Simulation and Experimental Validation of Tethered ...hemh1/SPICE/...MastersThesis.pdf · Abstract...

Transcript of Simulation and Experimental Validation of Tethered ...hemh1/SPICE/...MastersThesis.pdf · Abstract...

Modeling and Experimental Characterization of a Tethered

Spherical Aerostat

Philippe Coulombe-Pontbriand

Department of Mechanical Engineering

McGill University, Montreal, Canada

August 2005

A thesis submitted to McGill University, Montreal in partial

fulfillment of the requirements of the degree of

Masters of Science

Philippe Coulombe-Pontbriand, 2005

Abstract

Tethered helium balloons are known to be useful in applications where a payload

must be deployed at altitude for a long duration. Perhaps the simplest such system

is a helium-filled sphere tethered to the ground by a single cable. Despite its

relative simplicity, there exists little data about light tethered spheres in a fluid

stream. The current work focuses on an investigation of the dynamic

characteristics of a spherical aerostat on single tether. A test facility was

constructed to gather the experimental data required for a characterization of the

system. The balloon’s drag coefficient is extracted from the position

measurements. Our experiments were all in the supercritical range that is, at

Reynolds numbers greater than 3.7 × 105. We find that the balloon’s large

oscillations and surface roughness combined with the wind turbulence result in a

substantial increase in the drag coefficient. A model of the dynamics of a

spherical aerostat was previously developed at McGill University and our

experimental data was used to refine and improve that simulation. The aerostat is

modeled as a single body attached to the last node of a tether. It is subject to

buoyancy, aerodynamic drag and gravity. The tether is modeled using a lumped-

mass method. The dynamic simulation of the aerostat is obtained by setting up the

equations of motion in 3D space and integrating them numerically. Finally, the

model is validated through comparison with experimental data and a modal

analysis is performed.

ii

Résumé

Les ballons à hélium attachés au sol sont régulièrement utilisés lorsque des

charges doivent être déployées dans les airs pour une longue période. Le système

le plus simple consiste en un ballon sphérique attaché au sol par un seul câble.

Bien que ce système soit extrêmement simple, il n’existe que très peu

d’informations relatives aux sphères attachées dans un écoulement de fluide. Le

travail présenté dans cette thèse porte sur l’analyse de la dynamique d’un ballon

sphérique attaché au sol par un seul câble. La construction d’une installation

expérimentale a permis d’acquérir les données nécessaires à la caractérisation du

système. À partir des mesures de position, le coefficient de traînée du ballon a pu

être déduit. Toutes nos expériences ont été effectuées au delà du nombre critique

de Reynolds, i.e. supérieur à 3.7 × 105. Nous avons observé que les oscillations

du ballon ainsi que les imperfections de sa surface ont pour effet d’augmenter

considérablement le coefficient de traînée en comparaison avec un sphère fixe.

Nos données expérimentales ont été utilisées pour améliorer une simulation de la

dynamique du ballon développée à l’université McGill lors de recherches

antérieures. Le ballon est modélisé comme un corps rigide soumis à la gravité, à

la résistance de l’air et la force de poussée. La simulation est construite en

définissant les équations de mouvement du ballon en trois dimensions et en les

intégrant numériquement. Finalement, le modèle est validé en comparant les

résultats avec les données expérimentales.

iii

Acknowledgments

I would like to express my sincere gratitude to the people whose assistance and

support have allowed this research to be successful. First I want to thank my

supervisor Meyer Nahon for his constant guidance. You rarely meet someone who

inspires you for his human skills and research abilities. I would like to thank a

number of co-op students who brought fresh ideas and enthusiasm to this project.

These students are Domenico Mazzocca, Jennifer Perez and Magnus Nordenborg.

Thanks to my lab partners Jonathan Miller, Yuwen Li, François Deschênes and

Evgeni Kiriy for coming out to fly the balloons. A special thank to Casey Lambert

for his numerous advices and helping out with the experiment. Thanks to Alistair

Howard for biking with me.

Thanks to my brother Moïse for his support throughout the most difficult

years of my studies. I will never forget. Thanks to my loving sister Myriam who

inspired me courage and determination. I transmit a warm thanks to my parents,

Denis and Gilberte, for looking after me and reminding me that dreaming is

important, but more important still, is to live our dream.

Thanks to my friends, Dadou, Bast, Maestro, Regean (Big Monkey) et les

autres who are dancing and playing music tonight.

Finally, I want to express the warmest thanks to my girlfriend and life

partner Marleine Tremblay for being my life inspiration. Thank you for being

beside me day after day, thanks for allowing me to dream the world, thanks for

being who you are.

iv

Table of Contents

Abstract.................................................................................................................. ii Résumé .................................................................................................................. iii Acknowledgements .............................................................................................. iv Table of Contents .................................................................................................. v List of Figures...................................................................................................... vii List of Tables……………………………………………………………………..x 1. Introduction....................................................................................................... 1

1.1Overview........................................................................................................ 1 1.2 Motivation..................................................................................................... 2 1.3 Literature Survey .......................................................................................... 4

1.3.1 Tethered Aerostat Dynamics/Simulation............................................... 4 1.3.2 Sphere in Fluid Flow.............................................................................. 5

1.4 Thesis Contributions and Organisation......................................................... 6 2. Design of Test Facility ...................................................................................... 8

2.1 Requirements for the Experimental Set-Up.................................................. 8 2.2 Physical Platform .......................................................................................... 9

2.2.1 The Aerostat......................................................................................... 10 2.2.2 Tether ................................................................................................... 12 2.2.3 Winch................................................................................................... 15

2.3 Sensors and Communication Systems ........................................................ 15 2.3.1 GPS components .................................................................................. 16 2.3.2 Load Cell.............................................................................................. 18 2.3.3 SY016 A/D Board................................................................................ 18 2.3.4 Wind Sensors ....................................................................................... 19 2.3.5 Wireless Local Area Network (WLAN) .............................................. 21 2.3.6 Power ................................................................................................... 21 2.3.7 Summary .............................................................................................. 23

2.4 Software interface ....................................................................................... 23 2.5 The Instrument Platform ............................................................................. 24

2.5.1 Effect of the Platform on the Aerostat Properties ................................ 26 2.6. Experimental Procedure............................................................................. 27

3. Data Analysis ................................................................................................... 29 3.1 Days of experimentation ............................................................................. 29 3.2 Position ....................................................................................................... 30

3.2.1 Position Analysis ................................................................................. 30 3.3 Lift Force .................................................................................................... 34 3.4 Tension........................................................................................................ 35 3.5 Wind............................................................................................................ 37

3.5.1 Wind velocity, direction and frequency content .................................. 37

v

3.5.2 Power Law ........................................................................................... 39 3.5.3 Wind Extrapolation………………………………………………….. 40

3.6 Drag Force and Drag Coefficient................................................................ 41 3.6.1 Drag Force ........................................................................................... 41 3.6.2 Drag Coefficient................................................................................... 43

3.7 Aerostat Oscillations ................................................................................... 46 3.7.1 Axis Realignment................................................................................. 46 3.7.2 Oscillations .......................................................................................... 47 3.7.3 Scaling.................................................................................................. 49 3.7.4 Amplitude of Oscillation...................................................................... 50 3.7.5 Frequency of Oscillation...................................................................... 51 3.7.6 Nature of the Oscillations .................................................................... 53

4. Simulation of a Spherical Aerostat................................................................ 56 4.1 Original Model............................................................................................ 56

4.1.1 Cable Model......................................................................................... 57 4.1.2 Aerostat Model..................................................................................... 58 4.1.3 Wind Model ......................................................................................... 58

4.2 Proposed Model .......................................................................................... 59 4.2.1 Equations of Motion ............................................................................ 60 4.2.2 Revised Wind model…...……………………………………............ .65 4.2.3 Lateral Forces…………………………………………………………67

