Www.luxoft.com AngularJS Forms & validation. AngularJS form example First.

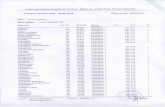

SOP - Method Validation Example-SAMPLE

-

Upload

endah-saat-santai -

Category

Documents

-

view

260 -

download

1

Transcript of SOP - Method Validation Example-SAMPLE

-

7/31/2019 SOP - Method Validation Example-SAMPLE

1/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 1 of 19

TABLE OF CONTENTS

1 OBJECTIVE ................................................................................................................................................ 1

2 REFERENCE MATERIAL ........................................................................................................................... 1

3 ROLES & RESPONSIBILITIES .................................................................................................................. 2

4 TRUSCAN SCHEMATIC & ACCESSORIES .............................................................................................. 2

5 SAFETY ....................................................................................................................................................... 3

6 CONFIGURATION OF TRUSCAN FOR SAMPLE ANALYSIS.................................................................. 3

7 PREPARATION OF SAMPLES FOR SAMPLE ANALYSIS ...................................................................... 4

8 USING THE ON-SCREEN KEYBOARD ..................................................................................................... 5

9 TRUSCAN LOGIN ....................................................................................................................................... 5

10 METHOD SELECTIVITY TESTING ............................................................................................................ 6

11 METHOD POSITIVE & ROBUSTNESS TESTING ................................................................................... 11

12 METHOD NEGATIVE TESTING ............................................................................................................... 14

13 COMPARABILITY PROTOCOL ............................................................................................................... 18

14 METHOD REVALIDATION ....................................................................................................................... 19

15 TRUSCAN LOGOUT / STAND-BY ........................................................................................................... 19

16 MODIFICATION / CHANGE CONTROL ................................................................................................... 19

17 APPROVALS ............................................................................................................................................ 19

1 OBJECTIVEThe objective of the SOP is to describe the operation of the Raman TruScan device for validation of methods used for

verifying the identity of raw materials. The objective of Method Validation is to assess the probability that other materials

used in a manufacturing facility, especially those chemically similar to the target material, could produce false positive

results when tested using the target materials method. In order to use TruScans onboard tools to streamline method

validation, methods for the target and challenge materials must first be created and added to the TruScan library. The

TruScan Selectivity utility then systematically challenges all onboard methods and searchable spectra with a sample

spectrum of the target to identify any materials with a potential for false positive results.

2 REFERENCE MATERIALAll Ahura Scientific user manual corresponding to software version 1.2.0

-

7/31/2019 SOP - Method Validation Example-SAMPLE

2/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 2 of 19

3 ROLES & RESPONSIBILITIESIt is the responsibility of QC management to insure that all operators are trained in performing specified tasks utilizing the

TruScan device. It is the responsibility of the all users of the system to insure that the equipment is in good working order,

that it is properly maintained, and that it is operated according to training procedures.

Administrator: Responsible for the administration of user accounts/passwords and system settings.

Developer: Responsible for acquisition of reference spectra signatures and creation and validation of identification test

methods.

User: Responsible for testing of raw, intermediate, and final product materials using the TruScan spectrometer. Users are

also responsible for initiating data synchronization for transfer on the TruScan spectrometers and performing system SelfTests.

Reviewer: Responsible for reviewing data transferred from the TruScan spectrometers, releasing materials based on review

of data transferred, and ensuring that data is moved to a secure directory on the company network.

4 TRUSCAN SCHEMATIC & ACCESSORIES

TruScan Front View Schematic TruScan Battery Compartment

Point-n-Shoot Nose Cone Optional Vial Holder

-

7/31/2019 SOP - Method Validation Example-SAMPLE

3/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 3 of 19

5 SAFETYThe TruScan spectrometer contains a class IIIB laser. Exposure to the laser beam within 14 inches (35 cm) of the laser

aperture could result cause damage to eyes. Never point the laser beam towards any individual. Do not use the TruScan to

measure thermally sensitive materials. Some materials can absorb laser energy and ignite. Examples of sensitive materials

include black powders, silver azide, match tips, black plastic, latex paint, and cardboard.

