Spectral selectivity of composite enamel coatings on 321 stainless steel

-

Upload

milene-almeida -

Category

Documents

-

view

7 -

download

1

description

Transcript of Spectral selectivity of composite enamel coatings on 321 stainless steel

-

l. E

, Al

el

e-g

zed

ted

ed

epe

sele

requibsorptaxhibite commerciapositepor de

le solalop sg me

peratures that can approach 500 1C for concentrated solar-power

degradation at high temperature and long-term instability on

glass. The

particularly in the case of dark-colored enamels, or by the

ARTICLE IN PRESS

Contents lists available at ScienceDirect

.els

Solar Energy Mater

Solar Energy Materials & Solar Cells 93 (2009) 14041410results to commercial black porcelain-enamel coatings.E-mail address: [email protected] (D.D. Edwards).receiver tubes. Resin-based systems have not found widespread crystallization of secondary phases. In this paper, we report onthe processing and optical properties of composite porcelain-enamel coatings consisting of spinel-type oxide pigments em-bedded in a clear porcelain-enamel matrix and compare the

0927-0248/$ - see front matter & 2009 Elsevier B.V. All rights reserved.

doi:10.1016/j.solmat.2009.03.009

Corresponding author. Tel.: +16078712284; fax: +16078713407.coatings must meet performance requirements such as mechan-ical durability and thermo-chemical stability at operating tem-

optical properties of traditional porcelain enamels are typicallycontrolled by the use of the dissolved transition-metal ions,components, by coating thickness, and by particle-size-dependentscattering [315].

In addition to exhibiting solar-selective optical properties,

sinter the glass particles to form a dense protective coating.Porcelain-enamel frits are generally complex silicate

systems formulated to adhere to a specic type of metalresearchers at the National Institute of Chemistry in Slovenia havereported extensively on the properties of thickness-sensitivespectrally selective (TSSS) paints containing various pigments inphenoxy and silicon binders. They have shown that opticalproperties are governed by the intrinsic optical properties of the

moderately corrosive environments. The coatings are prepared bydepositing glass powder or frit on a steel substrate usingprocesses that are readily adaptable to large-scale manufacturing,such as wet-spray, electrostatic spray, or screen-printing techni-ques. After deposition, the coated sample is heated to soften and1. Introduction

Many solar-power applicationscoatings that exhibit high solar aemittance. Because few materials eity, most solar-selective coatings aror textured structures. Most comtrated solar-power systems use comprepared using vacuum physical vaques [1,2].

In the quest for more affordabresearchers have sought to devedeposited using inexpensive coatinre spectrally selectivence and low thermalintrinsic solar selectiv-posite, layered, graded,l trough-type concen-and/or graded coatingsposition (PVD) techni-

r-energy components,olar-selective coatingsthods. As an example,

exposure to ultraviolet radiation [14]. The oxidation of some solar-selective coatings resulting from air leaks into the evacuatedannulus between the coated steel tube and its protective glasssleeve is a signicant problem for the long-term operation oftrough-type solar-receiver tubes in the eld [2].

Porcelain-enamel coatings have been examined as solarabsorbing coatings but do not exhibit solar selectivity unlesscoated with a low-emissivity coating like doped tin oxide [16,17].Nevertheless, if porcelain-enamel coatings could be formulated toexhibit solar selectivity, they may be an attractive alternative toexisting coating technology, especially for high-temperature anduse in concentrated solar-power systems because of thermalSpectral selectivity of composite ename

Harlan J. Brown-Shaklee, William Carty, Doreen D

Department of Materials Science and Engineering, Kazuo Inamori School of Engineering

a r t i c l e i n f o

Article history:

Received 29 September 2008

Received in revised form

23 February 2009

Accepted 7 March 2009Available online 21 April 2009

Keywords:

Spectrally selective coatings

Solar absorptance

Thermal emittance

Solar collectors

Enamel coatings

Solar absorber

a b s t r a c t

Composite porcelain-enam

embedded in a borosilicat

techniques and characteri

composite coatings exhibi

Solar absorptance (a) rangfrom 0.46 to 0.79. Both d

example, the highest solar

and 0.46, respectively.

