Storing & Issuing Controls

-

Upload

subas-shrestha -

Category

Documents

-

view

261 -

download

0

Transcript of Storing & Issuing Controls

-

8/2/2019 Storing & Issuing Controls

1/17

Stored products represent money in terms of bothinitial cost & the cost of replacing them if stolen, spoiled,or damaged because of incorrect storing.

In many food service businesses, products are put in the

storeroom and then removed when needed

there is a lotmore to an effective storage system than this.

-

8/2/2019 Storing & Issuing Controls

2/17

Storing Control: General

Procedures

The principles of effective storage systems for F & B

products focuses on three primary concerns: Keeping products secure from theft

Retaining product quality

Providing information necessary for the financial

accounting system

-

8/2/2019 Storing & Issuing Controls

3/17

Inventory Control Policy Every F & operation is unique therefore determining

the type of storage controls to put in place will vary.Some businesses focus only on storage controls formeats, seafood & alcohol, with less control over lessexpensive & theft-prone products

-

8/2/2019 Storing & Issuing Controls

4/17

ABCD Inventory Classification

System

This system categorises products based on perishability

& cost per serving: Category A items high perishability and cost per serving

Category B items high in cost, low perishability

Category C items low cost per serving, high perishability

Category D items

low perishability, low cost per serving

-

8/2/2019 Storing & Issuing Controls

5/17

ABCD Inventory Classification

System ActivitySpend a few minutes thinking about the types of foodthat would come under the following headings:

Class A

Class B

Class C

Class D

-

8/2/2019 Storing & Issuing Controls

6/17

Why use the ABCD Inventory

classification system?

-

8/2/2019 Storing & Issuing Controls

7/17

Direct

For inventory purposes, food products are separated intotwo categories;

Direct

inexpensive, perishable products usuallypurchased several times per week for immediate use.Examples: fresh produce, baked goods, dairy products

Direct items are NOT entered into any storage records,

they are NOT considered part of the inventory controlsystem

Recordkeeping is concerned with receiving of theseproducts; not storage of these products

-

8/2/2019 Storing & Issuing Controls

8/17

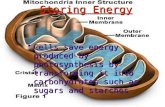

Stores

These items are expensive, purchased less often thandirects. Examples include: meats, seafood, frozen &

canned products, staples (flour, sugar, cereals etc) May be purchased weekly or monthly depending on

usage rates, inventory levels, type of product

-

8/2/2019 Storing & Issuing Controls

9/17

Security Concerns iin Storage Areas

Limited Access permit only authorised staff, keep areaslocked, in smaller operations involve management inreceiving/issuing activities (presence of mgmt. reduces

theft) Lockable Storage Areas storerooms, freezers, coolrooms

should all be lockable; install lockable shelving withincoolrooms

Behind-the-Bar Storage

keep minimal products as thisspace is less secure than central storage area, alcoholshould be locked when bar is closed, lockable cabinets &rolldown screens are advisable to reduce theft

-

8/2/2019 Storing & Issuing Controls

10/17

Security Concerns iin Storage Areas

Storeroom Key Control only those staff members whoneed keys should have them, key locks/combinationsshould be changed routinely, all keys to remain at theproperty at all times locked in the managers office whennot in use

Coded cards similar to guest room access cards areincreasingly popular in BOH areas

-

8/2/2019 Storing & Issuing Controls

11/17

Maintaining Quality duriing Storage Product rotation FIFO

Controlled environment:

Dry stores at 10 21C

Cool rooms at 1 4C

Freezers at -18C

Sanitation practices regular cleaning, pest control

services Proper storage original packaging, allow air

circulation, strong-smelling/absorbent foods storedseparately, store in clean, labeled, covered containers

-

8/2/2019 Storing & Issuing Controls

12/17

Inventory Turnover Rate If too much money is being used to purchase excess

products for inventory, cash flow problems will occurcreating many other problems for the organisation.

Products may spoil & deteriorate due to too muchstock in storage

Highly perishable items (meats, seafood, fruits &

vegetables) should turn over more quickly than lessperishable items (spices, staples, frozen/cannedproducts)

-

8/2/2019 Storing & Issuing Controls

13/17

Physical / Perpetual Inventory

System Physical Inventory System the practice of physically

counting stored products on a periodic basis

Perpetual Inventory System

a running balance of thequantity of stored products is kept by recording allnewly purchased items as they enter storage areas & allquantities issued from storage to production areas

-

8/2/2019 Storing & Issuing Controls

14/17

Issuing Controls: General

Procedures

A well-designed issuing system has the following aims:

limit access to storage areas to authorised staffmembers only

match items removed from storage with actual

production needs assess quantities & costs of products removed from

storage

-

8/2/2019 Storing & Issuing Controls

15/17

Issuing Procedures

Use requisition forms

Assign issuing responsibilities to employees working

in storerooms at limited times only Limit issues to specific times (eg. breakfast items

issued 6am 7am, lunch item issued 10am 1100am)

-

8/2/2019 Storing & Issuing Controls

16/17

Summary

This week was the first part of two, discussing theoperational phase, which is the second function ofmanagement, along with quality control and certain

HR aspects. Today we focused on purchasing, receivingand storage, and we discussed specifications as well asdocumentation and monitoring requirements. Inregards to receiving products, we examined quantityand quality inspections and documentations, in orderto learn about specific storage tasks, such as recording.Finally we discussed receiving and storage procedures

within the operational

-

8/2/2019 Storing & Issuing Controls

17/17

Recap

Describe the purchasing, receiving and storage phaseswithin the operational function

Explain the documentation required within eachphase

List and explain the requirements within each phase,including-product related requirements, quality and

quantity requirements (receiving) and records, pricingand stocktaking (storage)