Specifications Almost Ready-To-Fly€¦ · ARF (Almost Ready-To-Fly) kit. This aircraft was...

Transcript of Specifications Almost Ready-To-Fly€¦ · ARF (Almost Ready-To-Fly) kit. This aircraft was...

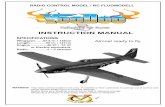

SpecificationsWingspan: . . . . . . 63 in (1600 mm)Length: . . . . . . . 52.5 in (1334 mm)Wing Area: . 710 sq in (45.8 sq dm)Weight: . . . . . 5–6 lb (2.27–2.72 kg)

ASSEMBLY MANUAL

Almost Ready-To-Fly

2

Table of Contents

Introduction ............................................................................ 2Warning ............................................................................ 2Contents of Kit .......................................................................... 3Additional Required Equipment ................................................ 3Additional Required Adhesives and Tools ................................ 4 Required Field Equipment ........................................................ 4Other Items Needed .................................................................. 4Section 1: Hinging the Ailerons ............................................ 5Section 2: Joining the Wing Halves ...................................... 7Section 3: Installing the Aileron Servo Tray .......................... 9Section 4: Installing the Aileron Servo and Linkages .......... 11Section 5: Installing the Landing Gear & Wheels ................ 13Section 6: Installing the Horizontal and

Vertical Stabilizer................................................ 15

Section 7: Hinging the Elevator and Rudder ........................ 18Section 8: Installing the Elevator and

Rudder Control Horns ........................................ 20Section 9: Assembling the Fuel Tank .................................. 22Section 10: Mounting the Engine .......................................... 24Section 11: Installing the Radio System ................................25Section 12: Installing the Rudder, Elevator and

Throttle Linkage.................................................. 27Section 13: Installing the Spinner and Propeller .................. 30Section 14: Balancing and Control Throw

Recommendations.............................................. 32 Preflight Checks at the Field .................................................. 33Flying Your Alpha Trainer........................................................ 33AMA Safety Code.................................................................... 34

Introduction

Congratulations on your purchase of the Hangar 9® Alpha TrainerARF (Almost Ready-To-Fly) kit. This aircraft was designed withthe beginning modeler in mind. It is an ideal trainer for thenovice pilot with gentle and forgiving flight characteristics. Onceyou have some flight time under your belt, you can put yourAlpha through some basic aerobatics; rolls and loops are smoothand graceful. The Alpha Trainer ARF kit also includes largewheels to make ground handling easy, whether your flying fieldhas a paved runway or grass. And the Alpha Trainer ARF comesout of the box 90% prebuilt and will have you out at the flyingfield in only a few, short evenings.

Care has been taken to write a manual that will guide youthrough the assembly of your aircraft. It is important to carefullyread through the instructions before beginning the assembly ofyour aircraft. If you encounter difficulty in any constructionsequence, please feel free to contact one of our technicians—we stand ready to provide any assistance we can concerning theconstruction of your Hangar 9 Alpha Trainer ARF. Contact us at:

Horizon Hobby4105 Fieldstone Road

Champaign, Illinois 61822(217) 355-9511

www.horizonhobby.com

Warning

An R/C aircraft is not a toy; it can cause serious bodily harm and damage to property. Fly only in open areas, preferably

AMA (Academy of Model Aeronautics) approved flying sites, following all instructions included with your radio and engine.

3

Contents of Kit

Large Partsa. Fuselage (HAN2452)b. Wing Set with Joiner (HAN2451)c. Tail Set (HAN2453) d. Pushrodse. Landing Gear Set (HAN2454)

Small Parts1. Fuel Tank (HAN2479)2. Engine Mount and Hardware3. Wheel Collars4. Clevises and Wire Keepers5. Control Horns and Hardware6. CA Hinges 7. Aileron Servo Mount8. Decal Set (HAN2455) (not pictured)

Additional Required Equipment

• 4-channel radio (minimum) • 4 standard servos (JRP5527)• Engine .40–.48 2-cycle

.50–.72 4-cycle• Standard 650mAh receiver battery

Recommended Radio Systems• J-Line Quattro • JR XF421• JR XF631• JR XP652• JR XP662• JR X-378• JR XP8103

Recommended Engines2-cycle

• Evolution Trainer Power System• MDS™ .40 FS Pro • MDS .48 FS Pro • Webra™ .50GT

4-cycle• Saito FA-50• Saito FA-56• Saito FA-65• Saito FA-72

J-Line Quattro

Evolution TrainerPower System

a

bc

d

e

1

2

3

4

56

7

4

Additional Required Adhesives and Tools

Adhesives• CA (cyanoacrylate) Glue: thick and thin• CA remover/debonder• 6-minute epoxy • 30-minute epoxy• Threadlock (Pacer Z42)

Tools • Hobby knife w/#11 blade• Drill • Drill Bits: 1/16”• Phillips screwdriver• Pliers

Other• Measuring device (e.g. ruler, tape measure)• Straight edge• Epoxy brushes• Mixing sticks• Rubbing alcohol• Paper towels• Wax paper• Masking tape• Felt-tipped pen/pencil • RC foam

