Shell World Philippines magazine (Issue 3)

-

Upload

jun-jay-jimenez -

Category

Documents

-

view

217 -

download

1

description

Transcript of Shell World Philippines magazine (Issue 3)

ISSUE 3 2011

SHELL WORLD PHILIPPINES

Can a Formula One car run on road car fuel?

Scuderia Ferrari driver Fernando Alonso was pretty surprised at

the result.

Powering Luzon for years to come

The Malampaya Deepwater Gas-to-Power project is entering a new phase, unlocking further

energy self-sufficiency.

Shell introduces breakthrough fuels

that improve engine performance and help

motorists save fuel.

Pushing the boundaries for fuel efficiency

MEET THE TEAM

PHILIPPINES

SHELLWORLD

Editorial AdvisorsRoberto S. KanapiMylene M. Santos

Editor-in-ChiefSankie G. Simbulan

Managing EditorJun Jay G. Jimenez

Copy EditorFatima Cruz

WritersFatima CruzJocelyn Diana-DigaJun Jay G. Jimenez

ContributorsAnna Katrina BarriosMary Ann de ChavezDanny KumarAngela TweedieNimfa VillamayorChiro Yap

TO CONTACT THE SWP TEAM:

Mailing AddressShell World Philippines14/F Shell House156 Valero St., Salcedo VillageMakati City 1227

Websitewww.shell.com.ph/shellworldphilippines

External Recognition

ISSUE 3 2011

WELCOME04Can a Formula One car run on road car fuel?Scuderia Ferrari Driver Fernando Alonso was surprised at how his F1 race car performed on the road using the Shell V-Power road fuel.

2 SHELL WORLD PHILIPPINES

Dear SWP Readers,

In 2007, Shell launched the Shell FuelSave Challenge programme to help drivers save on fuel. The programme is all about teaching drivers how fostering more efficient driving habits combined with the use of more efficient fuels can spell the difference not only in saving money spent on fuel, but in saving the environment by conserving energy and better managing CO² emissions. By using Shell fuels with Fuel Economy Formula, combined with applying fuel saving techniques, the most fuel efficient drivers saved 24% on fuel.

Continuing the advocacy of helping our transport customers all over the world to find smarter ways of going farther using less energy, Shell has trained over 160,000 drivers across 11 countries on smarter mobility by 2010. This year, Shell celebrated another milestone in its fuel efficiency journey when it set a Guinness World Record for hosting the world’s largest fuel efficiency lesson ever, with over 3,000 motorists from 11 cities across Europe and Asia simultaneously trained on October 15, 2011, the historic Global Shell FuelSave Day.

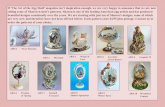

This issue of Shell World Philippines features on its cover the breakthrough fuel Shell FuelSave, an innovation in fuels technology with its Shell Efficiency Improver designed to help drivers save with every tank of fuel, at no extra cost. Our cover story shows how the Philippines participated in Global Shell FuelSave Day and how more and more Filipinos are cutting on their fuel consumption by learning how to drive more efficiently and using Shell FuelSave, a cleaner and more economic fuel product that helps Filipino drivers go farther with every tank fill-up.

Let’s continue squeezing the most out of every drop of precious fuel. LET’S GO!

SANKIE G. SIMBULANBusiness and Corporate Communications Manager

Shell World Philippines is published quarterly for the employees of Shell companies in the Philippines and for interested readers outside the business. Opinions expressed do not necessarily reflect the official views of any Shell company.

The following expressions are inherent to Shell businesses in the Philippines: SciP (Shell companies in the Philippines), which encompasses its companies in the country; and Pilipinas Shell (Pilipinas Shell Petroleum Corporation). The specific names of other Shell companies will be duly mentioned in the article.

Shell World Philippines is published by the Communications Department for the Shell companies in the Philippines (SciP). www.shell.com.ph/shellworldphilippines

18Shell sets new Guinness World RecordShell FuelSave Day sets a new world record by encouraging fuel efficiency around the world.

19Shell Gas introduces Telemetry: A pioneering innovation in the LPG IndustryShell Gas introduced a web-based fuel tank level monitoring that helps its customers manage stock inventory in the most cost-efficient way.

20Winning the Fight: Anti-malaria missionShell helps save lives through the Movement Against Malaria, a successful social investment initiative that has grown into a nationwide health programme.

22Shell eServe: Driving business efficiency and value to Shell customersUsing the power of technology, Shell is helping its customers do business more efficiently with just a press of a button.

24To lead is to share: A winner's perspectiveThis year's CEO Excel Awardee, AGC Flat Glass President Emmanuel Go, shares his viewpoints on the value of communication for effective leadership.

27 Living with LSR: The Walter Flores storyLorry driver Walter Flores embraces Shell’s Life-Saving Rules in his everyday activities.

06Powering Luzon for years to comeThe Malampaya Deepwater Gas-To-Power project is entering a new phase, unlocking further energy self-sufficiency.

14ON SPOTLIGHT: Pushing the boundaries for fuel efficiencyMotorists are getting the most out of every drop of fuel using the new breakthrough Shell fuels designed to improve fuel efficiency.

08 NEWS IN BRIEFA mix of stories about the various business and social development activities of Shell companies in the Philippines that support our country’s quest for progress.

SHELL WORLD PHILIPPINES 3

2406

2014

CONTENTS

1414

ONLINE VERSION OF SHELL WORLD PHILIPPINES MAGAZINERead the online version of Shell World Philippines magazine by typing the link into a web browser. Alternatively, use a smartphone with a QR reader app to scan this symbol.

4 SHELL WORLD PHILIPPINES

Can a Formula One car run on road car fuel?

Shell’s technical partnership with Ferrari is one of the longest and strongest in the Formula One paddock with over 60 years of innovation and shared passion

for performance. The technical partnership is key to developing better road fuels for our customers – from track to road.

In fact, the Federacion Internationale de l'Automobile (FIA) regulations stipulate that Formula One race fuels must be composed of compounds normally found in commercial fuels, meaning that Shell V-Power race fuel and Shell V-Power road fuel are by definition very similar.

Despite that, many customers on Shell forecourts around the world may not be aware of just how closely the Shell V-Power formulation they put in their cars actually matches

the one powering Scuderia Ferrari cars in Formula One.

Cara Tredget, Shell Technology Manager for Ferrari, says, “One of the things I always get asked is, ‘How similar is the Shell V-Power racing fuel that we deliver to Ferrari to that of the Shell V-Power Unleaded fuel that everyday motorists use?”

“We decided to answer that question by fuelling the 2009 F1 Ferrari car with Shell V-Power road fuel from a Shell service station in order to show that it’s really very similar to the racing fuel that we provide Scuderia Ferrari.”

To demonstrate it, Fernando Alonso, official Scuderia Ferrari driver, was invited to post a lap time of Ferrari’s Fiorano test track in Maranello, using Shell V-Power road fuel in his

WHAT HAPPENS IF YOU FILL UP AN F1 CAR WITH SHELL V-POWER FROM THE FORECOURT? SCUDERIA FERRARI DRIVER FERNANDO ALONSO FOUND OUT, AND HE WAS PRETTY SURPRISED AT THE RESULT.

