Solid biomass for energy

-

Upload

selfhelp-citizen-dream-merchant -

Category

Technology

-

view

39 -

download

0

Transcript of Solid biomass for energy

SOLID BIOMASS FOR ENERGY

WOOD - AGRO- RESIDUE - MSW

COMBUSTION PRINCIPLES - FUEL

PREPARATION - FURNACES

Comparison of Bio-fuel with Coal-1

• Biofuel is useful near forests / woodlands and

villages for decentralized and small / medium

scale operation over coal / char. Coal which is

useful for Thermal Power Plants.

• Biofuel restricts the emission of green house

gases and air pollutants (like SO2).

• In rural areas, available biofuel lessens the

dependence on transported fossil fuels like

coal and oil & gas.

2

Comparison of Bio-fuel with Coal-2

• Biofuel is location specific and limited in

availability; suitable for small applications

• Lower calorific value; variable particle size

• Preparation like drying, briquetting etc., needed

for wood /agro-residue

• Price depends on production system like

energy plantation, social forestry, saw mills,

paddy processing mill etc.

3

USES OF SOLID BIOFUEL

COMBUSTION

• RURAL DOMESTIC: COOKING, WATER, ROOM

HEATING

• HEAT & STEAM: SMALL FURNACES, KILNS,

BOILERS

• ELECTRIC POWER GENERATION:

SMALL SCALE: DECENTRALISED, RURAL

MEDIUM SCALE: COFIRING, COGENERATION /

COMBINED CYCLE

4

Sources of Solid Bio-fuels

(Agriculture, Plantation, Forestry)

WOOD - [Forestry, Trees outside Forests]

BAGASSE - [Agro-industry residue]

RICE HUSK- [Crop residue]

PROSOPIS ETC.- [Energy crops]

NEEM ETC.- [Multi-purpose trees]

5

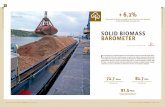

Biomass Power Potential (MW):

Source

Potential (MW)

From surplus Biomass

16,000

From bagasse based

co-generation in the

existing sugar mills

3,500

Total

19,500

Ref: MNES Annual Report, 1999

6

Important Fuel Properties

• MOISTURE CONTENT

• ELEMENTAL ANALYSIS

• CHEMICAL COMPOSITION

• PARTICLE SIZE & DISTRIBUTION

• BULK DENSITY, SPECIFIC GRAVITY

• POROSITY

7

Test Data needed for Combustion

• Proximate Analysis:

(1) Moisture, (2) Volatile, (3) Fixed carbon

(4) Ash. [Weight %]

• Ultimate Analysis:

C, H, O, N, S. [Weight %]

• Higher Heating Value, MJ / Kg

• Flue Gas Analysis: H2O,CO2,N2, CO, SO2

8

Draft-pressure drop for air flow

P required to make the air flow through the fuel

bed and to the flue gas discharge height is called

‘draft of air’ in a furnace and is expressed in

millimeters of water. Natural (by means of a

chimney). Forced: The fan is used to suck the

gases away from the furnace [induced draft], or to

force the air required [forced draft] through the

grate.

9

COMBUSTION PROCESS-1

• Combustion: Oxidation of reduced forms of

carbon and hydrogen by free radical processes at

higher temperatures.

• Chemical properties determine the higher heating

value & the pathways of combustion.

• Bio-fuel: A wet (50% moist), dirty, light in weight,

heterogeneous in particle size, and quite reactive

condition.

11

COMBUSTION PROCESS-2

• Biomass fuels are highly reactive, volatile,

oxygenated fuels of moderate heating value.

• Moisture content lowers the combustion efficiency

and affects the economics of the fuel utilization.

• Drying, pyrolysis of solid particle, release of volatiles

and formation of char are followed by pre-

combustion gas phase reactions and char oxidation

reactions. 12

Requirements of efficient

combustion:

o Sufficient air to provide oxygen needed for

complete burning; higher than theoretical air.

o Distribution of air supply: mix with fuel

o Secondary air to burn the volatile

o Volume of furnace; Flow path for flue gas

o Minimize heat losses

14

Factors influencing thermal

efficiency in wood combustion

o Enthalpy of the fuel

o Moisture content of the fuel

o Level of excess air employed

o Final stack temperature

o Note: Theoretical flame temperature depends

on moisture content, % excess air and

preheating of air 15

BRIQUETTING

[PELLETIZATION]

o IMPROVES STORAGE AND

o TRANSPORT CHARACTERISTICS

o SCREW PRESS AND

o RAM PRESS

Fuel Preparation:

Briquetting in India

• Indian briquettes made from: groundnut shell,

cotton stalk, saw dust, coffee husk, bagasse,

mustard stalk and press mud.

• Southern region: groundnut shell and saw dust

• Western and Northern regions: bagasse,

groundnut shell, cotton stalk, mustard stalk and

press mud briquettes.