Required Field Equipment

The following are included in the Hangar 9® Start-Up Field Accessory pack (HANSTART)• Sturdy cardboard construction tote box • Manual fuel pump • Two Hangar 9 glow plugs • 4-way wrench • Rechargeable glow driver with charger • Chicken stick

Other Items Needed (Not included in Start-Up Field Accessory pack)• Fuel, 10 to 15% nitro content (Cool Power or Powermaster recommended)• Electric Starter w/12V battery (optional)

5

Section 1: Hinging the Ailerons

Parts Needed• Right wing panel w/aileron• Left wing panel w/aileron• CA hinges (8)

Tools and Adhesives Needed• Thin CA• CA remover/debonder• 6-minute epoxy• Masking tape• T-pins• Rubbing alcohol• Paper towels

Note: The photos and instructions in this section are for the right wing panel. Repeat the same steps to hinge the aileron on the left wing panel.

Step 1 Locate the right wing panel and remove the aileron. Note that theleading edge of the aileron has a hole at one end that slides ontothe aileron torque rod already installed in the wing panel.

Step 2 Locate the CA hinges required for the aileron. Place a T-pin in thecenter of each hinge and slide them into the precut hinge slots ofthe wings trailing edge as shown.

Step 3 Trial fit the aileron to the wing; make sure there is no more than1/32" gap along the hinge line. Once satisfied with the fit, removethe aileron.

Step 4 Mix approximately 1/4 ounce of 6-minute epoxy. Using a tooth-pick, apply the epoxy to the inside of the hole in the aileron. Slidethe aileron onto the torque rod and hinges, being careful not toget any epoxy into the torque rod tube. Wipe away any excessepoxy with rubbing alcohol and paper towels. Remove the T-pinsand push the aileron completely against the wing trailing edge. Use masking tape to hold the aileron in place until the epoxycompletely cures.

6

Section 1: Hinging the Ailerons

Note: The hinges supplied with your Alpha™ Trainer ARF are constructed of a special material that allows the thin CA to “wick” or penetrate and distribute throughout the hinge, securely bonding them to the wood structure. It isimportant that you properly secure the hinges in place perthese instructions using high-quality thin CA glue.

Step 5 Once the epoxy has cured, check the aileron for freedom of movement. Fully defect the aileron down and using thin CA saturate each hinge. Turn the wing panel over and repeat theprocess saturating the hinges again from the other side. Use CA remover/debonder and a paper towel to remove any excessCA along the hinge line.

Step 6 Hinge the opposite wing panel and aileron by repeating Steps 2–5.

Step 7 When the CA has completely dried, test the ailerons for security.Firmly grasp the wing and aileron and using medium pressure tryto separate the aileron from the wing. Use caution not to crush thewing structure.

Continued

Section 2: Joining the Wing Halves

7

Parts Needed• Right and left wing halves• Wing joiner

Tools and Adhesives Needed• 30-minute epoxy• Ruler • Felt-tipped pen or pencil• Rubbing alcohol• Paper towels• Wax paper

Step 1Locate the wing joiner. Using a ruler and felt-tipped pen or pencil,measure and mark the exact center of the joiner as shown.

Step 2Trial fit the wing joiner into one of the wing panels. It shouldinsert smoothly up to the line marked in Step 1. If the fit is tootight, it may be necessary to lightly sand the wing joiner. Carefullyslide the other wing panel onto the joiner until the two panelsmeet. The wing panels should fit together with no gaps on eitherthe top or the bottom of the wing.

Step 3Use masking tape to hold the wing halves together while youcheck for the correct dihedral angle. Place the wing on a large flatsurface, with one wing panel resting flat on the surface the tip ofthe opposite wing panel should be 5" from the flat surface. Whenyou are satisfied with the dihedral, separate the wings and removethe joiner.

Note: Read through the remaining steps of this section before proceeding to glue the wing panels together.

Hint: It is extremely important to use plenty of epoxy whenjoining the wing panels together. It will also be helpful to use wax paper under the wing center joint to avoid gluing the wing to your worktop.

Step 4Mix approximately 1 ounce of 30-minute epoxy. Using an epoxybrush, apply a generous amount of epoxy to the wing joiner cavityof one wing panel.

Step 5Completely coat one half of the wing joiner with epoxy up to themark made in Step 1. Insert the epoxy coated side of the joinerinto the joiner cavity up to the mark.

5"

8

Section 2: Joining the Wing HalvesContinued

Step 6Apply a generous amount of epoxy to the other wing panel joiner cavity.

Step 7Apply epoxy to the exposed portion of the wing joiner and to bothwing roots and carefully slide both wing panels together. Firmlypress both halves together allowing the epoxy to run out. Usingalcohol and paper towels, wipe off the excess epoxy. Check tomake sure there are no visible gaps between the two wing panels.

Step 8Use masking tape to securely hold both wing halves together.Place the wing assembly back onto the flat work surface (coveredwith wax paper) and check the dihedral again as in Step 3.

Step 9Double-check the wing center joint for any gaps and allow theepoxy to cure.