Fetching Shell V-Power road fuel from a service station

SHELL WORLD PHILIPPINES 5

Formula One car. The run also was filmed by the BBC.

Having driven four intense laps of Fiorano using his familiar Shell V-Power race fuel, setting a fastest lap time of 1:03.950, Fernando then returned on the racetrack to experience how the Shell V-Power road fuel fared with the extreme demands of his 2009 F1 Ferrari race car. He was somewhat surprised by the results, saying: “The Shell V-Power road fuel felt just as quick as the Formula One fuel.”

What supported his observation was the fact that the road fuel, formulated with unique Shell technology, actually managed to produce a higher top speed at the end of the straight when compared to Shell V-Power race fuel. The race fuel pulled off a noticeably better performance.

Fernando was clearly delighted with the results, saying, “I think it’s very exciting to be able to stop in the service station and know that you are refuelling with the same kind of fuel that the Ferrari cars are using in Formula One,”

he said. “It’s really great that through using Shell V-Power fuel, people can be very happy and content that they are putting a very special fuel in their cars.”

With Fernando’s lap time on Shell V-Power road fuel registering at 1:04.850 in the telemetry readings, the difference between the two fuels was only nine tenths of a second.

On the close outcome, Cara says, “I think the fact that the results were roughly within a second per lap of each other is an absolutely fantastic result, and a real testimony to how incredible the Shell V-Power road fuel is.”

The technical partnership with Scuderia Ferrari gives Shell an extreme, yet controlled test environment, in which to develop advanced fuels and lubricants for road users. Each year, Shell invests more than 21,000 working hours in a partnership that’s seen Ferrari achieve 10 Formula One Constructors’ World Championships and 12 Formula One Drivers’ World Championship titles. SWP

Out on the track

Looking at the difference (or similarity?)

6 SHELL WORLD PHILIPPINES

Powering Luzon for years to come

ONE OF THE BIGGEST INDUSTRIAL ENDEAVOURS IN PHILIPPINE HISTORY, THE MALAMPAYA DEEPWATER GAS-TO-POWER PROJECT IS ENTERING A NEW

PHASE, UNLOCKING FURTHER ENERGY SELF-SUFFICIENCY.

SHELL WORLD PHILIPPINES 7

The Malampaya Deepwater Gas-to-Power project, which celebrates its 10th anniversary

this year, is the largest and most significant industrial investment in Philippine economic history. It also boasts of having heralded the birth of the country’s natural gas industry.

Malampaya is the project providing the largest Philippine island of Luzon with 40 to 50% of its power generation needs, thanks to cleaner-burning natural gas recovered from deep water.

The island is home to the country’s capital city Manila and more than half of the Philippine population. With its reliable supply of indigenous natural gas, Malampaya helps reduce the country’s dependence on imported fuel for its domestic and industrial power requirements.

Earlier this month, Philippine President Benigno Aquino III kicked-off the next-phase development of the Malampaya project with a visit to its onshore gas processing plant in Batangas, where he witnessed the signing of the first contract awarded by the Service Contract 38 consortium*, which includes Shell as developer and operator. At the same time, an Executive Order

was issued by the Department of Energy creating inter-agency committees to ensure success of the government project.

While maintaining current production levels, the next phase will look to maximise the recovery of indigenous natural gas from the Malampaya and Camago reservoirs. Malampaya Phase 2 will see the drilling and development of two additional wells by 2014, and Phase 3 will involve the installation of a new platform which will house additional equipment and facilities by 2015.

The new investments are designed to further benefit the Philippines in energy self-sufficiency and government revenues, and will continue to be a major source of power for Luzon’s energy requirements in the years to come. SWP

* Malampaya is a joint undertaking between the Philippine national government and the private sector under “Service Contract 38”. It is spearheaded by the Department of Energy, and developed and operated by Shell Philippines Exploration on behalf of joint venture partners Chevron Malampaya and the Philippine National Oil Company Exploration Corporation.

Philippine President Benigno Aquino III (middle) with the Shell Philippines Exploration team at the

onshore gas processing plant in Batangas.

news in briefShell Instapave Applicator closes major deal for Alabang Viaduct Micro-surfacing Project

Shell Bitumen Solution Centre receives Quality Management System Certification The Shell Bitumen Solution Centre has been awarded the certification of ISO 9001:2008 Quality Management System for Bitumen Product and Application Solution Development and Technology Delivery Support Services on January 20, 2011. The certification was awarded by TÜV SÜD PSB Philippines, Inc. in a simple handover ceremony on March 23, 2011.

“This is a very significant quality management milestone. Another compelling reason why customers should buy from us,” said Shell Specialities Country Business Manager Randy Anastacio. “This certification further reinforces our product quality as a value proposition to our customers.”

Shell Bitumen Regional Technology Manager Yut Janyajarasporn said, “This only further encourages us to

strengthen our product quality and aim to make our clients become more confident in our products and services.”

The Shell Bitumen Solution Centre, located at the Bitumen Import Facility in Shell Tabangao Refinery, is fully equipped to develop bitumen emulsion products and applications solutions required for road construction and maintenance. The Solution Centre, which serves as a showcase of Bitumen’s technology and product quality, has hosted several visits by road consultants, contractors and road engineers from different district engineering offices nationwide. It is also accredited by the Department of Public Works and Highways (DPWH) Bureau of Research and Standards for quality testing of aggregates, asphalt,

and Instapave job mix design. The Tabangao Solution Centre is one of four Shell Solution Centres in Specialities business worldwide. The others are located in Bangkok, Thailand; Beijing, China; and Strasbourg, France. [Mary Ann de Chavez, Technology Development Manager-Products]

Last July 12, 2011, Shell Bitumen Instapave Applicator HL Trading Co. Inc. sealed a micro-surfacing contract with MTD Construction, the construction arm of MTD Capital Berhad based in Malaysia. HL Trading Co. Inc. shall be applying micro-surfacing technology over the 840 linear metre area of the Alabang Viaduct (northbound & southbound) along South Luzon Expressway, which covers eight (8) road lanes.

Pilipinas Shell Petroleum Corporation shall be providing the emulsion product requirements, mix design, performance testing & technical support during the 60-day application. Microsurfacing is a cost effective cold-mix surface dressing pavement solution with a wet thickness of six (6) to seven (7) millimetre. It is designed to lengthen the lifespan of roads, tollways & bridgedecks. It is also

used for preventive maintenance. The contract signing was held at the MTD office in Sta. Rosa, Laguna. [Chiro Yap]

8 SHELL WORLD PHILIPPINES

(Left photo) Malampaya Onshore Gas Plant; (middle

photo) Shallow Water Platform; (right photo)

Batangas Supply Base

Present during the contract signing are (seated, l-r) Senior Quality Supervisor Clarence Quismundo, Construction Manager Oscar Rayo, Construction Manager Choong Yuk Kee & President of HL Trading Co. Inc. Lucio Horfilla, Jr., together with the Shell Bitumen team (standing, l-r) Technology Applications Manager Allan Cañedo, Instapave Manager Chiro Yap, Bitumen Country Manager Randy Luis Anastacio, and Key Accounts Manager Jay Macaspac.