journal homepage: wwwcoatings on 321 stainless steel

dwards

fred University, 2 Pine Street, Alfred, NY 14802, USA

coatings consisting of spinel-type transition-metal-oxide pigments

lass matrix were deposited on 321 stainless steel using screen-printing

using total reectance over the spectral range of 200nm to 25mm. Themoderate spectral selectivity and excellent thermal stability at 450 1C.from 0.82 to 0.90 and calculated thermal emittance at 500 1C (e) rangednded on coating thickness and pigment volume concentrations. As an

ctivity was measured in a 0.9mm coating with a and e (500 1C) being 0.82

& 2009 Elsevier B.V. All rights reserved.

evier.com/locate/solmat

ials & Solar Cells

-

2. Experimental

Two different types of porcelain-enamel coatings were appliedto 1.5mm thick 321 stainless-steel coupons (5 cm5 cm) usingscreen printing, as summarized in Table 1. The rst is acommercial black enamel (PL-214, Ferro Corp., Cleveland, OH).The second was a composite coating consisting of a black spinel-type pigment embedded in a clear enamel (XG-201, Ferro Corp.,Cleveland, OH). Two different pigments were used in the study(10456 and F6331-2, Ferro Corp., Cleveland, OH).

The properties of frits and pigments are summarized in Tables2 and 3. Density, specic surface area (SSA), and particle size weremeasured using a helium pycnometer (Micrometrics, AccuPyc1330, Norcross, GA), BET surface area analyzer (Micrometrics,Gemini 236, Norcross, GA), and particle size analyzer (Micro-metrics, Sedigragh 5100, Norcross, GA), respectively. The glasstransition temperature (Tg) of the frit was determined usingdifferential thermal analysis (DTA; TA Instruments, SDT 2960,New Castle, DE) and hot-stage microscopy (Expert Systems,M31600/80/2, Italy). Phase analysis was determined by X-raydiffraction (XRD), and chemical composition was determined viachemical assay performed by ACME Analytical Laboratories Ltd.

ARTICLE IN PRESS

Table 1Summary of fritpigment combinations studieda.

Coating Glass frit Pigment

Commercial black enamel PL-214

Composite enamel-1 XG-201 10456

Composite enamel-2 XG-201 F6331-2

a All products are manufactured by Ferro, Corp.

Table 2Chemical and physical properties of glass frits.

Characteristic Black enamel Clear enamel

Product name PL-214 XG-201

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 14041410 1405Manufacture Ferro, Corp. Ferro, Corp.

Description Alkali borosilicate Barium borosilicate

Density (g/cm3) 2.64 3.57

Surface area (m2/g) 0.37 0.55

Sieved particle size (mm) o53 o53Mean particle size (mm) 13Refractive index 1.572 1.616

Reectivity coefcient 0.222 0.235

Glass transition temperature (1C) 489 680

Table 3Chemical and physical properties of pigments.

Characteristic Pigment 1 Pigment 2

Product name 10456 F6331-2

Manufacture Ferro, Corp. Ferro, Corp.

Description Spinel-type oxide Spinel-type oxide

Density (g/cm3) 5.56 5.68

Surface area (m2/g) 3.0 38.1

Equivalent mean spherical diametera (mm) 0.36 0.03Reported mean particle size (mm) 2.2 o10

a Calculated from surface area measurement.The refractive index of the frit was measured using the Becke linemethod; the frit was immersed in oils of known refractive indicesand imaged using an optical microscope with a 40 objectivelens (Leica, Laboralux 2, Germany).

Screen-printing inks were prepared by suspending frits andpigments in a screen-printing vehicle. The vehicle was preparedby dissolving 3.5 g ethyl cellulose (EthocelTM, Dows ChemicalCompany, Midland, MI) in 96.5 g a-terpineol (Laboratory Grade,Fisher Scientic, Hampton, NH) and heating to 90 1C underconstant stirring. Prior to preparing the inks, the frits were sievedto remove particlesX53mm. The pigments were used as received.Weighed portions of the pigment and frit were blended with thescreen-printing vehicle to produce inks with different solidloadings (350 vol%) and different pigment volume concentra-tions (060 vol%). All inks were passed through a three-roll mill(Exakt, 120S/303, Okalahoma City, OK) three times to dispersepigment particles and immediately printed to prevent sedimenta-tion.

Coatings were printed on 20 0 20 0 coupons of 321 stainless steelusing a screen printer (Engineering Technical Products, L-555)equipped with a 350 mesh screen (RIV Incorporated, Merrimack,NH) having a 4.8 cm4.8 cm print pattern and a black neoprenesqueegee (6070 Durometer). Printed samples were dried at 60 1Cfor 24h and red in a dental furnace (Whip Mixs Corp., Firelite,Louisville, KY) in air or in vacuum. A ramp rate of 50K/min to peaktemperature was followed by a 10min soak at peak temperatureand a 20K/min ramp down to room temperature.