9

Section 3: Installing the Aileron Servo Tray

Parts Needed• Completed wing• Plywood servo tray• Wood servo rails• Aileron servo w/mounting hardware

Tools and Adhesives Needed• 6-minute epoxy• Thick CA• Hobby knife

Step 1Locate the servo tray and two servo mount rails (3/8"x 2"). Usingthick CA, glue the servo rails to the servo tray as shown. Thebeveled edge of the rails should form a “V” to allow the tray tomount to the bottom of the wing. Allow the CA to dry.

Step 2Install the mounting hardware (rubber grommets and brass eyelets)supplied with your radio system on to the aileron servo.Temporarily install the aileron servo on the servo tray as shownand test fit the entire assembly to the wing. Make sure the servooutput shaft is oriented towards the trailing edge of the wing.

Note: It may be necessary to trim away some of the sheetingon the bottom of the wing to allow the servo to slide down into the opening. Using a sharp hobby knife, carefully trim only a small amount at a time.

10

Section 3: Installing the Aileron Servo TrayContinued

Step 3Use a felt-tipped pen or pencil to trace the outline of servo trayonto the bottom of the wing. Remove the servo and servo tray.Using a sharp hobby knife, cut away the covering along the lineyou just traced.

Caution: Only cut deep enough to cut the covering. Do not cut into the wood sheeting underneath.

Step 4Mix a small amount of 6-minute epoxy (approximately 1/4 ounce)and coat both the bare wood of the wing and the servo tray rails.Position the servo tray on the wing and secure it with maskingtape and allow the epoxy to fully cure.

11

Section 4: Installing the Aileron Servoand Linkages

Parts Needed• Wing assembly• Aileron servo • Aileron mounting screws (4)• Aileron control wire (2)• Nylon clevis w/keeper (2)• Wire keeper (2)• Nylon horn bracket (2)

Tools and Adhesives Needed• Thin CA • Drill • Drill Bit: 1/16"• Small Phillips screwdriver• Pliers• Felt-tipped pen• Ruler

Step 1Temporarily install the aileron servo into the wing oriented asshown. Using a felt-tipped pen, mark the location of the servomounting screws. Remove the servo from the wing.

Step 2Using a 1/16" drill bit, drill the four locations marked in the previousstep for the mounting screws. Drill all the way through the servotray and wing sheeting. To strengthen the screw holes, place adrop of thin CA into each hole and allow the CA to dry.

Step 3Install the aileron servo and secure it to the wing using themounting screws provided with your radio system. Use cautionwhen installing the screws as not to contact the servo wire.

Step 4Locate the nylon horn brackets and thread them onto the ailerontorque rods until the torque rod just begins to come through thebracket as shown.

Step 5Locate the aileron control wires (2) and clevises with keepers (2).Thread a clevis onto each wire a minimum of 12 turns and connectthe clevises to the aileron horn brackets.

12

Section 4: Installing the Aileron Servoand Linkages

Continued

Step 6Install an “X” servo arm onto the aileron servo as shown. Youshould clip off the shorter arms so they will not interfere with thecontrol wires. Position the servo arm so it is parallel with thetrailing edge of the wing.

Step 7Use masking tape to hold the ailerons in their neutral position,(even with the wings trailing edge). With the aileron servo arm atneutral (parallel to the trailing edge of the wing), lay the aileroncontrol wires across the outer most hole and mark the wire with afelt-tipped pen.

Step 8Remove the control wires you just marked and make a 90-degree(“L”) bend at the mark. Cut off the excess wire 5/16" past the bend.

Step 9Install the control wires back onto the horn brackets and slide the L-bend of the wires into the servo arm. Secure the aileron controlwire L- bends with the wire keepers as shown.

13

Section 5: Installing the Landing Gearand Wheels

Parts Needed• Main landing gear wire (2)• Nose landing gear wire• 23/4" main wheel (2)• 21/2" nose wheel• Large wheel collar w/setscrew (6)• Nylon nose wheel steering block w/arm• Nylon landing gear strap w/1/2" wood screws

Tools and Adhesives Needed• Threadlock• Phillips screwdriver• Drill • Drill Bit: 1/16"

Step 1Locate the main landing gear wires (2) hold down straps (2) andmounting screws (4) provided in your kit.

Step 2Locate the main landing gear mounting location on the undersideof the fuselage and insert the wires into the predrilled holes asshown. Note that the wires lay side by side in the precut groove inthe landing gear block.

Step 3Locate the mounting screw holes drilled on either side of thelanding gear wires. Secure the main landing gear wires using thestraps and the 1/2" wood screws provided with your model.

Step 4Locate the two main wheels (23/4") and 4 wheel collarsw/setscrew. Slide a wheel collar onto each axle approximately 1"and tighten the setscrew, next slide the wheel on and then anotherwheel collar. Adjust the collars so that the wheel spins freely.

Note: Use Threadlock on each setscrew to prevent the wheels from falling off in flight.

14

Section 5: Installing the Landing Gearand Wheels

Continued

Step 5Locate the nose wheel steering block. Mount the steering block tothe firewall of the fuselage as shown.

Step 6Slide the nose gear wire through the steering block and steeringarm as shown and tighten the setscrew on the steering arm tosecure the nose gear. You want the setscrew to tighten against theflat ground into the nose gear wire.