In photo are (l-r) Wencie Alano- BIF Plant Supervisor, Ann de Chavez-Technology Devt Manager-Products, Randy Anastacio-Bitumen Business Manager, Janet Marcellana-Technology Devt Executive QA/QC/GPC, Marco Garcia-Facilities Engineer, Michelle Padrilan-Visaya-Product Engineer, Ralph Pineda-Laboratory Technician.

For four straight years, Pilipinas Shell Petroleum Corporation (PSPC) received a Certificate of Appreciation from Team Energy Corporation.The recognition was accorded to PSPC for its exemplary performance, valuable support, and contribution to fulfill Team Energy Corporation’s fuels and lubricants requirements for the year 2010. Team Energy owns and operates two clean coal-fired plant facilities in Luzon, providing both immediate and long-term solutions to the country's evolving energy needs.

Shell Commercial Fuels Business Development Manager Mao Vergel

De Dios and Global Lubricants Business-to-Business (B2B) Direct Account Managers Wella Atayde and Danny Kumar received the Certificate of Appreciation on July 1, 2011 at the Villamor Golf Club, Col. Jesus Villamor Airbase in Pasay City. Global Lubricants Sales Manager Bryan Nazareno and Global Lubricants B2B Direct Account Managers Paul

Villadolid and Ed Capati also graced the event. [Danny Kumar]

Team Energy recognises Pilipinas Shell as outstanding supplier

Malampaya acquires ISO 14001 Certification Malampaya has recently been granted a continuous certification to ISO 14001 for its facilities at the Asian Star Building in Alabang, the Malampaya Onshore Gas Plant in Batangas, the Batangas Supply Base, and the Malampaya Shallow Water Platform off Palawan. ISO 14001 is a certification of compliance to environmental standards, the aim of which is to reduce a company’s environmental footprint by decreasing pollution and waste.

Anglo-Japanese American (AJA) Registrar Philippines was the team that audited the said Malampaya sites. The Audit Team headed by Lead Auditor Gilmore Rivera recommended

Malampaya-operator Shell Philippines Exploration B.V. (SPEX) for continuous certification for having zero non-conformance, which proves the company’s application of effective systems to control its environmental impact and constantly improve performance in a systematic, effective and sustainable manner.

The increased monitoring of its effluent or outflow of water and gas, the reduction of hydrocarbons being flared, and the continuous partnership with the government for the establishment of appropriate offshore standards, are a few of the more recent measures adopted by SPEX with the aim of

improving the environmental impact of its operations.

The International Organisation for Standardisation (ISO) is a global network that identifies what International Standards are required by business, government and society. For consumers, conformity of products and services to these standards provide assurance about their quality, safety and reliability. The International Standards on air, water and soil quality, as well as on the environmental impact of products and the companies that produce them, contribute to the cause of preserving the environment.

SHELL WORLD PHILIPPINES 9

Shell team receives certificate from Team Energy officials

news in brief

Pilipinas Shell Petroleum Corporation (Shell) has contributed its paving systems technology for the construction of the Gawad Kalinga (GK) Enchanted Farm in Angat, Bulacan. The one kilometre rough road of the farm is now paved with Shell’s Instapave technology, an all-weather paving system ideal for rural roads.

Roads connect, support and help communities. With Shell Instapave, more people can now benefit from Gawad Kalinga’s livelihood programmes at the GK Enchanted Farm, helping to improve the quality of life in local communities. “We recognise that everyone should have access to basic services and livelihood opportunities. This is why we develop paving systems which are designed to meet the social, economic and environmental needs of local communities,” said Shell Instapave Manager Chiro Yap.

During the inauguration of the Enchanted Farm last June 24, 2011, GK Chairman Tony Meloto expressed his appreciation for Shell’s contribution to promote community development. “Shell employees have helped us greatly,” said Meloto, “I thank Shell for their support in paving our roads.”

Shell has been a staunch partner of GK since the inception of GK villages for the homeless, supporting four Shell-GK villages in the Batangas, Southern Leyte and Camarines Sur Provinces. Shell is also working with GK for Bayan-Anihan (Community Harvest), GK’s food sustenance programme that aims to eradicate hunger one family at a time by empowering GK communities to produce food for

themselves. Twenty-three Shell-GK Bayan-Anihan farms have been established in the Bicol region since 2009. In 2010, on the occasion of GK’s seventh anniversary, Shell staged “The Gift of Art”, an art sale for the benefit of GK that showcased the masterpieces of renowned Filipino artists who are past winners of Shell’s long-running arts programme, the Shell National Students Art Competition.

This year, Shell further expands its partnership with GK by supporting the GK Centre for Social Innovation (CSI), which produces affordable and high-quality Filipino products using organic Philippine-grown ingredients, promoting the culture of entrepreneurship among the new generation of social Filipino entrepreneurs and aims to establish socially relevant and high impact businesses that will promote an environment of healthy competition.

One element of the GK CSI, the Enchanted Farm transforms a once idle land into a landscape of vast opportunities by creating sustainable communities through education, entrepreneurship and social tourism. It is the first of 24 CSI sites in the Philippines.

President Benigno Aquino III graced the inauguration of the Enchanted Farm and lauded GK and its partners for their efforts to uplift the lives of many Filipinos from poverty by providing houses, livelihood and encouraging entrepreneurship in the country. “Walang dudang ang paglulunsad ng Gawad Kalinga Centre for Social Innovation ang

Shell Instapave links people to Gawad Kalinga’s Enchanted Farm

magbubuklod sa mga pribado at publikong sektor upang maglatag ng makabuhuluhang programa at napapanahong edukasyon dito sa ating bansa (There is no doubt that the launch of Gawad Kalinga’s Centre for Social Innovation will unite the public and private sector towards sculpting the bedrock of significant programmes and timely, substantial education here in our country)," President Aquino said.

10 SHELL WORLD PHILIPPINES

President Benigno Aquino III graces the inauguration of the GK Enchanted Farm in Angat, Bulacan. He lauded GK and its partners’ poverty alleviation efforts in the country. Also shown in photo are Finance Secretary Cesar Purisima (2nd from left), GK Chairman Tony Meloto and Pilipinas Shell Petroleum Corporation Sustainable Development Manager Ronald Suarez (3rd from right).

Shell renews its partnership with the Philippine National Police to promote peace and order in the community. Shown in photo during the signing of the agreement are PNP Chief Police Director General Raul Bacalzo (4th from left) and Association of Pilipinas Shell Dealers Inc. President Rolando Villanueva (5th from left). Witnessing the signing are Ricky Altonaga, HSSE Manager for Retail, Mike Ramolete, Retail District Manager for Metro Manila, Ret. Gen. Arturo Lumibao, and PSPC HSSE Manager Arsenio Isidro, with officers from the Philippine National Police.