Sample cross-sections were mounted in glass-lled thermo-setting epoxy, polished, and imaged for lm thickness, pigmentdispersion, and surface contour using scanning electron micro-scopy (SEM; FEI, Quanta 200F, Hillsboro, OR). The surfaceroughness of the samples was examined using an opticalinterferometer (ZYGO, NV5000 5200, Middleeld, CT).

Grazing-incidence X-ray diffraction (Siemens D-500) wasemployed to detect pigment decomposition and pigment dissolu-tion in post-red samples. Grazing-incidence XRD scans between101 and 701 2y were completed with Cu-Ka radiation. In situ high-temperature XRD was conducted on a 3:1 mixture of Ferro XG-201 frit and Ferro F6331-2 pigment with Co-Ka radiation. In situXRD scans (10701 2y) were completed from 10 to 810 1C at 100 1Csteps and from 810 to 910 1C at 10 1C steps using a ramp of 50K/min (Siemens thetatheta diffractometer with custom furnace).Scans were taken during cooling to determine if the startingspinel phase reformed.

Solar absorptance and thermal emittance were determinedfrom total reectance measurements. For the range 2002500nm,diffuse reectance (81-normal) was measured using a UVvisNIRspectrometer (Perkin Elmer, Lambda 900, Wellesley, MA) cali-brated with NIST-traceable Spectralon diffuse reectance stan-dards. For the range 250025,000nm (4000400 cm1), an FT-IRspectrometer (Thermo, FT-IR Nexus 6700, Waltham, MA)equipped with a gold-coated integrating sphere with a mercur-ycadmium-telluride (MCT) detector (Pike Tech., IntegratIR, 048-1040, Madison, WI) was used. At 2500nm, there was sometimes amismatch between the data collected using the two differentspectrometers. The mismatch was typically less than 5% offull scale, and the absorptivity measured using the FT-IR spectro-meter was typically lower than that measured using theUVvisNIR spectrometer. The FT-IR spectra were corrected byshifting them to match the UVvisNIR spectra at 2500nm. Solarabsorptance was calculated using a weighted integration overthe 121 selected point solar spectrum using global standardradiation [18]. Emissivity was extracted from the spectra assum-ing Kirchoffs Law. Thermal emittance was determined using aweighted integration over the Planck distribution for a specic

temperature.

-

3. Results

3.1. Commercial black porcelain-enamel coatings

Fig. 1 shows the thickness of black-enamel coatings (Ferro PL-214) printed on sandblasted stainless steel using six different inkswith solid loadings ranging from 5 to 50vol%. All coatings werered at 750 1C and exhibited good adhesion to the substrate. Forinks with solid loadings less than 30vol%, thickness increasedwith increasing solid loading. For solid loading greater than 30%,the thickness remained at 25mm and was governed by theproperties of the screen (emulsion thickness and screen mesh).The thinnest coatings followed the contour of the substrate andhad a measured surface roughness on the order of the coatingthickness, ca. 12mm. The 25mm thick coatings were smootherwith surface roughness of 0.25mm rms.

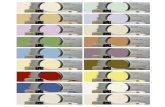

Fig. 2 shows the absorption spectra for the commercial black-enamel coatings. The absorptivity of the coatings is above 75%over the entire spectral range measured, leading to poor solarselectivity shown in Table 4. Common in all spectra is a strongabsorption peak at 8mm, which can be attributed to resonanceabsorption of SiO bonds in the silicate glass. Note that

volume concentration, i.e. 70% liquid vehicle, 21% glass frit, and 9%10456 pigment. Below 800nm, the coatings exhibit high (485%)and nearly constant absorption. Above 800nm, absorptiondecreases with increasing wavelength. For samples red below

ARTICLE IN PRESS

10000100060

80

%A

Wavelength (nm)

A) 10 vol. %B) 20 vol. %C) 30 vol. %D) 40 vol. %

A

B

Fig. 2. Absorption spectra of PL-214 commercial black enamel printed using inkswith different solid loadings.

Table 4Thickness and optical properties of PL-214 commercial black enamel coatings.