Step 7Install the 21/2" nose wheel using two wheel collars as you did forthe main wheels in Step 6 centering the wheel on the axle.

15

Section 6: Installing the Horizontal andVertical Stabilizer

Parts Needed• Fuselage assembly• Wing assembly• Horizontal stabilizer• Vertical stabilizer

Tools and Adhesives Needed• 30-minute epoxy • Hobby knife• 90-degree square• Tape measure• Masking tape• Rubbing alcohol• Paper towels

Step 1Locate the horizontal stabilizer and elevator assembly and removethe elevator. Use a felt-tipped pen/pencil and ruler to mark thecenter of the stabilizer at the trailing edge as shown. Using a triangle, extend the center mark forward to the leading edge of the stabilizer. Make sure the line is 90 degrees to the trailing edgeof the stabilizer.

Step 2Mark the center of the stabilizer saddle at the trailing edge of thesaddle as shown.

Step 3Lay the horizontal stabilizer on the saddle and align the rear markof the stabilizer with the mark on the saddle. Align the front of thestabilizer with in the middle of the opening for the vertical fin.Once you are satisfied with the alignment, carefully place a coupleof T-pins through the stabilizer and the saddle.

16

Section 6: Installing the Horizontal andVertical Stabilizer

Continued

Step 4With the horizontal stabilizer properly aligned, use a felt-tippedpen or pencil to carefully mark the bottom of the stabilizer whereit meets the fuselage.

Step 5Remove the stabilizer. Using a sharp hobby knife, carefullyremove the covering from the center of the stabilizer, cutting 1/8"inside the lines you marked in the previous step. Use only enoughpressure to cut the covering and not the wood underneath, as doingso will severely weaken the structure of the horizontal stabilizer.

Step 6Before gluing the horizontal stabilizer in place, reposition the stabilizer onto the stabilizer saddle. Use the lines drawn in Step 4to reposition the stab correctly. Using a 90-degree square, makesure the stabilizer is square to the fuselage as shown. Make anyadjustment needed by sanding the stabilizer saddle until theproper alignment is achieved. Remove the horizontal stabilizerfrom the fuselage.

Step 7Mix at least 1/ 2 ounce of 30-minute epoxy and coat the horizontalstabilizer saddle and stabilizer center section.

Step 8Lay the horizontal stabilizer onto the saddle, lining up the centermark of the stabilizer with the rear of the saddle and the openingfor the vertical fin. Wipe away any excess epoxy with rubbingalcohol and paper towels.

Step 9Use masking tape to hold the stabilizer in place as the epoxycures. Allow the glue to cure before moving on to Step 10.

17

Section 6: Installing the Horizontal andVertical Stabilizer

Continued

Step 10Locate the vertical fin and rudder assembly. Remove the rudderand test fit the vertical fin in place. Make sure the rear of the finsits flat on the forward portion of the stabilizer. Once satisfied, usea felt-tipped pen to mark the fin where it inserts into the fuselage.Also mark the top of the stabilizer where the fin contacts.

Step 11Remove the fin and use a sharp hobby knife to remove the coveringwhere the fin inserts into the fuselage, cutting 1/16" inside thelines you drew in the previous step. Also cut away the coveringon top of the horizontal stabilizer, 1/16" inside the lines. Use onlyenough pressure to cut the covering not the wood underneath.Re-install the fin into the fuselage to check the fit.

Step 12Mix at least 1/2 ounce of 30-minute epoxy and coat the verticalfin where it meets the fuselage and stabilizer. Also coat the fin slotin the fuselage.

Step 13Insert the fin into the fuselage and wipe away any excess epoxyusing rubbing alcohol and a paper towel. Make sure the fin is 90 degrees to the stabilizer as shown.

Step 14Use masking tape to hold the fin in place as the epoxy cures.Allow the epoxy to cure before hinging the rudder.

18

Section 7: Hinging the Elevator and Rudder

Parts Needed• Fuselage assembly• Elevator• Rudder• Hinges (7)

Tools and Adhesives Needed•Thin CA• CA remover/debonder• T-pins• Rubbing alcohol• Paper towels

Caution: The hinges included with the Alpha™ Trainer ARF are made of a special material that allows the thin CA to “wick” or penetrate and distribute throughout the hinge, securely bonding them to the wood structure. It isimperative that you properly secure the hinges in place perthese instructions using high quality thin CA glue.

Step 1Locate the four elevator hinges, place a T-pin in the center of eachhinge and slide them into the horizontal stabilizer until the T-pinis snug against the trailing edge as shown.

Step 2Install the elevator onto the hinges. Remove the T-pins and pushthe elevator up against the stabilizer until there is only a slightgap (1/32" or less) at the hinge line.

Step 3Using high-quality thin CA glue, deflect the elevator down andcompletely saturate each hinge.

Step 4Turn the fuselage over and repeat the hinge-gluing process bydeflecting the elevator in the opposite direction and again completely saturating each hinge with thin CA. Wipe away anyexcess CA with CA remover/debonder and a paper towel. Allowthe CA to completely dry.

Step 5Once the CA has dried, check the hinges for security by trying topull the elevator from the stabilizer. Use only slight pressure andbe sure not to crush the wood structure of the stabilizer or elevator.