Shell Pepeng Pasada Club (PPC) was established more than 10 years ago and until now, it has continued to increase the number of Shell’s loyal customers. It caters exclusively to the Public Utility Vehicle (PUV) drivers, encouraging them to become cardholders. Active members of PPC get the S.I.R. benefits—S for Scholarship, I for Insurance and R for Rewards.

Shell Pepeng Pasada Club Each Shell PPC member, upon purchase of Shell products, earns points that get reflected in the Loyalty systems. An active member, with an average basket size of 200 litres of fuel per month, will be eligible to receive the S.I.R. benefits. The Scholarship benefit is an offering from the partnership between Shell Retail and Pilipinas Shell Foundation Inc. (PSFI), enabling active members to attend free basic skills and livelihood courses. For the Insurance benefit, members get free accident insurance which covers claims for partial and

permanent disability and death. The Rewards benefit enables members to exchange their points for items like major and minor home appliances, gadgets and PPC driver apparels like t-shirts, umbrellas, among others. These benefits are available to PPC members for their loyalty to Shell which substantially contributes to Shell Retail Philippines' fuel sales volume.

Unlad sa PasadaTo enhance the customer value proposition (CVP) to club members, Shell Retail launched Unlad sa Pasada, a free education programme for the dependents of the most loyal and active members of the PPC. Unlad sa Pasada is a nationwide scholarship programme which offers

technical vocational training such as welding, automotive mechanic, consumer electronics, food and beverage servicing, bookkeeping, and basic computer and mobile phone repair.

Through Unlad sa Pasada, a valuable long-term support programme for Shell Retail networks’ most active customers has been firmly established. With the scholarship, customer loyalty is assured and more importantly, a better future awaits the dependents of Shell retail stations’ most loyal customers. [Maria Fatima Cruz]

Unlad sa Pasada: Giving opportunities for dependents of Shell Retail Stations’ most loyal customers

Pilipinas Shell Petroleum Corporation (PSPC) and the Philippine National Police (PNP) revitalised its long-standing partnership to promote peace and order within and around the vicinity of Shell stations all over the country, through the recent signing of the PNP-Shell Memorandum of Understanding.

The agreement was signed by the Association of Pilipinas Shell Dealers, Inc. (APSDI) – President Rolando Villanueva and the PNP Chief Police Director General Raul M. Bacalzo on July 19, 2011 at the Shell House in Makati City. APSDI is an association of PSPC dealers engaged in the business of retailing

petroleum products through the Shell service stations.

Speaking to Shell dealers, General Bacalzo recognised Shell’s unwavering commitment to ensure safety and security in communities where it operates. “The Philippine National Police appreciates Shell’s strong support to our initiatives in promoting and strengthening peace and order all over the country. With Shell’s network of retail stations available to PNP personnel, our joint efforts in preventing crimes all over the country will go a long way in meeting our objectives,” said General Bacalzo.

PSPC Retail District Manager for Metro Manila Mike Ramolete likewise thanked the PNP for the valuable assistance it has been extending to Shell. “Our Shell sites nationwide are always available to the PNP in maintaining peace and order in the communities. May this partnership grow further and promote safety and security all over the country,” said Ramolete.

Shell’s partnership with the PNP started in 2007, which resulted to heightened police visibility in the areas of Shell retail stations. With the renewal of this partnership, a dynamic police-community cooperation is promoted towards a common goal of ensuring a safer society for all. [Jun Jay Jimenez]

Pilipinas Shell and the Philippine National Police strengthen partnership for peace and order

SHELL WORLD PHILIPPINES 11

news in brief

The Pilipinas Shell Foundation, Inc. (PSFI) was given a Special Citation for its outstanding social development programmes at the 7th Governor’s Award, held recently at Hotel Centro, Puerto Princesa City, Palawan.

In the field of health, PSFI opened the Palawan Adventist Charity Programme, which makes upgraded healthcare facilities available to indigents through a charity system. The programme also provides local health volunteers with training and equipment and has developed a local health insurance system for low-income earners in the community.

Through Kilusan Ligtas Malaria (KLM) and with the help of its partner agencies, PSFI contributed to over 80% decrease in Malaria infections in the province. From an alarming figure of over 50,000 cases in 1999, reported Malaria cases dropped to just 8,071 in 2010.

PSFI volunteers have likewise participated in countless medical

missions, making the foundation a valuable counterpart of the local government in reaching far-flung communities, including those of indigenous groups.

The foundation was also recognised for spearheading relevant social development projects like the Sanayan sa Kakayahang Agrikultura (SAKA)—a one-year agricultural skills training and scholarship programme for out-of-school youths and fresh high school graduates. Another project known as the Integrated Farming Bio System (IFBS), offers mentorship in new technologies and backyard livelihood for farmers and fishermen.

Through the Specialised English Enhancement Course for Elementary and High School (SPEECH) programme, PSFI provided public elementary schools with microscopes, books, and teaching tools for science subjects. The Brigada Eskwela is also held annually through the foundation’s efforts.

The Foundation has likewise made

significant contributions in the areas of environmental preservation and arts and culture, by participating in local environmental activities, and by showcasing local talents in the fields of music and literature.

According to Palawan Governor Abraham Kahlil Mitra, “PSFI has truly responded to the needs of the times and has played a significant role in nation-building.” The Provincial Government of Palawan conducts the annual Governor’s Award in recognition of the men, women and institutions who have made significant contributions to the care and progress of the province. [SPEX Communications]

PSFI cited at the 7th Governor’s Award in Palawan

Pilipinas Shell Petroleum Corporation (PSPC) partners with Gawad Kalinga (GK) to support the GK Center for Social Innovation (CSI) which aims to provide livelihood opportunities to the youth by exposing them to social entrepreneurship and infusing positive business values. PSPC and GK forged the partnership through the recent signing of a Memorandum of Agreement in Makati City and the

turnover of a corporate donation of 9 million pesos.

Shown in photo is Edgar Chua, PSPC Chairman and President, as he hands over the cheque to GK Chairman Tony Meloto. Meloto expressed his gratitude to Shell whom he cites as GK’s biggest corporate partner, and a partner in nation building. Joining them in the photo are (l-r) Head of

Gawad Kalinga Center for Social Innovation (CSI) Frank Chiu, GK Finance Manager Delfin Mangona, GK Board Member Mike Goco, PSPC Vice President for Communications Roberto Kanapi, PSPC Sustainable Development Manager Ronald

Shell supports Gawad Kalinga Center for Social Innovation project

12 SHELL WORLD PHILIPPINES

A PSFI representative facilitates the blood smearing activity in

Culion, Palawan.

Through the Malampaya Foundation, the Malampaya joint venture partners Shell Philippines Exploration B.V. (SPEX), Chevron Malampaya LLC and the Philippine National Oil Company (PNOC) Exploration Corporation, donated to the fundraising campaign of the University of the Philippines (UP) Institute of Chemistry, spearheaded by the University of the Philippines Chemistry Alumni Foundation, Inc. (UPCAF).