6 CONFIGURATION OF TRUSCAN FOR SAMPLE ANALYSIS1. Installing the Point-n-Shoot nose cone

a. You will use the nose cone accessory when scanning a substance in a bag or bottle, or when scanning a substancedirectly. The nose cone ensures that the units laser aperture is the correct distance from the substance.

b. Install the nose as shown in the figure below

2. Installing the optional vial holdera. Inspect the inside of the vial holder for any dirt or other foreign matterb. Align the vial holder with the laser aperture on the nose of the unitc. Press the vial holder toward the unit until seatedd. The vial holder should be aligned with the centerline of the unit and the "Laser Aperture" labels

-

7/31/2019 SOP - Method Validation Example-SAMPLE

4/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 4 of 19

7 PREPARATION OF SAMPLES FOR SAMPLE ANALYSIS1. The key to getting a good scan is to accurately position the laser focal point on the unknown substance. The focal

point is the spot in the laser beam that is the most intense and produces the greatest molecular signal.

a. Regions in the beam before and after this point are less intense and may not produce enough signal foridentification.

2. Using the Point-n-Shoot nose cone for materials contained in transparent or semi-transparent bags or containers:a. If the material is in a bag, prepare a flat area on the bag for testing. Pull the bag surface taunt and push the

material in the bag around (without opening the bag) to ensure that the testing area is flat and that there are no gaps

between the bag and the sample material.

b. Position the nose cone on the TruScan so that it is in good contact with the container.i. An improperly positioned nose cone can result in an air gap and poor test results.

3. For thick transparent containers (between 3mm to 7 mm thick):a. Remove the nose cone or vial holder if they are attached.b. Position the nose of the TruScan directly in contact with the container. Ensure that there is good contact and that

there are no gaps.

i. Some thick containers can significantly increase the sample testing time. If the TruScan reports that thesample time is relatively long, it may be necessary to cancel the test, remove some of the sample material andplace it in a vial or bag for testing.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

5/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 5 of 19

4. Using the optional vial holder for vials (4 mL vial approximately 14mm diameter or less):a. At minimum place approximately 600 l or more of material in the vial, or fill to a depth of at least 5 mm.b. When possible, place enough reference material into a 4 mL TruScan vial to fill it approximately 1/3 full.

i. It is good practice to gently tap the vial down on a table or counter to compress powders and eliminate largeair pockets

c. Place the vial into the vial holder.d. It is normally recommended to using this configuration for selectivity testing

8 USING THE ON-SCREEN KEYBOARD1. When you need to enter your password or a Sample ID name, the on-screen keyboard appears. It is laid out like a

computer keyboard.

2. Enter one character at a time.3. Use the Arrow keys to select a character or space. Press the enter key to accept it4. To remove a character, select Delete, and press the enter key. To delete several characters, press and hold the enter

key.

5. To change from the lower case/numerals to upper case/symbols keyboard, select Caps and press the enter key.6. When you are finished entering the name, select Done, and press the enter key.

9 TRUSCAN LOGIN1. TruScan has password control to prevent unauthorized use. Use your user name and password to log into the unit.2. In order to acquire reference spectra signatures, one must have Developer or Administrator level access.3. Press the Wake/Sleep key, if necessary, to wake TruScan.4. After the unit starts up, the Welcome screen appears.5. Press the Login key6. Use the Arrow keys to select your user name from the list that appears.7. Enter your password on the keyboard screen that appears.8. After you select Done and press the enter key, the Main menu appears

-

7/31/2019 SOP - Method Validation Example-SAMPLE

6/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 6 of 19

Password Entry Screen TruScan Main Menu Screen

10 METHOD SELECTIVITY TESTING1. According to USP Category 4 and ICH-Q2 guidelines, the critical performance attribute to be validated for an

identity test is selectivity (specificity). Selectivity (specificity) is described as the ability of a method to selectively

discriminate the identity of the chosen analyte from that of all potential interfering substances.

2. For validation concerns, besides positive testing, it is common to demonstrate each method's selectivity through aprocedure referred to frequently as negative testing. The objective is to ensure TruScan consistently rejects/Fails

challenge materials, which have spectra similar to the method of interest. Identification of potential challenge

materials may be performed via the TruScan Selectivity feature.