Solid loading (vol%) Thickness (mm) a e at 500 1C a/e

5 1.25 0.621

10 3.25 0.809 0.877 0.92

20 12.5 0.863 0.923 0.94

30 23.1 0.850 0.940 0.90

40 24.6 0.915 0.875 1.05

50 0.918

10000

10

20

30

40

50

60

70

80

90

100

%A

Wavelength (nm)

A) 600 CB) 650 CC) 700 CD) 750 CE) 800 CF) 850 CG) 900 C

A-G

Fig. 3. Absorption spectra of composite coating prepared with XG-201 frit and10456 pigment and processed at different temperatures. Both solid loading and

pigment volume concentration are 30%.

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 140414101406absorptivity values exceed 100% at this peak due to the way inwhich the FT-IR data were corrected to match with theUVvisNIR data at 2500nm, as discussed in the ExperimentalSection.

3.2. Composite porcelain-enamel coatings

Composite porcelain-enamel coatings were prepared using aclear glass frit (XG-201, Ferro Corp.) combined with three differentpigments, all of which are transition-metal-oxide spinels. Initialstudies were conducted with the 10456 pigment (Ferro Corp.) andprovided information about the appropriate processing conditionsfor the XG-201 matrix. Because the particle size of the 10456pigment prevented the deposition of very thin coatings, experi-ments aimed at understanding the effect of coating thicknesswere conducted with the F6331-2 pigment (Ferro Corp.)

Fig. 3 shows the effect of ring temperature on the absorptionspectra of composite enamel coatings prepared with 10456pigment and XG-201 glass frit. All coatings were printed withan ink containing 30vol% solids (Table 5) and 30vol% pigment

00

5

10

15

20

25

Ena

mel

Thi

ckne

ss (

m)

Ink Solids Loading (vol. %)

10 20 30 40 50

Fig. 1. Coating thickness of PL-214 commercial black-enamel coatings a as a

function of solid loading.100 DC700 1C, there was a signicant decrease in absorption at higher

-

wavelengths, suggesting some spectra selectivity, but the coatingsexhibited poor adhesion to the substrate because the ringtemperature was too low to soften the frit particles. As shownin Fig. 4, the microstructure of the underred coatings is very non-uniform, consisting of relatively large particles of unsoftened glassinterspersed with regions containing the spinel pigment em-bedded in a glass matrix presumably formed by softening thesmaller glass particles. Additional experiments, not reported indetail here, indicated that ring temperatures 4850 1C wererequired to ensure a good bond to the steel substrate.

Fig. 5 shows in situ high-temperature XRD patterns of the XG-201 frit mixed with the pigment in a 3:1 ratio with the F6331pigment. Data were collected at room temperature, at 100 1Cincrements between 110 and 810 1C, at 10 1C increments between810 and 910 1C, and then during cooling. The room temperaturepattern shows peaks consistent with the spinel-type structure of

ARTICLE IN PRESS

Table 5Thickness and optical properties of composite coatings.

Solid loading (vol%) PVC (vol%) Thickness (mm) a e at 500 1C a/e

30 0 22.3 0.859 0.774 1.11

3 18 0.9 0.824 0.463 1.78

5 18 3.2 0.867 0.553 1.57

7 18 6.3 0.871 0.570 1.53

10 18 5.3 0.899 0.707 1.27

20 18 12.6 0.899 0.757 1.19

30 18 21.3 0.902 0.790 1.14

5 5 2.3 0.830 0.529 1.57

5 10 0.851 0.629 1.35

5 15 0.899 0.627 1.43

5 20 0.888 0.596 1.49

5 25 0.904 0.635 1.42

5 30 0.90 0.641 1.40

5 60 0.89 0.755 1.18

Substrate

Frit

Pigment

b

Fig. 4. SEM micrograph of underred coating prepared with XG-201frit and 10456 pigment.

860 C

10 20 30Two-Th

25 C

810 C

910 C

25 C

cooling

Fig. 5. High-temperature X-ray diffraction patterns of a sample c

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 14041410 140740eta (deg)

50 60 70onsisting of a 3:1 ratio of XG-201 frit and F6331-2 pigment.

-

the pigment. When the temperature exceeded 860 1C, the spinelbegan to decompose, forming various oxides of copper, iron, andmanganese. When the sample was cooled, the spinel did notreform, indicating that heating above 860 1C would irreversiblydestroy the pigment. Thus, 850 1C was chosen as the processingtemperature for all coatings.

