Staff - Rifle Magazine · Defining Overbore Capacity ... (Also publisher of Rifle Magazine ......

Transcript of Staff - Rifle Magazine · Defining Overbore Capacity ... (Also publisher of Rifle Magazine ......

clkle S t a f f DAVE WOLFE

Publisher NEAL KNOX

Editor HELEN A. MARTIN

Asst. to Editor ROGER T. WOLFE, Ph.D.

Associate Editor JAMES D. CARMICHEL

Associate Editor NORM LAMMERS

Tech n ica I A d viser HOMER POWLEY

Ballistics Adviser MAJ. GEORGE C. NONTE JR.

General Assignment WALLACE LABISKY

Shotshells JOHN WOOTTERS

Gun Tests HARVEY A. DONALDSON

Historical Adviser KEN WATERS

"Pe t L oa ds '' EDWARD M. YARD

General Assignment DON ZUTZ

General Assignment BOB HAGEL

Hunting A dviser JOHN BUHMILLER

African Cartridges DAVE LeGATE

Production BARBARA LAFFEY

Circulation Manager JANE CLARK

Ass t. Cir cu la t io n Mgr. POLLY STARBUCK

Exec. Secretary

ROY STARBUCK Administrative Asst.

The

Handloader - - - -

Magazine July-August, 1971 Vol. 6-No. 4 Box 3030, Prescott, A r k . 86301

FEATURES: Reviewing the Basics: Shotshell Loading . . . . . . John Wootters

Rounds for Ringnecks . . . . . . . . . . . . . Wallace Labisky The .358 Norma Magnum. . . . . . . . . . . . Jon R. Sundra

Talented Stepchild - The .41 Magnum . . . . . . . Jim Carmichel Pet Loads: The .264 Winchester . . . . . . . . . . Ken Waters

Defining Overbore Capacity . . . . . . . . . . . . Chris Englert The Forgotten 16 Gauge. . . . . . . . . . . . . . Don Zutz

Expanding on the .45ACP. . . . . . . . . . . Maj. George Nonte The .45-70 Resurrected . . . . . . . . . . . . . Bob Hagel

DEPARTMENTS: Editorial. . . . . . . . . 6 Propellant Profiles . . . . . Lock, Stock and Barrel . . . . 8 Reader Bylines . . . . . . Tip to Tip . . . . . . . . 12 ProducTests . . . . . . .

Harvey Donaldson . . . . . 66

18 22 26

30 32

34 38 40 42

15 16 63

The H A N D L O A D E R , Copyr ight 1971. i s published b i -month ly b y the Dave Wolfe Publishing Company, P.O. Box 3030, Prescott. Ar izona 86301. (A lso publisher o f Ri f le Magazine.) Telephone (602) 445-7810. Second Class Postage paid a t Prescott. Arizona, and addi t ional mai l ing offices. Single copy pr ice o f current issue $1.00. Subscr ipt ion price: six issues $5.00; 1 2 issues $9.00; 1 8 issues $12.50. Outside U.S. possessions and Canada $6.00. $11.00 and $15.50. Recommended foreign single copy price, $1.25. Advert is ing rates furnished o n request.

Publisher o f The H A N D L O A D E R i s n o t responsible fo r mishaps o f

f r o m recommendat ions b y any member o f The Staff. N o part o f th is pub l i ca t ion may be reproduced w i t h o u t wr i t ten permission f r o m t h e editor. Manuscripts f r o m free-lance writers must be accompanied b y stamped self-addressed envelope and t h e publisher cannot accept responsibi l i ty fo r lost o r mut i la ted manuscripts.

Change o f address: Please give one month's notice. Send b o t h o l d and new address, plus mai l ing label i f possible. t o Circulat ion Dept., The H A N D L O A D E R Magazine, P.O. B o x 3030, Prescott, Ar izona 86301.

SHOOT1 NG

any nature wh ich migh t occur f r o m use o f publ ished loading data, o r

Official Publication of Santa Barbara Reloading Association

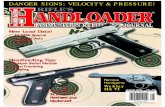

Your July-August Cover Shotshell loading presses are far f r o m new, as the 1886 model Belcher on t h e cover shows.

This 12 gauge press in near-new cond i t ion was purchased b y H. E. Her r ick of Yarnell, Ar izona, in 1942. It used a separate ro l l -c r imp ing t o o l similar t o t h e ear ly L y m a n fo r paper cases, but otherwise will do about any th ing a modern press can. A n d more-both the shot and powder measures are easily adjusted fo r a w ide range o f loads and are h igh ly accurate. Wads were held in the cast t ray at l e f t and pushed under t h e r a m as needed. The o l d Mason jars shown in t h e p h o t o are replacements-the or ig inal shot and powder hoppers were doub leended hal f - gal lon bo t t les w i t h lids on the i r tops. T h e y cou ld be drained b y removing corks in t h e casting. The press or ig inal ly sold fo r $10, w h i c h was more than t h e pr ice o f some guns. Photo b y Jim Carmichel.