The fundraiser known as “Project IC - Bagong Gusali”, aims to furnish the rooms of the new Teaching and Research Building, located within the 22-hectare National Science Complex and Technology Incubation Park (NSCTIP) in the state university’s main campus in Diliman, Quezon City.

Malampaya adopted five laboratory rooms in the said location through the fundraiser’s Adopt-A-Room Donation

Scheme. The UP Institute of Chemistry, for its part, shall actively assist Malampaya Foundation, Inc. (MFI) should the foundation need the Institute’s expertise for analytical and technical services, as well as in research.

UPCAF Director Florian del Mundo, UPCAF Chairman Renan M. del Rosario, MFI Executive Director Luke

Esteban and SPEX Managing Director Sebastian Quiniones formalised the donation by signing a Memorandum of Agreement in June 2011. UP President Federico Pascual graced the occasion.

It is hoped that this contribution would foster the growth of the Philippines’ scientific endeavours in the field of Chemistry. [SPEX Communications]

Shell companies in the Philippines (SciP)’s Country Chairman Edgar Chua graced the Grand Ballroom of Intercontinental Manila Hotel last June 14, 2011, to participate in Philippine Development (PhilDev) Foundation’s “Innovation and Entrepreneurship for a Globally Competitive Philippines” forum.

True to its title, the whole day forum called on renowned speakers from government, academe and business to discuss about strategies, specifically entailing science, technology and innovation, for a more progressive economic growth and development in the Philippines.

Chua, PhilDev’s private sector co-chair, took part in the forum by being one of the speakers in the Innovation and Industry Development Conversation, wherein the PhilDev Multisectoral Alliance for Science and Technology (MAST) was launched.

He expressed faith in the development potential of our country especially with the help of improved science and technology competencies. “There are many things we can do with MAST: partnerships, collaborations with the academe, government, among others. To attain our goal of

producing competent science and engineering graduates, we will start a fundraising drive of initially a billion pesos,” said Chua. He explained that no matter how difficult the endeavour may be, Shell will remain steadfast in contributing to the economic development of the country, especially through science and technology. Chua, in behalf of Shell, committed a corporate donation of Php 100 million pesos to kick-start the fund that aimed to accumulate 5 billion pesos in five years. [Maria Fatima Cruz]

Malampaya Partners donate to UP’s Science Complex

Shell supports PhilDev Foundation’s forum

Suarez and PSPC Consultant Rudy Naguit. [Maria Fatima Cruz]

SHELL WORLD PHILIPPINES 13

Members from the UPCAF, Shell and Malampaya Foundation formalised the donation through the signing of the Memorandum of Agreement in June 2011. Among the guests were UPCAF Director Florian del Mundo (seated, 3rd from left), UPCAF Chairman Renan M. del Rosario (seated, 4th from left), MFI Executive Director Luke Esteban (seated, 3rd from right), SPEX Managing Director Sebastian Quiniones (seated, 2nd from right), SPEX External Affairs Manager Karen Agabin (seated, rightmost) and Shell GM for Communications Bobby Kanapi (standing, rightmost).

COVER STORY

14 SHELL WORLD PHILIPPINES

BY JOCELYN DIANA-DIGA

PUSHING THE BOUNDARIES

FOR FUEL EFFICIENCY

Shell fuel efficiency lesson at the Bonifacio Global City during the Global Shell FuelSave Day.

Shell fuel efficiency lesson at the Bonifacio Global City during the Global Shell FuelSave Day.

Shell fuel efficiency lesson at the Bonifacio Global City during the Global Shell FuelSave Day.

Shell fuel efficiency lesson at the Bonifacio Global City during the Global Shell FuelSave Day.

SHELL WORLD PHILIPPINES 15

I n these cost-conscious times, every Filipino is looking for ways to save and ensure that money is well

spent, not only on products but also on services. For everyday drivers, getting the most out of every drop of fuel, whether through smarter driving habits or using the right fuels, is both a challenge and an aspiration. That’s why, to help motorists do just that, Shell launched Shell FuelSave Unleaded and Shell FuelSave Diesel, two new breakthrough fuels designed to help drivers save on fuel at no extra cost. The advanced innovative technology from Shell which replaced regular unleaded and diesel, contains the most advanced fuel economy to date.

“We go to great lengths to understand the needs of motorists. Over the years, we’ve performed road trials equivalent to going round the world hundreds of times in order to be sure that the fuels we deliver will work in the real world. Closely monitored from refinery to road, we know that Shell FuelSave is a quality fuel, developed to help keep your engine clean and to maintain its efficiency,” said Pilipinas Shell Retail Marketing Manager Arlene Manalo. “The new Shell FuelSave formula is also designed to give instant benefits, meaning the fuel gets to work from the time you fill up.”

Asian drivers and fuel economySince 2007, Shell has been carrying out international research to find out more about drivers’ attitude towards fuel efficiency. In 2010, around 3,300 drivers in 11 different countries across Europe and Asia were surveyed to find out what motorists are currently doing to save on fuel. Findings in Asia revealed that Asian drivers are more conscious of fuel efficiency and are willing to take steps to save further than their European counterparts. The majority of Asian drivers are in the right mindset to save fuel but many still lack the resources and knowledge to do so. The study further revealed that nine out of 10 Asian drivers are

willing to change their behaviour to save fuel. In the Philippines, research shows that 96% of Filipino drivers said they were hungry for help to drive more efficiently.

In response, Shell has intensified its campaign on fuel efficiency by training over 160,000 drivers across 11 countries on smarter mobility. With the application of fuelsaving techniques and using Shell fuels with the Fuel Economy Formula, drivers have saved up to 24% on fuel. Breakthrough fuelThe new Shell FuelSave Unleaded and Shell FuelSave Diesel have been developed over the years by Shell scientists dedicated to creating innovative fuels for drivers. These formulations are enriched with an advanced efficiency improver, designed to improve fuel efficiency from the very first fill of the tank.

So how does it work? “We found that the top of the cylinder and the piston heads were often inconsistently coated with oil, which results in greater friction. We came up with a solution that will improve the lubrication of the piston rings. This new fuel is formulated to lubricate where normal engine oils can’t easily reach. This enables the engine to turn more freely and make more of the fuel’s energy available to drive the wheels,” said John Lambert, Shell Fuel Technology Senior Scientist, resource speaker at the Philippines’ Shell FuelSave launch.

Shell FuelSave Unleaded reduces energy loss by lubricating parts of the engine where oils are less effective. Shell FuelSave Diesel, on the other hand, is designed to ignite and burn more effectively than regular diesel, helping to produce more efficient combustion in the engine. Both Shell FuelSave Unleaded and Shell FuelSave Diesel contain special detergents to keep the engine’s valves clean and prevent mileage robbing deposits.

COVER STORY

16 SHELL WORLD PHILIPPINES

John explained that combustion is most efficient when precise amounts of air and fuel are mixed together at the right time. “With some conventional fuels, deposits may form over time at the back of the inlet valves that can lead to delays in the required fuel charge entering the engine and a poor mix of fuel and air, all of which leads to a reduction in the engine’s efficiency and therefore worsens fuel consumption.”