19

Section 7: Hinging the Elevator and Rudder

Step 6Install the three rudder hinges as you did for the elevator placinga T-pin through the center of each hinge to keep it centered whileinstalling the rudder. Install the rudder and remove the T-pins andpush the rudder against fin until there is only a slight gap (1/32"or less). Deflect the rudder in one direction and using high qualitythin CA glue completely saturate each hinge.

Step 7Deflect the rudder in the opposite direction and again saturateeach hinge with thin CA. Using CA remover/debonder wipe offany excess CA on the rudder hinge line. Allow the CA to dry.

Step 8Once the CA has completely dried, check the rudder for securityby trying to pull the rudder from the fuselage. Use only enoughpressure to test for security and be careful not to damage thewood structure of the rudder or fin.

Continued

20

Section 8: Installing the Elevator andRudder Control Horns

Parts Needed• Fuselage assembly• Control horn w/back plate (2)• Mounting screws (6)

Tools and Adhesives Needed• Drill • Drill Bit: 1/16"• Felt-tipped pen or pencil

Important: When installing the control horns, it’s important that the holes in the control horns where the pushrod attaches are directly in line with the control surface hinge line.

Step 1To locate the elevator control horn position, measure the centerbottom of the elevator. Mark the elevator as shown with a felt-tipped pen or a pencil. This mark will be the center of the elevatorcontrol horn location.

Step 2Place the center of the control horn on the elevator at the markmade in the previous step. Align the holes in the control with thehinge line as noted above. Mark the mounting holes of the controlhorn with a felt-tipped pen or pencil.

Step 3Drill 1/16" holes through the elevator as marked. Make sure todrill these holes parallel to each other to allow the back plate ofthe horn to fit properly.

Step 4Using the three screws and the back plate provided, attach theelevator control horn and fasten in place with a Phillips screwdriver.

21

Section 8: Installing the Elevator andRudder Control Horns

Continued

Step 5Measure 3/4" up from the bottom of the rudder on the left side.Mark the location with a felt-tipped pen or pencil. This mark willserve as the center for the rudder control horn.

Step 6Center the control horn over the mark you’ve just made and paral-lel to the horizontal stabilizer as shown. Make sure the horn ispositioned over the hinge line, just like you did for the elevator.Mark the mounting screw hole locations on the rudder.

Step 7Using a 1/16" drill bit, drill the mounting screw holes on themarks made in the previous step and install the rudder controlhorn, using the three screws and back plate provided.

22

Section 9: Assembling the Fuel Tank

Parts Needed• Metal tubes (2)• Clunk (fuel pickup)• Fuel pickup tubing• Fuel tank• Metal caps (2)• Rubber stopper• 3mm screw

Tools and Adhesives Needed• Hobby knife• Medium screwdriver

Step 1Locate the tank parts.

Note: The stopper provided with the Alpha Trainer has three holes that are not bore completely through the stopper.You will only be using two holes: one for the fuel pickup and one for the fuel vent. Make sure not to open the third hole, as this will cause a fuel leak.

Step 2Locate the rubber stopper. Insert the short straight metal fuel tubeinto one of the holes in the stopper so that an equal amount oftube extends from each side of the stopper. This tube will be thefuel tank pickup that provides fuel to the engine.

Step 3Slide the smaller of the two caps over the tube on the smaller endof the rubber stopper. The small end will be inserted into the fueltank. The larger cap is placed on the other side of the rubberstopper that makes the cap.

Step 4Locate the other metal fuel tube with the Bend in it. This will bethe fuel tank vent tube. Slide the vent tube into one of the tworemaining holes in the stopper from the tank (small cap) side.Loosely install the 3mm screw as shown.

Step 5Locate the short piece of silicone fuel tubing and the fuel tank clunk.Install the clunk onto one end of the silicone tubing and the otherend onto the fuel tank pickup tube (straight tube) in the stopper.

23

Section 9: Assembling the Fuel TankContinued

Step 6Carefully insert the assembly into the fuel tank. Note the positionof the vent tube. It must be at the top portion of the fuel tank tofunction properly. Also, it may be necessary to shorten the lengthof the fuel pickup tubing to ensure the clunk does not rub againstthe back of the fuel tank. You should be able to turn the tankupside down, which allows the clunk to freely drop to the top ofthe tank.

Step 7Tighten the 3mm screw carefully—do not over tighten. Thisallows the rubber stopper to form a seal by being slightly compressed, thus sealing the fuel tank opening.

Step 8Locate the two pieces of fuel tubing (red and green). Install thered tubing onto the fuel pickup tube (the short strait tube) andinstall the green tubing onto the tank vent tube (the bent tubegoing to the top of the tank).

Step 9Install the tank into the front of the fuselage with the fuel tubingcoming through the hole in the firewall.

Note: The tank will be secured in place after the radio installation.

24

Section 10: Mounting the Engine

Parts Needed• Fuselage assembly• Engine mount w/hardware• Propeller• Spinner

Tools and Adhesives Needed• Phillips screwdriver• Threadlock

Step 1Locate the supplied engine mount and mounting hardware [8-32 x 3/4" screw (4), 8-32 x 1" screw (4), 8-32 locknuts (4), #8 washers (4)].