4.3 Physical Parameters .................................................................................... 69 4.3.1 Aerostat parameters ............................................................................. 69 4.3.2 Tether Parameters ................................................................................ 70

4.4 Non-linear Simulation Results and Comparison......................................... 71 4.5 Linear Model............................................................................................... 74

4.5.1 Description and Validation of the Linear Model ................................. 75 4.5.2 Decoupling........................................................................................... 77 4.5.3 Eigenvectors and Eigenvalues ............................................................. 78 4.5.4 Results.................................................................................................. 79 4.5.5 Reference Frequencies ......................................................................... 83

4.5.6 Damping Ratio..………………………………………………………86 5. Conclusion ....................................................................................................... 90

5.1 Test Facility .......................................................................................... 90 5.2 Data Analysis .............................................................................................. 91 5.3 Simulation ................................................................................................... 92 5.4 Recommendations....................................................................................... 94

References…...…………………………………………………………………..95

vi

List of Figures

Figure 1.1: Flight of the Montgolfier brother on June 1783[1] .............................. 1 Figure 1.2: Explosion of the Hindenburg on May 3, 1937[2] ................................ 2 Figure 1.3: Picture of a streamlined aerostat[3]...................................................... 3 Figure 2.1: Picture of the physical platform.. ......................................................... 9 Figure 2.2: Example of streamlined aerostat. The picture shows a TIF-460®

aerostat from Aerostar[36] ............................................................................ 10 Figure 2.3: Examples of variable lift aerostats. The balloon on the left is the

Skydoc® from FLOATOGRAPH[37] and the one on the right is the Helikite® from ALLSOPP[38]...................................................................................... 11

Figure 2.4: Technical drawing of the balloon showing the tether arrangement .. 14 Figure 2.5: Picture of the tether attachment configuration. A zoom on a strap used

to distribute the load is also shown ............................................................... 14 Figure 2.6: Picture of the CSW-1 winch supplied by A.G.O. Environmental

Electronics Ltd. ............................................................................................. 15 Figure 2.7: Diagram of the sensors/communication system. ................................ 16 Figure 2.8: Picture of the MLP75 load cell from Transducer Techniques. The two

eyebolt screws and carabiners were used to attached the cables at the confluence point............................................................................................ 18

Figure 2.9: Plot of the SY016 board calibration. The figure shows the highly linear response of the load system. ............................................................... 19

Figure 2.10: Picture of the wind tower with the Young wind sensors at 3, 5 and 10 m. ............................................................................................................. 19

Figure 2.11: Plots of the raw outputs of the Young anemometers. The top graph is the wind speed channel output. The middle graph is the excitation for the wind direction acquisition shown and the lower graph is the returned wind direction pulse. .............................................................................................. 20

Figure 2.12: Time variation of the voltage and current for a continuous acquisition. The tension acquisition failed after 6.5 hours. .......................... 22

Figure 2.13: Information flow of the software interface....................................... 24 Figure 2.14: On the left is a Pro-E drawing of the platform. The picture on the

right shows how the platform was attached to the balloon........................... 25 Figure 2.15: The left picture shows a technical drawing of the platform that with the four stabilization lines. On the right is a picture of the actual platform.......... 26 Figure 2.16: The ground handling of the balloon was perfromed by one person. A

soft carpet was used to keep the balloon close to the ground. ...................... 28 Figure 3.1: Schematic of the relative positions of the components of the aerostat system. .................................................................................................................. 31 Figure 3.2: Magnitude of rWA for Flight 9. ........................................................... 32

vii

Figure 3.3: Components of rWA for Flight 9.......................................................... 32 Figure 3.4: Schematic of the variable relevant to the calculation of the mean

angle. ............................................................................................................. 33 Figure 3.5: Time history of the angle for Flight 9. ............................................... 34 Figure 3.6: Plot of the free lift measured with the Transducer Techniques load cell

....................................................................................................................... 35 Figure 3.7: Plot of the tension data for Flight 9, compared to the aerostat free lift

line................................................................................................................. 36 Figure 3.8: Tether tension at the different cable lengths. ..................................... 36 Figure 3.9: Graph of the wind speed and direction at 3, 5 and 10 metre for Flight

9..................................................................................................................... 37 Figure 3.10: Power spectrum of the wind of Flight 9 at 10m height. ................... 38 Figure 3.11: Plot of the average wind speed against the height for Flight 9. A power law is fitted to extract the value of the exponent…………………………39 Figure 3.12: Plot of the fitted wind speed of Flight 9. The wind speed at 3m is

shown to show how the 10th order polynomial smoothes the curve. ............ 41 Figure 3.13: Ideal sketch of the aerostat equivalent static system. ....................... 42 Figure 3.14: This figure shows the drag force versus the wind speed. A curve is

fitted to demonstrate the quadratic dependence on the velocity. .................. 43 Figure 3.15: Comparison of the sphere drag coefficients ..................................... 45 Figure 3.16: Top view of the aerostat to show the new coordinate frame aligned

with the wind direction ................................................................................. 46 Figure 3.17: Typical projection trajectory in the horizontal plane ....................... 48 Figure 3.18: Oscillatory behaviour of the aerostat for Flight 9.. .......................... 48 Figure 3.19: Comparison of the normalized oscillation amplitude of the tethered

sphere used in experiment with the Govardhan and Williamson results. ..... 51 Figure 3.20: Power spectrum of the transverse motion for Flight 9 ..................... 52 Figure 4.1: 2-D sketch of the original model showing the discretization of cable.

....................................................................................................................... 57 Figure 4.2: Cable element and node representation.............................................. 58 Figure 4.3: Idealized sketch of the proposed aerostat model. rT is the vector from

centre of gravity to the confluence point and FT is the resultant force of the last element acting on the aerostat. ............................................................... 59

Figure 4.4: Idealized sketch of the aerostat system showing the body-fixed and inertial frames. .............................................................................................. 60

Figure 4.5: Free body diagram of a tethered sphere in a fluid flow...................... 61 Figure 4.6: Comparison of the turbulent intensities vs. height from various

sources. A zoom on heights below 50 m is presented to better show the region of interest. .......................................................................................... 66

Figure 4.7: The power spectral density for the measured and simulated horizontal turbulence along the wind direction for Flight 9 and Flight 4. ..................... 67

Figure 4.8: Comparison of experimental and simulated results for the aerostat position for Flight 9 at L=15m...................................................................... 74

Figure 4.9: Comparison of the experimental and simulated results for the tether tension for Flight 9 at L=15m ....................................................................... 74

viii

Figure 4.10:Comparison of the linear and non-linear response of the aerostat motion for a tether length L=45 m and wind speed U =1 m/s ..................... 77

Figure 4.11: Magnitude of the response of the different state variables fo the lowest 4 longitudinal modes. ........................................................................ 80

Figure 4.12: Graphical representation of the various modes of oscillation of a spherical tethered aerostat............................................................................. 82

Figure 4.13: Spectral density of the tension for Flight 9 for the various tether lengths. The black spike shows the values of the theoretical frequencies. ........... 86 Figure 4.14: The schematic on the left shows a free body diagram of a pure x-

motion of the aerostat.................................................................................... 86

ix

List of Tables

Table 2.1 Comparison of streamlined and spherical aerostat properties[33]........ 11 Table 2.2: Comparison of the properties of the Plasma® rope from Cortland

cable[37] and of a simple Nylon Cable......................................................... 13 Table 2.3 System Components ............................................................................. 23 Table 2.4: Total load on the aerostat..................................................................... 25 Table 2.5: Comparison of the Physical Properties of the Aerostat and a Spherical

