Steel Plates

-

Upload

antonio-grade -

Category

Documents

-

view

334 -

download

9

Transcript of Steel Plates

PlatesPlatesproduct catalogueproduct catalogue

2

Presentation of the Plates rolling millin VÍTKOVICE STEEL, a. s.

P L A T E S

THE 3.5 M FOUR-HIGH ROLLING MILL

The roll ing mill was founded in 1971 and underwent a large modernization in 1999 which facil itated a considerable improvement of the rolled material geometry, surface quality and expansion of the product mix. Plates are made from concast slabs. Plates are rolled in the thickness range from 5 to 80 mm, and in the width range from 1,000 to 3,300 mm.

THE PLATE PRODUCT MIX IS DESIGNED FOR:

• Steel and bridge structures• Ship building• Transport machines and vehicles• Abrasion resistant plates• Pressure vessels used in normal, or elevated

temperatures• Special military engineering• Plates resistant against atmospheric corrosion• Special use (e.g. longitudinally profiled plates)• Flame cut shapes• Pipelines• Offshore structures

QUALITY MANAGEMENT SYSTEM AND ENVIRONMENTAL MANAGEMENT SYSTEM,PRODUCT CERTIFICATION

VÍTKOVICE STEEL, a. s. holds the Quality Management Sys-tem (QMS) Certificate acc. to EN ISO 9001:2000, API Spec. Q1 and Environmental Management System Certificate (EMS) acc. to EN ISO 14001:2004.VÍTKOVICE STEEL, a. s. has also certification of its products according to the requirements of classification societies and legislation.

3

Table of Contents

P L A T E S

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PLATES MADE OF STRUCTURAL STEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 • Plates made of steel according to EN 10025-2

• Plates made of fine-grained steel according to EN 10025-3

• Plates made of fine-grained steel rolled thermomechanically according to EN 10025-4

• Plates made of steel according to ASTM

PLATES MADE OF STRUCTURAL STEEL WITH IMPROVEDATMOSPHERIC CORROSION RESISTANCE – ATMOFIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 • Plates made of steel according to EN 10025-5

• Plates made of steel according to ASTM

PLATES FOR OFFSHORE STRUCTURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 • Plates made of steel according to API 2H

THERMOMECHANICALLY ROLLED PLATES FOR WELDED PIPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 • Plates made of steel according to API 5L

• Plates made of steel according to EN 10208-2

PLATES FOR SHIP BUILDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 • Plates according to individual shipping companies

• Plates according to designation A 131

HOT-ROLLED PLATES MADE OF STEEL FOR COLD FORMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 • Thermomechanically rolled plates of steel according to EN 10149-2

• Normalized (rolled) plates of steel according to EN 10149-3

QUENCHED AND TEMPERED PLATES MADE OF THE 690 Q STEEL GRADE . . . . . . . . . . . . . . . . . . . . 16

PLATES MADE OF STRUCTURAL QUALITY ALLOY OR CARBON STEEL . . . . . . . . . . . . . . . . . . . . . . . . 17 • Plates made of steel according to EN 10083-1 + A1 and EN 10083-2 + A1

• Plates made of steel according to designation A 827, A 829 and A 830

PLATES RESISTANT AGAINST MECHANICAL WEAR (ABRASIVE WEAR) . . . . . . . . . . . . . . . . . . . . . . 19 • Plates made of steel according to VN 414320 (ABRAZIT)

PLATES MADE OF STEEL FOR PRESSURE VESSELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 • Plates made of steel for simple pressure vessels according to EN 10207 (April 2005)

• Plates made of steel according to EN 10028-2

• Plates made of fine-grained steel according to EN 10028-3

• Plates made of fine-grained steel thermomechanically rolled according to EN 10028-5

• Plates made of steel according to ASTM

ARMOUR PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

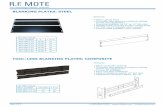

LONGITUDINALLY PROFILED PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DELIVERY CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MATERIAL CERTIFICATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MARKING OF PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DIMENSIONAL TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 • Table 1 – Maximum available plates length of steel having minimum tensile strength Rm up to 530 MPa

• Table 2 – Maximum available plates length of steel having minimum tensile strength Rm more than 530 MPa

• Table 3 – Maximum available plates length of thermomechanically rolled plates

4

Introduction

This catalogue briefly outlines chemical and mechanical properties of commonly used steel plates.

Properties of commonly used steel plates 1 )

Length (max.) 16,000 mm

Width (max.) 3,300 mm

Thickness 2) 5–80 mm

1) Al l d imensions l isted are approximate. Actual plate sizes avai lable depend on the combination of length, width and thickness as wel l as on material specif icat ion. For part icular information, contact VÍTKOVICE STEEL, a . s .2) Higher thicknesses on agreement

STATE OF SUPPLIED PLATES (HEAT TREATMENT):

AR – As rolledNR – Normalizing roll ingN+T – Normalized and temperedN – NormalizedA – AnnealedM (TMCP) – Thermomechanical roll ingQ+T – Quenched and tempered

FOR MORE INFORMATION OR ASSISTANCE REGARDING YOUR STEEL PLATE NEEDS, PLEASE, CONTACT VÍTKOVICE STEEL, a. s.

Phone: +420 595 952 435Fax: +420 595 952 144E-mail : [email protected]

P L A T E S

5

Plates made of structural steel

PLATES MADE OF STEEL ACCORDING TO EN 10025-2

The most commonly used structural steel having minimum yield strength 235 MPa and guaranteed weldabil ity that can be used for low demanding steel structures for bridges, halls, parts of railway and motor vehicles, etc.

Grade Min. Yield Strength 2)

ReH [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– longitudinalCEV max. 1 ) Dimension

Table No.

S235JR(C) 235 360–510 24 +20/27 0.35 1

S235J0(C) 235 360–510 24 0/27 0.35 1

S235J2(C) 235 360–510 24 -20/27 0.35 1

S275JR(C) 275 410–560 21 +20/27 0.40 1

S275J0(C) 275 410–560 21 0/27 0.40 1

S275J2(C) 275 410–560 21 -20/27 0.40 1

S355JR(C) 355 470–630 20 +20/27 0.45 1

S355J0(C) 355 470–630 20 0/27 0.45 1

S355J2(C) 355 470–630 20 -20/27 0.45 1

S355K2(C) 355 470–630 20 -20/40 0.45 1

1) CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15 ; val id for thickness up to 30 mm, for thicker plates refer to the standard

2) Val id for thickness up to 16 mm, for higher thickness refer to the standard

EQUIVALENT STEEL GRADES

EN 10025-2 EN 10025+A1 ČSN DIN 17100 BS 4360 NFA 35-501S235JR(C) S235JRG2(C) 11375 RSt 37 - 2 40 B E 24 - 2

S235J0(C) S235J0(C) 11378 St 37 - 3U 40 C E 24 - 3

S235J2(C) S235J2G4(C) 11378 St 37 - 3N 40 D E 24 - 4

S275JR(C) S275JR(C) 11443 St 44 - 2 43 B E 28 - 2

S275J0(C) S275J0(C) 11445 St 44 - 3U 43 C E 28 - 3

S275J2(C) S275J2G4(C) 11448 St 44 - 3N 43 D E 28 - 4

S355JR(C) S355JR(C) – – 50 B E 36 - 2

S355J0(C) S355J0(C) 11523 St 52 - 3U 50 C E 36 - 3

S355J2(C) S355J2G4(C) – St 52 - 3N 50 D –

S355K2(C) S355K2G4(C) – – 50 DD E 36 - 4

P L A T E S

6

Plates made of structural steel

PLATES MADE OF FINE-GRAINED STEEL ACCORDING TO EN 10025-3

Structural steel with guaranteed fine-grained structure and low carbon equivalent. Because of the yield strength up to 460 MPa and impact energy guaranteed at temperature -50 °C these steel grades are suitable for more demanding steel structures and their supporting elements. They are suitable for construction of railway and motor vehicles, too.