3. When TruScan compares two spectra, it calculates a p-value indicating the probability that the two spectra represent a"match." When the p-value is greater than or equal to 0.05, TruScan declares a "Pass." The higher the p-value, the

stronger the match.

4.

TruScan can perform a Selectivity analysis to determine which materials in the unit's searchable library are associatedwith spectra similar to the method being validated with p-values less than 0.05 but greater than 0.001. It is advisable to

run any reported materials against the method of interest to record their proper rejection as part of a complete method

validation protocol.

5. Follow the steps below to perform this selectivity analysis.6. Collect a suitable sample material for the creation of a signature (reference spectrum signature) provided the material

has been deemed acceptable for Raman identification.

a. Suitable sources include:i. Reference standardsii. Purchased chemicals with COA.iii. Sample material which has been identified prior by compendial ID test methods.iv. Sample material for which there is an authoritative reference (e.g. published documentation) to authenticate

the spectrum once created.

(1) Note: Some mixtures may be unsuitable for ID by Raman. ID by Raman spectroscopy is a bulk ID testand may not be sensitive to detect minor components.

7. Determine how the sample will be prepared for collection of the signature and setup the TruScan to for that preparation(refer to section 7).

8. Normally the acquisition of reference spectrum signature is performed using the optional vial holder configurationsbecause the sample in the vial can be held motionless for long periods of time; however, in some cases such as thick

pastes or gels, it is not always possible to present the sample in a vial.

i. Note: the method of acquiring the signature does not have to be the same as that for sample identification;however, in some very limited cases where the packaging itself is adding enough spectral variation to cause

the method based on a signature acquired through a vial it maybe necessary to acquire a second signature of

-

7/31/2019 SOP - Method Validation Example-SAMPLE

7/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 7 of 19

the material in that type of container to also add to the method in order to have those spectral properties also

represented in the method.

9. Ensure that the TruScan has had the Self Test performed prior.a. Refer to the TruScan Self Test SOP ID ##### for instructions.

10. Ensure the TruScan has sufficient power to perform the required operations.a. The icon indicates the batterys charge, from one to seven bars.b. The battery has sufficient charge for scanning when it indicates at least three bars.c. If the battery doesnt have sufficient power, refer to the TruScan Battery Recharge / Replacement SOP ID #####

for instructions

11. One may turn off the Discovery Library to limit the Active Signatures to only those from the new user-defined library12. If desired and, if installed, turn off the Discovery Library to limit the Active Signatures to only those from the new

user-defined library.

a. Log in as an Administrator on the TruScan, select Tools-Signatures-Discover Library.b. Select any compound and press the enter key.c. Highlight Factory Items: ON/OFF. Press the Enter key to toggle between ON/OFF state. Press the Esc key to

return to the Discover Library list.

d. NOTE: Testing with the factory library ON may be done, if desired, and there are over 4000 compounds in thelibrary that would be tested against. Since all results need to be explained this may result in some additional work

for the test technician, if an apparent false positive arises.

13. Place the test sample in a vial and insert it into the vial holder.14. In the Main menu, highlight Tools.15. Press the enter key. The Tools menu appears.16. Highlight Methods. Press the enter key. A list appears of the methods on the unit.17. Highlight the desired method. Press the enter key and a menu appears.18. Highlight Selectivity and press the enter key.19. A message appears telling you to place the sample in the position for scanning, either in a vial in the vial holder, orusing the nose cone.

20. Place the sample in the correct position.21. Highlight Continue and press the enter key.22. The on-screen keyboard appears.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

8/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 8 of 19

23.

Using the arrow key and enter key, enter the material batch/lot/sample ID number, or, if a barcode is available, pressthe barcode key and aim the barcode reader at the lot barcode label.

Sample ID Screen Bar code reader scanning angle

24. After the number has been entered, use the arrow key to highlight the Done menu item, and press the enter key.25. TruScan begins a scan and displays a progress bar while performing the selectivity scan and analysis.