Shell filled with helium................................................................................. 27 Table 3.1 Wind condition for the different days of experimentation.................... 30 Table 3.2: Position data of Flight 9....................................................................... 33 Table 3.3: Mean tension at the different cable lengths for Flight 9 ...................... 37 Table 3.4: Wind characteristics of Flight 9........................................................... 38 Table 3.5: List of parameters of interest for the calculation of the drag coefficient

CD .................................................................................................................. 44 Table 3.6: Position data of Flight 9 after realignment .......................................... 47 Table 3.7: Comparison of the dimensionless quantities for the aerostat used in

this experiment and the Williamson’s tethered sphere. ................................ 50 Table 3.8: Comparison of the dominant frequency in power spectrum with the

theoretical pendulum frequency of the system for Flight 9 .......................... 52 Table 4.1: Physical parameters ............................................................................. 70 Table 4.2: Tether parameters ................................................................................ 71 Table 4.3: Comparison of experimental and simulated results for the three flight

sections of Flight 9........................................................................................ 72 Table 4.4: Comparison of the analytical and model modal frequencies for L =

45m ............................................................................................................... 84 Table 4.5: Comparison of the simulated and theoretical damping ratio for U=1m/s

and L=45m.................................................................................................... 88

x

Chapter 1

Introduction

1.1 Overview

The Montgolfier brothers, born in Annonay, France, are the inventors of the first practical

balloon for flight. The first demonstrated flight of a hot air balloon took place on June 4,

1783, in Annonay, France in front of an astonished crowd.

Figure 1.1: Flight of the Montgolfier brothers on June 1783[1].

Less than six months after the ground-breaking Montgolfier flight, the French physicist

Jacques Charles (1746-1823) and Nicolas Robert (1758-1820) made the first untethered

ascension with a hydrogen filled balloon on December 1, 1783. On that same day was

born a completely new research area, the study of lighter-than-air systems. These types of

systems include any vehicle capable of deriving its lift from the buoyancy of its internal

gasses rather than from its aerodynamics. The golden age of lighter-than-air systems

1

happened during the beginning of the 20th century with the advent of the Zeppelin

airships. These were gigantic rigid dirigibles filled with hydrogen to transport civilians

and soldiers. Unfortunately, the infamous explosion of the Hindenburg on May 6, 1937

led to the end of most research and development on new lighter-than-air technologies.

Until recently, little advance had been achieved in this field.

Figure 1.2: Explosion of the Hindenburg on May 6, 1937[2].

With the constant increase in fuel price, aircraft and helicopters have become an

increasingly expensive choice for payload carriage and transportation. Consequently, the

aerospace community is attracted by flight technologies that can derive their lift at lower

cost. This has resulted in renewed interest in lighter-than-air systems, especially for

applications where a payload must be airborne for long duration. Tethered helium

aerostats have been shown to be a natural option to perform this type of task and are now

commonly used in a wide range of applications ranging from surveillance systems such

as the T.A.R.S. (Tethered Aerostat Radar System) at the border of Mexico and the United

States, to advertising in public spaces. In Canada, the proposed LAR system[1] uses a

tethered balloon to carry the receiver of a large radio telescope.

1.2 Motivation

Although tethered helium balloons are now used for various applications, a limited

amount of research has been performed on them. Until recently, most of the knowledge

2

of these systems was based on experiments and qualitative research. Some understanding

of their behaviour was attained, but very little was known about the forces and moments

acting on balloons in flight. With the advent of new technologies and the increasing

desire to use tethered aerostats in advanced applications where reliability is critical,

systematic studies of the system stability and nonlinear simulation have become more

important to better understand the system behaviour. This understanding comprises a

challenge that can only be resolved using a multidisciplinary perspective including

system dynamics, fluid-structure interaction, simulation and meteorology. Questions such

as how a tethered balloon would react in strong turbulent winds are still to be answered

and the tools to answer it are yet to be developed and integrated.

Most of the past research has been performed on so-called streamlined or blimp

shaped balloons as shown in Figure 1.3.

Figure 1.3: Picture of a streamlined aerostat[3].

This appears to be a natural choice since they present advantages for flight such as low

aerodynamic drag and the ability to produce aerodynamic lift. However, with the desire

to apply lighter than air technology in innovative applications such as payload carriage,

fast deployment surveillance systems, or even low cost aerial photography, some new

variables have to be taken into account like the stability of the system in winds and ease

of deployment and use. New balloon shapes might be more suitable for these

applications, but there exists very little research in the open literature in this field. A

3

natural candidate to study is the spherical shape tethered helium aerostat which presents

the advantage of having no preferred orientation with respect to the wind, being relatively

easy and fast to build and having the most efficient volume to free lift ratio (due to its low

surface area). Surprisingly enough, although a spherical object attached to the ground by

a single tether in a flow is one of the simplest engineering systems one can think of, there

exists little data about it in the open literature.

1.3 Literature Survey

This thesis spans many different subjects in the literature from meteorology for wind

characterization to balloon design. However the main subject of interest is the study and

simulation of the dynamics of a tethered spherical aerostat in a wind field. This requires

an accurate knowledge of past research done on the simulation of aerostats and on the

interaction of a sphere with a fluid flow.

1.3.1 Tethered Aerostat Dynamics/Simulation

Tethered aerostats have received limited attention in the literature and most of the focus

has been directed at large streamlined aerostat. The study of the dynamics of a spherical

aerostat in wind and its simulation is still an almost untouched subject. One exception is

the work of Lambert[4], who performed a preliminary simulation of the dynamics of a

spherical tethered aerostat in a fluid flow, without experimental validation. Furthermore,

to the author’s knowledge, no data about tethered spherical aerostat motion in wind fields

has been published. The simulation of tethered streamlined aerostats has greatly

influenced this work and includes the work of Delaurier in 1972, who was the first to

study the dynamics of a tethered aerostat with a comprehensive cable model[5]. In 1973,

Redd et al., used experimental data to validate their linear simulation[6]. Jones and

Krausman in 1982 completed the first 3-D nonlinear dynamics model with a lumped

mass discretized tether[7]. Jones and Delaurier further developed this concept to come up

with a model based on semi-empirical values[8]. In 1999, Nahon presented a 3-D

nonlinear method to study a tri-tethered spherical aerostat in a wind field using a lumped

mass cable model[9]. The method was based on prior work performed on autonomous

underwater vehicles[10], submerged cable[11] and towed underwater vehicle[12]. More

4

recently, in 2001 Jones and Schroeder, performed a validation of their nonlinear model

using results from full scale flights test of an instrumented tethered aerostat[13] provided

by the U.S. army. In 2003, Lambert and Nahon presented a nonlinear model of a tethered

streamlined aerostat and suggested a method to assess the stability of a single tethered

aerostat by linearization of the equations of motion[14]. The response of the streamlined

tethered aerostat to extreme turbulence was studied by Stanney and Rahn who used a

sophisticated wind model[15]. Lambert in 2005[16] used the results from experiments

performed on a fully instrumented 20 m long tethered streamlined aerostat that was

deployed in the scope of the LAR[17] project to perform a validation of its nonlinear

model.

1.3.2 Sphere in Fluid Flow

The interaction of fixed sphere with a fluid flow and the wake that results behind it are

encountered so frequently that large numbers of experiments have been conducted and an

enormous amount of data has been accumulated. An excellent summary of the

characteristics of vortex shedding of a fixed sphere in fluid flow over a wide range of

Reynolds number is presented by Sakamoto and Haniu[18]. They divided the vortex

shedding into three regimes based on Reynolds number and vortex structure. Below a

Reynolds number of 300, there is no vortex shedding; between 300 and 2×104 the vortex

shedding is periodic and finally, above 2×104 there is strong vortex shedding although not

periodic. At a critical value of the Reynolds number, the previously laminar boundary

layer becomes turbulent. This corresponds with a sudden drop in the drag because of a

decrease in the size of the wake. Achenbach[19] in 1972 and Tenada in 1977[20]

described in detail the shape and characteristics of the wake of a fixed sphere at very high

Reynolds number (above 3.5×105), past the supercritical regime of flow where the

present experiment is performed. Willmarth and Enlow in 1969 measured for the first

time the unsteady lateral lift force generated by the vortex shedding acting on the fixed

sphere in the supercritical regime and provided a detailed study of its magnitude and

frequency content[21]. Thirty years later, Howe et al.,[22] performed measurement of the

lift force on a fixed sphere for a similar flow regime that were in agreement with

Willmarth and Enlow. They also discussed the possible contribution of the lift force to

5

the erratic motion of rising spherical weather balloon discussed by Scoggins in 1967[23,

24].