HANDLOADER - July-August, 1971 4

- something that few cartridges have, even if only because it forms a link with an historic past.

Modern single-shot rifles like the Ruger Number 1 and Colt's Sharps 78 (which is just starting production) are ideally adapted to the .45-70 and other rimmed cartridges, so it was no great surprise when Ruger started chamber- ing for the old war horse. The great advantage of these modern single-shot actions is that they will stand the pressures churned up by high-intensity cartridges, so cartridges like the old .45-70 can be loaded to the full poten- tial of the case.

I Actually, when the .45-70 became

a smokeless-powder cartridge very little was gained. In fact, the only bonuses were the lack of a smoke screen every time you touched off a shot and the ease of cleaning the bore. If we assume velocity figures of black powder days are correct, velocity with the 405-grain bullet is almost identical with factory ammunition using either black or smo- keless powders at just over 1,300 fps.

The reason is that many of the Trap- door Springfields, and other single-shot actions of similar vintage and strength are still being used. The Model 1886 winchester had a much stronger action and would withstand higher pressures, but factory loads are rounded down to safe pressures for the weakest rifle action commercially chambered for it.

L

rifles with adequate strength were cham- bered for the .45-70, both single-shot and repeating types, perhaps the most prominent being the Model 1886 Win- chester. The '86 Winchester was pro- bably the last commercial rifle cham- bered for the old cartridge, and it was discontinued in the mid-thirties.

Yet the -45-70 has remained quite popular despite the fact that no rifles have been chambered for it commer- cially for nearly 35 years. This is difficult to understand when one con- siders that ammunition is no longer made for more modern, and, in this writer's opinion, more practical hunting numbers such as the .35 and .405 Win- chester. The awwer probably lies in the fact that there are still many '86 Winchester rifles and '73 Springfields in use, to say nothing of a host of others chambered for the .45-70, while 1895 Winchesters for either the .35 or .405 are scarce.

At any rate, when a cartridge starts out as a coal burner, graduates to smokeless, and the ammo is still made almost 100 years later, it must have

This composite target, showing some of the average groups taped into place, illustrates the radical change in impact caused by varying loads. All were held center except the 500-grain load, which was fired with a 12 o%lock hold to keep the group on the paper.

Many -45-70 fans load the '86 Win- chester rifles with ammo developing considerably higher velocity than fact- ory ammunition, and most of these handloads are apparently safe in this rifle. However, some of the loads I have seen listed are fairly stiff, even in an action made of modern steels, and I can't help wondering how long the old '86 action would hold up under them before the bolt started setting back and developing headspace. At any rate, I certainly do not suggest that any of the loads listed with this article be used in Winchester 1886 rifles, or any other of the older rifles originally cham- bered for the cartridge.

There was no doubt that the .45-70 cartridge could be loaded to much higher velocities in a good strong action than any of the original rifles would allow, but just how much more? Also, which powders would give the highest velocity with various bullet weights,

43 HANDLOADER - July-AUguSt, 1871

Loaded .45-70 cartridges with different bullets and various seating The cast bullets were seated in the crimping groove, but crimping depths tried were, from left, Remington 405-grain factory load, in the first lubricating groove and forcing the bullets into the lands 300-grain Hornady HP, 350 Hornady SP, 405 Winchester seated was tried, however, ,chambering required considerable force and to factory depth, 405 Remington seated to crimp in second cannelure, accuracy did not improve. 500-grain Hornady, Lyman No. 457124 and Lyman NO. 457121.

and which would provide the best accuracy?

When Ruger announced that they would chamber the Ruger Number 1 for the .45-70 cartridge, editor Neal Knox and I decided to find answers to some of these questions, and requested one of the rifles for test work.

Much has been written on the Ruger Number 1, so we won’t re-cover that ground here. The test rifle did have a very nice piece of wood in the butt-

stock, and workmanship on both wood and metal was in a class not often seen today in production factory rifles. Even the checkering is very well done, which is certainly refreshing. The rifle func- tioned perfectly in every way and proved extremely accurate with any load it liked. The one complaint I have is that the chamber is a little larger than seems necessary for factory cart- ridge dimensions, although some lots of ammunition may have dimensions large enough to warrant it. Even so, case life was very good with several

Loading both cast and jacketed bullets for the .45-70 requires three dies: full-length sizing die, left, expanding die which also bells mouth of case for starting the bullet, and the seat- crimp die, at right.

cases being 4 e d as many as 20 times with full-length resizing every time.