Grade Min. Yield Strength 2)

ReH [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– longitudinalCEV max. 1 ) Dimension

Table No.

S275N (NL) 275 370–510 24 -20/40 (-50/27) 0.40 1

S355N (NL) 355 470–630 22 -20/40 (-50/27) 0.43 1

S420N (NL) 420 520–680 19 -20/40 (-50/27) 0.48 1

S460N (NL) 460 550–720 17 -20/40 (-50/27) 0.53 2

1) CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15 ; val id for thickness up to 63 mm; for thicker plates refer to the standard

2) Val id for thickness up to 16 mm, for higher thickness refer to the standard

EQUIVALENT STEEL GRADES

EN 10025-3 EN 10113-2 ČSN DIN 17102S275N S275N – StE 285

S275NL S275NL 11449 TStE 285

S355N S355N – StE 355

S355NL S355NL 11503 TStE 355

S420N S420N – StE 420

S420NL S420NL 16328 TStE 420

S460N S460N 16229 StE 460

S460NL S460NL – TStE 460

P L A T E S

7

Plates made of structural steel

PLATES MADE OF FINE-GRAINED STEEL ROLLED THERMOMECHANICALLY ACCORDING TO EN 10025-4

Thermomechanically rolled plates of structural steel having low carbon equivalent, and thus an excellent weldabil ity. They are used for more demanding steel structures and their supporting elements. The impact energy is guaranteed also at temperature -50 °C which facil itates a wide range for their usage.

Grade Min. Yield Strength 2)

ReH [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– longitudinalCEV max. 1 ) Dimension

Table No.

S275M (ML) 275 370–530 24 -20/40 (-50/27) 0.34 3

S355M (ML) 355 470–630 22 -20/40 (-50/27) 0.39 3

S420M (ML) 420 520–680 19 -20/40 (-50/27) 0.43 3

S460M (ML) 460 540–720 17 -20/40 (-50/27) 0.45 3

1) CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15 ; val id for thickness up to 63 mm; for thicker plates refer to the standard

2) Val id for thickness up to 16 mm, for greater thickness refer to the standard

EQUIVALENT STEEL GRADES

EN 10025-4 EN 10113-3 SEW 092S275M S275M –

S275ML S275ML –

S355M S355M QStE 380 TM

S355ML S355ML –

S420M S420M QStE 420 TM

S420ML S420ML –

S460M S460M QStE 460 TM

S460ML S460ML –

P L A T E S

8

Plates made of structural steel

P L A T E S

PLATES MADE OF STEEL ACCORDING TO ASTM

Designation GradeMin. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. Impact Energy 1) KV [°C/J]

– longitudinal

DimensionTable No.

A 36 250 400–550 20/23 3) 1

A 242 2) 345 480 min. 18/21 3) 1

A 283

A 165 310–415 27/30 3) 1

B 185 345–450 25/28 3) 1

C 205 380–515 22/25 3) 1

D 230 415–550 20/23 3) 1

A 52950 (345) 345 485–690 18/21 3) 1

55 (380) 380 485–690 17/20 3) 1

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing on agreement2) This steel grade is resistant to atmospheric corrosion 3) Testing temperature and min. impact energy to be agreed with the customer

FINE-GRAINED STEEL

Designation GradeMin. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. Impact Energy 1) KV [°C/J]

– longitudinal

DimensionTable No.

A 572 2)

(type 1, 2, 3, 4)

42 (290) 290 415 min. 20/24 3) 1

50 (345) 345 450 min. 18/21 3) 1

55 (380) 380 485 min. 17/20 3) 1

60 (415) 415 520 min. 16/18 3) 1

65 (450) 450 550 min. 15/17 3) 2

A 573

58 (400) 220 400–490 21/24 3) 1

65 (450) 240 450–530 20/23 3) 1

70 (485) 290 485–620 18/21 3) 1

A 633

A 290 430–570 18/23 -60/20 1

C 345 485–620 18/23 -60/20 1

D 345 485–620 18/23 -60/20 1

E 415 550–690 18/23 -60/20 2

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing on agreement 2) Fine-grained structure to be agreed with the customer3) Testing temperature and impact energy to be agreed with the customer

9

Plates made of structural steel with improved atmospheric corrosion resistance – ATMOFIX

P L A T E S

Plates made of structural steel with increased resistance against atmospheric corrosion do not require – unlike common steels – expensive surface treatments (painting). They feature increased resistance even against impacts of atmosphere which con-tains sulphur. Their key use is in the area of construction and building of bridges but they can be used for chimney/stack and waste gas ducts structures, too.

PLATES MADE OF STEEL ACCORDING TO 10025-5

Grade Min. Yield Strength 2)

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– longitudinalCEV max. 1 ) Dimension

Table No.

S235J0W 235 360–510 24 0/27 0.44 1

S235J2W 235 360–510 24 -20/27 0.44 1

S355J0WP 3) 355 470–630 20 0/27 0.52 1

S355J2WP 3) 355 470–630 20 -20/27 0.52 1

S355J0W 355 470–630 20 0/27 0.52 1

S355J2W 355 470–630 20 -20/27 0.52 1

S355K2W 355 470–630 20 -20/40 0.52 1

1) CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15

2) Val id for plates with thickness up to 16 mm, for thicker plates refer to the standard 3) Plates with thickness up to 12 mm only

EQUIVALENT STEEL GRADES

EN 10025-5 EN 10155 ČSN SEW 087 CAN/CSA – G40.21-MS235J0W S235J0W – – –

S235J2W S235J2W – WTSt 37 - 3 –

S355J0WP S355J0WP 15217 – –

S355J2WP S355J2WP – – –

S355J0W S355J0W – – –

S355J2W S355J2G2W 15127 WTSt 52 - 3 350AT

S355K2W S355K2G2W – – –

PLATES MADE OF STEEL ACCORDING TO ASTM

Designation GradeMin. YieldStrength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. ImpactEnergy 1) KV [°C/J]

– longitudinal

Dimension Table No.

A 588

A 345 485 min. 18/21 2) 1

B 345 485 min. 18/21 2) 1

C 345 485 min. 18/21 2) 1

K 345 485 min. 18/21 2) 1

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing on agreement2) Testing temperature and minimum impact energy to be agreed with the customer

10

Plates made of the steel grades listed below are used for offshore structures. These steel grades show especially good impact resistance, fatigue resistance and lamellar cracking resistance.

PLATES MADE OF STEEL ACCORDING TO API 2H

GradeMin. YieldStrength

ReH [MPa]

TensileStrengthRm [MPa]

Minimum Elongation [%]

200/50

Min. Impact Energy KV [°C/J]

– transverseCEV max. 1 ) Dimension

Table No.

42 289 427–565 20/24 -40/270.43 2)

10.45 3)

50345 2)

483–620 18/23 -40/340.43 4)

2324 3) 0.45 5)

1) CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15

2) For width to 2 1/2' '3) For width over 2 1/2' '4) For width to 2 ' '5) For width over 2 ' '

Plates for offshore structures

P L A T E S

11

The most common used thermomechanically rolled plates made of non-alloyed and micro-alloyed steel grades with excellent weldabil ity, designed exclusively for welded piping for combustible, and non-combustible media.

PLATES MADE OF STEEL ACCORDING TO API 5L

GradeYield

StrengthReH [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

Min. Impact Energy KV [°C/J]

– transverseCEV max. Dimension

Table No.