To the author’s knowledge the first reported study of the oscillation of tethered

spheres in a fluid flow was performed in Moscow university by Kruchinin[25]. He

attributed the oscillation of the tethered sphere to its acceleration, which created a surface

pressure unbalance at the critical Reynolds number. Other studies in the literature are

concerned with the action of surface waves on a tethered buoyant spherical structure.

These include the work by Harleman and Shapiro in 1961[26], Shi-Igai and Kono

1969[27] and Ogihara in 1980[28]. They employed empirically determined drag and

inertia coefficient to predict the sphere dynamics. The first group to give systematic

attention to the transverse oscillations of tethered sphere in a fluid flow was Govardhan

and Williamson and Williamson and Govardhan 1997[29] [30]. In 2001, Jauvtis et al.,

explained the sphere oscillations by a ‘lock in’ phenomenon of the principal vortex

shedding as described for a fixed sphere and the body motion[31]. They also discovered

the existence of a mode of oscillation at much higher flow speeds that could not be

explained by the classical ‘lock in’ theory since the vortex shedding of the fixed sphere in

that flow regime would have no frequency content close to the natural pendulum

frequency of the tethered sphere. Govardhan and Williamson provided the explanation to

the unexpected phenomenon in 2005[32]. They attributed the oscillations of the tethered

sphere to ‘movement induced vibration’ as categorized by Naudasher and Rockwell in

1994[33] where the sphere motion generates self-sustaining vortex forces. Other research

in that field includes the work of Bearman in 1984[34] and Anagnostopoulos in 2002[35].

1.4 Thesis Contributions and Organisation

The focus of the present work is the analysis and simulation of the dynamics of a tethered

spherical aerostat in a wind field. This includes the design and construction of an

experimental platform capable of recording the tether forces and the motion of the

aerostat; the analysis of the motion data; and a computer simulation of the aerostat

behaviour.

In Chapter 2, a detailed description of the experimental platform is presented. It

discusses a method to accurately measure the time history of the aerostat position and of

6

the tether tension. A rationale for the choice of sensors, tether, aerostat size and other

physical components is provided. The chapter ends with a discussion of the experimental

procedure.

Chapter 3 presents a detailed examination of the dynamics of the 3.5 m diameter

spherical aerostat used in the experiment. A method to extract the average drag

coefficient of the tethered buoyant sphere in an outdoor environment is presented. The

experimental motion data present clear perpendicular to flow oscillations of the aerostat.

A characterization of the aerostat’s large transverse vibration is presented and various

potential explanations for the phenomenon are explored.

In Chapter 4, the dynamics model developed by Lambert[4] for a spherical

aerostat is used as basis to generate a more detailed and accurate model. A brief

introduction to the dynamics model by Lambert is presented first. This is followed by

details of the modifications made to the original model to make it more representative of

the tethered aerostat system used in the experiment. The results of the nonlinear model

are then compared to experimental data and conclusions are drawn. Finally, the dynamics

model is used to conduct a linear analysis of the system. The equations of motion are

linearized about an equilibrium state and a thorough modal analysis is performed.

Chapter 5 presents the conclusions of the research as well as recommendations for

future work.

7

Chapter 2

Design of Test Facility

In this chapter, the construction and operation of a portable experimental set-up for the

characterization of the dynamics of a tethered aerostat are presented. The experimental

set-up is divided into four subsystems, the physical platform, the sensor system, the

communication system and the software interface. Section 2.1 discusses the performance

requirements used to guide the design of the set-up. Section 2.2 describes the design of

the system, which includes the balloon, the tether, the winch and the instrument platform.

In Section 2.3, descriptions of the sensors and of the communication system are

presented. The different options considered for the communication system are compared.

Section 2.4 gives a description of the interfacing software DATAS (Dynamics

Acquisition of a Tethered Aerostat System), an in-house software for sensor integration

and time synchronization. In Section 2.5 a description of the platform that carries the

airborne instrumentations is given. Finally, Section 2.6 describes the experimental

procedure, including the process from ground handling to launching.

2.1 Requirements for the Experimental Set-Up

Prior to giving a detailed description of the experimental set-up, it is important to

describe the goals and performance requirements of the facility. The ultimate goal was to

develop a light and compact experimental set-up that would allow accurate measurement

of the time history of the balloon’s motion and of the tension in the cable. These two

variables are sufficient to fully describe the dynamics of the system; to extract all the

forces acting on the aerostat. The design of the facility was adopted based on the

following requirements:

8

The sensors should provide centimetre level accuracy on position measurement,

and frequency bandwidth of 2.5 Hz both on the position and tension acquisitions.

The aerostat free lift (net upward force) should be at least 12 kg without the

instruments onboard.

The total weight of the instrumentation carried by the balloon should be as low as

possible.

The entire set-up should be compact and convenient to use. It should not require

more than 2 people to operate safely.

A single experiment should not take more than 5 hours to perform.

The facility should accommodate different shapes of aerostat.

The sensing system should have a minimal impact on the natural dynamics of the

system.

The system should withstand gusts of up to 15 m/s and operating wind speed of

10 m/s.

2.2 Physical Platform

The facility includes the following elements: the aerostat, the tether and the winch, as

shown in Figure 2.1.

Figure 2.1: Picture of the physical platform. The black spot at the bottom of the balloon is the instrument platform.

9

2.2.1 The Aerostat

The main factors that influence the choice of a particular aerostat are its shape, its size, its

survivability its cost and its availability.

The two most popular shapes of aerostats available on the market are the

streamlined and the spherical aerostat. Figure 2.2 shows a picture of the TIF-460®, a

streamlined aerostat manufactured by Aerostar. An example of a spherical aerostat is

shown in Figure 2.1.

Figure 2.2: Example of streamlined aerostat. The picture shows a TIF-460® aerostat from Aerostar[36].

Other shapes of aerostat that provide variable lift are available but are quite uncommon.

Figure 2.3 shows two examples of this kind of aerostat, the Skydoc® from

FLOATOGRAPH technologies and the Helikite® from ALLSOPP.

10

Figure 2.3: Examples of variable lift aerostats. The balloon on the left is the Skydoc® from FLOATOGRAPH[37] and the one on the right is the Helikite® from ALLSOPP[38]

A compact aerostat facilitates the storage when inflated and makes the ground handling

easier. An interesting point to note is that a spherical shape maximizes the internal

volume for a given surface area. Thus, in terms of compactness, a spherical aerostat is

desirable. As an example, Table 2.1 shows the physical characteristics of a streamlined

and a spherical aerostat from Aerostar both having free lift around 16 kg and made out of

the same material (urethane coated nylon).