26. When analysis is complete, the screen shows the Method Selectivity results for the method you selected.a. The Method Selectivity results screen shows any materials in the TruScan onboard library that resulted in either

i. A p-value of 0.05 or greater, which "match" the method you're testing, indicated by "+" (plus sign), or a p-value between 0.001 and 0.05, indicated by "" (minus sign). These are materials with Raman characteristics

similar to your sample material, and they could occasionally produce a false positive result when the method

you are validating is run against them. These similar materials are sometimes called "Nearest Neighbors," and

as part of the validation process, you will evaluate the risk associated with them in your application

-

7/31/2019 SOP - Method Validation Example-SAMPLE

9/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 9 of 19

ii. A yellow triangle next to an item indicates that it is a method. To expand a method to see the associatedsignatures, highlight the method, and press the Right Arrow key. The signatures appear beneath the method.

Press the Left Arrow key, and the Signatures disappear.

iii. Items without triangles are signatures in the unit's onboard library.iv. You can view the info screens or spectrum for any item. Highlight the item and press the enter key. In the

menu that appears, highlight View Info or View Spectrum and press the enter key

27. Three reports are generated during analysis: Selectivity,Discovery and Textreports.28. To view the reports, perform Sync of the TruScan archive the generated reports (refer to Data Sync SOP ID#####).29. The three reports are generated during analysis contain the following information.

a. Selectivity Report: This report identifies and shows spectra of the "Nearest Neighbors" materials found in theunit's onboard library that yield p-values between 0.001 and 0.05 when compared with the current quick scan.

i. Normally, these materials would Fail, when run against the method, but has a higher risk of producing a falsePass results.

b. Discover Report: This report shows the spectrum from the current scan and the spectra of materials that wouldresult in p-values of 0.05 or greater when the current quick scan is compared with materials in the unit's onboard

library. These materials can be expected to yield a false Pass result.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

10/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 10 of 19

c. Text Report: This report lists information about the current scan, including the matches and "Nearest Neighbors"The text report summarizes the results of both reports above into one file using a (+) sign to indicate matches with

p-values of 0.05 or greater, and a (-) sign to indicate Nearest Neighbors with p-values between 0.001 and 0.05.

30. If any materials other than the tested method, show up on the Discovery report.a. Matches are acceptable provided a method or Discovery library spectrum matches have the same chemical identityas the material being tested.

i. Note: Be aware that if multiple drug codes are associated with one material (e.g., different suppliers) duringtesting they should also appear in the Discovery report. This is a positive outcome of material authenticity

and further evidence of the uniqueness of the method.

b. Some samples which are mixtures may generate positive matches for the major component, especially when thatcomponent comprises over 80% of the mixture (e.g. 3A Alcohol will result in a positive match for ethanol).

i. This is acceptable provided that it is documented in the memo authored for the method created that this is anacceptable test for the main constituent and not a test for minor components.

c. Materials with positive matches to chemically different materials should be evaluated for selectivity suitability forRaman identification by TruScan.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

11/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 11 of 19

31. In any materials show up on the Selectivity report, as recommended by the USP Category 4 and ICH-Q2Guidelines, samples of materials identified as Selectivity Matches should be tested against the method being tested to

determine that they will reliably return Fail results, even though their p-values are in proximity to the 0.05 acceptance

threshold. Refer to section 12.

11 METHOD POSITIVE & ROBUSTNESS TESTING1. First it is suggested to screen the method candidacy with independent samples chemically representative of the method

via standard Run mode.

a. WHY: To verify the level of false-negative results that could occur and overall robustness of the system.2. The number of replicates performed during validation of analytical methods is not specified in USP, FDA, or ICH-Q2

guidance: however, performing validation activities in triplicate is generally recognized in the industry as standard.

3. Collect suitable sample materials for the testing.a. Suitable sources include:

i. Reference standardsii. Purchased chemicals with COA.iii. Sample material which has been identified prior by compendial ID test methods.iv. Sample material for which there is an authoritative reference (e.g. published documentation) to authenticate

4. Determine how the sample will be prepared for collection of the signature and setup the TruScan to for that preparation(refer to section 7).

a. Note: Good standard practice to include all sampling configurations, which might be expected in routine operation(e.g. plastic bags, number of layer of bags, glass bottle, clear and/or amber, etc.)

i. Why: the method of acquiring the signature does not have to be the same as that for sample identification;however, in some very limited cases where the packaging itself is adding enough spectral variation to cause

the method based on a signature acquired through a vial it maybe necessary to acquire a second signature ofthe material in that type of container to also add to the method in order to have those spectral properties also

represented in the method.