Step 2Using the 8-32 x 3/4" screws and preinstalled T-nuts, secure theengine mount to the firewall of the Alpha. Use Threadlock on thescrews to prevent them from coming loose during flight.

Step 3Place the engine centered between the beams of the engine mountand using the metal clamps, 8-32 x 1" screws, locknuts and #8 washers secure the engine in place. Be sure the nuts are captured in the bottom of the engine mount.

Step 4Install the muffler onto your engine, using the hardware suppliedwith your engine.

Step 5Connect the fuel pickup line (red) to the carburetor nipple andconnect the vent/pressure line (green) to the pressure nipple onthe muffler.

Note: The spinner and propeller will be installed in Section 13.

(Step 3 Photo)

(Step 3 Photo)

25

Section 11: Installing the Radio

Parts Needed• Fuselage assembly• Receiver• Receiver battery• Standard servos (3)• RC foam• 12" servo lead

Tools and Adhesives Needed• Phillips screwdriver• Hobby knife w/#11 blade• Drill• Drill Bit: 1/16"

Step 1Install the mounting hardware (rubber grommets and brass eyelets)supplied with your radio system on to the elevator, rudder andthrottle servos.

Step 2Mount the servos into the servo tray of the fuselage as shown. Securethe servos with the mounting screws provided with your radio system.

Step 3Mount the battery switch to the left side of the fuselage as shown.

Step 4Using RC foam, cut three layers of foam the size of the receivercompartment (approximately 41/2" by 31/4"). Trace the outline ofyour receiver and receiver battery pack onto one layer and cutthem out using a sharp hobby knife.

Step 5Place one layer of foam in the fuselage and then the cut layer.Connect the servos to the receiver in the appropriate channel.Also connect a 12" servo lead into the aileron channel, this willallow easy removal and installation on the wing. Run the receiverantenna down the tube installed in the right side of the fuselage.

26

Section 11: Installing the Radio Continued

Step 6Place the third layer over the receiver and battery pack, leavingthe aileron servo lead free. Locate the plywood radio compartmentcover and slide it into the fuselage until it contacts the back of thefuel tank.

Step 7Drill a 1/16" pilot hole through the cover and into the post in thefuselage. Secure the cover with the screw provided in the AlphaARF kit. (Step 7 Photo)

(Step 7 Photo)

27

Section 12: Installing the Rudder,Elevator and Throttle Linkage

Parts Needed• Fuselage assembly• Nylon clevis w/clevis keepers (3)• L-bend keepers (3)• Easy connector• Control wires (4)

- 283/4" threaded on one end ............ Elevator- 251/2" threaded on one end ............ Rudder- 20" threaded on one end ................ Throttle- 173/4" no threads ............................ Nose wheel steering

Tools and Adhesives Needed• Pliers• Side cutters• Z-bend pliers• Phillips screwdriver • Felt-tipped pen/pencil

Step 1Locate the three control wires threaded on one end and threenylon clevises with clevis keepers. Thread a clevis onto thethreaded end of each control wire with the keeper in place asshown. Thread each clevis on a minimum of 12 turns.

Step 2Looking at the rear of the fuselage locate the pre-installed elevatorcontrol wire tube. Slide the elevator control wire (283/4") throughthe tube and connect the clevis to the elevator control horn.

Step 3With the elevator at the neutral position and the elevator servocentered, mark the control wire where it crosses the outer hole ofthe servo arm.

28

Section 12: Installing the Rudder,Elevator and Throttle Linkage

Continued

Step 4Remove the control wire and make a 90-degree “L” bend asshown. Cut off the excess wire 5/16" from the bend. Remove theclevis and slide the control wire through the tube from inside thefuselage and connect the wire to the servo arm using an L-bendkeeper. Thread the clevis back on to the wire and reconnect theclevis to the control horn on the elevator.

Note: To prevent the control wire from binding, trim off the servo arm pointing to the rear.

Step 5Locate the throttle control wire (20") and slide it through the pre-installed throttle tube in the firewall. Connect the clevis to thethrottle of your engine. With the servo centered (half throttle) andthe carburetor half open mark the throttle wire where it crossesthe outer hole of the servo arm.

Step 6Remove the throttle control wire and make a 90-degree L-bend asshown. Cut off the excess wire 5/16" from the bend. Remove theclevis and slide the control wire through the tube from inside thefuselage and connect the wire to the servo arm using an L-bendkeeper. Thread the clevis back on to the wire and reconnect theclevis to the throttle.

Note: To prevent the control wire from binding, trim off the servo arm pointing forward towards the engine.

Step 7Remove the servo arm from the rudder servo. Trim off the twoshorter arms and install the easy connector included in the Alphahardware package as shown. Re-install the servo arm with theeasy connector positioned to the left side of the fuselage.

(Step 5 Photo)

29

Section 12: Installing the Rudder,Elevator and Throttle Linkage

Continued

Step 8Locate the nose wheel steering control wire (173/4" non-threaded)and make a Z-bend on one end. Slide the wire through the pre-installed steering tube in the firewall and through the easyconnector on the rudder servo. Remove the steering arm from the nose gear and connect the Z-bend. Re-install the steering armon to the nose gear.