B 241–448 414–758 22 0/27 0.40 3

X 42 290–496 414–758 21 0/27 0.40 3

X 46 317–524 434–758 20 0/27 0.41 3

X 52 359–531 455–758 20 0/27 0.41 3

X 56 386–544 490–758 18 0/27 0.42 3

X 60 414–565 517–758 18 0/27 0.42 3

X 65 448–600 531–758 18 0/27 0.43 3

X 70 483–621 565–758 18 0/27 0.43 3

PLATES MADE OF STEEL ACCORDING TO EN 10208-2

GradeYield

Strength Rt0.5 [MPa]

Min. TensileStrengthRm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– transverseCEV max. Dimension

Table No.

L245MB 245–440 415 22 0/40 0.40 3

L290MB 290–440 415 21 0/42 0.40 3

L360MB 360–510 460 20 0/42 0.41 3

L415MB 415–565 520 18 0/51 0.42 3

L450MB 450–570 535 18 0/57 0.43 3

L485MB 485–605 570 18 0/77 0.43 3

EQUIVALENT STEEL GRADES ACCORDING TO THE MINIMUM YIELD STRENGTH

API 5L EN 10208-2B L 245 MB

X 42 L 290 MB

X 52 L 360 MB

X 60 L 415 MB

X 65 L 450 MB

X 70 L 485 MB

Thermomechanically rolled plates for welded pipes

P L A T E S

12

PLATES ACCORDING TO INDIVIDUAL SHIPPING COMPANIES

Plates made of structural steel grades according to the requirements of the inspection companies ABS, BV, DNV, LR, and others, with a yield strength 235 to 355 MPa, are used for ship and watercraft construction. Quality of this assortment is guaranteed by product approbations awarded by individual shipping companies.

Min.

Yield

Stre

ngth

R eH [

MPa]

Min.

Impa

ct En

ergy

KV [

°C/J

] – lo

ngitu

dinal

ABS –

Ame

rican

Bu

reau

of Sh

ipping

BV –

Bure

au Ve

ritas

ČLPR

– Cz

ech S

hippin

g an

d Ind

ustri

al re

gister

GL –

Germ

anisc

her L

loyd

DNV –

Det

Nors

ke Ve

ritas

LR –

Lioyd

's Re

gister

of

Shipp

ing

RINA

– Re

gistro

Itali

ano N

avale

PC –

Mors

koj R

egist

rSu

doch

odstv

a

Dime

nsion

Table

No.

Norm

al St

reng

thSt

eel G

rade

s

235

– A A A A A A A/24 A 1

0/27 B B B B B B S/24 B 1

-20/27 D D D D D D SS/24 D 1

-40/27 E E E E E E E/24 E 1

High

Stre

ngth

Stee

l Gra

des 315

0/31 AH 32 AH 32 A 32 A 32 A 32 AH 32 S/32 A 32 1

-20/31 DH 32 DH 32 D 32 D 32 D 32 DH 32 SS/32 D 32 1

-40/31 EH 32 EH 32 E 32 E 32 E 32 EH 32 E/32 E 32 1

355

0/34 AH 36 AH 36 A 36 A 36 A 36 AH 36 S/36 A 36 1

-20/34 DH 36 DH 36 D 36 D 36 D 36 DH 36 SS/36 D 36 1

-40/34 EH 36 EH 36 E 36 E 36 E 36 EH 36 E/36 E 36 1

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

Plates for ship building

P L A T E S

13

Plates for ship building

PLATES ACCORDING TO DESIGNATION A 131

Designation GradeMin. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. ImpactEnergy KV [°C/J]

– longitudinal

DimensionTable No.

A 131

A 235 400–490 21/24 +20/27 1

B 235 400–490 21/24 0/27 1

D 235 400–490 21/24 -10/27 1

E 235 400–490 21/24 -40/27 1

CS 235 400–490 21/24 -40/27 1

DS 235 400–490 21/24 -10/27 1

AH 32 315 470–585 19/22 0/34 1

DH 32 315 470–585 19/22 -20/34 1

EH 32 315 470–585 19/22 -40/34 1

AH 36 360 490–620 19/22 0/34 1

DH 36 360 490–620 19/22 -20/34 1

EH 36 360 490–620 19/22 -40/34 1

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

P L A T E S

14

Hot-rolled plates made of steel for cold forming

THERMOMECHANICALLY ROLLED PLATES OF STEEL ACCORDING TO EN 10149-2

Standard methods used for processing these plates are bending, flanging, profil ing, etc. Based on agreement the plates can be delivered in the condition suitable for hot-dip zinc coating. The plates have excellent weldabil ity because of low carbon equivalent.

GradeYield

Strength ReH [MPa]

Tensile Strength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy 1) KV [°C/J]

– longitudinal

TransverseBend Test 2)

DimensionTable No.

S315MC 315 390–510 24 -20/40 0 t 3

S355MC 355 430–550 23 -20/40 0.5 t 3

S420MC 420 480–620 19 -20/40 0.5 t 3

S460MC 460 520–670 17 -20/40 1 t 3

S500MC 500 550–700 14 -20/40 1 t 3

S550MC 550 600–760 14 -20/40 1.5 t 3

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing on agreement 2) Minimum former diameter for 180° bend, t – plate thickness

EQUIVALENT STEEL GRADES

EN SEW 092 (1990)S315MC (QStE 340 TM)

S355MC (QStE 380 TM)

S420MC QStE 420 TM

S460MC QStE 460 TM

S500MC QStE 500 TM

S550MC QStE 550 TM

P L A T E S

15

Hot-rolled plates made of steel for cold forming

NORMALIZED (ROLLED) PLATES OF STEEL ACCORDING TO EN 10149-3

The plates guarantee suitabil ity for cold forming because of their technological processing. Standard methods used for processing these plates are bending, flanging, profil ing, etc. Based on agreement the plates can be delivered in the condition suitable for hot-dip zinc coating.

GradeMin. Yield Strength

ReH [MPa]

Tensile Strength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy 1) KV [°C/J]

– longitudinal

TransverseBend Test 2)

DimensionTable No.

S260NC 260 370–490 30 -20/40 0 t 1

S315NC 315 430–550 27 -20/40 0,5 t 1

S355NC 355 470–610 25 -20/40 0,5 t 1

S420NC 420 530–670 23 -20/40 0,5 t 2

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing on agreement 2) Minimum former diameter for 180° bend, t – plate thickness

EQUIVALENT STEEL GRADES

EN SEW 092S260NC QStE 260N

S315NC (QStE 340N)

S355NC (QStE 380N)

S420NC QStE 420N

P L A T E S

16

Quenched and tempered plates made of the 690 Q steel grade

QUENCHED AND TEMPERED PLATES MADE OF THE 690 Q STEEL GRADE

Quenched and tempered plates made of the 690 Q steel grade are supplied in the form suitable for steel structures (S690 .. .) as per EN 10025-6 or in the form suitable for pressure vessels (P690 .. .) as per EN 10028-6.

Steel grades as per EN 10025-6: S690 Q, S690 QL, S690 QL1.Steel grades as per EN 10028-6: P690 Q, P690 QH, P690 QL1, P690 QL2.

PARAMETERS FOR PLATES PURCHASE ORDER

Thickness 20–80 mm

Width 1,000–3,300 mm

Length max. 7,000 mm

Weight of one piece of plate max. 8.5 t

Total volume of plates ordered multiples of 50 t

MECHANICAL PROPERTIES AND CARBON EQUIVALENT

SteelGrade

Min. YieldStrength 1) ReH (MPa)

Min. YieldStrength

Rp0,2 (MPa)

Tensile Strength 1) Rm (MPa)

Min. Elongation (%) (Lo=5.65√So)

Min. Impact Energy KV (°C/J)

– transverseCEV max.