5. Ensure that the TruScan has had the Self Test performed prior.a. Refer to the TruScan Self Test SOP ID ##### for instructions.

6. Ensure the TruScan has sufficient power to perform the required operations.a. The icon indicates the batterys charge, from one to seven bars.b. The battery has sufficient charge for scanning when it indicates at least three bars.c. If the battery doesnt have sufficient power, refer to the TruScan Battery Recharge / Replacement SOP ID #####

for instructions

7. From TruScan main menu, select Run using the arrow key then press the enter key.8. Highlight the method, which has been designated for method testing.9. Press the enter key to run the method.10. Using the arrow key and enter key, enter the material batch/lot/sample ID number, or, if a barcode is available, pressthe barcode key and aim the barcode reader at the lot/batch barcode label.11. After the number has been entered, use the arrow key to highlight the Done menu item, and press the enter key.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

12/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 12 of 19

Sample ID Screen Bar code reader scanning angle

12. Press the enter key to select the Go menu option to start the test and note the time you are starting the scan.13. Press the enter key to initiate the Run.14. The unit performs a scan and then performs an analysis and shows a Method Result screen.15. Upon completion of the Run, the TruScan will report if the identification test for that material resulted in a Pass or a

Fail.

a. Once the Pass/Fail screen appears, the analysis is complete and the electronic record has been created on TruScan.

Example Sample Pass Screen Example Sample Fail Screen

16. A Pass should be the expected result.17. If the Run resulted in a Fail, first check to make sure that the TruScan and sample are properly positioned, the correct

method was selected, correct sample chosen, etc.

18. If the root cause of the error was easily identified, one can add a note to the test record.19. In the Method Result or Test Result screen, highlight Add Note, press the enter key and a list of Notes

appears.

a. Add a pre-defined note or a new note:b. If you want to add one of the listed pre-defined Notes, highlight it and press the enter key. The Result screen

re-appears, and a field at the bottom of the screen now shows the Note you selected.

c. If you want to enter a note that is not listed, highlight Other and press the enter key.d. Use the keyboard screen to enter a brief note.e. When you are done, the Result screen re-appears, and a field at the bottom of the screen now shows your Note.

i. If you enter a longer note, it may appear truncated on the Result screen; however, it will appear correctly onthe Run or Test report.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

13/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 13 of 19

20.

If your TruScan has the optional Discovery Library factory option, Developers and Administrators can view additionalinformation about a Fail result.

i. In a Fail result screen, highlight Discover, and press the enter key.ii. The Discover screen appears, listing any methods or active reference spectra signatures consistent with the

measured data.

(1) The TruScan compared the measured spectrum with the user created method, active signatures, spectra inthe Discovery library, and display the results of the comparison.

Example Sample Fail Screen Example Discover Result Screen

21. If desired and, if installed, turn off the Discovery Library to limit the Active Signatures to only those from the newuser-defined library.

a. Log in as an Administrator on the TruScan, select Tools-Signatures-Discover Library.b. Select any compound and press the enter key.c. Highlight Factory Items: ON/OFF. Press the Enter key to toggle between ON/OFF state. Press the Esc key to

return to the Discover Library list.

d.

NOTE: Testing with the factory library ON

may be done if desired and there are over 4000 compounds in thelibrary that would be tested against. Since all results need to be explained this may result in some additional work

for the test technician if an apparent false positive arises.

22. If the reason for the Run Fail is unknown, report the failure to the unit manager/designee for a more detailed root causeinvestigation.

a. Poor results can result from things such as:i. Not enough sample in vials. The level should be at least 600 l or more of material in the vial or a depth of at

least 5 mm

ii. Air gaps between the TruScan and the sample material. This can be due to air bubbles in packaging materialor due to holding the TruScan at an angle.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

14/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 14 of 19

iii. Sample container is too thick or opaque. Remove some sample and place it in another suitable container, suchas a clear glass vial or think plastic bag.