Table 2.1 Comparison of streamlined and spherical aerostat properties[39]

Shape Size L × D

(m)

Material

Weight (kg) Volume (m3)

Free lift

(kg)

Drag (N) at

U = 15 m/s

Streamlined

(TIF-1000®) 10.5 ×2.5 14.15 28.32 15.87 52.9

Spherical 3.5 × 3.5 6.52 22.45 17.22 532.1

Another factor to consider when choosing a type of aerostat is survivability,

which refers to the aerostat’s ability to remain intact in high winds. Referring to our

requirements, the aerostat should withstand a 10 m/s operating wind and gusts up to 15

m/s. It is known that, for a given wind speed, the external force on the hull will be less for

a streamlined aerostat than for a spherical one since it has a lower drag coefficient and a

smaller frontal area. A drag coefficient of 0.078 is given from experimental data of a

11

streamlined body in McCormick[40]. The drag coefficient of the sphere was estimated

based on values for rough fixed sphere. Goldstein[41] mentions that the surface

roughness considerably reduces the supercritical drop in drag coefficient that normally

occurs around a Reynolds number of 3.7×105 [42], leading to an almost constant

coefficient. Thus the value of drag coefficient was estimated to 0.4, which corresponds

to that of a fixed sphere in the subcritical region[42]. A better estimate of the drag

coefficient will be obtained in Chapter 4. The drag force is expressed as

Da ACUD 2

21 ρ= (2.1)

where CD is the drag coefficient, aρ is the air density taken as 1.229 kg/m3, U the free

stream velocity and A is the sphere’s frontal area, πr2, where r is equal to 1.75 m for the

spherical balloon and 1.25 for the streamlined one. As seen in Table 2.1, the estimated

drag force for U = 15 m/s on a spherical aerostat with 16 kg lift is about eight times larger

than for a streamlined balloon with similar lift. However, balloons that withstand our

operating conditions are available on the market in both shapes. In terms of cost,

streamlined aerostats are more expensive than spherical ones. Normally, a streamlined

aerostat will cost 30 to 50 percent more for the same free lift.

A decision was made to use a 3.5 m spherical aerostat made out of urethane

coated nylon to keep the system as small a possible. Also, from a scientific perspective,

the experimental characterization of the dynamics of a spherical tethered body in

turbulent flow is of prime interest since there is little data available on the subject even

though such systems are commonly used. The balloon was bought from Aerostar, due to

their professional approach at answering our numerous questions, and their interest in

collaboration.

2.2.2 Tether

The choice of tether material was made based on expertise developed at McGill in the

context of the LAR project [17]. That system has successfully used Plasma® rope from

Cortland Cable to tether their streamlined aerostat to the ground. This particular material

is characterized by a very high elastic modulus and strength to weight ratio. It is clear that

12

lighter tethers are desirable since a heavy cable would reduce the lift available to carry

the instrumentation.

In order to determine the required cable diameter, an estimate was made of the

static tension for a wind of 15 m/s. Assuming an equilibrium of forces acting on the

balloon between the free lift L, the cable tension T and the aerodynamic drag D, we can

solve for T using

22 LDT += (2.2)

where D is calculated using equation (2.1) and equals to 532.1 N at 15 m/s. For these

calculations, the lift was taken to be 168.8 N, thus yielding a tension of 558.2 N. In a real

environment, the acceleration of the balloon would contribute to increase the maximum

tension. For that reason, a factor of safety of at least three should be respected on the

breaking strength. The properties of the selected 1.5 mm 12 strand Plasma® rope are

presented in Table 2.2 and are compared to those of a nylon cable.

Table 2.2: Comparison of the properties of the Plasma® rope from Cortland cable[43] and of a simple

Nylon Cable

Tether

material

Diameter

(mm)

Density, ρt (kg/m3)

Breaking

strength Sb

(N)

Elastic

Modulus, E

(Gpa)

Sb/ ρt

(m4/s2)

Plasma® 1.5 980 2100 38 2.14

Nylon 1.5 1140 1100 3.9 0.96

The balloon is tethered using a single 1.5 mm cable that further divides at the

confluence point into four 1 mm secondary lines as shown on Figure 2.4.

13

Figure 2.4 Technical drawing of the balloon showing the tether arrangement.

Using multiple secondary lines contributes to reducing stress on the aerostat

fabric at the attachment. To further distribute the stress on the fabric, two straps were

sewn along the surface of the balloon, each starting from one of the secondary lines, over

the top of the balloon, ending at the opposing secondary line. The four secondary lines

were attached to these straps as shown on Figure 2.5.

Figure 2.5: Picture of the tether attachment configuration. A zoom on a strap used to distribute the load is also shown

14

2.2.3 Winch

Winch selection was inspired by previous research in the scope of the LAR project. The

CSW-1 model, shown in Figure 2.6, was purchased from A.G.O. Environmental

Electronics Ltd .

Figure 2.6: Picture of the CSW-1 winch supplied by A.G.O. Environmental Electronics Ltd.

The main advantages of the CSW-1 winch are that it is compact and is battery powered.

These features are desirable since it allows flexibility in the choice of launch site. The

winch weighs 30 Kg and has outer dimensions of 63.5 × 55.9 × 45.7 cm (L×W×H). A

standard permanent magnet, face mount Leeson motor (model M1120046) drives the

winch. The motor rating is 124 Watts at 12 VDC for a typical current load of about 10 A.

The winch is powered by a standard 12 V lead/acid car battery and can retrieve a 30 kg

load at a rate of 6-10 m/min. The motor speed reducer system consists of a gearbox and a

sprocket drive. The gearbox has a 30:1 ratio and the sprocket drive 1:2.5 for an

equivalent gearing of 12:1. The winch is manually controlled through a control box with

buttons for forward and reverse operation. The winch is equipped with a manual brake

and manual crank drive in case of emergency. To facilitate its transportation, it was

bolted to a wheeled platform.

2.3 Sensors and Communication Systems

The sensors and communication systems are used to collect experimental data for the

characterization of the aerostat dynamics. The systems must be able to accurately

measure the environmental conditions as well as the aerostat response without altering

15

the natural behaviour of the aerostat. Different options were considered by David

Aristizabal, a work-term student. The final sensors and communication system can be

divided into two subsystems: the ground-based components, which enable ground

handling and operation, and the airborne components flying with the aerostat. All the

components are shown in Figure 2.7. These components are now considered in more

detail.

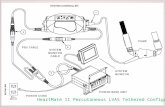

Figure 2.7: Diagram of the sensors/communication system

2.3.1 GPS components

The choice of GPS system was based upon compactness and accuracy. A minimal

accuracy of 5 cm on the position was required in order to describe the motion of the

16

aerostat precisely. One of the only commercially available technology that can achieve

this accuracy over long distances is differential GPS or DGPS[44]. The underlying

premise of DGPS requires that a GPS receiver, known as the base station, be set up at a

precisely known location. The base station receiver calculates its position based on

satellite signals and compares this location to the known location. The corrections thus

obtained can then be applied to the GPS data recorded by the roving GPS receiver located

on at the aerostat.

The DGPS hardware was purchased from NovAtel a Calgary based company and

consists of two GPS receivers and two antennas. The base receiver is the DL-4 plus. It is

powered by an OEM4-G2L card which is L1/L2 carrier phase compatible. The DL-4 plus

features 2 RS-232 ports with speeds up to 230,400 bits per second. One of the ports is

used for data collection while the other is used for time synchronisation of the different

sensors. This GPS unit can achieve an accuracy of 1.5 m on position before differential

correction at a rate of 20 Hz. The enclosure size is 185×154×71 mm and it weighs 1200

g. Nominal power consumption is 3.5 W with an input voltage of 9-18 VDC. The base

receiver antenna model is the GPS-702. It is also compatible with L1/L2 carrier phase

measurements and designed for very high accuracy measurement.

For its part, the rover receiver/antenna system has to be low power, compact, very

accurate, and most of all very light. For that purpose a FlexPak receiver and a GPS-512

antenna from NovAtel were used. The FlexPak receiver offers L1/L2 compatibility and

offers two RS-232 output ports. The main characteristics and operation of the rover

receiver are identical to the base receiver except for its compact size 147×123×45 mm, its

low weight, 307 g, and its low power consumption, 2.6 W, with an input voltage of 6-18

VDC. The GPS-512 antenna is also L1/L2 compatible. It measures 76×119× 19 mm and

weighs only 0.198 kg. The bandwidth of the GPS-512 is slightly less than that of the

GPS-702 and the noise level a little higher.