S690 Q 690 – 770–940 14 -20/27 3) 0.65 4)

S690 QL 690 – 770–940 14 -40/27 3) 0.65 4)

S690 QL1 690 – 770–940 14 -60/27 3) 0.65 4)

P690 Q 690 – 770–940 14 -20/27 3) –

P690 QH 690 570 2) 770–940 14 -20/27 3) –

P690 QL1 690 570 2) 770–940 14 -40/27 3) –

P690 QL2 690 570 2) 770–940 14 -60/27 3) –

1) Val id for plates with thickness ≤ 50 mm, for greater thickness refer to the standard 2) By agreement; val id for temperature 300 °C and thickness ≤ 50 mm; for other temperatures ( lower) or greater thickness

materials refer to the standard EN 10028-63) For other temperatures (higher) refer to the standard 4) Only for plates suppl ied as per EN 10025-6 and thickness ≤ 50 mm; for greater thickness refer to the standard

EN 10025-6; other values ( lower) by agreement

P L A T E S

17

Plates made of structural quality alloy or carbon steel

PLATES MADE OF STEEL ACCORDING TO EN 10083-1 + A1 AND EN 10083-2 + A1

These plates are further processed with heat treatment (usually quenching and tempering); after such treatment they obtain their typical properties, i .e. high toughness, hardness and strength. They are used for machinery parts in all machinery produ-ction areas. They are difficult for welding in most cases.

Grade Min. Yield Strength 1)

ReH [MPa]

Tensile Strength 1)

Rm [MPa]

Minimum Elongation [%]

(L0 = 5.65√S0)HB max. Dimension

table No.

C22/C22E 240 430 24 – 1C25/C25E 260 470 22 – 1C30/C30E 280 510 20 – 1C35/C35E 300 550 18 – 2C40/C40E 320 580 16 – 2C45/C45E 340 620 14 207 2C50/C50E 355 650 12 217 2C55/C55E 370 680 11 229 2C60/C60E 380 710 10 241 2

28Mn6 345 630 17 223 238Cr2 – – – 207 246Cr2 – – – 223 234Cr4 – – – 223 237Cr4 – – – 235 241Cr4 – – – 241 2

25CrMo4 – – – 212 234CrMo4 – – – 223 242CrMo4 – – – 241 250CrMo4 – – – 248 2

36CrNiMo4 – – – 248 234CrNiMo6 – – – 248 230CrNiMo8 – – – 248 2

1) Val id for plates in normal ized condit ion up to 16 mm of thickness, for thicker plates refer to the standard

EQUIVALENT STEEL GRADES

EN DIN 1720 ČSN Great Britain FranceC22/C22E C22/CK22 12024 070M20 XC18C25/C25E C25/CK25 12030 070M26 XC25C30/C30E C30/CK30 12031 080M30 XC32C35/C35E C35/CK35 12040 080M36 XC38H1C40/C40E C40/CK40 12041 080M40 XC42H1C45/C45E C45/CK45 12050 080M46 XC48H1C50/C50E C50/CK50 12051 080M50 –C55/C55E C55/CK55 12060 070M55 XC55H1C60/C60E C60/CK60 12061 070M60 –

28Mn6 28Mn6 13141 150M19 –38Cr2 38Cr2 – – 38C246Cr2 46Cr2 – – –34Cr4 34Cr4 – 530M32 32C437Cr4 37Cr4 14140 530M36 38C441Cr4 41Cr4 – 530M40 42C4

25CrMo4 25CrMo4 15130 708M25 25CD434CrMo4 34CrMo4 - 708M32 34CD442CrMo4 42CrMo4 15142 708M40 42CD450CrMo4 50CrMo4 – 708M50 –

36CrNiMo4 36CrNiMo4 – 817M37 –34CrNiMo6 34CrNiMo6 16343 817M40 –30CrNiMo8 30CrNiMo8 16430 823M30 –

P L A T E S

18

Plates made of structural quality alloy or carbon steel

Designation Grade(SAE Number)

Dimension table

number

A 827

1009 1

1020 1

1035 2

1040 2

1045 2

1050 2

A 829

1330 2

1335 2

1340 2

1345 2

4118 2

4130 2

4135 2

4137 2

4140 2

4142 2

4145 2

4150 2

4615 2

4617 2

4620 2

8615 2

8617 2

9620 2

8622 2

8625 2

8627 2

8630 2

8637 2

8640 2

8742 2

Heat treatment and mechanical propert ies on agreement

PLATES MADE OF STEEL ACCORDING TO DESIGNATION A 827, A 829, A 830

Designation Grade(SAE Number)

Dimension table

number

A 830

1006 1

1008 1

1009 1

1010 1

1012 1

1015 1

1016 1

1017 1

1018 1

1019 1

1020 1

1021 1

1022 1

1023 1

1025 1

1026 1

1030 1

1033 1

1035 2

1037 2

1038 2

1039 2

1040 2

1042 2

1043 2

1045 2

1046 2

1049 2

1050 2

1055 2

1060 2

1524 2

1527 2

1536 2

1541 2

1548 2

1552 2

P L A T E S

19

Plates resistant against mechanical wear (abrasive wear)

PLATES MADE OF STEEL ACCORDING TO VN 414320 (ABRAZIT)

Grade 14320 is fine-grained steel which is used for roll ing of plates for production of parts exposed to extreme abrasion and mechanical wear.

These plates can be used for transport routes and chutes for gravel, stone, coal, cement etc. Resistance against abrasion, and hardness are guaranteed either in the condition without heat treatment (so called as rolled – 14320.0), or after quenching.

Machining in the condition without heat treatment (14320.0) is difficult; in the soft annealed condition (14320.3) it is good. Cold forming is not possible, hot forming at temperature of 850–1,150 °C is good.

Joints between parts are usually made as bolted joints; or in the form of fixing welds, using preheating up to 200 °C at mini-mum (thickness up to 10 mm without preheating); however the welded joint does not reach the strength of the parent base. Cutting plates by means of flame cutting, or flame cutting shaped plates is also performed with preheating up to 200 °C at minimum. Shearing is not recommended for plate cutting.

The plates can be delivered as semi-trimmed plates having thickness from 8 to 25 mm in the condition without heat treatment (14320.0), or from 8 to 30 mm in the soft annealed condition (14320). Other gages and dimensions are available based on agreement.

Tensile strength (Rm) it the condition without heat treatment (14320.0) is approx. 930 to 1,370 MPa, the lowest yield strength (ReH) is approx. 75 % of the tensile strength, the lowest elongation (A5) is 8 % and Brinell hardness is approx. 270 to 400 HB. Tensile strength can be improved to approx. 1,400 MPa by quenching. Tensile strength, yield strength, and elongation are not subject to testing and acceptance inspections because test samples are difficult to be made.

In the soft annealed condition (14320.3) the Brinell hardness is max. 260 HB.

P L A T E S

20

Plates made of steel for pressure vessels

PLATES MADE OF STEEL FOR SIMPLE PRESSURE VESSELS ACCORDING TO EN 10207 (APRIL 2005)

Plates with low yield strength for simple pressure vessels and storage facil ities, e.g. for compressed air or other media ope-rating under normal outdoor temperatures.

Grade Min. Yield Strength 1)

ReH [MPa]

Min. Yield Strength 2)

Rp0,2 [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV [°C/J]

– longitudinal

DimensionTable No.