1. If more samples are required for Identification testing, repeat steps 1 through 14 for each sample to be tested.23. If no further testing is required, press the Esc key to return to the Main menu24. After all the sample data has been acquired, perform Sync of the TruScan archive the generated reports (refer to SOP

Data Sync SOP ID #####).

25. Locate the Run reports (e.g. *.jpg, *pdf, and/or *.txt) for the test performed in steps 1 through 14 above.a. Open and print those reports.

26. On the hardcopy, look at the number listed for p-val in the report header.a. During method robustness testing, Pass results in the range of 0.1 > p-values > 0.05 may indicate the need for

multiple Signatures to create a fully robust method.

i. WHY: Including multiple lots of a perfectly acceptable incoming raw material increases the probability of aPass even though it may be possible to spectroscopically differentiate lots due to their respectivemanufacturing process or supplier

b. In robustness testing of the method, Pass results with a p-values in the range of 0.1 > p-values > 0.05 may occurdue to packaging making a significant contribution to observed spectral data (e.g. features observable from

polyethylene bag or weak luminescence of a glass vial). To create a fully robust method, acquire additional

reference Signatures as appropriate through packaging material to encompass expected measurement conditions.

i. WHY: If the container is adding spectral features to the spectrum of the reference material, including anadditional Signature, which has both features represented simultaneously, identifies this as an acceptable

spectral representation of the raw material

27. If more Signatures are required to increase the robustness of the method, refer to (refer to Method Creation SOP ID#####).

12 METHOD NEGATIVE TESTING1. A demonstration of specificity for the method would entail running all risk materials against the method of interest,

and cataloging the results of the challenges using the Run reports repeatedly showing Fail for the risk materials.

2. It is suggested to screen the method candidacy with independent samples chemically different but especially includingthose materials structurally similar or closely related to the chemical method being tested via standard Run mode.

For example, a site that has built a TruScan method for lactose monohydrate may choose to challenge the method with

lactose anhydrate, dextrose monohydrate, fructose, sucrose, and maltodextrose. These choices will typically be very

-

7/31/2019 SOP - Method Validation Example-SAMPLE

15/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 15 of 19

site-specific and may be a consequence of such factors as the other materials handled at the site, the materials provided

or offered by their suppliers of lactose monohydrate, expert input and historical knowledge.

a. WHY: To verify the level of false-positive results that could occur and overall robustness of the system.3. The selection of 1 to 5 compounds similar in nature and structure to the compound under test is generally recognized as

sufficient for absence testing. The TruScan Selectivity feature can be used as to help determine this selection. Refer

to section 10.

a. Based on risk assessment for the TruScan performed by Ahura Scientific, absence testing for all compounds is notrequired especially if the TruScan Selectivity function analysis was executed.

4. The number of replicates performed during validation of analytical methods is not specified in USP, FDA, or ICH-Q2guidance; however, performing validation activities in triplicate is generally recognized in the industry as standard.

5. Collect suitable sample materials for the testing.a. Suitable sources include:

i. Reference standardsii. Purchased chemicals with COA.iii. Sample material which has been identified prior by compendial ID test methods.iv. Sample material for which there is an authoritative reference (e.g. published documentation) to authenticate

6. Determine how the sample will be prepared for collection of the signature and setup the TruScan to for that preparation(refer to section 7).

a. Note: Good standard practice to include all sampling configurations, which might be expected in routine operation(e.g. plastic bags, number of layer of bags, glass bottle, clear and/or amber, etc.)

i. Why: the method of acquiring the signature does not have to be the same as that for sample identification;however, in some very limited cases where the packaging itself is adding enough spectral variation to cause

the method based on a signature acquired through a vial it maybe necessary to acquire a second signature of

the material in that type of container to also add to the method in order to have those spectral properties also

represented in the method.

7.

Ensure that the TruScan has had the Self Test performed prior.a. Refer to the TruScan Self Test SOP ID ##### for instructions.

