analysis

3.4.1 Economic analysis

A comparative analysis of the costs and benefits both in the case of executing the project ("With

project") and not executing the project ("Without project") is carried out from the viewpoint of the

national economy. Costs of "With project" consist of investment costs (including additional iii

investment costs) and operation and maintenance (O&M) costs. The quantified benefits of Vehicle

Operating Cost (VOC) savings are estimated in the analysis.

The results of preliminary economic analysis are summarized in Table 3-6.

The EIRR obtained from the analysis is Case-1 40.4%, Case-2 34.4%, Case-3 36.3% . Compared with

the social discount rate of 5.2%, the project is deemed to be economically feasible.

Table 3-6 Results of Economic Analysis

(Social discount rate = 5.2%)

Case Economic Internal Rate

of Return (EIRR)

Benefit and Cost Ratio

(B/C Ratio)

Economic Net Present

Value (ENPV)

1 40.4% 9.3 24,010 million Yen

2 34.4% 9.0 23,830 million Yen

3 36.3% 8.9 23,820 million Yen

Source: Study team

3.4.2 Financial analysis

Financial Internal Rate of Return (FIRR) on Project (Project FIRR) from the viewpoint of efficiency of

investment is estimated as evaluation index. The Project FIRR is evaluated in comparison to the

Financial Opportunity Cost of Capital (FOCC). In the analysis, the Weighted Average Cost of Capital

(WACC) serves as a proxy for the FOCC combined with the financial sources. Table 3-7 shows the

results of financial analysis. As a result, the Project FIRR is found to be Case-1 37.3%, Case-2 36.4%,

Case-3 38.8% and is considered financially viable compared with 1.6% of WACC.

Table 3-7 Results of Financial Analysis

Case Financial Internal Rate

of Return (FIRR)

Weighted Average Cost

of Capital (WACC)

Financial Net Present Value

(FNPV)

1 37.3% 1.6% 822,250 million Yen

2 36.4% 1.6% 825,650 million Yen

3 38.8% 1.6% 821,820 million Yen

Source: Study team

3.5 Evaluation of Environmental and Social Impacts

3.5.1 Features of the Project

The Project is to rehabilitate and extend life of electric locomotives that are currently used for mineral

phosphate transportation and to introduce new electric locomotives to accommodate production increase

plan of the mineral resources in the future.

The motors used for the existing electric locomotives after the rehabilitation work for life extension and

those that are planned to be newly introduced are superior to DC motors that are currently used for the

existing locomotives in terms of power consumption and maintenance.

The project implementation shall have the following advantages:

Reduction of power consumption, which also results in reduction of greenhouse gas emissions

Reduction of failures of electric locomotives (improvement of operation rate)

Promotion of employment for rehabilitation and extension of life of existing locomotives and supply

of new locomotives

Increase in employment and GDP growth as a result of mineral phosphate production increase

planned by OCP

3.5.2 Project Effects of Environmental Improvement

(1) Study

Reduction of CO2 emissions of electric locomotives as a result of the Project implementation are

estimated. Estimation of CO2 emissions when all the railway transportation with the current electric

locomotives is replaced with truck transportation shows that the current railway transportation imposes

less environmental burden. The case study is shown as follows:

Case 1) Measurement of environmental advantage of current railway transportation

Truck

Transportation Assumption of 100% truck transportation

Railway

transportation

Assumption of 100% railway transportation

Assumption that all electric locomotives have DC motor

Source: Study team

Case 2) Measurement of environmental improvement effects of project implementation

Project is not

implemented

Assumption that all electric locomotives are not rehabilitated (DC motor)

Assumption that increased operations are replaced with truck transportation

Project is

implemented

Assumption of 100% railway transportation

Assumption that both rehabilitated and new locomotives have AC motor

Source: Study team

(2) Measurement of Project Effects of Environmental Improvement

Estimated CO2 emission by implementing of this project is about 76,000t-CO2/y. However, recently,

transaction price has been tumbling down. For example, as of July 2012, transaction price in

Nikkei-JBIC Carbon Quotation Index is 252 yen/t-CO2. This value is one fifth of transaction price as of

July 2011.

It will be difficult to apply this project to CDM from the aspect of yield.

Table 3-8 Measurement Results of Project Effects of Environmental Improvement

CO2 Emission

(t-CO2/y)

Present a. Transportation by Truck 490,055

(2012) b. Transportation by Railway 68,672

c. Environmental Contribution (=a-b) 421,383

Future d. NOT Implementing the project (Without Case) 140,580

(2020) e. Implementing the project (With Case) 64,239

f. Environmental Improvement (=d-e) 76,340

Source: Study team

4. Planned Project Schedule Figure 4-1 shows the planned project schedule.

Figure 4-1 Planned Project Schedule

Note: This table is shown the project schedule for 52 quantities of the

locomotives for both rehabilitation and new manufacturing.