A post-processing DGPS software called GrafNav was purchased from Waypoint

Consulting Inc. GrafNav has the capability to post-process kinematic baseline to cm level

accuracy and static baseline to sub-millimetre accuracy. It also uses Kalman filtering to

fix otherwise unrecoverable cycle slips. With this software, an accuracy of about 5 cm

was achieved on the position. The software package also comes with a GPS data logger,

17

which was used to log the rover and receiver GPS position directly into ‘.gpb’ files, the

native GrafNav format.

2.3.2 Load Cell

To meet our load requirement, an MLP75 load cell from Transducer Techniques was

selected. This lightweight and compact unit can measure loads up to 75 pounds with a

safe overload of 150%. Its size is 41.66×19.05×12.7 mm and it weighs 70 g. The rated

output is 2 mV/V and the excitation voltage is 5 VDC. The temperature compensation

goes from 15.5 to 71°C with a maximum effect of 0.005% on the output. Tension in the

main tether was measured by placing the cell directly at the confluence point using two

eye-bolt screws and two karabiners as shown in Figure 2.8.

Figure 2.8: Picture of the MLP75 load cell from Transducer Techniques. The two eyebolt screws and karabiners were used to attach the cables at the confluence point

2.3.3 SY016 A/D Board

The load cell analog signal was digitized to RS-232 using a SY016 digital conditioner

and amplifier from Synectic Design. It was enclosed in an aluminium box measuring

62×43×33 mm for a total weight of 90 g. The board consumes on average 0.6 W with an

input voltage of 10-12 VDC and provides a 5 V bridge excitation. It can send up to 400

readings/sec. with a baud rate of 2400-115 200 bits/sec.

The board was calibrated in the laboratory by applying known loads to the cell

and recording the output at 10 hertz for periods of 30 seconds at each different load. The

18

data was then averaged over each 30 seconds plateau. From these measurements, a linear

plot of the load versus the amplifier output was determined as shown in Figure 2.9.

Figure 2.9: Plot of the SY016 board calibration. The figure shows the highly linear response of the load system.

The equation of the interpolated curve is used to convert the SY016 board readings into

Newtons during post-processing.

2.3.4 Wind Sensors

Wind monitoring was performed using three Young 05103-10 anemometers from

Campbell Scientific located on a tower at 3, 5 and 10m above ground as shown in Figure

2.10.

Figure 2.10: Picture of the wind tower with the Young wind sensors at 3, 5 and 10 m.

19

Each sensor records the wind speed and the wind direction relative to the true north. The

raw voltage signals from the sensors were sampled and stored at 300 hertz using a PMD-

1208FS digitizer from Measurement Computing. For that purpose, six channels of the

digitizer were used, one recording the wind speed and one recording the wind direction

for each sensor. Figure 2.11 presents the shape of typical raw output signals from a

Young anemometer. The top plot is the sinusoidal wind speed voltage, the middle plot is

the returned wind direction pulse, and the lower plot is the excitation signal that triggers

the wind direction pulse.

Figure 2.11: Plots of the raw outputs of the Young anemometers. The top graph is the wind speed channel output. The middle graph is the returned wind direction pulse and the lower graph is the excitation for the wind direction acquisition.

The wind acquisition is post-processed using the DATAS software (to be discussed in

Section 2.4). The frequency of the sinusoidal output voltage is converted using the

following equation [45]:

0.098U f= (2.3)

where U is the wind speed in m/s and f is the number of cycles per second. The frequency

f of the sinusoidal wave was obtained during post-processing by counting the number of

cycles over each 0.2 second period of acquisition thus, leading to a wind speed

acquisition rate of 5 Hz.

The wind direction sensor had a 5 degrees deadband between 355º and 360º, and

it is given by 3552.5 W where 2.5 is the excitation voltage amplitude and W is the returned

wind direction voltage. The wind direction sensors have been calibrated so that the zero

20

volt output occurs when the wind blows from true north, and voltage increases as the

wind direction increases clockwise. The acquisition rate on the wind direction is limited

by the 0.5 Hz excitation rate over which we had no control.

2.3.5 Wireless Local Area Network (WLAN)

Although a slip ring was available on the winch to allow transmission of data and power

through the tether, the line length was greater than could be accommodated by the RS-

232 protocol used by the GPS unit. Wireless communication was therefore used. For our

system, the GPS is the most demanding sensor. Each position log is 4640 bits long and

thus, to log the position at 10 Hz, an effective baud rate of at least 46400 is required. The

tension log is only 176 bits long, thus requiring an additional baud rate of 1760.

A WLAN was assembled to transmit the roving GPS and the tension data to

ground. It consists of a DataHunter dual RS-232 SeriaLan and a D-Link DI-614 802.11g

wireless router used as an access point (refer to Figure 2.7). The outer casing of the

SeriaLan measures 116×88×27 mm and its total weight is 310 g. In normal operating

condition, the DataHunter consumes 3 W with 5-15 VDC input. It features two RS-232

ports that can be configured from 300 to 115200 baud rate. The roving GPS uses one of

the ports and the load cell digital amplifier the other. The data is transmitted to the D-

Link router via a radio link and then to the PC via the Ethernet port. The data stream is

finally converted back into RS-232 format using TCPCOM, a software by TAL

Technologies that creates two virtual COM ports on the computer.

The SeriaLan ports were set to 115200 baud rate since 56200 is too close to the

data transmission requirement. In order to determine the effective baud rate of the

system, a stream of 10 kilobytes was sent to the LAN and retransferred to PC via the

virtual RS-232 wireless connection. The effective baud rate was determined to be about

93000 when the base station was located 100 meters from the instrument platform. Since

the aerostat does not fly above 45 m, the WLAN set-up meets our requirements.

2.3.6 Power

Two options were considered: onboard batteries and power transmitted from the ground

through the winch and tether. The onboard battery system led to a lower system weight

(batteries are lighter than copper wires) and was therefore chosen.

21

A typical experiment takes about 2 hours to perform, and it is desirable to have

the batteries last for at least three experiments. Thus the batteries are required to last at

least six hours. The sensors and communication modules all operate in the 8-12 volts

range. To determine the power requirements of the sensors and communication systems,

a continuous acquisition was performed while monitoring the current and voltage. A set

of 8 alkaline D-cell 1.5 Volt batteries in series was used to power the system. The

acquisition lasted six and a half hours before the tension acquisition failed. As shown in

Figure 2.12 the average power consumption P=VI of the complete system is about 4.75

W.

Battery Voltage(V)

02468

101214

12:00 13:12 14:24 15:36 16:48 18:00 19:12 20:24 21:36

Sample Time

Volta

ge (V

)

Battery Current(A)

0

0.1

0.2

0.3

0.4

0.5

0.6

12:00 13:12 14:24 15:36 16:48 18:00 19:12 20:24 21:36

Sample Time

Cur

rent

(A)

Figure 2.12: Time variation of the voltage and current for a continuous acquisition. The tension acquisition failed after six and a half hours.

Based on this experiment, it was decided to use 8 D-Cell alkaline batteries to

provide power. Alkaline batteries were chosen since they have high energy density and

are easy to obtain.

22

2.3.7 Summary

Table 2.3 presents a summary of the components used in the final design of the sensor

and communication system. The model number as well as the price and weight of the

airborne components are included.