First Philippine Shell FuelSave Ambassador and TeamWho would have thought that the country’s avowed biggest fuel spenders would emerge as Philippine advocates for fuel saving and fuel efficiency, introduced to the public as the first Philippine Shell FuelSave Team.

From more than 150 entries received in an online competition launched by Shell early last year, a rigorous selection process shortlisted 10 finalists who underwent the Fuel Economy Boot Camp. They battled on the tracks to determine the most fuel efficient driver – that is, the one who can go the farthest on a limited amount of fuel. After a fuel efficiency makeover, HR Specialist from Baguio Vanessa Santos, Geographic Information System Specialist from Cavite Roland Patrick Villareal, Entrepreneur from Quezon City Adrian Mark Law, and Franchise Manager Mel Anthony Endozo, proved to be the most promising individuals to cut

on fuel bills and at the same time become expert fuel savers.

On being a part of the Shell FuelSave Team who will inspire the country’s drivers to be more fuel efficient, Vanessa Santos shares, “being someone who’s often on the internet, I can inspire other drivers by sharing my experiences through social media such as Facebook and Twitter. Surely, when they read firsthand experiences of an everyday driver who has been able to save money and help the environment simply by taking fuel saving tips to heart and practicing them, then who wouldn’t want to do the same thing?”

Shell teamed up with television personality and actor Ryan Agoncillo to be the official Shell FuelSave Ambassador. Together with the Philippine Shell Fuelsave Team, Ryan underwent an intensive training on fuel economy along with the Shell FuelSave Teams from Singapore, Malaysia, Hong Kong and Thailand.

“I had no idea that by using the right fuel and making a few simple changes to my driving habits, I could be so much more fuel-efficient. It really is that simple – which is why I am working with Shell to help drivers all over the Philippines learn how to save fuel and money,” shares Ryan.

The Shell FuelSave 1 Litre ChallengeAt the Sepang International Circuit in Malaysia, everyday motorists were

put to test during the Shell 1 Litre Challenge staged at the sidelines of the 2nd Shell Eco-marathon Asia competition last July 6-9, 2011. The Philippine Shell FuelSave Team were among the five teams from five countries that competed in the Shell FuelSave 1 Litre Challenge. Led by Shell FuelSave Ambassador Ryan Agoncillo, the Philippine team competed at the Sepang race track not for speed, but on how far can they go on a litre of fuel in a typical car.

The Shell FuelSave 1 Litre Challenge pitted five-man teams from Malaysia, Philippines, Singapore, Hong Kong and Thailand to see which team could travel the farthest distance on a single litre of Shell FuelSave.

The Philippine FuelSave Team posted an average of 15.136 kilometres/litre (km/l). The Thailand Shell FuelSave Team won the region’s Shell FuelSave Challenge with an average score of 15.952 km/l.

The Shell FuelSave Challenge was launched in 2007 to help drivers save on fuel. It supports the Smarter Use aspect of Shell’s Smarter Mobility initiative – alongside Smarter Products and Smarter Infrastructure.

Setting the Guinness World Record for fuel efficiencyLast October 15, 2011, Shell Philippines joined the rest of the world in setting a new Guinness World Record for the Largest Fuel

Shell FuelSave Ambassador for the Philippines Ryan Agoncillo (middle) together with the Shell FuelSave team FuelSave Godparenting

SHELL WORLD PHILIPPINES 17

Efficiency Lesson with simultaneous interactive trainings held in 11 cities across Europe and Asia. A total of 3,243 motorists from Denmark, Germany, Hong Kong, Malaysia, the Netherlands, Philippines, Thailand, Turkey, and the UK, successfully set the Guinness World Record in the Global Shell FuelSave Day.

In the Philippines, around 736 Filipino motorists from Manila and Iloilo City united in the true spirit of 'bayanihan' or Filipino solidarity and made history with their desire to achieve better fuel efficiency. Through the Global Shell FuelSave Day, more Filipino drivers learned more about saving fuel by just changing their driving habits and using the right fuel for their cars.

A Philippine fiesta-inspired revelry greeted hundreds of Filipino drivers in the grand celebration, with street performers such as mimes, jugglers and street dancers adding pomp to the event. To add excitement to the festivity dedicated to fuel saving, dance competitions from different universities battled for supremacy, while popular local band Freestyle entertained participants and guests in the grand celebration. Meanwhile, Shell FuelSave Philippine Ambassador and television personality Ryan Agoncillo, together with popular disc jockey and television host Sam YG, spiced up the fuel efficiency lesson and imparted valuable Shell FuelSave tips to educate Filipino drivers to be more fuel efficient.

“I’m really proud to have been part of this world record attempt and see thousands of Filipinos come together to learn how to save fuel. To think that thousands of people across the globe were all learning how to be more fuel-efficient simultaneously is incredible,” said Philippine Shell FuelSave Ambassador Ryan Agoncillo. “It may sound ironic that a fuel company wants drivers to reduce their fuel consumption. However, Shell’s thrust for Smarter Mobility, as evident in the introduction of the Shell FuelSave fuels, the Shell Eco-marathon, and now, the Global Shell FuelSave Day, is proof of its commitment to help motorists save more fuel and money on the road for life.” Immediately after the lesson, Guinness World Records adjudicators who oversaw the attempt in each city, confirmed that the new record was set by Shell – truly a historic day, as Shell set the first ever Guinness World Record for the Largest Fuel Efficiency Lesson.

“To see so many people come together and achieve a Guinness World Record for fuel efficiency pushed our passion to help motorists get the most out of every drop of fuel. We know that Filipino motorists are looking for ways to bring down their driving costs, so I hope that through the Global Shell FuelSave Day, we’ve been able to show them how easily this can be achieved by choosing the right fuel and making a few simple changes to their driving habits,” said Pilipinas Shell General Manager for Retail Oying Yam. SWP

GETTING SMART ABOUT MOBILITY

The number of cars on the road is expected to triple by 2050. A variety of fuels and techniques will be needed to meet the growing demand for mobility while limiting CO² emissions. These will be influenced by government policies, advances in technology, cost and environmental concerns. At Shell, we continue to find innovative ways to help move the growing number of people and goods efficiently. Our “Smarter Mobility” programme includes developing more energy-efficient fuels and lubricants; investing in lower carbon alternatives; offering drivers fuel-saving tips; working in technical partnerships; and helping to reduce CO² emissions from road-building.

Smarter Use is about encouraging our customers to use less fuel by changing their driving behaviour and inspiring future generations to design energy efficient cars. Smarter Products is about offering our customers advanced fuels and lubricants for better driving performance, lower CO² emissions and fuel savings compared to conventional fuels and lubricants

Smarter Infrastructure is about developing products that can make road-building more efficient, with less energy and greater strength and flexibility.

The De La Salle University - Manila team stands proud with the DLSU 100 car during the FuelSave Day celebration.