As a check for future loading, and to get new cases, a new lot of ammuni- tion was procured directly from Re- mington. This ammo was loaded with the standard 405-grain bullet and 36.5 grains of extruded powder that re- sembled 3031. I was immediately im- pressed by the accuracy it delivered, and just a little confused when I discovered many granules of unburned powder remaining in the case. It seemed odd that this kind of accuracy could come from cartridges that obviously were not developing enough pressure to properly burn the powder used. The first ten-shot groups with this ammo, with a Weaver K4 mounted on the rifle, went into less than three inches vertically by about half that horizon- tally. This with an untuned rifle.

After examining the groups I de- cided that tuning would improve mat- ters. The fore-end was pulled and a shim placed between wood and hanger around the fore-end screw; this serves to float the barrel. The next groups with Remington factory ammunition dropped down to around one MOA and stayed there with only an oc- casional flyer, which probably came

44 HANDLOADER - July-August. 1971

was number 457121, a flat-point bullet that weighed 310 grains when cast from hard type metal, the other was number 457124, a round-point bullet that weighed 376 grains from the same material.

from the unburned powder and not the gun.

The Remington factory ammunition was clocked at 1,206 fps. This is about 100 fps less than factory figures show, and could be due to the Ruger’s 22-inch barrel. If this is true, (no rifle with a longer barrel was available to check against), then perhaps 100 fps could be added to all velocities taken with this rifle for comparison with rifles such as the ’86 Winchester.

L

The barrel of the Ruger was slugged and miked at .458, but no sizing die in that diameter was available from Lyman for the old 45 sizer-lubricator I use. Lyman sent ,457 and .459 dies and both were tried. I soon found that the .459 die was too large. Bullets sized with it, being larger than the bore, were too tight in the throat, and made it hard t o chamber a cartridge. A few were fired with very poor accuracy.

Switching to the .457-size die, born bullets were tried extensively. Lubricant was the new Lyman Deluxe Bullet Lubricant, a blend of Alox and pure beeswax. Incidentally, this lubricant seems to be very good and flows better in a lubricator than many others I have used, yet is not overly messy.

J Wanting to try all readily available

bullets in this caliber, 405-grain Re- mington and Winchester factory bullets were obtained, as well as Hornady 300-grain HP, 350grain soft point, and also the 500-grain soft point made for the .458 Winchester Magnum.

Although cast bullets were not the object of this test, two Lyman moulds were used just to see how the rifle handled lead-alloy bullets. One mould

As a starter, 48 grains of 3031, the accuracy load suggested for bullet NO. 457124 in the 45th Edition Lyman Handbook (1970) was tried. Results were very poor; groups ran around four

These are the bullets Hagel used in testing the .45-70 performance in the Ruger. From top are the 3OO-grain Hornady HP, 350 Hornady SP, 405 Winchester SP, 405 Remington SP, 500 Hornady SP and Lyman cast bullets Nos. 457124 and 45712 1.

I .45-70 Ruger Number 2-inch barrel. R-P cases, weight 189 grains. Federal 210 primers. Oehler No. 10 chronograph. Temp 60 degrees.

Charg

36.5

60 60 56 58 53 47

60 55 50 45

55

50

45

1,87 57 48

ads dge.

EANDLOAPER - luly-Augu6t8 1971 45

inches at 100 yards. Bullet No, 457121 with the same load gave even poorer results. Loads of 3031 were tried up to those used with jacketed 350-grain bullets, and we also dropped to loads approximating factory velocity figures, but none were much better. Both 4198 and 4227 powders were tried in various charges with similar results. In fact, many groups ran to 8-inch patterns. The best load found was 36 grains of 4198 behind the No. 457124 bullet, which averaged around 3 inches at 100 yards.

Other bullets, perhaps other bullet metal alloys, and possibly some other powder, should give better results. However, the twist in the Ruger barrel may be a little fast for the best results with cast bullets.

Jacketed bullet loads were started using the 300-grain Hornady hollow point, and it was soon discovered that stick powders like 4895 and 3031 were too slow to give top velocity with this

Dutch Ackennan’s

Deluxe American Plan Fly-in Drive-in

Lodge In Ontario Wilderness

H u n t i n g - C o m p l e t e f a l l package-bear , deer, moose, ducks, grouse.

Fishing- Tops in bass, walleye, Northerns, trout, pan fish.

Special-Excellent Spring bear hunting.

Outfitting service to fly-in fishing and hunting camps.

Write for free brochure

Caribou Falls Lodge

P.O. Box 22R Minaki Ontario - Canada

TEL: CARIBOU LODGE (VIA YINAKI) 8.4~01

46

bullet weight. Charges of 60 grains of either powder is about all that the bullet can be seated over and crimped in the cannelure. With 4895, velocity runs about 2,000 fps, and about 2,100 with 3031. Going to faster powders, 4198 gave 2,382 from a charge of 58 grains and 2400 the same velocity by using 47 grains. The highest velocity was obtained with 4227 and a charge of 53 grains for an MV of 2,440 fps.