Step 9With the rudder servo and nose wheel at neutral (centered), tightenthe setscrew on the easy connector.

Step 10Locate the rudder control wire (251/2") and slide it through thepre-installed rudder tube in the left rear top of the fuselage.Connect the clevis to the rudder control horn. With the servo centered and the rudder at neutral mark the rudder wire where itcrosses the outer hole of the servo arm.

Step 11Remove the control wire and make a 90-degree L-bend as shown.Cut off the excess wire 5/16 from the bend. Remove the clevisand slide the control wire through the tube from inside the fuselageand connect the wire to the servo arm using an L-bend keeper.Thread the clevis back on to the wire and reconnect the clevis tothe control horn on the rudder.

30

Section 13: Installing the Spinner and Propeller

Parts Needed• Fuselage assembly• Spinner (included)• Evolution 3-bladed trainer propeller (EVOE100P)

Tools and Adhesives Needed• Adjustable wrench• Phillips screwdriver

Step 1Remove the prop nut and washer from the Evolution engine, noting the position of the washer and flywheel.

Step 2Locate the spinner included in your Alpha Trainer and remove thethree self-tapping screws and remove the back plate.

Step 3With the flywheel in place, install the spinner back plate onto theengine as shown.

Note: The flywheel is keyed in place onto the engines crank-shaft and should be tight against the front engine bearing.

Step 4Slide the propeller onto the engine with the molded “E” facingforward as shown.

Step 5Install the prop washer and prop nut removed in Step 1. Makesure to position the beveled edge of the washer forward.

31

Section 13: Installing the Spinner and Propeller

Continued

Step 6Using an adjustable wrench, tighten the prop nut while holdingthe propeller in place.

Warning: The propeller must be securely tightened beforeattempting to run your evolution engine. Be sure to check the security of the propeller before each flying session.

Note: The propeller must be positioned to allow the spinner cone to fit into the slots in the back plate. Test fit the spinner cone before attempting to install the self-tapping screws of the spinner.

Step 7Using a Phillips head screwdriver, secure the spinner cone inplace with the three self-tapping screws provided.

32

Section 14: Balancing and ControlThrow Recommendations

Parts Needed• Fuselage assembly• Wing assembly• Wing dowels (2)• #64 rubber bands (10) (included)

Step 1Install the two wing dowels through the holes located at the frontand rear of the wing saddle. Leave an equal amount extendingfrom the sides of the fuselage.

Step 2Mount the wing onto the fuselage using the #64 rubber bandsprovided. Be sure to connect the aileron servo lead to the aileronextension lead you connected to the aileron channel of your receiver.

The following control throws are recommended for your firstflights. We recommend only one rate setting for the Alpha Trainer,as you gain flight experience and become more familiar with thehandling of your model you may wish to add a second rate set-ting. We also recommend that you have an experienced modelerhelp you with control throws and CG set-up of your Alpha ARF.Your local hobby shop can put you in contact with the RC clubsin your area.

Recommended Control ThrowsAileron 5/16” up 1/4” downElevator 3/8” up 3/8” downRudder 3/4” right and left

Recommended CG LocationAn important part of preparing the aircraft for flight is properlybalancing the model. This is especially important when variousengines are mounted.

Caution: Do not inadvertently skip this step!!

The recommended Center of Gravity (CG) location for the AlphaTrainer ARF is a range from 23/4" to 3" behind the leading edge ofthe wing measured at the fuselage sides.

If necessary, move the battery pack or add weight to either thenose or the tail until the correct balance is achieved. Stick-onweights are available at your local hobby shop and work well forthis purpose.

(Step 2 Photo)

23/4" 3"

33

Preflight Checks at the Flying Field

Important: Be sure your batteries are fully charged, per the instructions included with your radio system.

Before each flight, check the screws and nuts that secure themetal plate holding the motor in place on the motor mount. Also check the clevises of each control surface for security andpresence of a clevis keeper.

Perform a ground range check before each day’s flying.Proceed as follows:

1. Do not extend the transmitter antenna. Turn the transmitter on.

2. Turn the model on.3. Slowly walk away from the model while moving the

control surfaces. The aircraft should function properly at a distance of 75–100 feet.

4. Make sure all trim levers on the transmitter are in the proper position.

5. Make sure all servos and switch harness plugs are secure in the receiver.

Flying Your Alpha Trainer

For first-time pilots, the thought of flying their Alpha Trainerthrough loops, rolls, and perfect three-point landings can bethrilling. Learning to fly, however, takes time, patience, and mostimportantly, a good instructor. If you’re a first-time pilot, don’t tryto fly your model without an instructor. Seek an experiencedinstructor. Your local hobby shop can put you in touch with aninstructor in your area who can fly and trim your Alpha Trainer,and then give you your first chance on the “sticks” with very littlerisk of damage to the airplane. We cannot over emphasize the

importance of having a qualified instructor to help you throughyour first flights.

More experienced pilots will find the Alpha Trainer to be a confidence-inspiring airplane. Super stable and slow flight characteristics make pinpoint landings easy as pie. At full throttle,the Alpha Trainer is more than capable of most sport aerobaticsmaneuvers. The self-righting stability of the model also makes itone of the easiest airplanes you’ll ever fly.