P235S 235 117 360–480 26 -20/28 1

P265S 265 140 410–530 22 -20/28 1

P275SL 275 132 390–510 24 -50/28 1

1) Val id for plates with thickness up to 16 mm, for thicker plates refer to the standard 2) Val id for temperature 300 °C, for other temperatures ( lower) refer to the standard

P L A T E S

21

Plates made of steel for pressure vessels

PLATES MADE OF STEEL ACCORDING TO EN 10028-2

Plates made of unalloyed as well as alloyed steel grades for pressure loaded vessels and facil ities, operating under normal as well as elevated temperatures. These plates are usually delivered in normalized condition, and/or in normalized and tempered condition.

Grade Min. Yield Strength 1)

ReH [MPa]

Min. Yield Strength 2)

Rp0,2 [MPa]

TensileStrength Rm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy KV 3) [°C/J]

– transverse

DimensionTable No.

P235GH 4) 235 153 360–480 24 -20/27 1

P265GH 4) 265 173 410–530 22 -20/27 1

P295GH 4) 295 192 460–580 21 -20/27 1

P355GH 4) 355 232 510–650 20 -20/27 1

16Mo3 275 194 440–590 22 +20/31 1

18MnMo4-5 345 285 510–650 20 -20/27 1

15NiCuMoNb5-6-4 460 380 610–780 16 -20/27 2

13CrMo4-5 300 216 450–600 19 +20/31 1

13CrMoSi5-5 310 233 510–690 20 0/27 1

10CrMo9-10 310 236 480–630 18 +20/31 1

12CrMo9-10 355 295 540–690 18 -20/27 2

1) Val id for plates with thickness up to 16 mm, for thicker plates refer to the standard 2) On agreement with the order ; val id for temperature 300 °C and thickness up to 16 mm; for other temperatures or thicker

plates refer to the standard 3) For other temperatures refer to the standard or on agreement4) Maximum value of the carbon equivalent on agreement when ordering for steel grades P235GH, P265GH, P295GH and

P355GH based on the fol lowing formula CEV CMn Cr Mo V Ni Cu= + + + + + +6 5 15

EQUIVALENT STEEL GRADES

EN ČSN DIN 17155P235 GH 11368 H I

P265 GH 11418 H II

P295 GH 13030 (11478) 17Mn4

P355 GH 11523 19Mn6

16Mo3 15020 15Mo3

13CrMo4-5 15121 13CrMo44

10CrMo9-10 15313 10CrMo910

18MnMo4-5 15223 (15219) –

P L A T E S

22

Plates made of steel for pressure vessels

PLATES MADE OF FINE-GRAINED STEEL ACCORDING TO EN 10028-3

These steel grades feature guaranteed fine-grained structure and low carbon equivalent. Mechanical properties of these plates are guaranteed at high temperatures (up to 400 °C) – yield strength Rp0,2 as well as at low temperatures (down to -50 °C) – im-pact energy KV; therefore, they can be used for constructions of more demanding pressure vessels working under high as well as low temperatures.

Grade Min. YieldStrength 1)

ReH [MPa]

Min. YieldStrength 2)

Rp0,2 [MPa]

Tensile StrengthRm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. ImpactEnergy 3) KV [°C/J]

– transverseCEV max. 4) Dimension

Table No.

P275NH 275 179 390–510 24 -20/30 0.40 1

P275NL1 275 179 390–510 24 -40/27 0.40 1

P275NL2 275 179 390–510 24 -50/27 0.40 1

P355N 355 – 490–630 22 -20/30 0.43 1

P355NH 355 232 490–630 22 -20/30 0.43 1

P355NL1 355 232 490–630 22 -40/27 0.43 1

P355NL2 355 232 490–630 22 -50/27 0.43 1

P460NH 460 300 570–720 17 -20/30 0.53 2

P460NL1 460 300 570–720 17 -40/27 0.53 2

P460NL2 460 300 570–720 17 -50/27 0.53 2

1) Val id for thickness up to 16 mm, for higher thickness refer to the standard2) By agreement with the order ; val id for temperature 300 °C and thickness up to 16 mm, for other temperatures and/or

higher thickness refer to the standard3) For other temperatures refer to the standard4) On agreement; CEV C

Mn Cr Mo V Ni Cu= + + + + + +6 5 15

; val id for thickness up to 60 mm, for thicker plates refer to the standard

EQUIVALENT STEEL GRADES

EN ČSN DIN 17102P275NH 11448 WStE 285

P275NL1 11449 TStE 285

P275NL2 – EStE 285

P355N – StE 355

P355NH – WStE 355

P355NL1 11503 TStE 355

P355NL2 – EStE 355

P460NH – WStE 460

P460NL1 – TStE 460

P460NL2 – EStE 460

P L A T E S

23

Plates made of steel for pressure vessels

PLATES MADE OF FINE-GRAINED STEEL THERMOMECHANICALLY ROLLED ACCORDING TO EN 10028-5

Thermomechanically rolled plates having higher yield strength up to 460 MPa are designed for pressure vessels and facil ities working under normal or low temperatures. This steel grade has excellent weldabil ity because of low carbon equivalent. Im-pact energy is guaranteed even at temperature -50 °C.

Grade Min. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

(L0 = 5.65√S0)

Min. Impact Energy 3) KV [°C/J]

– transverseCEV max. 4) Dimension

Table No.

P355M 355 1) 450–610 22 -20/27 0.39 3

P355ML1 355 1) 450–610 22 -40/27 0.39 3

P355ML2 355 1) 450–610 22 -50/27 0.39 3

P420M 420 2) 500–660 19 -20/27 0.43 3

P420ML1 420 2) 500–660 19 -40/27 0.43 3

P420ML2 420 2) 500–660 19 -50/27 0.43 3

P460M 460 2) 530–720 17 -20/27 0.45 3

P460ML1 460 2) 530–720 17 -40/27 0.45 3

P460ML2 460 2) 530–720 17 -50/27 0.45 3

1) Val id for thickness up to 40 mm, for higher thickness refer to the standard2) Val id for thickness up to 16 mm, for higher thickness refer to the standard3) For other temperatures refer to the standard4) On agreement; CEV C

Mn Cr Mo V Ni Cu= + + + + + +6 5 15

; val id for thickness up to 16 mm, for thicker plates refer to the standard

P L A T E S

24

Plates made of steel for pressure vessels

PLATES MADE OF STEEL ACCORDING TO ASTM

Designation GradeMin. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. Impact Energy 1) KV [°C/J]

– longitudinal

DimensionTable No.

A 202A 310 515–655 16/19 2) 1

B 325 585–760 15/18 2) 2

A 204

A 255 450–585 19/23 2) 1

B 275 485–620 17/21 2) 1

C 295 515–655 16/20 2) 1

A 285

A 165 310–450 27/30 4/14 1

B 185 345–485 25/28 10/14 1

C 205 380–515 23/27 16/14 1

A 387

2 310 485–620 18/22 2) 1

11 310 515–690 18/22 2) 1

12 275 450–585 19/22 2) 1

22 310 515–690 –/18 2) 1

A 455 260 515–655 15/22 -4/18 1

A 515

60 (415) 220 415–550 21/25 2) 1

65 (450) 240 450–585 19/23 2) 1

70 (485) 260 485–620 17/21 2) 1

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing is optional . 2) Testing temperature and minimum impact energy to be clar if ied with the customer

FINE-GRAINED STEEL

Designation GradeMin. Yield Strength

ReH [MPa]

TensileStrengthRm [MPa]

MinimumElongation [%]

200/50

Min. Impact Energy 1) KV [°C/J]

– longitudinal

DimensionTable No.