With the 350-grain Hornady soft point you are still restricted to the 60-grain charge of 3031 because of seating depth to crimp. This case will not hold bullets with heavily com- pressed loads by friction alone. This load gave a velocity reading of 2,028 fps, while 4198 and 2400 ran neck and neck at just under 2,200. Again, 4227 gave top velocity at 2,237 fps with a charge of 50 grains.

The 405-grain Remington bullet is crimped against a flange just ahead of the forward cannelure, which requires very deep seating. With this seating depth the charge of 55 grains of 3031 is all that can be seated over, and delivers 1,895 fps. However, this bullet has yet another cannelure behind the first, and since the Ruger rifle is throated long enough, the bullet can be crimped in this groove. With this arrangement the case will take a charge of 58 grains and velocity can be increased to 1,968. Using Winchester factory 405-grain bullets this arrange- ment is possible in this single-shot rifle when only a few rounds are to be loaded and fired, but the single cannel- ure is too far forward to use for a crimp. It isn’t a good idea to carry this ammo with uncrimped bullets. With this bullet weight, 4198 and’4227 gave about the same velocity-just over 2,000 fps. These two powders could be used with the Winchester bullet and factory seating depth without compression, but charges should be cut somewhat.

Results with the big 500-grain Hor-

GET YOUR SCOPE OFF THE BARREL with this unique one piece bridge mount for target scopes providing easy, positive alignment. Made from light weight oluminum alloy, and desigred for usc with Remlngton rifle model 40X. 40x6. and short model 700 series-and Redfield #3200 and Unertl Posa-mount scopes, this bridge mount makes barrel tapping un- necessary. Price $15.00 postpaid. Bridge Mount Company P. 0. Box 3344

Lubbock. Texas 79410

nady soft point, made for the .458 Winchester Magnum, were quite im- pressive-on both ends of the rifle. This bullet had the crimping cannelure set well to the rear for rather shallow seating, and fit the throat of the Ruger perfectly, leaving just a little clearance between bullet and lands. A charge of 57 grains of 3031 seemed about maxi- mum and was about all that the case would hold. Velocity was an imposing 1,877 fps. A charge of 48 grains of 4198 was near top and lowered velo- city to 1,818, so 4227 was not tried;

As accuracy testing progressed, it became apparent that 3031 and 4198 gave by far the best results. The 4198 averaged better with most bullets, while 4227 came in a poor third. No bullet shot well with 2400. It might do better with reduced charges, but this was not the reason for the tests.

No load was especially accurate in this rifle with the 300-grain bullet, but it averaged around three inches, with some groups down to around two inches. Again, lighter loads might do better, but the few tried did not im- prove groups. Actually, this accuracy is not at all bad.

The 350-grain Hornady did better; most groups with either 4198 or 3031 went into less than 1% inches. This bullet would, I suspect, be ideal for use on deer, black bear, and similar game. It should expand rapidly and give fast kills. I seriously doubt that it would give good penetration on heavier game.

The 405-grain factory bullets, both Remington and Winchester, gave the finest accuracy of all-many groups fued with either 3031 or 4198 going into around one MOA! I prefer the Remington bullet since it can be crimped with shallow seating.

I was agreeably surprised at the accuracy delivered by the 500-grain Hornady. It did almost as well as the 405-grain, with groups averaging 1% inches with full charges of 3031. I didn’t fire too many groups with this bullet from the bench. I’m not in the least allergic to recoil, but this rifle weighs only 7% pounds complete with scope, and with only a very firm rubber butt pad instead of a recoil pad, I didn’t enjoy shooting the 500- grain load at full throttle.

For use with these heavy powder charges and bullets, a rifle with an

HANDLOADER - Zuly-August, 1971

extra pound or so of weight would be desirable. A 24 inch or even 26 inch barrel would give this needed weight and damp muzzle jump and recoil, yet the overall rifle length would not be greater than a bolt or lever action with a 22-inch tube. Remember that with the .45-70 cartridge loaded to these velocity levels with heavy bullets you are approaching the .458 Winchester cartridge in potency and recoil, and few people would consider a 7% pound .458!

One point to keep in mind con- cerning the .45-70 cartridge, at least in this Ruger rifle, is that no two bullet weights shoot to the same point of impact. In fact, few bullets give the same point of impact when loaded with different powders, even though velocity does not change more than 100 fps. There is often as much as three to four inches change of impact between groups fired with the same bullet using dif- ferent powders that give equal velocity. Even when all bullets are loaded to full throttle, there is as much as a 16- inch difference in point of impact at 100 yards. You will have to sight-in with one load and stay with it if you want to hit anything.