Shell Companies in the Philippines Country Chairman Edgar Chua enjoins everyone to get smart about mobility.

Shell Retail GM Oying Yam receives the Guinness world Record from Guinness adjudicator Louise Alexandra Toms.

18 SHELL WORLD PHILIPPINES

Shell has set a new Guinness World Record after more than 3,000 motorists in 11 cities

across Europe and Asia took part in simultaneous fuel efficiency lessons on October 15, 2011.

The world record was set on Global Shell FuelSave Day, when drivers in all 11 cities participated in a simultaneous 30-minute interactive fuel economy training session showing them how making a few simple changes to their driving habits and using the right fuel could help them save fuel costs. It also gave them the chance to be part of the first ever Guinness World Record attempt of its kind.

Each event was aimed at inspiring drivers about fuel saving, while also raising brand awareness of Shell FuelSave through direct customer engagement and securing Shell’s position as the leading brand in helping motorists save fuel.

Shell FuelSave Day events were held in: Allerød, Denmark; Bangkok, Thailand; Hamburg, Germany; Hong Kong, China; IloiIo City, Philippines; Istanbul, Turkey; Kuala Lumpur, Malaysia; London, UK; Manila, Philippines; and Valkenburg, Netherlands.

The events ranged from Hamburg’s first ever live music and car

enthusiasts concert, to a family fiesta in Manila which invited drivers to unite in saving fuel. Dutch VW Beetle Club members took part in a fuel economy driving challenge around an airport. While in London, participants competed in a fastest finger first competition, answering questions on fuel efficiency and the Shell FuelSave tips in the fastest time, to win a car.

Guinness World Records adjudicators attended the events to oversee the world record attempt in each city and gave official confirmation that a new record had been set immediately after the lesson. SWP

Shell sets new Guinness World Record

GLOBAL SHELL FUELSAVE DAY SETS A NEW WORLD RECORD BY ENCOURAGING FUEL EFFICIENCY AROUND THE WORLD

Shell’s Smarter Driving tips

Shell FuelSave day is part of Smarter Driving and reflects Shell’s Smarter Mobility initiative, with its focus on smarter products, smarter use and smarter infrastructure – helping customers use less and emit less.

• Service your engine • Use the correct oil • Keep tyres at the right pressure • Keep the windows closed • Use air conditioning sparingly • Use a higher gear • Use cruise control • Avoid high speeds • Take the roof rack off • Drive smoothly • Conserve momentum • Avoid excess idling • Plan trips carefully • Avoid carrying excess weight • Fuel matters

Shell Gas introduces Telemetry: A pioneering innovation in the LPG Industry

After the resounding success of its new Road Transport fleet launch in June 2011,

Shell Gas once again proved to the industry that it is indeed the leader in innovation and technology with the launch of Telemetry - a web-based automated fuel tank level monitoring system that allows for efficient inventory management in order to improve forecasting accuracy and timely product delivery. Telemetry simplifies fuel tank monitoring from data collection, to notification of order point trigger, and to report generation.

Why Telemetry?For LPG industrial accounts, billing and invoicing is primarily based on consumption determined by the amount delivered and received in the customer’s site. Each delivery is carefully planned and is dictated by the tank level at the time of request for delivery. However, determining the correct tank level is a challenging task as it entails specific personnel to be assigned to view tank levels at different intervals. The time difference between the recorded tank level and actual delivery of product poses a gap which would mean differences in actual need versus actual delivered product.

In order to drive the importance of proper tank level monitoring and management, Shell Gas launched and implemented the Delivery Promise (DP) in 2010. The DP roll-out created an attitude of compliance and vigilance in getting things right in order to avoid penalties arising from inefficient deliveries. It also helped Shell Gas lessen its losses from Residual on Board (ROB), as well as save time and effort through better delivery planning. In its continuing effort to improve its services to valued customers, Shell Gas sought more ways to improve delivery accuracy and customer service. Telemetry proved to be the most cost-efficient way, as it enables a more accurate reading while lessening trips to the tank farm. This, in turn, saves valuable time for the customers, which can be spent in more business-building activities.

How does it work?Telemetry, once installed, can instantly capture data per tank and transmit data via the Global System for Mobile Communications (GSM) network. Data then passes through the vendor's network and can be easily accessed via internet. Each system can read up to six (6) tanks

per installation and Shell Gas can access each tank's level at any given point in time. Data reports ensure that Telemetry offers quick and accurate decision-making and can create trending reports that can assist in delivery projections and cost analysis.

Other features include an ordering point alarm that can trigger Shell Gas Road

Transport and alerts the Customer Service Centre (CSC) team when a particular tank has reached the level that signals replenishment. This is programmed based on estimated daily consumption and factors in delivery lead times.

Telemetry is truly the next phase in inventory management. It can prevent dead stock, emergency deliveries that cost time and money, and insufficient tank refills. It cuts across all functions in terms of benefits and provides peace of mind for customers.

These times demand more efficient operations partnered with lower product and service cost. Hence, Shell Gas aims to be the most preferred LPG supplier for the industrial segment, and with Telemetry, the aim to become the top-of-mind choice is now a reality. SWP

BY ANNA KATRINA BARRIOS

LPG bulk tanks in Toyota Motors Philippines Corporation fitted with

Telemetry remote reader

Close up of the remote reader installed on the tank gauge

Metron ATEX unit at the site, which contains the sim card used for sending relevant info

Metron ATEX unit at the site, which contains the sim card used for sending relevant info

SHELL WORLD PHILIPPINES 19

Winning Photo. The American Chamber (AmCham) of Commerce of the Philippines awarded this Movement Against Malaria photo in the 2011 AmCham Photo Competition. The photograph, entitled “Show Me What You’ve Got” was taken by Darius Dela Cruz, Movement Against Malaria Monitoring and Evaluation Officer.

20 SHELL WORLD PHILIPPINES

Recognised at government level, by the United Nations (UN) and the World Health Organisation

(WHO), the initiative could eliminate malaria in the Philippines.

"When Shell arrived in Palawan 12 years ago, we knew that this area topped the Philippines' 59 provinces where malaria was commonly found," says Edgar Veron Cruz, Pilipinas Shell Foundation Executive Director.

The Malampaya project is one of the most significant industrial investments

in the history of the country. Shell is providing the natural gas which powers almost half the electricity needs of the island of Luzon, home to the capital Manila. Yet, while Shell was providing characteristic innovation and state-of-the-art technology to improve lives in the region, a preventable disease was still claiming lives. That’s when Shell’s social performance kicked into action.

"We wanted to make a difference," says Edgar. "But I don't think any of us realised how much of a difference

Winning the fight Anti-malaria mission

MALAMPAYA, THE SHELL-OPERATED DEEPWATER GAS-TO-POWER PROJECT IN PALAWAN, WHICH IS CELEBRATING

ITS TENTH ANNIVERSARY THIS YEAR, CAN CONGRATULATE ITSELF ON MEETING MORE THAN THE ENERGY NEEDS OF A RAPIDLY DEVELOPING SOCIETY. THROUGH THE MOVEMENT AGAINST MALARIA, SHELL IS LITERALLY

SAVING LIVES WITH A SUCCESSFUL SOCIAL INVESTMENT INITIATIVE THAT HAS GROWN INTO A NATIONWIDE

HEALTH PROGRAMME.