A 225 D 415 550–725 17/19 2) 2

A 299 290 515–655 16/19 -7/20 1

A 302

A 310 515–655 15/19 2) 1

B 345 550–690 15/18 2) 2

C 345 550–690 17/20 2) 2

D 345 550–690 17/20 2) 2

A 516

55 (380) 205 380–515 23/27 -51/18 1

60 (415) 220 415–550 21/25 -51/18 1

65 (450) 240 450–585 19/23 -51/18 1

70 (485) 260 485–620 17/21 -46/20 1

A 537 class 1 345 485–620 18/22 -62/20 1

A 612 345 570–725 16/22 -46/27 2

A 662

A 275 400–540 20/23 -60/18 1

B 275 450–585 20/23 -51/18 1

C 295 485–620 18/22 -46/20 1

A 737B 345 485–620 18/23 2) 1

C 415 550–690 18/23 2) 2

On agreement, carbon equivalent guarantee is avai lable as per the fol lowing formula C Mn Cr Mo V Ni Cu+ + + + + +6 5 15

1) Impact energy testing is optional . 2) Testing temperature and minimum impact energy to be clar if ied with the customer

P L A T E S

25

Plates made of armour steels are manufactured in several degrees of hardness, or shooting resistance. Armours of middle hardness are used mostly for armouring heavy vehicles; armours of high hardness are used for l ightweight military vehicles, resistant mainly against infantry weapons. Armour plates made of martenzitic steels can be welded util izing usually manual arc welding or automatic submerged-arc welding methods. An advantageous method is shielded welding.

Grade Min. Yield Strength 1)

ReH [MPa]

TensileStrength 1)

Rm [MPa]

Minimum Elongation 1) [%](L0 = 5.65√S0)

CEV 2) HB Hardness

Condition after heat treatment

Dimensiontable No.

43 PSM (A)49 S (A)

42 SM (A)52 S (A)

400 600 25

0.95

180–250 soft annealed

2

850 1,050 7 280–340 heat treated

2 P (A)V 2–9

450 650 250.65

200–250 soft annealed2

1,200 1,400 10 370–430 heat treated

Armox 500 S450 650 25

0.75200–250 soft annealed

21,500 1,700 8 450–550 heat treated

1) approximate values2) CEV values for information only

Armour plates

P L A T E S

26

Longitudinally profiled plates

Longitudinally profiled plates (also tapered plates) are plates whose thickness varies along their longitudinal axis, with the thickness variation reached by continuous adjusting of the roll gap when the material passes through the roll stand. Longitu-dinally profiled plates can generally have linear or non-linear thickness course.

Tapered plates are used especially for various types of steel structures where their usage results in considerable economical savings (structure weight reduction, reduction of welded joints, etc.)

In order to reach as much economical contribution as possible, and easy application in all steel structures, various shapes of tapered plates consisting of several tapered and flat segments can be manufactured and used.

Tapered plates are manufactured of steel grades according to the standards EN 10025-2 and EN 10025-3.

The dimensional standard applicable for longitudinally profiled plates is VN 425321.

BASIC PARAMETERS OF LONGITUDINALLY PROFILED PLATES

Plate thickness 15–80 mm

Max. wedge shapes 5 mm/1 m

Max. thickness difference 40 mm

Min. length of tapered part 1,000 mm

Max. number of segments having different thickness 5

Plate width 1,000–3,000 mm

Max. plate length depends on shape, dimensions with respect to the maximum weight

Max. plate weight 8,700 kg

BASIC TYPES OF LONGITUDINALLY PROFILED PLATES

P L A T E S

27

Delivery conditions

APPLICABLE STANDARDS

Dimension, flatness EN 10029, A(SA)20/A(SA)20M, A(SA)6/A(SA)6M, ČSN 425 310, VN425 312

Surface EN 10163, ČSN 420 209, ČSN 420 109, ČSN 420 165

Ultrasound EN 10160, SEL 072/77, A(SA)435, A(SA)578, other standards by agreement

Certificates EN 10204

Testing as per EN, ASTM, ASME, shipping company standards, ČSN, DIN, other standards by agreement

INTERNAL SOUNDNESS HOMOGENEITY ULTRASONIC TESTING

Automatic ultrasonic RW TÜV certified line is used or manual testing is available to meet stricter conditions.

P L A T E S

28

Material certificates

QUALITY ASSURANCE CERTIFICATES AS PER EN 10204 : 2004

Quality Assurance certificates shall be issued by the Quality Assurance Department stating chemical composition of heat and material testing results (e.g. ultrasound, mechanical testing) as required by the customer:

Customer Order Compliance Declaration “2.1”The document is issued by the manufacturer to certify that the products delivered comply with customer order requirements. The document does not state any test results.

Testing Protocol “2.2”The document is issued by the manufacturer to certify that products delivered comply with customer order requirements. The document states general test results.

Inspection Certificate “3.1”This is a document issued by the manufacturer in which the manufacturer confirms that the products supplied are in line with the requirements of the order and in which the manufacturer indicates the results of the tests.The testing unit and the tests executed are indicated in the product’s specification, in the official specifications, in the corre-sponding technical specifications and/or in the order. The document is confirmed by an authorized representative of the manufacturer independent of the production units.In the Inspection Certificate “3.1”, the manufacturer may indicate the results of tests obtained from testing as specified by the specification on the basic materials or input products used on condition that the manufacturer uses tracing procedures and can provide the necessary corresponding inspection documents.

Inspection Certificate “3.2”This is a document prepared by an authorized representative of the manufacturer independent of the production units and either by an authorized representative of the client (inspection company) or by an inspector indicated in the official specifications in which they declare that the products supplied are in line with the requirements of the order and which indi-cates the results of the tests.In the Inspection Certificate “3.2”, the manufacturer may indicate the results of tests obtained from testing as specified by the specification on the basic materials or input products used on condition that the manufacturer uses tracing procedures and can provide the necessary corresponding inspection documents.

Inspection Companiesa) national : ŘJ, ČD, ZVS, INSPEKTA, ČLPR, and othersb) international : LR, DNV, ABS, BV, GL, TÜV, RINA, Russian Naval Register of Shipping, and othersc) inspection carried out directly by the customer

Multiple certification available on request.

P L A T E S

29

Product marking is performed by stamping and painting. A punch for stamping in cold condition is used for marking of plates (Four-High Mill) in low-stress spot method. Manual low-stress stamping (Two-High Mill) the low-stress method has to be agreed in the order. White paint marking is carried out with automatic marking machines, or manually (usually using templates). In case of any specific customer‘s requirement for a special plate marking, either in the form of a text (sprayed with white color on the plate), or in the form of color marking, marking is carried out within the frame of each individual order based on agreement. The “Colour Marking Catalogue” containing individual patterns is available to make the color marking easier.

EXAMPLE OF PLATE MARKING WITH COLD STAMPING

EXAMPLE OF PLATE MARKING WITH COLOUR

Marking of plates

P L A T E S

Rolled product No. Plate serial No. from the rolled product Manufacturer’s symbol Heat origin Heat No.

Steel grade (and/or heat treatment code) Sample No.

Plate widthRolled product No. Heat origin Heat no. Plate serial No. from the rolled product

Internal localization code

Heat treatmentcode

Order No.