8. Ensure the TruScan has sufficient power to perform the required operations.a. The icon indicates the batterys charge, from one to seven bars.b. The battery has sufficient charge for scanning when it indicates at least three bars.c. If the battery doesnt have sufficient power, refer to the TruScan Battery Recharge / Replacement SOP ID #####

for instructions

9. From TruScan main menu, select Run using the arrow key then press the enter key.10. Highlight the method, which has been designated for method testing.11. Press the enter key to run the method.12. Using the arrow key and enter key, enter the material batch/lot/sample ID number, or, if a barcode is available, press

the barcode key and aim the barcode reader at the lot barcode label.

13. After the number has been entered, use the arrow key to highlight the Done menu item, and press the enter key.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

16/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 16 of 19

Sample ID Screen Bar code reader scanning angle

14. Press the enter key to select the Go menu option to start the test and note the time you are starting the scan.15. Press the enter key to initiate the Run.16. The unit performs a scan and then performs an analysis and shows a Method Result screen.17. Upon completion of the Run, the TruScan will report, if the identification test for that material, resulted in a Pass or a

Fail.

a. Once the Pass/Fail screen appears, the analysis is complete and the electronic record has been created on TruScan.

Example Sample Pass Screen Example Sample Fail Screen

18. A Fail should be the expected result.19. If the Run resulted in a Pass, first check to make sure that the TruScan and sample are properly positioned, the correct

method was selected, correct sample chosen, etc.

20. If the root cause of the error was easily identified, one can add a note to the test record.21. In the Method Result or Test Result screen, highlight Add Note, press the enter key and a list of Notes appears.

a. Add a pre-defined note or a new note:b. If you want to add one of the listed pre-defined Notes, highlight it and press the enter key. The Result screen re-

appears, and a field at the bottom of the screen now shows the Note you selected.

c. If you want to enter a note that is not listed, highlight Other and press the enter key.d. Use the keyboard screen to enter a brief note.e. When you are done, the Result screen re-appears, and a field at the bottom of the screen now shows your Notes.

i. If you enter a longer note, it may appear truncated on the Result screen; however, it will appear correctly onthe Run or Test report.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

17/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 17 of 19

22.

If your TruScan has the optional Discovery Library factory option, Developers and Administrators can view additionalinformation about a Fail result.

i. In a Fail result screen, highlight Discover, and press the enter key.ii. The Discover screen appears, listing any methods or active reference spectra signatures consistent with the

measured data.

(1) The TruScan compared the measured spectrum with the user created method, active signatures, andspectra in the Discovery library, and display the results of the comparison.

Example Sample Fail Screen Example Discover Result Screen

23. If desired and, if installed, turn off the Discovery Library to limit the Active Signatures to only those from the newuser-defined library.

a. Log in as an Administrator on the TruScan, select Tools-Signatures-Discover Library.b. Select any compound and press the enter key.c. Highlight Factory Items: ON/OFF. Press the Enter key to toggle between ON/OFF state. Press the Esc key to

return to the Discover Library list.

d.

NOTE: Testing with the factory library ON

may be done if desired and there are over 4000 compounds in thelibrary that would be tested against. Since all results need to be explained this may result in some additional work

for the test technician if an apparent false positive arises.

24. If the reason for the Run Pass is unknown, report the failure to the unit manager/designee for a more detailed rootcause investigation.

a. Matches are acceptable provided a method or Discovery library spectrum matches have the same chemical identityas the material being tested.

i. Note: Be aware that if multiple drug codes are associated with one material (e.g., different suppliers) duringtesting they should also appear in the Discovery report. This is a positive outcome of material authenticity

and further evidence of the uniqueness of the method.

-

7/31/2019 SOP - Method Validation Example-SAMPLE

18/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 18 of 19

b. Some samples which are mixtures may generate positive matches for the major component, especially when thatcomponent comprises over 80% of the mixture (e.g. 3A Alcohol will result in a positive match for ethanol).

i. This is acceptable provided that it is documented in the memo authored for the method created that this is anacceptable test for the main constituent and not a test for minor components.

c. Materials with positive matches to chemically different materials should be evaluated for selectivity suitability forRaman identification by TruScan.