Table 5 summarizes the thickness and optical properties ofcomposite coatings made with F6331-2 pigment and XG-201 frit.Figs. 6 and 7 show the thickness and absorption spectra ofcoatings prepared with 18% PVC processed at 800 1C. Coatingthickness increases linearly with solid content, producing a20mm coating from inks with a solid content of 30vol%. Allof the coatings are spectrally selective and exhibit a region ofrelatively high constant absorption at low wavelengths followedby a region in which absorption generally decreases withincreasing wavelength. All of the coatings also show a strongabsorption band at around 8mm, which is attributed to theresonance absorption of the SiO bond in the glass frit. The

wavelength at which transition between the two regions occursdepends on coating thickness, i.e. the coatings are thickness-sensitive spectrally selective. For the thinnest coatings, thistransition occurs at 500nm. For the thickest coatings(20mm), this transition occurs at 1mm.

For the coatings prepared with 18% PVC, the solar absorptanceincreased with increasing thickness, ranging from 0.82 to 0.90 asshown in Table 4. The thermal emissivity (500 1C) also increasedwith increasing thickness, ranging from 0.46 to 0.79. Theselectivity of the coatings ranged from 1.14 for the thickestcoating to 1.78 for the thinnest.

Fig. 7 also illustrates the effect of substrate preparation on theoptical properties of the coatings. Both sandblasted and as-received steel substrates were coated using 10 vol% solids and 18%PVC. The coating on the sandblasted substrate had higherabsorption above 1mm, and thus higher thermal emittance.

A series of coatings was prepared on as-received substrateswith constant solid loadings (5 vol%) and a range of pigmentvolume concentration. Fig. 8 is a representative scanning electronmicrograph of the coatings, which were 23mm thick. As can beseen in the micrograph, coating thickness is relatively uniform.The large crack in the coating is thought to be an artifact of sample

ARTICLE IN PRESS

0

0

5

10

15

20

25

Ena

mel

Thi

ckne

ss (

m)

Ink Solids Loading (vol. %)5 10 15 20 25 30

Fig. 6. Thickness of coatings prepared with XG-201 frit and F6331-2 (PVC 18%)as a function of solid loading.

90

100A

B

D

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 1404141014081000010000

10

20

30

40

50

60

70

80

A) 30 vol. %B) 20 vol. %C) 10 vol. % on Untreated SteelD) 10 vol. % on Sandblasted SteelE) 7 vol. %F) 5 vol. %G) 3 vol. %

%A

Wavelength (nm)

CE

G

F

Fig. 7. Absorption spectra of composite coating prepared with XG-201 frit andF6331-2 pigment and different solid loadings. The pigment volume concentrationof all coatings is 18%.preparation as no cracks were observed on the surface of the as-prepared samples. The pigment particles (5% PVC for this sample)are not homogenously distributed throughout the coating butappear to reside near the substrate, which likely is a consequenceof particle segregation during printing and drying.

Fig. 9 shows the absorption spectra of the coatings preparedwith 5 vol% solids, and the corresponding optical properties aresummarized in the lower half of Table 5. The spectra are similar tothose shown in Fig. 7 in that they exhibit a region of relativelyhigh constant absorption at low wavelengths followed by a regionin which absorption generally decreases with increasing wave-length. The transition between the two regions depends onpigment concentration. For samples with 510% PVC, the transi-tion occurs at 400500nm. For samples with 1530% PVC, thetransition occurs around 9001000nm. The samples with 60%PVC show the transition around 2000nm. With the exception ofthe coating prepared with 60% PVC, the optical properties ofcoatings prepared with 5 vol% solids showed very little variationwith pigment volume concentration. Excluding the sampleprepared with 60% PVC, the solar absorptance of the coatings

Fig. 8. SEM micrograph of enamel coating prepared with XG-201 frit and F6331-2

pigment. The coating was prepared with 5 vol% solids and 18% PVC.

-

was heated at 450 1C in air for over 1200h. The spectra of the

thermal emittance of 0.2.Similar to the TSSS paint coatings, the performance of the

composite porcelain-enamel coatings was found to depend onpigment volume concentration and thickness. Similarly, we

ARTICLE IN PRESS

0.4

olar

C

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 14041410 1409sample before and after heating were essentially identical,indicating no notable degradation under expected operatingconditions. Glancing angle XRD of the coating after heatingshowed no evidence of decomposition of the spinel-type pigment.