Another obvious point; the velocity of the .45-70 cartridge is restricted by case capacity rather than by case strength or the action in the Ruger NO. 1. This is especially true with heavier bullets where powders of the burning rate of 3031 and 4895 give the highest velocity. Some ball powders might give even higher velocities due to their density if one experimented long enough to find the right combination for accuracy and velocity. However, I sus- pect that pressures were running quite high, judging by the flatness of the primers and the fact that the case body was expanding to fill the chamber right up to the solid web section. There was no sign of extraction problems with any load, even with cases that had been fired 15 to 20 times.

The potency of the .45-70 cartridge can’t be doubted when handloaded to its full potential in the Ruger Number 1. For the big-bore enthusiast who isn’t partial to a long range cartridge, likes a short, handy rifle in the brush, isn’t sensitive to recoil, and likes to roll his own, the .45-70 Ruger should send him into fits of ecstasy. And he doesn’t need to feel undergunned in any com- pany with the 500-grain blockbuster delivering nearly two tons of energy!

0

,264 Winchester (Continued from Page 33)

and components, has been a marked increase in uniformity. And uniformity is a major factor in both accuracy and reliability.

Our modern slow-burning powders have made it possible to increase vel- ocities in rifles of .33 caliber and under without exceeding allowable pressure limitations, while bullets of superior design with stronger jackets have proven capable of withstanding those higher velocities and greater centrifugal spin.

Any rifle cartridge is, of necessity, a compromise between bullet diameter, bullet weight, ballistic coefficient (in- cluding sectional density), muzzle vel- ocity and the recoil developed. Such a balancing of forces becomes more critical as increases in range or velocity are sought, and bore size becomes smaller.

Kinetic energy is said to be an almost linear function of caliber. With a given weight bullet, the big bores will generate more muzzle energy, within a specified pressure limitation, than will a small bore. If that were the only consideration, the ballistician’s task would be a simple one. However, the key word here is “muzzle.77 Very little game is shot at the muzzle, hence we are concerned with bullet perfor- mance at various distances. To minimize bullet drop and wind drift at long ranges, the largest permissible powder charge is indicated, in conjunction with the smallest practicable bore and bullets of optimum point shape.

Like it or not, we thus become in- volved in other matters which tend to change the picture. The smaller a bullet’s diameter, the longer it will be for a given weight, resulting in greater sectional density. Give that bullet a

streamlined shape and you endow it with a better ballistic coefficient; it will retain more of its initial velocity and energy out to longer ranges. Ob- viously, the heavier a bullet is, the more momentum it strikes with, but its recoil will be heavier. Conversely, the lighter bullet will start out at higher speeds.

So a stand-off situation develops which can only be resolved in com- promise. Winchester-Western ballisti- cians decided that a ratio of bullet weight to the square of the caliber somewhere between 0.15 and 0.35 is most practical; bullets with lower values are too short to effectively maintain velocities and energies over long ranges, while those with higher values (longer in proportion to weight) prove difficult to stabilize. Eventually, these considerations induced them to settle on the 6.5mm or .264 caliber as the practical minimum diameter, with a moderately long bullet weighing 140 grains.

Next to be determined was a suitable powder charge. Assuming a cartridge designer must stay within practical limits of barrel length-say, not to exceed 26 inches-as well as reasonable chamber pressures (50 to 55,000 psi or CUP-copper units of pressure), the questions were:

(1) Which propellant is best suited to generate maximum velocity in re- lation to pressure?

How much of a selected pro- pellant could be efficiently burned in a 6.5mm bore not over 26 inches?

And what level of efficiency is attainable in converting potential 0

(2)

(3)

Shooting Supplies, Archery, Fishing Camping, Books, Scopes, Binoculars

Send $7.00, Refunded wirh $10 Order

CASANOVA GUNS 1601 W. Greenfield Avenue Mi I wa u kee Wisconsin 63204

I THE SUPERIOR DESIGN OF ACKU REST OUT PERFORMS ALL OTHERS

GIVES NEW t YOUR PRICE

NAME IN GOLil,,, SET 121 RESTS 17,95 FILLING FORMULAE

s4.25 SUPERIOR RESULTS SET I21 $1.25 SINGLE REST SINGLE P I 3. BOX 25H1 NEW KENNEDY YORK

HANDLOADER - July-August, 1971 47

Winchester-Western “Handicap” Wad

When Winchester first announced a new “Handicap” load complete with a freshly designed, single-unit polyethelene wad, trap shooters hereabouts merely assumed the forthcoming wad would feature an unslit shotcup perched atop conventional Double-A underpinnings. But such has not come to pass, and the Winchester Handicap wad is almost totally unlike the Double-A entry.