Plate thickness

Steel grade

Inspection Plate length

width [mm] thickness [mm]

1,001 1,101 1,251 1,301 1,401 1,501 1,601 1,701 1,801 1,901 2,001

1,000 1,100 1,250 1,300 1,400 1,500 1,600 1,700 1 800 1,900 2,000 2,100

5 12 10 10 12 12 12 12 12

6 12 12 12 10 10 10 12 12 12 12 12 12

7 14 14 14 14 14 14 14 14 14 14 14 14

8 15 15 15 15 15 15 15 15 15 15 15 15

9 16 16 16 16 16 16 16 16 16 16 16 16

10 16 16 16 16 16 16 16 16 16 16 16 16

11 16 16 16 16 16 16 16 16 16 16 16 16

12 16 16 16 16 16 16 16 16 16 16 16 16

13 16 16 16 16 16 16 16 16 16 16 16 16

14 16 16 16 16 16 16 16 16 16 16 16 16

15 16 16 16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 16 16 16 16

17 16 16 16 16 16 16 16 16 16 16 16 16

18 16 16 16 16 16 16 16 16 16 16 16 16

19 16 16 16 16 16 16 16 16 16 16 16 16

20 16 16 16 16 16 16 16 16 16 16 16 16

21 16 16 16 16 16 16 16 16 16 16 16 16

22 16 16 16 16 16 16 16 16 16 16 16 16

23 16 16 16 16 16 16 16 16 16 16 16 16

24 16 16 16 16 16 16 16 16 16 16 16 16

25 16 16 16 16 16 16 16 16 16 16 16 16

26 16 16 16 16 16 16 16 16 16 16 16 16

28 16 16 16 16 16 16 16 16 16 16 16 16

30 16 16 16 16 16 16 16 16 16 16 16 16

32 16 16 16 16 16 16 16 16 16 16 16 15

34 16 16 15 16 16 16 16 16 16 16 15 14

36 16 16 15 16 16 16 16 16 16 15 14 13

38 16 16 14 16 16 15 16 16 15 14 13 12

40 16 15 13 16 15 14 16 15 14 13 12 12

42 16 14 12 16 14 13 15 14 13 12 12 11

44 15 13 12 15 14 13 14 13 13 12 11 11

46 14 13 11 14 13 12 14 13 12 11 11 10

48 14 12 11 14 13 12 13 12 11 11 10 10

50 13 12 10 13 12 11 12 12 11 10 10 9

52 12 11 10 12 11 11 12 11 10 10 9 9

54 12 11 9 12 11 10 11 11 10 9 9 8

56 11 10 9 11 11 10 11 10 10 9 9 8

58 11 10 9 11 10 9 11 10 9 9 8 8

60 11 10 8 11 10 9 10 9 9 8 8 7

65 10 9 8 10 9 8 9 9 8 8 7 7

70 9 8 7 9 8 8 9 8 7 7 7 6

75 8 7 6 8 8 7 8 7 7 7 6 6

80 8 7 6 8 7 7 7 7 6 6 6 5

Other plate dimensions on agreement

TABLE 1 – MAXIMUM AVAILABLE PLATES LENGTH OF STEEL HAVING MINIMUM TENSILE STRENGTH Rm up to 530 MPa

2,101 2,201 2,301 2,401 2,501 2,601 2,701 2,801 2,901 3,001 3,101 3,201 width [mm]thickness [mm]2,200 2,300 2,400 2,500 2,600 2,700 2,800 2,900 3,000 3,100 3,200 3,300

10 10 10 10 10 5

12 12 12 12 12 10 10 10 10 6

14 14 14 14 14 13 13 12 12 7

15 15 15 15 15 15 15 15 15 15 8

16 16 16 16 16 16 16 16 16 16 16 16 9

16 16 16 16 16 16 16 16 16 16 16 16 10

16 16 16 16 16 16 16 16 16 16 16 16 11

16 16 16 16 16 16 16 16 16 16 16 16 12

16 16 16 16 16 16 16 16 16 16 16 16 13

16 16 16 16 16 16 16 16 16 16 16 16 14

16 16 16 16 16 16 16 16 16 16 16 16 15

16 16 16 16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 16 16 16 17

16 16 16 16 16 16 16 16 16 16 16 16 18

16 16 16 16 16 16 16 16 16 16 16 16 19

16 16 16 16 16 16 16 16 16 16 16 15 20

16 16 16 16 16 16 16 16 16 15 15 14 21

16 16 16 16 16 16 16 16 15 15 14 14 22

16 16 16 16 16 16 16 15 15 14 14 13 23

16 16 16 16 16 16 15 14 14 13 13 13 24

16 16 16 16 15 15 14 14 13 13 12 12 25

16 16 16 15 15 14 14 13 13 12 12 11 26

16 16 15 14 14 13 13 12 12 11 11 11 28

15 15 14 13 13 12 12 11 11 11 10 10 30

14 14 13 12 12 11 11 11 10 10 9 9 32

13 13 12 12 11 11 10 10 9 9 9 9 34

13 12 11 11 10 10 10 9 9 9 8 8 36

12 11 11 10 10 9 9 9 8 8 8 8 38

11 11 10 10 9 9 9 8 8 8 7 7 40

11 10 10 9 9 8 8 8 7 7 7 7 42

10 10 9 9 8 8 8 7 7 7 7 6 44

10 9 9 8 8 8 7 7 7 7 6 6 46

9 9 8 8 8 7 7 7 6 6 6 6 48

9 8 8 8 7 7 7 6 6 6 6 5 50

8 8 8 7 7 7 6 6 6 6 5 5 52

8 8 7 7 7 6 6 6 6 5 5 5 54

8 7 7 7 6 6 6 6 5 5 5 5 56

7 7 7 6 6 6 6 5 5 5 5 5 58

7 7 6 6 6 6 5 5 5 5 5 60

6 6 6 6 5 5 5 5 65

6 6 5 5 5 5 70

5 5 5 5 75

5 5 5 80

width [mm] thickness [mm]