Table 2.3 System Components

Device Device Selection Weight (g) Price (C$) Location GPS1 (airborne) Novatel – FlexPack 307 7,000 Balloon GPS2 (ground) Novatel – DL4 7,000 Ground

SeriaLan Data Hunter – SeriaLan 280 283 Balloon

Wireless Access Point D-Link DI-614+ 70 Ground

Load Cell

Transducer Techniques-MLP-75 70 560 Balloon

Digital Load Cell Amplifier

Synectic Design SY016 90 337 Balloon

Cable with no wires (1.5mm) Cortland 100 450 Balloon Power Pack 8 D Cells 1200 20 Balloon GPS1 Antenna GPS 512 230 1,500 Balloon GPS2 Antenna GPS 702 1,800 Ground Total 2277 19,020

2.4 Software interface

A multithreaded software called DATAS (Dynamics Acquisition of Tethered Aerostat

System) was developed in the Visual C++ environment, to acquire, store and synchronize

the data coming from the different sensors. Time stamps for the sensors are all

synchronized on the GPS time (GPST). The data acquisition proceeds as follows: first,

two instances of WayPoint logging software are launched. One will start logging the base

GPS position on COM1 at 10 Hz and the other one logs the roving GPS position at the

same rate. All logs are time stamped with the GPST. Then, DATAS is launched

independently of the WayPoint software to log the wind and the tension. The base GPS is

prompted through COM2 to return the GPST continuously at 10 Hz. Upon receiving the

first GPST response from COM2, the Measurement Computing digitizer (PMD-1208FS)

23

starts logging the wind speed and direction voltage from the Young anemometer

continuously at 300 Hz. The PMD-1208FS will log the wind voltages for the entire flight

duration based on its own clock and the data will be realigned with GPST later, during

the post-processing stage. Immediately after the wind acquisition is launched, a first

tension measurement is performed. DATAS then waits for the next GPST acquisition and

upon arrival, triggers a tension acquisition. The tension is therefore logged at 10 Hz along

with GPST. The first GPST reading is used during post processing to align the wind data

in time if required. Figure 2.13 presents a simplified flow chart of the software interface.

Figure 2.13: Information flow of the software interface

Apart from the very first acquisition, the wind speed and direction are logged

independently from the GPST. It is thus important to determine the drift of the PMD-

1208FS clock with respect the GPST clock. The drift over 1 hour was found to be 170 ms

which was considered small enough to be neglected.

2.5 The Instrument Platform

In order to carry the instruments aloft, a platform, shown in Fig 2.14, was designed and

constructed.

24

Figure 2.14: On the left is a Pro-E drawing of the platform. The picture on the right shows how the

platform was attached to the balloon.

Two types of material were considered for the platform (to which the instruments

are attached): composite materials, such as carbon fibre/epoxy, and plastics. The

composite materials have a higher strength to weight ratio and higher stiffness. However,

they are difficult to machine. Of the plastics considered, acrylics present the better

balance between good mechanical properties, ease of fabrication and availability. Based

on that, the base platform was made of 3/8 inch thick construction grade clear acrylic.

As seen Figure 2.14, a flexible vinyl membrane with a VelcroTM patch is attached

to the platform using eight aluminium rods. The patch can in turn be attached solidly to

the aerostat. The result is a light portable instrument platform that has the potential to fit

different shapes of aerostat. The total weight of the platform, not including the

instruments and the batteries, is 680 g. Table 2.4 presents a list of the airborne

components weight along with the total load on the balloon.

Table 2.4: Total load on the aerostat

Item (description) Quantity Weight (g) Platform (acrylic) 1 440 Load cell 1 70 Digital load cell amplifier 1 90 Spacers (aluminum) 8 80 GPS antenna 1 198 GPS coaxial cable 1 310 GPS receiver 1 307 GPS screws (steel) 2 120 GPS serial cable 1 150

25

LAN 1 310 Membrane (rubber carpet) 1 127 Battery (alkaline D-cell ) 8 1200 Screws and bolts (steel) n/a 20 Wire grip 4 90 ¾” washer 8 50 Cortland 1.5 mm 100m 1 100 Cortland 1mm 33m 1 30 Total 3692

To further reduce the relative motion of the platform with respect to the aerostat,

the acrylic base of the platform was attached to the aerostat through a set of four 1 mm

stabilization Plasma® lines under tension as shown in Figure 2.15.

Figure 2.15: The left picture shows a technical drawing of the platform that with the four stabilization lines. On the right is a picture of the actual platform.

2.5.1 Effect of the Platform on the Aerostat Properties

While designing the instrument platform, particular care was devoted to minimize

its effect on the aerostat’s natural behaviour. All the instruments were positioned on the

platform so that their effect on the aerostat properties would also be minimized. The

batteries were placed at the centre of the platform since they constitute the heaviest

component. That way, the centre of mass of the system is lowered along the vertical axis

of the balloon and an offset moment is avoided. The other instruments were distributed

uniformly around the batteries except for the GPS antenna, which was placed in between

the vinyl membrane and the aerostat envelope along the vertical symmetry line.

26

To measure the effect of the physical platform on the aerostat properties, a

Pro/EngineeringTM technical drawing of the system was assembled. The main physical

properties of a 3.5 m diameter aerostat carrying a load were obtained from the model and

compared to the physical properties of an ideal 3.5 m diameter spherical shell filled with

helium. These are presented in Table 2.5.

Table 2.5: Comparison of the Physical Properties of the Aerostat and a Spherical Shell filled with

helium

Property Aerostat Spherical Shell Units

Ixx (about C.M.) 25.64 16.41 kg-m2

Iyy(about C.M.) 25.64 16.41 kg-m2

Izz(about C.M.) 16.44 16.41 kg-m2

CM displacement 0.52 n.a. m

Mass 14.01 10.31 kg

2.6. Experimental Procedure

The aerostat was stored in one of the barns at the Macdonald campus of McGill

University. The aerostat was thus protected when not in use. The ground handling of the

balloon was performed by tying the balloon to a soft carpet that was heavy enough (20

kg) to prevent the balloon from floating away and light enough for one person to handle

as shown in Figure 2.16. The carpet served the additional function of a comfortable work

space when working underneath the balloon.

27

Figure 2.16: The ground handling of the balloon was performed by one person. A soft carpet was used to

keep the balloon close to the ground

The balloon was launched manually from ground to its initial height using a 6 m long

launching line attached to a load patch on the side of the balloon.

This prevents any impact that could hurt the cables or the platform. The launching line

was then tied to the confluence point to avoid tangling. From there, the balloon was

released to 15, 30 and 45 m, about seven minutes at each height. This allows enough data

to be collected to extract the aerostat dynamics. The balloon was finally retrieved with

the reverse procedure.

28

Chapter 3

Data Analysis

Two essential questions were kept in mind while analysing the experimental data. First,

how does the balloon move in turbulent wind, and second, what is the nature of the forces

acting on the system? The answer to the second question will provide information

relevant to a simulation of the tethered aerostat system. The answer to the first question

will give useful insight in our understanding of the behaviour of a spherical object in a

turbulent flow and will be used in Chapter 4 to validate simulation output.

3.1 Days of experimentation

The goal of the experiments was to collect data for a broad range of wind conditions and

a total of 5 days of data were acquired. For some days, more than one flight was

performed; and there were a total of 9 flights. The experiments were performed over a

one-month period in Oct-Nov 2005, as shown in Table 3.1. For each flight, the table

shows: the date of the selected sample; refU the mean of the horizontal wind speed at 10

m and its dispersion σU; the mean of the wind direction wθ and its dispersion σθ. For

Flight 1-3, the wind speeds only were recorded since the wind direction sensing was not

fully operational yet.