With an overall length of 1 19/32 inches, the Handicap wad is 1/32-inch shorter than the well-known Double-A. However, the Handicap has a slightly deeper shot cup showing a 25/32-inch depth as compared to the %-inch depth of the AA. The shot cup is again divided into four segments with long- itudinal slits stopping approximately 3/32-inch above the shot cup base. Corners of the Handicap wad are squared, whereas the Double-A’s have rounded corners. For all practical pur- poses, the gas-sealing overpowder bases of the Handicap wad and Double-A’s are identical.

The important difference between normal AA and the newer Handicap lies in the design and principle of the cushioning section. The Handicap wad has three equally spaced supports sta- tioned around the circumference. These supports are 3/8-inch long and roughly 11/32-inch wide at thc tvad’s circum- ference. However, they tapcr inwdiri abruptly and have a hollow spot on

HANDLOADER - July-August. 1971

their inner surfaces. Viewed from the outside, these hollow spots look like a large bubble in each leg, and their purpose is to direct the cushioning or “bending” action of each support. Under stress, the supports of a Handicap wad belly out, not in as with most single- unit plastics.

Because the cushioning supports of a Handicap wad press out against hull wall and bore, there is a possibility that timelpressure curves for this new item will not duplicate those of the normal Double-A; consequently, I would not become too “creative” with this wad until the results of pressure tests are made available. In other words, data for the AA and Handicap wad may not be fully interchangeable. In the pat- terning tests I have run, using popular loadings for the AA wad, I was able to detect no excess pressure signs. How- ever, that is a difficult chore anyway when working with only empirical equipment, and I look forward to the results of pressure gun or strain gauge tests.

Unlike most other single-unit wads now on the market, the Winchester Handicap wad has absolutely no support directly under the center of the shotcup; and if Winchester engineers can claim any innovations and higher pattern percentages from this wad, their claims must be based upon the theory which underlies this cushioning principle. It is common knowledge that much pellet deformation occurs at the bottom of a shot charge upon ignition when lower pellets are trapped betwixt the weight of upper pellets and the shotcup’s hard plastic base. Check any fired plastic wad or shot wrapper and you will find deeper impressions on the lower portion than on the upper areas.

The problem, of course, has always been finding a way t o provide relief for lower pellets. Theoretically, if they could find relief by moving backward, there would be less deformation. The British long ago attempted to minimize shot deformation by employing an “air cushion” wad which allowcrl r h - lowcr laye:& s h t f t to ~ L X : . drlct.\\. . t l t L ~ l c .

pressurcs. Francis F. ’+I! h writreri

with regularity of a variation of this air cushion wad, advocating the use of perforated filler wads to supply the necessary rearward expansion room.

Thus, although the W-W Handicap wad does not employ a closed air space, it does exhibit the same principle, namely, a weakened center so that lower pellets can avoid excessive deformation by finding rearward relief under ignition and acceleration jamming. And if pat- terns show greater long-range density, the sweetened qualities .can well be attributed to fewer deformed pellets.

The solid supports of the W-W Handicap will not compress under seating pressures as will Double-A and Power Piston wads. Size-wise, they will fit in loads suited to the 7/8-inch Federal “Pellet Protector” and those which slightly compress WAAl2(white) Double-A’s. As with the white Double-A wads, the Handicap cushion requires hulls with low base wads, such as the compression formed W-W cases, Federal paper and plastic target tubes, and Remington SP’s.

My initial investigations indicate that this Handicap wad fills the case better when used with powder charges listed as three-dram equivalent doses. With charges less bulky than 22.0 grains of Green Dot or PB, crimp depth may have to be lowered. Light loads, such as 18.0 grains of “Hi-Skor” 700X or 18.0 grains of Grey B, may leave more room than necessary for the crimp. Some reloaders may compensate for this by placing a 16 gauge nitro card on the base of the shotcup, but that is a mistake with the Handicap unit be- cause it negates the cushioning principle.

Whether the Handicap wad will really tighten patterns with universal reliability is still a moot question-though Win- chester is extremely proud of its new baby, and has great hopes for it. My limited testing indicates that its per- formance, as a reloading component, will vary from gun-to-gun. But that testing was far from conclusive for the wads used had been pulled from loaded factory ammunition-the only available source at this writing.

Using the Federal paper target case, Winchester 209 primer, 22.0 grain5 of Green Dot and 1 l /8 ounces of No. 8 s!iot w i n i m , fiv, roLind aver.

( 1 r I

< . J

standard AA and 55 percent with the new Handicap wad.

Then, with the same components, except 22.0 grains of PB, and using a High Standard Model 8165 Trap, the standard AA wad showed an average 67 percent while the Handicap wad showed 65 percent.

Both guns used will do over 70 percent at 40 yards with 18.0/Hi-Skor 700X under a Power Piston and 1 1/8 ounces of No. 8 shot in Remington All-American hulls, so there is no blaming the barrels. Since the standard AA wad will give good trap performance, yet didn’t in either of the tests, it’s obvious that the loads used are unsuited to these Full choke tubes. However, in the tests the AA Handicap wads didn’t perform any miracles.

