NANO REVIEW Open Access Cellulose fibres, nanofibrils and ...

Simultaneous In-situ Analysis of Instabilities and First ... · Hydrogels comprising cellulose...

Transcript of Simultaneous In-situ Analysis of Instabilities and First ... · Hydrogels comprising cellulose...

Hydrogels comprising cellulose nanofibrils (CNF) can be used in the synthesis of continuous, renewable filaments via wet-spinning as demonstrated earlier.1-4 However, understanding has been limited concerning the effects determining the spinnability of CNF and the interactions of the ensuing filaments with water. In this study, hydrogel viscosity and spinnability, as well as orientation and strength of the spun filaments, were found to be strongly affected by the osmotic pressure as determined by CNF surface charge and solid fraction in the spinning dope. The strength of filaments with a 83% degree of

orientation as shown by wide-angle X-ray scattering (WAXS) reached remarkable values, as high as 297 MPa and 21 GPa for the tensile strength and Young’s modulus, respectively. A thorough investigation of the interactions with water using dynamic vapour sorption (DVS) measurements revealed the role of sorption sites in the stability of the filaments in wet conditions. DVS analysis during cycles of relative humidity (RH) between 0 and 95% revealed major differences in water uptake by the filaments spun from alternative types of hydrogels. It is concluded that the mechanical performance of filaments in the

Strength and Water Interactions of Cellulose I Filaments Wet-Spun from

Cellulose Nanofibril Hydrogels

Meri J. Lundahl1, A. Gisela Cunha1, Ester Rojo1, Anastassios C. Papageorgiou2, Lauri Rautkari1, Julio C. Arboleda1 and Orlando J. Rojas1

1 Aalto University, Department of Forest Products Technology. P.O. Box 16300,

00076 Aalto, Finland 2 Turku Centre for Biotechnology, University of Turku and Åbo Akademi University,

20520 Turku, Finland

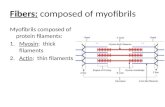

Figure 1. Left, top: Bundles of CNF filaments holding probing weights. Right, top: SEM micrographs of filament surface. Left, bottom: X-ray diffractogram of a filament. Right, bottom: graphical representation of the arrangement of CNF in the filament.

Simultaneous In-situ Analysis of Instabilities and First Normal StressDifference during Polymer Melt Extrusion Flows

Roland Kádár1,2, Ingo F. C. Naue2 and Manfred Wilhelm2

1 Chalmers University of Technology, 41258 Gothenburg, Sweden2 Karlsruhe Institute of Technology - KIT, 76128 Karlsruhe, Germany

ANNUAL TRANSACTIONS OF THE NORDIC RHEOLOGY SOCIETY, VOL. 24, 2016

ABSTRACTA high sensitivity system for capillaryrheometry capable of simultaneously de-tecting the onset and propagation of insta-bilities and the first normal stress differ-ence during polymer melt extrusion flowsis here presented. The main goals of thestudy are to analyse the nonlinear dynam-ics of extrusion instabilities and to deter-mine the first normal stress difference inthe presence of an induced streamline cur-vature via the so-called ’hole effect’. Anoverview of the system, general analysisprinciples, preliminary results and overallframework are herein discussed.

INTRODUCTIONCapillary rheometry is the preferredrheological characterisation method forpressure-driven processing applications,e.g. extrusion, injection moulding. Themain reason is that capillary rheometry isthe only method of probing material rheo-logical properties in processing-like condi-tions, i.e. high shear rate, nonlinear vis-coelastic regime, albeit in a controlledenvironment and using a comparativelysmall amount of material.1 Thus, it isof paramount importance to develop newtechniques to enhance capillary rheome-ters for a more comprehensive probing ofmaterial properties. Extrusion alone ac-counts for the processing of approximately35% of the worldwide production of plas-tics, currently 280⇥ 106 tons (Plastics Eu-rope, 2014). This makes it the most im-portant single polymer processing opera-

tion for the industry and can be found ina variety of forms in many manufacturingoperations. Extrusion throughput is lim-ited by the onset of instabilities, i.e. prod-uct defects. Comprehensive reviews on thesubject of polymer melt extrusion insta-bilities can be found elsewhere.4,6 A re-cent method proposed for the detectionand analysis of these instabilities is that ofa high sensitivity in-situ mechanical pres-sure instability detection system for cap-illary rheometry.8,10 The system consistsof high sensitivity piezoelectric transducersplaced along the extrusion slit die. In thisway all instability types detectable, thusopening new means of scientific inquiry. Asa result, new insights into the nonlinear dy-namics of the flow have been provided.9,14

Moreover, the possibility of investigatingthe reconstructed nonlinear dynamics wasconsidered, whereby a reconstructed phasespace is an embedding of the original phasespace.2,14 It was shown that a positive Lya-punov exponent was detected for the pri-mary and secondary instabilities in lin-ear and linear low density polyethylenes,LDPE and LLDPE,.14 Furthermore, it wasdetermined that Lyapunov exponents aresensitive to the changes in flow regime andbehave qualitatively different for the iden-tified transition sequences.14 It was alsoshown that it is possible to transfer thehigh sensitivity instability detection sys-tem to lab-sized extruders for inline ad-vanced processing control and quality con-trol systems.13

A very recent possibility considered

129

presence of water deteriorates drastically by the same factors that facilitate fibril alignment (WAXS) and, consequently, dry strength. For the most oriented filaments, the maximum water sorption (RH 95%) was 39% and degree of hornification 9%.

REFERENCES 1. Iwamoto, S., Isogai, A., Iwata, T (2011), "Structure and Mechanical Properties of Wet-Spun Fibers Made from Natural Cellulose Nanofibers", Biomacromolecules, 12, 831-836. 2. Walther, A., Timonen, J.V.I., Diez, I., Laukkanen, A., Ikkala, O. (2011), "Multifunctional High-Performance Biofibers Based on Wet-Extrusion of Renewable Native Cellulose Nanofibrils", Adv. Mater., 23, 2924-2928. 3. Håkansson, K.M.O., Fall, A.B., Lundell, F., Yu, S., Krywka, C., Roth, S.V., Santoro, G., Kvick, M., Wittberg, L.P., Wågberg, L., Söderberg, L.D. (2014), "Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments", Nat. Commun., 5, 4018. 4. Torres-Rendon, J.G., Schacher, F.H., Ifuku, S., Walther, A. (2014), "Mechanical Performance of Macrofibers of Cellulose and Chitin Nanofibrils Aligned by Wet-Stretching: A Critical Comparison", Biomacromolecules., 15, 2709-2717.

M. J. Lundahl et al.

130