Source: Study team

Des

ign

of

equ

ipm

ent

for

E1

200

,

E12

50

, an

d d

esig

n f

or

ou

tfit

tin

g

Equ

ipm

ent

man

ufa

ctu

rin

g f

or

mas

s p

rodu

cts

Man

ufa

ctu

rin

g f

or

pro

toty

pe

loco

Ap

pli

cati

on

of

yen

lo

an

New ManufactureRehabilitation

Ten

der

Pre

par

ato

ry S

urv

eyItem

Ou

tfit

tin

g f

or

mas

s p

rod

uct

s an

d

tran

sport

to t

he

Moro

cco

Des

ign

Ou

tfit

tin

g a

t lo

cal

Equ

ipm

ent

man

ufa

ctu

rin

g a

nd

tran

sport

to t

he

Moro

cco

Des

ign

and

man

ufa

ctu

rin

g o

f

equ

ipm

ent

for

E110

0 p

roto

typ

e,

and

des

ign

for

ou

tfit

tin

g

’20

’19

’18

’17

’16

’15

’14

’13

’12

Des

ign

of

equ

ipm

ent

for

E1

200

,

E12

50

, an

d d

esig

n f

or

ou

tfit

tin

g

Equ

ipm

ent

man

ufa

ctu

rin

g f

or

mas

s p

rodu

cts

Man

ufa

ctu

rin

g f

or

pro

toty

pe

loco

Ap

pli

cati

on

of

yen

lo

an

New ManufactureRehabilitation

Ten

der

Pre

par

ato

ry S

urv

eyItem

Ou

tfit

tin

g f

or

mas

s p

rod

uct

s an

d

tran

sport

to t

he

Moro

cco

Des

ign

Ou

tfit

tin

g a

t lo

cal

Equ

ipm

ent

man

ufa

ctu

rin

g a

nd

tran

sport

to t

he

Moro

cco

Des

ign

and

man

ufa

ctu

rin

g o

f

equ

ipm

ent

for

E110

0 p

roto

typ

e,

and

des

ign

for

ou

tfit

tin

g

’20

’19

’18

’17

’16

’15

’14

’13

’12 D

ec.

Ten

der

pre

par

atio

n

enfo

rcem

ent

Appra

isal

(Sep

t.)

Exchange

of

No

te,

Lo

an A

gre

em

ent

(Oct

.)

Ten

der

(Ja

n.)

Co

ntr

act

(Feb

.)

9m

on

th f

or

man

ufa

ctu

re,

1.5

mon

th f

or

tran

spo

rt

per

4 l

oco

moti

ve

3 m

on

th f

or

4 l

oco

E1100

Des

ign/M

anu

fact

ure

/Tra

nsp

ort

/Outf

itti

ng

/Tes

t ru

n

E1200

E1250

Aft

er c

erti

fica

tio

n,

sequenti

all

y

Manu

fact

uri

ng/O

utf

itti

ng/T

ransp

ort

atio

n

3 m

on

th f

or

4 l

oco

3 m

on

th f

or

4 l

oco

Des

ign/M

anu

fact

ure

/T

ransp

ort

/Outf

itti

ng

/T

est

run

Dec

.

Ten

der

pre

par

atio

n

enfo

rcem

ent

Appra

isal

(Sep

t.)

Exchange

of

No

te,

Lo

an A

gre

em

ent

(Oct

.)

Ten

der

(Ja

n.)

Co

ntr

act

(Feb

.)

9m

on

th f

or

man

ufa

ctu

re,

1.5

mon

th f

or

tran

spo

rt

per

4 l

oco

moti

ve

3 m

on

th f

or

4 l

oco

E1100

Des

ign/M

anu

fact

ure

/Tra

nsp

ort

/Outf

itti

ng

/Tes

t ru

n

E1200

E1250

Aft

er c

erti

fica

tio

n,

sequenti

all

y

Manu

fact

uri

ng/O

utf

itti

ng/T

ransp

ort

atio

n

3 m

on

th f

or

4 l

oco

3 m

on

th f

or

4 l

oco

Des

ign/M

anu

fact

ure

/T

ransp

ort

/Outf

itti

ng

/T

est

run

5. Technical Advantages of Japanese Companies Japanese manufacturers that are considering participation in the Project has supplied a total of 42 electric

locomotives to ONCF in three deliveries; 22 E1100 locomotives in 1977, 8 E1200 locomotives in 1982

and 12 E1250 locomotives in 1987.

Currently, out of the 89 electric locomotives owned by ONCF, 42, nearly half, are Japanese-made. There

are 22 E1100 electric locomotives, which is the biggest force among the 6 types of electric locomotives

owned by ONCF. (The second biggest force is 20 E1400 locomotives made in France.)

The two Japanese electric locomotive manufacturers who are considering participation in the Project

have ensured high reliability and safety of the railway vehicles delivered to customers inside and outside

Japan.

Based on the knowhow accumulated in Japan about the development and production of railway vehicles,

they develop and produce train vehicles for export. They can also deal with projects that require

compliance with international standards such as UIC (International Union of Railways) standards and

EN (European Standard), and specifications and safety performance required by the country of delivery

and the route of use.

Considering their past deliveries to ONCF from 1977 and recent order receipts from and deliveries to

other foreign countries, it is deemed that the companies have advantage in the supplier selection for

rehabilitation of existing Japanese electric locomotives and manufacturing of new ones for Morocco.

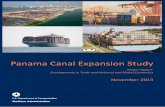

6. Project Location Map

Figure 6-1 Project Location Map

Source: Illustrated by Study Team based on OCP (Office Chérifien des Phosphates; The national Moroccan

phosphates company) publications, ONCF publications.

Main rock phosphate mines

Khouribga, Benguerir, Youssoufia

Main ports of shipment

Casablanca, Jorf Lasfer, Safi

Coastal fertilizer plant

Jorf Lasfer, Safi

Railway lines for

transportation of rock phosphate

Khouribga – Casablanca

Khouribga – Jorf Lasfer

Benguerir – Youssoufia – Safi

Jorf Lasfer

Casablanca

Safi

Khouribga

Benguerir

Youssoufia