34

2002 Official AMA National ModelAircraft Safety Code

Effective January 1, 2002

Model Flying MUST be in accordance with this Code inorder for AMA Liability Protection to apply.

General

1) I will not fly my model aircraft in sanctioned events, airshows, or model flying demonstrations until it has beenproven to be airworthy by having been previously, successfully flight-tested.

2) I will not fly my model higher than approximately 400 feetwithin 3 miles of an airport without notifying the airport operator. I will give right-of-way and avoid flying in the proximity of full-scale aircraft. Where necessary, an observershall be utilized to supervise flying to avoid having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the flyingsite I use, and I will not willfully and deliberately fly my modelsin a careless, reckless and/or dangerous manner.

4) At all flying sites a straight or curved line(s) must be established in front of which all flying takes place with theother side for spectators. Only personnel involved with flyingthe aircraft are allowed in front of the flight line. Flying overthe spectator side of the line is prohibited, unless beyond thecontrol of the pilot(s). In any case, the maximum permissibletakeoff weight of the models with fuel is 55 pounds.

5) At air shows or model flying demonstrations a single straightline must be established, one side of which is for flying, withthe other side for spectators. Only those persons accreditedby the contest director or other appropriate official as necessaryfor flight operations or as having duties or functions relatingto the conduct of the show or demonstration are to be permittedon the flying side of the line. The only exceptions that may bepermitted to the single straight-line requirements, under specialcircumstances involving consideration of site conditions andmodel size, weight, speed, and power, must be jointlyapproved by the AMA President and the Executive Director.

6) Under all circumstances, if my model weighs over 20 pounds,I will fly it in accordance with paragraph 5 of this section ofthe AMA Safety Code.

7) I will not fly my model unless it is identified with my nameand address or AMA number, on or in the model.

Note: This does not apply to models while being flownindoors.

8) I will not operate models with metal-bladed propellers or with gaseous boosts, in which gases other than air enter theirinternal combustion engine(s); nor will I operate models with extremely hazardous fuels such as those containingtetranitromethane or hydrazine.

9) I will not operate models with pyrotechnics (any device thatexplodes, burns, or propels a projectile of any kind) including,but not limited to, rockets, explosive bombs dropped frommodels, smoke bombs, all explosive gases (such as hydrogenfilled balloons), ground mounted devices launching a projectile.The only exceptions permitted are rockets flown in accordancewith the National Model Rocketry Safety Code or those permanently attached (as per JATO use); also those itemsauthorized for Air Show Team use as defined by AST AdvisoryCommittee (document available from AMA HQ). In any case,models using rocket motors as a primary means of propulsionare limited to a maximum weight of 3.3 pounds and a G seriesmotor. A model aircraft is defined as an aircraft with or withoutengine, not able to carry a human being.

10) I will not consume alcoholic beverages prior to, nor during,participation in any model operations.

Radio Control

1) I will have completed a successful radio equipment groundrange check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectatorsuntil I become a qualified flier, unless assisted by an experienced helper.

3) I will perform my initial turn after takeoff away from the pit orspectator areas, and I will not thereafter fly over pit or spectatorareas, unless beyond my control.

4) I will operate my model using only radio control frequenciescurrently allowed by the Federal Communications Commission.(Only properly licensed Amateurs are authorized to operateequipment on Amateur Band frequencies.)

5) Separation of less than three miles between flying sites isonly acceptable if testing has been accomplished to determinethat no interference potential exists or a frequency sharingarrangement between the clubs and/or individuals involved is developed. Written confirmation of either of these two alternatives, signed by a club officer of both clubs, or individual AMA members from both clubs shall be providedto AMA Headquarters.

6) For Combat, distance between flight line and spectator linewill be 500 feet per cubic inch of engine displacement. (ex: .40 engine = 200 feet)

35

7) An RC racing event, whether or not an AMA Rule Book event,is one in which model aircraft compete in flight over a prescribed course with the objective of finishing the coursefaster to determine the winner.

A. In every organized racing event in which contestants,callers and officials are on the course:

1. All officials, callers and contestants must properlywear helmets that are OSHA, DOT, ANSI, SNELL orNOCSAE approved or comparable standard while on the racecourse.

2. All officials will be off the course except for the starter and their assistant.

3. “On the course” is defined to mean any area beyondthe pilot/staging area where actual flying takes place.

B. I will not fly my model aircraft in any organized racingevent which does not comply with paragraph A above or which allows models over 20 pounds unless that competition event is AMA sanctioned.

C. Distance from the pylon to the nearest spectator (line) willbe in accordance with the current Competition Regulationsunder the RC Pylon Racing section for the specific eventpending two or three pylon course layout.

8) R/C Night Flying is limited to low-performance models (lessthan 100 mph). The models must be equipped with a lightingsystem that clearly defines the aircraft’s attitude at all times.

2002 Official AMA National ModelAircraft Safety Code

Continued

© Copyright 2002, Horizon Hobby, Inc. 1-800-535-5551 www.horizonhobby.com

WE GET PEOPLE FLYING

TM®

5161