1,001 1,101 1,251 1,301 1,401 1,501 1,601 1,701 1,801 1,901 2,001

1,000 1,100 1,250 1,300 1,400 1,500 1,600 1,700 1 800 1,900 2,000 2,100

5 10 10 10 10 10 10 10 10

6 12 12 12 10 10 10 12 12 12 12 12 12

7 12 12 12 14 14 14 14 14 14 14 14 14

8 14 14 14 14 14 14 14 14 14 14 14 14

9 15 16 16 16 16 16 16 16 16 16 16 16

10 16 16 16 16 16 16 16 16 16 16 16 16

11 16 16 16 16 16 16 16 16 16 16 16 16

12 16 16 16 16 16 16 16 16 16 16 16 16

13 16 16 16 16 16 16 16 16 16 16 16 16

14 16 16 16 16 16 16 16 16 16 16 16 16

15 16 16 16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 16 16 16 16

17 16 16 16 16 16 16 16 16 16 16 16 16

18 16 16 16 16 16 16 16 16 16 16 16 16

19 16 16 16 16 16 16 16 16 16 16 16 16

20 16 16 16 16 16 16 16 16 16 16 16 16

21 16 16 16 16 16 16 16 16 16 16 16 16

22 16 16 16 16 16 16 16 16 16 16 16 16

23 16 16 16 16 16 16 16 16 16 16 16 16

24 16 16 16 16 16 16 16 16 16 16 16 16

25 16 16 16 16 16 16 16 16 16 16 16 16

26 16 16 16 16 16 16 16 16 16 16 16 16

28 16 16 16 16 16 16 16 16 16 16 16 16

30 16 16 16 16 16 16 16 16 16 16 16 16

32 16 16 16 16 16 16 16 16 16 16 16 15

34 16 16 15 16 16 16 16 16 16 16 15 14

36 16 16 15 16 16 16 16 16 16 15 14 13

38 16 16 14 16 16 15 16 16 15 14 13 12

40 16 15 13 16 15 14 16 15 14 13 12 12

42 16 14 12 16 14 13 15 14 13 12 12 11

44 15 13 12 15 14 13 14 13 13 12 11 11

46 14 13 11 14 13 12 14 13 12 11 11 10

48 14 12 11 14 13 12 13 12 11 11 10 10

50 13 12 10 13 12 11 12 12 11 10 10 9

52 12 11 10 12 11 11 12 11 10 10 9 9

54 12 11 9 12 11 10 11 11 10 9 9 8

56 11 10 9 11 11 10 11 10 10 9 9 8

58 11 10 9 11 10 9 11 10 9 9 8 8

60 11 10 8 11 10 9 10 9 9 8 8 7

65 10 9 8 10 9 8 9 9 8 8 7 7

70 9 8 7 9 8 8 9 8 7 7 7 6

75 8 7 6 8 8 7 8 7 7 7 6 6

80 8 7 6 8 7 7 7 7 6 6 6 5

Other plate dimensions on agreement

TABLE 2 – MAXIMUM AVAILABLE PLATES LENGTH OF STEEL HAVING MINIMUM TENSILE STRENGTH Rm more than 530 MPa

2,101 2,201 2,301 2,401 2,501 2,601 2,701 2,801 2,901 3,001 3,101 3,201 width [mm]thickness [mm]2,200 2,300 2,400 2,500 2,600 2,700 2,800 2,900 3,000 3,100 3,200 3,300

10 10 10 10 10 5

12 12 12 12 12 10’ 10’ 10’ 10’ 6

14 14 14 12 12 10 10 10 10 7

14 14 14 14 14 13 13 13 13 12 8

16 16 16 14 14 13 13 13 13 12 12 12 9

16 16 16 16 16 16 16 16 16 16 16 16 10

16 16 16 16 16 16 16 16 16 16 16 16 11

16 16 16 16 16 16 16 16 16 16 16 16 12

16 16 16 16 16 16 16 16 16 16 16 16 13

16 16 16 16 16 16 16 16 16 16 16 16 14

16 16 16 16 16 16 16 16 16 16 16 16 15

16 16 16 16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 16 16 16 17

16 16 16 16 16 16 16 16 16 16 16 16 18

16 16 16 16 16 16 16 16 16 16 16 16 19

16 16 16 16 16 16 16 16 16 16 16 15 20

16 16 16 16 16 16 16 16 16 15 15 14 21

16 16 16 16 16 16 16 16 15 15 14 14 22

16 16 16 16 16 16 16 15 15 14 14 13 23

16 16 16 16 16 16 15 14 14 13 13 13 24

16 16 16 16 15 15 14 14 13 13 12 12 25

16 16 16 15 15 14 14 13 13 12 12 11 26

16 16 15 14 14 13 13 12 12 11 11 11 28

15 15 14 13 13 12 12 11 11 11 10 10 30

14 14 13 12 12 11 11 11 10 10 9 9 32

13 13 12 12 11 11 10 10 9 9 9 9 34

13 12 11 11 10 10 10 9 9 9 8 8 36

12 11 11 10 10 9 9 9 8 8 8 8 38

11 11 10 10 9 9 9 8 8 8 7 7 40

11 10 10 9 9 8 8 8 7 7 7 7 42

10 10 9 9 8 8 8 7 7 7 7 6 44

10 9 9 8 8 8 7 7 7 7 6 6 46

9 9 8 8 8 7 7 7 6 6 6 6 48

9 8 8 8 7 7 7 6 6 6 6 5 50

8 8 8 7 7 7 6 6 6 6 5 5 52

8 8 7 7 7 6 6 6 6 5 5 5 54

8 7 7 7 6 6 6 6 5 5 5 5 56

7 7 7 6 6 6 6 5 5 5 5 5 58

7 7 6 6 6 6 5 5 5 5 5 60

6 6 6 6 5 5 5 5 65

6 6 5 5 5 5 70

5 5 5 5 75

5 5 5 80

TABLE 3 – MAXIMUM AVAILABLE PLATES LENGTH OF THERMOMECHANICALLY ROLLED PLATES

width [mm] thickness [mm]

1,001 1,101 1,251 1,301 1,401 1,501 1,601 1,701 1,801 1,901 2,001

1,000 1,100 1,250 1,300 1,400 1,500 1,600 1,700 1 800 1,900 2,000 2,100

8 14 14 14 14 14 14 14 14 14 14 14 14

9 15 16 16 16 16 16 16 16 16 16 16 16

10 16 16 16 16 16 16 16 16 16 16 16 16

11 16 16 16 16 16 16 16 16 16 16 16 16

12 16 16 16 16 16 16 16 16 16 16 16 16

13 16 16 16 16 16 16 16 16 16 16 16 16

14 16 16 16 16 16 16 16 16 16 16 16 16

15 16 16 16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 16 16 16 16

17 16 16 16 16 16 16 16 16 16 16 16 16

18 16 16 16 16 16 16 16 16 16 16 16 16

19 16 16 16 16 16 16 16 16 16 16 16 16

20 16 16 16 16 16 16 16 16 16 16 16 16

21 16 16 16 16 16 16 16 16 16 16 16 16

22 16 16 16 16 16 16 16 16 16 16 16 16

23 16 16 16 16 16 16 16 16 16 16 16 16

24 16 16 16 16 16 16 16 16 16 16 16 16

25 16 16 16 16 16 16 16 16 16 16 16 16

26 16 16 16 16 16 16 16 16 16 16 16 16

28 16 16 16 16 16 16 16 16 16 16 16 16

30 16 16 16 16 16 16 16 16 16 16 16 16

32 16 16 16 16 16 16 16 16 16 16 16 15

34 16 16 15 16 16 16 16 16 16 16 15 14

36 16 16 15 16 16 16 16 16 16 15 14 13

38 16 16 14 16 16 15 16 16 15 14 13 12

40 16 15 13 16 15 14 16 15 14 13 12 12

Other plate dimensions on agreement

2,101 2,201 2,301 2,401 2,501 2,601 2,701 2,801 2,901 width [mm]thickness [mm]2,200 2,300 2,400 2,500 2,600 2,700 2,800 2,900 3,000

14 14 14 14 14 8

16 16 16 14 14 9

16 16 16 16 16 16 16 10

16 16 16 16 16 16 16 11

16 16 16 16 16 16 16 12

16 16 16 16 16 16 16 13

16 16 16 16 16 16 16 16 16 14

16 16 16 16 16 16 16 16 16 15

16 16 16 16 16 16 16 16 16 16

16 16 16 16 16 16 16 16 16 17

16 16 16 16 16 16 16 16 16 18

16 16 16 16 16 16 16 16 16 19

16 16 16 16 16 16 16 16 16 20

16 16 16 16 16 16 16 16 16 21

16 16 16 16 16 16 16 16 15 22

16 16 16 16 16 16 16 15 15 23

16 16 16 16 16 16 15 14 14 24

16 16 16 16 15 15 14 14 13 25

16 16 16 15 15 14 14 13 13 26

16 16 15 14 14 13 13 12 12 28

15 15 14 13 13 12 12 11 11 30

14 14 13 12 12 11 11 11 10 32

13 13 12 12 11 11 10 10 9 34

13 12 11 11 10 10 10 9 9 36

12 11 11 10 10 9 9 9 8 38

11 11 10 10 9 9 9 8 8 40

VÍTKOVICE STEEL , a . s . Headquar te rs : Št ramberská 2871 /47 , 709 00 Ost rava-Hu lváky, Czech Repub l icPosta l address : V ÍTKOVICE STEEL , a . s . , 706 02 Ost rava-Ví tkov ice , Czech Repub l icPhone : +420 595 952 435 , fax : +420 595 952 144E-ma i l : t radestee l@v i tkov icestee l . com

Cut shapes Sheet Pi les

Plates Sections

Valid from: September 2006