29

Table 3.1 Wind condition for the different days of experimentation

Date refU

(m/s) σU

(m/s) ref

UU

σ wθ (deg)

σθ

(deg) Flight 1 18/10/04 3.01 0.91 0.30 ---- ---- Flight 2 18/10/04 3.44 0.99 0.29 ---- ---- Flight 3 18/10/04 3.60 1.21 0.34 ---- ---- Flight 4 27/10/02 1.98 0.56 0.28 225.1 15.96 Flight 5 27/10/04 2.40 0.74 0.31 247.0 24.37 Flight 6 29/10/04 3.26 0.78 0.24 95.32 17.22 Flight 7 03/11/04 5.74 1.21 0.21 300.60 14.21 Flight 8 03/11/04 5.64 1.22 0.22 288.83 12.78 Flight 9 04/11/04 4.55 1.01 0.22 76.95 12.19

3.2 Position

The following section presents the position results obtained with the NovAtel differential

GPS system described in Chapter 2.

3.2.1 Position Analysis

As mentioned in section 2.3.1, the position of the roving GPS and the base GPS were

recorded at 10 Hz. A single flight usually lasted about 30 minutes during which the

aerostat was flown at 15, 30 and 45 m tether length. The data was then post-processed

using the software GrafNav 7.01 from WayPoint Consulting. GrafNav offers a variety of

customizable roving GPS antenna position output formats ranging from geographic

coordinates (latitude, longitude) to inertial ‘local coordinates’. The local coordinates are

defined as the relative position of the roving GPS antenna with respect to the base GPS

antenna where the local x-axis points true east, the local y-axis points true north, the z-

axis is directed upward along the gravity vector and the origin is located at the center of

the base GPS. This inertial coordinate frame was selected for the description of position

of the roving GPS antenna.

In order calculate variables such as the tether angle, it is more convenient for the

position of the aerostat to be defined relative to the winch. This is achieved by subtracting

the base-winch rBW vector from the measured position vector rBA such that:

WA BA BW= −r r r (3.1)

30

where rWA is the position of the aerostat with respect to the winch. These vectors are

shown in Figure 3.1.

Figure 3.1: Schematic of the relative positions of the components of the aerostat system.

The base antenna and the winch were each positioned at the same location for every

flight by making use of markers, to ensure that rBW remained constant. To verify the

validity of the results, the magnitude of rWA, given by

2 2WA WAx WAy WAzr r= + + 2r r (3.2)

where rWAx, rWAy, rWAz are the components of rWA, was calculated for each experiment.

The magnitude of rWA is equivalent to the cable length L going from the winch to the

confluence point plus the distance from the confluence point to the experimental platform

and is expected not to vary by more than 15 cm over each of the 15, 30 and 45 m

‘constant’ tether length acquisition. This variation accounts for the maximum elongation

of cable as calculated from the manufacturer specifications[43] based on a maximum

31

tension of 350 N. A plot of rWA for flight 9 is presented in Figure 3.2 showing well-

defined constant tether length plateaus.

Figure 3.2: Magnitude of rWA for Flight 9.

A standard deviation of less than 5 cm in rWA was calculated for all plateaus and

maximum amplitude variation of less than 13.5 cm, thus confirming the validity of the

results. Figure 3.3 presents plots of the time history of the three components of rWA for

Flight 9. Plots of the magnitude rWA such as the one shown in Figure 3.2 were used to

subdivide the data sets into the 15, 30 and 45m cable length plateaus.

0 2 0 0 4 0 0 6 0 0 8 0 0 1 0 0 0 1 2 0 0 1 4 0 0 1 6 0 0 1 8 0 0 2 0 0 0-6 0-4 0-2 0

02 04 0

X P

ositi

on(m

) X P o s it io n vs Tim e

0 2 0 0 4 0 0 6 0 0 8 0 0 1 0 0 0 1 2 0 0 1 4 0 0 1 6 0 0 1 8 0 0 2 0 0 0-4 0-2 0

02 04 0

Y P

ositi

on(m

)

Y P o s it io n vs Tim e

0 2 0 0 4 0 0 6 0 0 8 0 0 1 0 0 0 1 2 0 0 1 4 0 0 1 6 0 0 1 8 0 0 2 0 0 00

2 0

4 0

Tim e (s )

Z P

ositi

on(m

)

Z P o s it io n vs Tim e

Figure 3.3: Components of rWA for Flight 9.

Table 3.2 presents the mean and the standard deviation σx,y,z of the components of rWA at

the different cable length for Flight 9. The large standard deviation of the y-component

of rWA indicates that the balloon is exhibiting large motion in that same direction.

32

Table 3.2: Position data of Flight 9

Cable length θ (rad) Mean (m) , ,x y zσ (m)

rWAx -6.59 2.44 rWAy 0.38 4.35 15m 0.445 rWAz 16.34 1.53 rWAx -13.12 4.99 rWAy 2.44 6.74 30m 0.468 rWAz 29.26 2.83 rWAx -21.14 7.88 rWAy 4.53 8.88 45m 0.519 rWAz 40.81 2.49

From the position measurement, it was possible to calculate the time history of the

tether angle. This will be useful in section 3.6 for drag estimation since the mean tether

angle θ can be related to the drag force. The tether angle was determined by first

calculating rWAxy the horizontal x-y projection of rWA at all time,

2 2WAxy WAx WAyr r r= + (3.3)

as shown in Figure 3.4.

Figure 3.4: Schematic of the variables relevant to the calculation of the mean tether angle.

33

The instantaneous angle θ is given by

1tan2

WAz

WAxy

rr

πθ − = −

(3.4)

A time history of the tether angle for each of the three flight sections is shown in Figure

3.5.

Figure 3.5: Time history of the tether angle for Flight 9.

The mean angle θ for the different flight sections was calculated by averaging the

instantaneous angle over the constant tether length sections and is shown in Table 3.2 for

Flight 9.

3.3 Lift Force

The free lift force is defined as,

L BF F mg= − (3.5)

where FB is the buoyancy and m = 14.01 kg is the total aerostat mass including the

instrument platform, the aerostat fabric, the tether and the helium. The buoyancy force is

directed upward and is given by

34

B aF V gρ= (3.6)

where ρa is the density of air taken as 1.229 Kg/m3 and V = 22.45 m3 is the internal

volume of the aerostat. Using equations (3.5) and (3.6) the free lift is calculated to be

133.6 N. In order to verify the calculation, the lift was measured by tethering the balloon

to the ground indoors in a controlled environment using the Transducer Techniques load

cell. Load cell measurements were performed for about 2 minutes at 10 Hz as shown in

Figure 3.6. The graph also gives us an indication of the noise level of the sensor.

igure 3.6: Plot of the free lift measured with the Transducer Techniques load cell.

A free lift of 136.5 N, including the tether weight, was determined by averaging the data

3.4 Tension

apter 2, the tension in the cable was measured at the confluence point

F

over time; which is 3 N higher than the calculated value. This discrepancy might be

explained by the fact that the inflated balloon diameter was slightly larger than the

manufacturer’s specifications indicate. The lift measurement performed with the load cell

was considered more reliable and kept as the reference for later sections.

As mentioned in Ch

using a MLP-75 load cell from Transducer Techniques connected to a SY016 digital

amplifier board by Synectic Design. The acquisition system for the tension performed

poorly and only the tension for the November 4th flight was considered reliable. The

35

processed data for that day are shown in Figure 3.7 and compared to the free lift of

aerostat.

0 2 0 0 4 0 0 6 0 0 8 0 0 1 0 0 0 1 2 0 0 1 4 0 0 1 6 0 0 1 8 0 0 2 0 0 0- 5 0

0

5 0

1 0 0

1 5 0

2 0 0

2 5 0

3 0 0

3 5 0

4 0 0

T i m e ( s )

Tens

ion

(N)

F r e e l i f t l i n e1 3 6 . 4 9 N

Figure 3.7: Plot of the tension data for Flight 9, compared to the aerostat free lift.

The tension in the cable falls below the free lift line at certain instants in time.

This behaviour is likely caused by downward gusts, which cause a slackening of the

cable and hence decrease of the tension. To compare the tension at different tether

lengths, it was divided into 15m, 30m, 45m cable length sections as shown in Figure 3.8.