4. Evaluation of composite porcelain-enamel coatings for solar-power applications

The solar-thermal conversion efciency of a simple solarwas 0.86774% and the thermal emittance at 500 1C was0.585710%. The highest selectivity, 1.57, was measured in thecoating prepared with the lowest PVC.

To test the stability of the composite coatings, a coated sample

100001000

40

50

60

70

80

90

100

E,FG

CBD

%A

Wavelength (nm)

A) PVC=5%B) PVC=10%C) PVC=15%D) PVC=20%E) PVC=25%F) PVC=30%G) PVC=60%

A

Fig. 9. Absorption spectra of composite coating prepared with XG-201 frit andF6331-2 pigment and with 5 vol% solid loading.concentrator system is given as

Z xasS tsT4

xS as

tsT4

xS(1)

where Z is the solar conversion efciency, x the solar concentra-tion factor, S the total solar-energy ux (960Wm2), as the solarabsorptance, et the thermal emittance, s the StefanBoltzmannconstant (5.6696108Wm2 K4), and T the absolute tempera-ture [1]. Fig. 10 compares the efciency of the two types ofcoatings examined in this study to that of the bare 321 stainless-steel substrates at 500 1C. Also shown in the plot is the efciencyof a hypothetical coating with solar absorption and thermalemittance values comparable to those reported for state-of-the-art solar-selective coatings, i.e. a 0.95 and e 0.05.

The efciency of the composite XG-201/F6331-2 coatingdeveloped in this study, which are moderately solar selective, issubstantially lower than that of state-of-the-art vacuum-depos-ited coatings. Nevertheless, the composite enamel coating isclearly more efcient than the commercial black-enamel coating.For concentration factors of 30, the composite XG-201/F6331-2coating is predicted to be twice as efcient (40% vs. 20%) as thecommercial black porcelain-enamel coatings (PL-214). For higherconcentration factors, the improvement is less dramatic.

The composite coatings investigated in this study are similar tothe thickness-sensitive solar-selective paints reported by Orel andco-workers [316] in that they consist of black pigment particlesimbedded in a matrix. In this case of our composite coatings, thematrix is a glass whereas the paints have an organic or siliconematrix. The performance of paint coatings is dependent onpigment volume concentration, coating thickness, particle disper-sion, substrate selection, and application technique. As a point ofcomparison, some of the best performing paint coatings onaluminum substrates have a solar absorptance X0.9 and a

0Concentration Factor, x

0.1

0.2

0.3S

321 Stainless SteelPL-214 Black EnamelXG-201/F6331-2 CompositeHypothetical coating (/ = 0.95/0.05)

20 40 60 80 100

Fig. 10. Solar conversion efciency of the two enamel coatings compared to as-received 321 stainless steel and a hypothetical solar-selective coating with a and ebeing 0.95 and 0.05, respectively.0.5

0.6

0.7

0.8

0.9

1

onve

rsio

n E

ffici

ency

, anticipate that improved performance may be possible withimprovements in particle distribution and dispersion as well aswith alternative deposition methods.

One of the factors that is expected to limit the ultimateselectivity of the composite coatings is the strong multi-phononabsorption band around 8mm. Unfortunately, the elimination ofthis absorption band it not feasible for porcelain-enamel coatingas most, if not all, porcelain enamels are based on borosilicateglasses.

5. Conclusions

Composite porcelain-enamel coatings consisting of spinel-typetransition-metal-oxide pigments embedded in a borosilicate-glassmatrix were deposited on 321 stainless-steel substrates. Coatingswith different thicknesses and different pigment volume concen-trations were prepared, characterized, and compared with thecommercial black porcelain-enamel coatings. The compositeporcelain-enamel coatings exhibited moderate solar selectivityand excellent thermal stability. While it may be possible toimprove the solar selectivity of the composite coatings withimproved processing, the performance of the coatings will belimited, in part, by a strong absorption band associated with SiObonds at 8mm.

-

Acknowledgements

Although the research described in this article has been fundedwholly or in part by the United States Environmental ProtectionAgency through Grant/Cooperative Agreement X83254101-0 toAlfred University, it has not been subjected to the Agencysrequired peer and policy review and therefore does not necessa-rily reect the views of the agency and no ofcial endorsementshould be inferred.

References

[1] R.A. Buhrman, H.G. Craighead, Composite lm selective-absorbers, in: L.E.Murr (Ed.), Solar Materials Science, Academic Press, New York, 1980, pp.277317.

