short name: PAL* - heco.de · Supply: dry or lubricated and filtered compressed air. * Springs per...

Transcript of short name: PAL* - heco.de · Supply: dry or lubricated and filtered compressed air. * Springs per...

> hard anodized aluminum

technical product sheet

short name: PAL*pneumatic actuator

RE-series

kgHBLDWPortNmModellFederAusf

45,680

23,860

0,000

11,270

8,660

5,625

4,580

3,220

1,820

1,135

0,880

36,800

19,720

10,500

7,280

5,360

3,495

2,740

1,680

1,183

298

246

177

157

145

127

112

102

85

69

62

298

246

157

145

127

112

102

85

69

222

182

164

150

134

120

104

94

86

75

64

222

182

150

134

120

104

94

86

75

527

424

398

335

304

257

239

203

155

138

141

527

424

335

304

257

239

203

155

138

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

NBR

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/8"

1/8"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/8"

519,6 bei 6 bar

283,8 bei 6 bar

205,2 bei 6 bar

129,8 bei 6 bar

100,9 bei 6 bar

64,6 bei 6 bar

35,7 bei 6 bar

28,5 bei 6 bar

14,1 bei 6 bar

8,5 bei 6 bar

13,0 bei 6 bar

1292,0 bei 6 bar

689,2 bei 6 bar

339,8 bei 6 bar

262,3 bei 6 bar

164,8 bei 6 bar

103,4 bei 6 bar

70,6 bei 6 bar

35,5 bei 6 bar

20,1 bei 6 bar

RE201

RE161

RE146

RE126

RE116

RE101

RE086

RE076

RE064

RE051

RE043

RE201

RE161

RE126

RE116

RE101

RE086

RE076

RE064

RE051

6/6

6/6

6/6

6/6

6/6

6/6

6/6

6/6

6/6

6/6

-

-

-

-

-

-

-

-

-

-

SR

SR

SR

SR

SR

SR

SR

SR

SR

SR

DA

DA

DA

DA

DA

DA

DA

DA

DA

DA

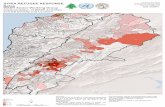

Industrial valves › ball valves › with actuator › pneumatic › actuators › standard

pneumatic actuatorRE-series> hard anodized aluminum

full description:

available material: ask

1/6created 09.11.2018 01:11

** Optionally made of high-alloyed stainless steel (AISI 316/ V4A).

>> see category special design

* Optional FPM / FKM for high temperature or silicone for low temperature.

(³) Pre-tensioned springs, safe and easy to replace (25-30µ Polyester coating)

protection, high mechanical weather resistance and good electrical insulation properties.

The powder is sprayed electrostatically on the ground and then baked. The result is a very high corrosion

Powder coating is a coating process in which the electrically conductive material is coated with powder coatings.

(²) Polyester painting (60-80µ)

properties.

and serves as wear and corrosion protection, is thermally and electrically insulating and has good tribological

to produce protective coatings on aluminum materials. The layer has a hardness of 400-600 HV (45-65 HRC)

Anodization (hard anodizing or hard coating) is the electrolytic oxidation of aluminum materials

(¹) Hard anodized (50µ - Ra=0,4-0,6)

-20°C to +80°C*

AISI 304 / V2A

-20°C to +80°C*

AISI 316 / V4A

20 µ nickel-plated**

-20°C to +80°C*

high sliding ability

ASTM B179

high sliding ability

3-6 per piston³

AISI 304/ V2A

powder coated²

optional (fig. 3/8)

hard anodized¹

Comment

NBR*

Stainless steel

NBR*

Stainless steel

Carbon steel

NBR*

Acetal resin

Aluminium alloyed

Acetal resin

Spring steel, PA 66, VA

Stainless steel

Aluminium alloyed

PA

Extruded aluminium

Material

Cover seal

Adjusting screws

Upper shaft seal

Cam

Shaft

Bottom shaft seal

Slide spring

Piston

Piston ring

Spring cartridge

Cover crews

End cap

Position indicator

Body

Description

14

13

12

11

10

9

8

7

6

5

4

3

2

1

No.

Parts list

created 09.11.2018 01:11 2/6

Supply: dry or lubricated and filtered compressed air.