Handicap wads retrieved after pat- terning tests showed a tendency of the overpowder cup to over-run the cush- ioning supports, thus creating a bulge between the circumference of the over- powder cup and hull or barrel wall. Such a condition could allow powder gases to seep past the sealing accouterments and affect shot distribution at the muzzle.

It is possible that the over-running may have been caused by a weakening of the legs due to having been first loaded by the factory, then by me. I f so, it would seem that the strength is marginal.

I look forward to more p,atterning with, the wads once they become avail- able as components, and I am especially interested in finding out whether other shotshell experimenters experience the same indifferent results that I have thus far obtained. If this is so, Winchester may well be forced into strengthening the three legs of the Handicap wad’s cushioning section. -Don Zutz

I WARNING MEDAL I I

1971 DuPont Loading Guide

Every two to three years Du Pont comes out with a revised edition of its Handloader’s Guide for Smokeless Pow- ders, and the new 1971-72 edition is bigger and better than previous offerings. Bigger because it now measures 8 by 10% inches in size, and better because it contains a wealth of fresh data on shotshell loads. Only Du Pont propell- ants are covered. of course.

Metallic buffs will find little change between this and the preceding guide. In fact, there has been no updating in the rifle-load section, and very little has been added that will be of interest to pistoleros, except for a few loads in 9mm Luger and .38 Special.

But shotshell stuffers will be kept busy halfway into next month digesting the vast amount of new information shown, with 15 of the 24 pages devoted to this avenue of handloading. In the field-load section alone, the new edition shows nearly 300 12 gauge loads, whereas the preceding guide listed only 182.

Following past format, the guide starts off with loads for trap and skeet (including many for International trap), and on the heels of this presentation comes dope on field loads from 10 gauge magnum right on down the line through .410. As before, muzzle velocity and chamber pressure are shown for each load, and all other pertinent details are also listed-such as case, primer and wad column. Any handloader wishing t o duplicate the ballistics shown must follow these recommendations to the letter.

Some data is included for buckshot loads in 10 and 12 gauge, as well as information on blank loads for the 12 gauge. However, the guide has nothing on rifled-slug loads.

In the target-load section of the 1968-69 guide, Du Pont began showing loads for shells other than Remington- Peters. In this latest edition, the practice has been extended to the field-load section. Except for the 10 gauge pre- scriptions, a great many loads are given for Alcan, Federal and Winchester- Western hulls, and this departure from the former policy of R/P-hulls-only will

surely win a round of applause from all hands.

A copy of Du Pont’s new guide belongs on every loading bench, and perhaps the best part is that it costs only the price of a postage stamp. Your free copy may be obtained by writing to E. I. Du Pont de Nemours & Co., Explosives Dept., Explosives Products Division, Wilmington, Delaware 19898.

-Wallace Labisky

RCBS Priming Tool

Case priming can be performed on almost all modern bench presses with reasonable satisfaction, but experienced reloaders feel that separate priming devices usually offer better uniformity. Such devices, if fitted with an auto- matic primer feed, also offer much greater speed in repriming a large batch of hulls.

The brand-new RCBS priming tool excels in this latter quality; it is the fastest I have ever used. When the shell- holder is empty and the handle is in the down position, the priming punch pro- trudes above the shellholder. The primer feed arm is then flipped forward, depositing a primer in the priming punch sleeve.

The handle is now raised to retract the punch, an unprimed case is set in the shellholder, and a downward stroke of the handle presses the primer into its

64 HANDLOADER - July-August, 1971

pocket. Very little practice is required to develop a rhythm which primes 50 cases in a matter of minutes.

The time spent filing the primer tube, however, must be added to the total time for the priming operation. In the case of this tool, the cotter pin is inserted, primers are turned anvil-down on the bench top (or in a primer “flipper”) and the mouth of the tube is pressed over each one, which is caught by a small spring so that it cannot drop back out of the tube.

This, too, is a very speedy process, but it is really not worthwhile if only a few cases (say, a dozen) are to be primed. In that case, primers can be manually positioned in the primer punch sleeve, just as with most bench presses.

Speed is the RCBS tool’s forte; it seems to me no more sensitive (if as much so) than the average bench- mounted reloading press-it is suf- ficiently powerful that minor differences in primer pocket tightness cannot readily be detected. Also, the priming stroke of the handle does not end on a positive stop, and some care is necessary (as with a bench press) to avoid slight crushing of seated primers. Still, great uniformity of seating is possible with the RCBS instrument.

The tool is exceptionally well-made throughout. It is designed to accept RCBS shellholders, of course, but many other brands can be used. Two primer magazines are furnished, one each for Large and Small primers. These tubes are identical to those supplied for the RCBS automatic primer feed apparatus on RCBS bench presses. Likewise, a priming punch for each size primer is provided, and these are installed by merely dropping them through the priming hole in the shellholder. Good instructions are included with the device.