[2] C.E. Kennedy, Review of mid- to high-temperature solar selective absorbermaterials, Technical Report NREL/TP-520-31267, National Renewable EnergyLaboratory, Golden, CO, July 2002.

[3] Z.C. Orel, M.K. Gunde, Spectrally selective paint coatings: preparation andcharacterization, Sol. Energy Mater. 68 (34) (2001) 337353.

[4] T. Tesfamichael, A. Hoel, E. Wackelgard, G.A. Niklasson, M.K. Gunde, Z.C. Orel,Optical characterization and modeling of black pigments used in thickness-sensitive solar-selective absorbing paints, Sol. Energy 69 (Suppl. 6) (2001) 3543.

[5] Z.C. Orel, N. Leskovsek, B. Orel, M.G. Hutchins, Spectrally selective siliconpaint coatings: inuence of pigment volume concentration ratio on theiroptical properties, Sol. Energy Mater. 40 (3) (1996) 197204.

[6] Z.C. Orel, M.K. Gunde, B. Orel, Application of the KubelkaMunk theory for thedetermination of the optical properties of solar absorbing paints, Prog. Org.Coatings 30 (12) (1997) 5966.

[7] Z.C. Orel, M.K. Gunde, M.G. Hutchins, Spectrally selective solar absorbers indifferent non-black colours, Sol. Energy Mater. 85 (1) (2005) 4150.

[8] Z.C. Orel, M.K. Gunde, Spectral selectivity of black and green painted surfaces,Sol. Energy Mater. 61 (4) (2000) 445450.

[9] B. Orel, Z.C. Orel, R. Jerman, I. Radoczy, Coil-coating paints for solar collectorpanels [II]FTIR spectroscopic investigations, Sol. Wind Technol. 7 (6) (1990)713717.

[10] B. Orel, Z.C. Orel, M. Bosanac, A. Krainer, Coil-Coating paints for solar collectorpanels [I]characterization and performance tests, Sol. Wind Technol. 7 (6)(1990) 699705.

[11] B. Orel, Z.C. Orel, I. Radoczy, Thickness sensitive spectrally selective(TSSS) paint for solar collectors: optical properties, surface characteri-zation and application properties, Sol. Energy Mater. 18 (12) (1988)97107.

[12] B. Orel, Z.C. Orel, A. Krainer, M.G. Hutchins, FTIR spectroscopic investigationsand the thermal stability of thickness sensitive spectrally selective (TSSS)paint coatings, Sol. Energy Mater. 22 (4) (1991) 259279.

[13] M.K. Gunde, J.K. Logar, Z.C. Orel, B. Orel, Optimum thickness determination tomaximise the spectral selectivity of black pigmented coatings for solarcollectors, Thin Solid Films 277 (12) (1996) 185191.

[14] Z.C. Orel, Characterisation of high-temperature-resistant spectrally selectivepaints for solar absorbers, Sol. Energy Mater. 57 (3) (1999) 291301.

[15] Z.C. Orel, M.K. Gunde, A. Lencek, N. Benz, The preparation and testing ofspectrally selective paints on different substrates for solar absorbers, Sol.Energy 69 (Suppl. 6) (2001) 131135.

[16] Z.C. Orel, B. Orel, M.K. Gunde, Spectrally selective SnO2: F lm on glass andblack enamelled steel substrates: spray pyrolytical deposition and opticalproperties, Sol. Energy Mater. 26 (12) (1992) 105116.

[17] F. Simonis, A.J. Faber, C.J. Hoogendoorn, Porcelain enamelled absorbers, coatedby spectral selective tin oxide, J. Sol. Energy Eng. 109 (1) (1987) 2225.

[18] Standard tables for terrestrial solar spectral irradiance at air mass 1.5 for a 371tilted surface, ASTM Designation E 892-87, American Society for Testing andMaterials, West Conshokocken, PA.

ARTICLE IN PRESS

H.J. Brown-Shaklee et al. / Solar Energy Materials & Solar Cells 93 (2009) 140414101410

Spectral selectivity of composite enamel coatings on 321 stainless steelIntroductionExperimentalResultsCommercial black porcelain-enamel coatingsComposite porcelain-enamel coatings

Evaluation of composite porcelain-enamel coatings for solar-power applicationsConclusionsAcknowledgementsReferences