* Springs per piston

129,8 Nm

100,9 Nm

64,6 Nm

35,7 Nm

28,5 Nm

14,1 Nm

8,5 Nm

6 Bar

108,2 Nm

84,1 Nm

53,8 Nm

29,7 Nm

23,8 Nm

11,8 Nm

7,1 Nm

5 Bar

86,5 Nm

67,3 Nm

43,0 Nm

23,8 Nm

19,0 Nm

9,4 Nm

5,7 Nm

4 Bar

64,9 Nm

50,5 Nm

32,3 Nm

17,8 Nm

14,3 Nm

7,1 Nm

4,3 Nm

3 Bar

RE126 / 6

RE126 / 5

RE126 / 4

RE126 / 3

RE116 / 6

RE116 / 5

RE116 / 4

RE116 / 3

RE101 / 6

RE101 / 5

RE101 / 4

RE101 / 3

RE086 / 6

RE086 / 5

RE086 / 4

RE086 / 3

RE076 / 6

RE076 / 5

RE076 / 4

RE076 / 3

RE064 / 6

RE064 / 5

RE064 / 4

RE064 / 3

RE051 / 6

RE051 / 5

RE051 / 4

RE051 / 3

Model / Spring *

Torques depend on the pressure control air applied and number of springs

Torque single-acting actuator

Values in Nm

453,0

349,7

219,7

137,8

94,2

47,4

26,8

8 Bar

396,4

306,0

192,2

120,6

82,4

41,4

23,4

7 Bar

339,8

262,3

164,8

103,4

70,6

35,5

20,1

6 Bar

283,2

218,6

137,3

86,1

58,9

29,6

16,7

5 Bar

226,5

174,9

109,8

68,9

47,1

23,7

13,4

4 Bar

169,9

131,1

82,4

51,7

35,3

17,8

10,0

3 Bar

RE126

RE116

RE101

RE086

RE076

RE064

RE051

Model

min. 3bar/ max. 8bar

Torques depend on the pressure control air applied

Torque double-acting actuator

created 09.11.2018 01:11 3/6

M10x15 mm

M8x12 mm

M6x9 mm

M5x8 mm

M5x8 mm

Dril holes

Ø-102 mm

Ø-70 mm

Ø-50 mm

Ø-42 mm

Ø-36 mm

Circular hole pattern

F 10

F 07

F 05

F 04

F 03

Hole pattern F

Hole pattern dimensions

* Designed as an octagon for simple parallel (0°) or diagonal (45°) installation

25 mm

20 mm

20 mm

16 mm

16 mm

13 mm

13 mm

t

22 mm

22 mm

22 mm

17 mm

17 mm

14 mm

11 mm

V (Square socket)*

F07/F10

F07/F10

F07/F10

F05/F07

F05/F07

F03/F05/F07

F03/F05

F (ISO 5211)

RE126

RE116

RE101

RE086

RE076

RE064

RE051

Model

(fig. 6/8)

> Flange fitting for mounting valves acc. to ISO 5211 / DIN 3337

Dimensions in mm

30

30

20

20

20

20

20

h

27

27

14

14

14

8

8

y

36

36

18

18

18

12

12

x

30

30

30

30

30

30

30

p

80

80

80

80

80

80

80

A

RE126

RE116

RE101

RE086

RE074

RE064

RE051

Model

(fig. 5/8)

> Device interface (limit switch, positioner) according to the NAMUR VDI /VDE 3845 standard

conditions in all fields of application. (fig. 3/8)

adjustment of the end positions, even when subject to the toughest requirements and ambient

and easy access to the end positions. The special adjustment system allows quick and precise

> An external end position adjustment covers all requirements in terms of adjustment accuracy

> Swivel angle 90° +/-5° adjustable in both end positions. Set to +/-1° upon delivery

Features

created 09.11.2018 01:11 4/6

>> see special versions heading

for industrial, chemical, pharmaceuticals, food, and offshore applications

> Various surface finishes

(individually certification of the product)

> Aluminum ratings plate with serial number

All actuators meet the requirements for power-on and life acc. to DIN EN 15714-2

Standard grease: molybdenum bisulfide or special grease for high and low temperatures

> Factory lubrication suitable for at least 1 million switching operations

(fig. 7/8)

> Compressed air connection with thread acc. to ISO 228-1

(fig. 7/8)

> Control connection for solenoid valve according to the NAMUR VDI / VDE 3845 standard

created 09.11.2018 01:11 5/6