The RCBS priming tool will not dis- place hand-operated priming devices in the affections of the benchrest shooters, who never load very many rounds of ammo at a sitting and who prize sen- sitivity in a primer-seater above all else, but for the man with 50 or 100 cases to fill this new RCBS tool is the answer to a prayer.

Available for $24.95, less shellholder, from RCBS, Inc., P.O. Box 1919, Oro- ville, Calif. 95965-John Wooters 0

HANDLOADER - July-AugUSt, 1971

Harvey Donaldson (Continued from Page 66)

metal case bullets were used and the ranges were 100 and 200 yards and 300 meters. Pope found he got the best accuracy in these slow twist barrels with his special cast bullet design, Lyman No. 308403. These 14 and 15 inch barrels very soon held all the records, up to 200 yards.

Many years later a friend of mine from Buffalo, N.Y. showed up on the Johnstown range with a bench rest rifle with a bull pup stock and a short heavy barrel chambered for the .308 Winchester case. The owner asked me what I thought of it. I told him that I figured that he was trying to shoot at 100 and 200 yards with a barrel twist correct for 1,000-yard shooting. He sort of shook his head and walked away.

The results he got in that match were exactly as I had suspected. Before this fellow was ready to return to his home, he walked over to say goodby. While we stood visiting I said, Bruno, if you insist in shooting a .30 caliber bench rest rifle, why not do as Harry Pope did back around 1923. I then related what Pope had done with his slow-twist .30 caliber barrels, giving him the data that would allow him to look up the old records. He said, maybe old Harry had something, at that, and it was worth giving it a try.

The next year, at our next match

in Johnstown, N.Y., I happened to be on the range when this same friend arrived. In fact I walked over to his car before he got out. This time, my friend was all smiles, and said, “Stick around awhile, I have something to show you.” He opened up the trunk of his car and brought out what looked like the same rifle he had the year before, but I noted the barrel was shorter and heavier. He kept the rifle in his hands while we were talking, but I reached over and said, ‘‘Let’s see the new job.’’ When I took the rifle I took out the bolt and looked up through the barrel, where I noted at once this barrel had the 14-inch twist. So 1 said, “Well Bruno, you are getting smart.” With that, he only laughed and said, “Keep it quiet.” Well, to make a long story short, from that very match friend Bruno made bench rest history, winning not only at Johnstown, but at every match he attended, including the NBRSA National Championship in 1962. This was the start of the use of the .308 case in bench rest shooting, where it has made many records.

Now I have to report the sad news that this good friend, Brunon Boro- szewski, passed away on February 20, 1971. One more good man has left the range.

Yours truly,

Harvey Donaldson

ADVERTISERS INDEX Bair Co. . . .. . Birchwood Casey . Blackhawk . . . Bonanza Sports . . Bridge Mount Co. . Brown Precision Co. C-H Tool & Die Corp. Caribou Falls Lodge Casanova‘s Guns, Inc. Cole’s Acku-Rest . Conetrol . . . . Du Pont Explosives . Hutton Rifle Ranch J & G Rifle Ranch . Javelina Products . Jet-Aer Corp. . . Johnson,A.A. . .

. . . . 59

. . . . 9.51

. . . . 13

. . . . 55

. . . . 46

. . . . 13

. . . . 17 , . . . 46 . . . . 47 . . . . 47 . . . . 55 . . . . 13 . . . . 16 . . . . 59 . . . . 50 . . . 8.16.49 . . . . 64

Norma Precision . . . . Nosler Bullets, Inc. . . . . Oehler Research . . . . . OmarkCCI . . . . . . PachmayrGun Works . . . PADCO . . . . . . . Parker Distributors . . . . Penguin Industries, Inc. . . Pennsylvania Gunsmith School Peterson‘s Labels . . . . Ponsness Warren, Inc. . . . Powley, Marian . . . . . Quinetics Corp. . . . . . RCBS, Inc. , . . . . . Ransom Rest . . . . . Redding Hunter, Inc. . . . Rifle Ranch . . . . . .

Lee Custom Engineering . . . 2.14 Sierra Bullets . . . . . Lyman Gun Sight Co. . . . . 3.11 Speer, Inc. . . . . . . Molded Products Co. . . . . 57 Sundtek . . . . . . . N. L. Industries . . . . . . 7 Texan Reloaders . . . . Nat‘l Reloading Mfgrs. Assn. . . 61 Thompson/Center Arms . .

Winchester Western . . . . . 5

. 10

. 6

. 57

. 67

. 53

. 9

. 50

. 7

. 62

. 58

. 10

. 60

. 49

. 8

. 12

. 16

. 13

. 12

. 68

. 54

. 14

. 17

65