17

Briquetting continued

A recent addition: Municipal solid waste

densified for use as fuel in process

industries (tea, tobacco, textile,

chemical, paper, starch, tire re-

treading, tiles, etc.) for thermal

applications.

18

Screw and Ram Press

• Both the machines give briquettes with a density

of 1-1.2 gm /cc, suitable as industrial solid fuels.

• The screw type machines: briquettes with a

concentric hole-- better combustibility- a preferred fuel.

• These briquettes can also be more conveniently

deployed in small furnaces and even cook-stoves

than solid briquettes generated by a ram press.

19

FURNACE FOR COMBUSTION OF BIOFUEL

• Horizontal grate furnace

• Inclined step grate furnace

• Spreader-stoker system

• Suspension burning system

• Cyclone firing system

• Fluidized bed combustion system 22

Inclined step grate furnace-1

• Fuel is fed to the top of the grate

• heating and drying can occur very near to the

fuel feed shoot.

• Solid phase pyrolysis can occur as the fuel is

sliding down the grate.

23

Inclined step grate furnace -2

• Char oxidation can occur at the base of the

grate and on the dumping grate.

• Gas phase reactions can be controlled by

over-fire air distribution and separated

completely from solid phase reactions

24

Spreader stoker-1

• Fuel particles are fed into the firebox and flung,

mechanically or pneumatically across the grate

• Some heating and drying and possibly some

pyrolysis occurs while the particle is in

suspension

• Solid phase pyrolysis and char oxidation occur on

the grate. 25

Spreader stoker-2

• Pre-combustion gas phase reactions occur

between the grate and the zone where

secondary air is introduced.

• Gas phase oxidation occurs either throughout

the firebox or in the vicinity of the zone where

secondary air is introduced if the under-grate

air is limited to sub-stoichiometric quantities.

26

Suspension burning system:

horizontal cyclone furnace

• A horizontal or slightly inclined cylinder lined

with firebricks into which air is ejected

tangentially at a velocity of 6000- 7000 m/min.

• The flame in the furnace revolves at a rpm of

1200 to 1800

• The fuel introduced at the cyclone tip is

entrained by the revolving mass and is thrown

against the cyclone walls where it burns.

27

Horizontal cyclone furnace

• The flue gases that escape at high velocities

through the aperture at the other end of the

cyclone are substantially free from fly ash.

• The heat release rate of (2-5 )X 106 kcal/m2-

hr can be achieved for pulverized coal in a

cyclone furnace

28

Fluidized Bed Biofuel

Combustion: Boiler

• Bio-fuel is dispersed and burned in a gas

fluidized bed of inert particles.

• Temperature [750 to 1000 o C ] to avoid

particle sintering .

• 50% of the heat transferred directly to

surfaces immersed within the bed.

• Remaining heat with gases leaving

29

COMBINED HEAT & POWER

• STEAM INJECTED GAS TURBINE

• INTERCOOLED STEAM INJECTED GAS

TURBINE

• COMBINED CYCLE

30

Cogeneration with biomass fuel

• SUITABLE FOR SMALL SCALE (<10 MW)

GENERATION

• PRODUCES LESS AIR POLLUTANTS AND

SOLID WASTES

• AUGMENTS POWER SUPPLY TO

INDUSTRY

31

BIOMASS INTEGRATED GASIFIER /GAS

TURBINE (BIG/ GT) TECHNOLOGY

HIGH THERMODYNAMIC CYCLE

EFFICIENCY

GAS TURBINES TECHNOLOGY IS MADE

AVAILABLE NOW AT REASONABLE COSTS

LOW UNIT CAPITAL COST AT MODEST

SCALES FEASIBLE

IT IS EXPECTED THAT THIS TECHNOLOGY

WILL BE COMMERCIALLY SUCCESSFUL IN

THE NEXT TEN YEARS.

32

Reference Books

• A. Chakraverthy, “Biotechnology and Alternative Technologies for Utilization of Biomass / Agricultural Wastes”, Oxford & IBH publishing Co., N. Delhi, 1989.

• Samir Sarkar, Fuels and Combustion, 2nd Edition, Orient Longman, 1990

• Chapters on Combustion process Stoichiometry and Thermodynamics, Combustion Kinetics and Combustion Appliances. pages 217 to 326

35

Reference Books / journals

Journal—‘Biomass and Bio-energy’,

a) 1996, 11(4): 271-281 ‘Biomass Combustion for power generation’

b) 1998, 14(1): 33-56 ‘De-centralized biomass combustion: state of the art and future development’

4. Wood Combustion, D A Tillman, Ch. 5 ‘Heat production & release from wood combustion’,

5. Progress in biomass Conversion, vol 3, Edited by K V Sarkanen, D A Tillman and. E C Jahn, Academic Press, 1982

36