2. If more samples are required for Identification testing, repeat steps 1 through 17 for each sample to be tested.25. If no further testing is required, press the Esc key to return to the Main menu26. After all the sample data has been acquired, perform Sync of the TruScan archive the generated reports (refer to Data

Sync SOP ID #####).

27. Locate the Run reports (e.g. *.jpg, *pdf, and/or *.txt) for the test performed in steps 1 through 17 abovea. Open and print those reports.

13 COMPARABILITY PROTOCOL1. If the raw material is part of a regulatory filing (e.g. NDA or ANDA), once TruScans method validation is completed

some customer have interpret the FDA suggestion for having CMC comparability protocol during the transition from

one approved method to a new one for existing validated processes, which applies to quantitative finished product

methods to also apply to the TruScan. The CMC protocol calls for a parallel testing for a defined period of time or

number of batches. During this period the results of the lab testing should be compared to TruScan results to identify

any inconsistencies. If none exist or all issues are explained then TruScan can become the method for ID testing of

these raw materials.

2. The protocol additionally calls for an extended period, usually one year, of observation where parallel testing is doneon a less frequent basis and where the replaced method is the secondary test (not required for release). This is to

account for seasonal and cycle differences that can affect product quality. Testing can be reduced from daily or by lotto spot checks, weekly or even monthly in some cases. Once the year long period has ended and a report showing the

favorable comparison of the techniques is issued, the old method(s) can be retired.

3. Its is Ahura Scientifics viewpoint that a comparability protocol is actually not as applicable to an identificationmethod as it is to a quantitative method. Regarding quantitative methods the purpose of side-by-side comparison is to

detect if there is any drift, inaccuracy, or in-precision in the new technique. For an identification method, the critical

performance criterion is selectivity, which is demonstrated through the rejection (e.g. failures) of chemically different

raw materials (e.g. low false-positive rate). During parallel testing usually includes only testing of incoming receipts

of the same raw material as the method. The probability of an incoming receipt being incorrectly labelled and actually

containing a chemically different raw material is an infrequent occurrence and the likelihood of that event occurring

during the short term comparability study is highly improbable. The only likely detection that will occur during the

comparability testing phase is false-negative results meaning the failure of a raw material by the TruScan that when

tested by primary test method(s) pass. The level of false-negative rate is a business decision more so than regulatory

one. From a regulatory perspective, it is acceptable to reject a raw material that is correct putting it in quarantine untilfurther analysis is performed but not acceptable to pass an incorrect raw material then allowing the material to enter

into the next stage of manufacturing. The negative testing phase, which establishes the false-negative rate of the

method, is established in the methods validation and not the comparability protocol. The comparability protocol does

have value if desired to confirm the robustness of the technique prior to full substitution from the primary method(s).

-

7/31/2019 SOP - Method Validation Example-SAMPLE

19/19

Standard Operating Procedure for

Method Validation

SOP ID:

Revision:

Issue date:

Page 19 of 19

14 METHOD REVALIDATION1. Whenever a new method is added to the TruScan library, it is important to confirm that its reference spectrum does not

generate false positive results when compared to the reference spectra contained in the previously developed and

validated methods.

2. When using TruScans Selectivity utility, if the Discover report has any matches for already previously validatedmethods, which the selectivity between these two materials was not already accounted for in the previous methods

validation report may require revalidation of that method or methods. The extent of the validation activities will be

determined after a risk assessment.

15 TRUSCAN LOGOUT / STAND-BY1. For logout, press the login key.2. To put the TruScan into stand-by mode, press the wake/sleep key.16 MODIFICATION / CHANGE CONTROLAny changes or modification to this SOP must be documented and approved. The likely impact of the change of the status

of the protocol should be evaluated, reviewed, approved and training of those responsible for its execution prior to

implementation.

17 APPROVALSWritten/Revised By: Date:

Name/Department DD-MMM-YYYY

Reviewed By: Date:

Name/Department DD-MMM-YYYY

Reviewed By: Date:

Name/Department DD-MMM-YYYY

Approved By: Date:

Name/Department DD-MMM-YYYY