BY SANKIE SIMBULAN AND ANGELA TWEEDIE (PUBLISHED IN U&I, SHELL UPSTREAM INTERNATIONAL’S GLOBAL NEWSLETTER)

Early detection. Along with equipping all community health centres in Palawan with microscopes, community health workers were likewise provided with intensive training in microscopy to empower them in detecting the malaria parasite, aiding in the early detection and diagnosis of the disease.

Protecting the most vulnerable. Pregnant women from the malaria-endemic province of Tawi-Tawi receive pregnancy packages containing Ferrous Sulfate for iron deficiency, de-worming tablets, Long Lasting Insecticide-Treated Nets (LLITN), Information, Education and Communication (IEC) materials on malaria and mother and child booklets during a Malaria Awareness Day activity.

SHELL WORLD PHILIPPINES 21

we could make. When we started in 1999, almost 16 million people, that's around 21% of the total population, were at risk of contracting malaria in the Philippines. In the island province of Palawan, over 40,000 people were suspected to have contracted malaria," Edgar adds.

In an attempt to address the issue, Shell established the Kilusan Ligtas Malaria (Movement Against Malaria) in Palawan in 1999 as a sustainable development programme.

Under the Shell Foundation, and by working with local government units, the Movement Against Malaria (MAM) has made huge strides in controlling malaria and could see the disease being eliminated.

Empowering communities The MAM programme began in the affected villages by promoting awareness

MalariaThis deadly parasitic disease carried by mosquitoes typically occurs in tropical countries like the Philippines. In many of the countries affected by malaria, it is a leading cause of illness and death and its costs to individuals, families and communities and governments are enormous.

Reaping the rewards2010 was a banner year for the Movement Against Malaria (MAM) programme, receiving external recognition from various award-giving bodies. These awards are tokens of recognition to the countless individuals who work on the ground, selflessly assisting in the noble work of empowering communities to fight the deadly malaria disease and have a better quality of life.• Excellence Award, Concern for

Health Category - 8th Asian Corporate Social Responsibility Awards

• MDG Warrior Award for substantial contributions in eradicating malaria - The United Nations Millennium Campaign, Probe Media Foundation and Kodak Philippines

• Anvil Award of Excellence, Public Relations Programmes on a Sustained Basis: Health Category - Public Relations Society of the Philippines

• Quill Award of Merit, Communication Management: Economic, Social and Environmental Development Category - International Association of Business Communicators

of the causes and on prevention of malaria. In addition, mosquito control and mosquito-bite preventive measures were taken, such as the clean-up of slow moving streams where mosquitoes can breed, encouraging people to sleep under mosquito nets at night, and wearing trousers and long-sleeved shirts in the evening.

MAM also established malaria microscopy centres in all malaria-prone villages in Palawan and trained health workers to detect the malaria parasite. This substantially aided early detection and treatment. By 2004, WHO external evaluators recognised that the village microscopists had become an important part of the health system in Palawan.

"As recently as 10 years ago, some people in this region had no real knowledge of how malaria was contracted, and held on to the notion

that the cause of infection was eating pineapple on an empty stomach or from drinking coconut juice. What we have been able to do is empower communities to fight malaria and have a better quality of life," says Edgar.

Since the programme started, MAM has helped reduce malaria deaths in Palawan by 93% (from an average of 85 per year to six in 2010), and has seen a 76% reduction in reported cases (from 42,394 to 10,371 last year).

Expanded programme The success of the programme led to the award, in 2006, of a $14 million, five-year grant from the Global Fund to Fight AIDS, Tuberculosis and Malaria. MAM used this funding, the first ever awarded to a private corporate foundation, to expand its work to four other provinces. A further grant from the Global Fund has provided an additional $31.4 million which MAM is using to extend its coverage to 35 more provinces.

While the work of MAM has been recognised through numerous awards, the most recently received accolade ensures the benefits of MAM will be felt for a long time to come. "Shell has operated in the Philippines for close to a century, it is helping to fuel the country’s economic development whilst showing respect for people and the environment," says Edgar. "All of that increases the feeling of pride in working for a company like Shell. MAM is one good reason for every Shell employee in the Philippines to feel 10 feet tall." SWP

22 SHELL WORLD PHILIPPINES

Shell eServe: Driving business efficiency and value to Shell customers

Shell touchless tools“A cornerstone of the Shell Touchless concept, our Shell eServe has introduced simple, standard processes and systems to provide better service to our customers when transacting with Shell online – from order to delivery,” said Shell Touchless Business Specialist Rina Chavez. Launched in the Philippines on July 1, 2009, the online service is currently available to sales accounts in Global Lubes, B2B Fuels, Marine and Retail. Customers using Shell eServe cover Commercial Road Transport, Industrial, Original Engine Manufacturers (OEM), Distributors, Mining/Cement, Power, Industry Fuels, Marine-Domestic businesses and other end-users.

In Shell, other Touchless tools being implemented are the interactive Voice Response System (IVRS) – an automated telephone service that helps customers to interact with Shell; and Vendor Managed Inventory (VMI) – a supply service where Shell monitors the inventory levels and usage patterns of customers’ storage tanks for replenishment.

Empowering customersPutting customers at the heart of the Shell business, eServe was designed to help customers in the areas of business efficiency, flexibility and security.

With a simplified approach, the system allows customers to transact

WHEN IT COMES TO E-BUSINESS SOLUTIONS, SHELL PHILIPPINES IS HELPING SHELL CUSTOMERS DO BUSINESS MORE EFFICIENTLY WITH JUST A TOUCH OF A BUTTON. THROUGH SHELL E-SERVE, A WEB-BASED SERVICE SYSTEM, CUSTOMERS CAN PLACE ORDERS ONLINE, ACCESS ACCOUNT AND FINANCIAL INFORMATION, VIEW PRODUCTS, AND MANAGE THEIR BUSINESS TRANSACTIONS WITH SHELL. MORE THAN AN ORDERING SYSTEM, E-SERVE IS ONE OF SHELL'S TOUCHLESS CONCEPTS THAT FEATURE MULTIPLE FUNCTIONS, HARNESSING THE SOPHISTICATION AND EASE OFFERED BY MODERN TECHNOLOGY. BY JOCELYN DIANA-DIGA

Shell Touchless Business Specialist Rina Chavez

SHELL WORLD PHILIPPINES 23

with Shell at a time that is most convenient for them. “Customers are empowered to place their own orders, thereby ensuring accurate information, access to Shell products online, and low cost of operation from order taking to billing information or financial summary download readily available 24/7,” says Chavez. She adds that the system allows for faster and more efficient processing of payments, while helping customers optimise, monitor and control their payment plans.

Customer benefits“Shell eServe is the most convenient way of doing business with Shell. It offers a variety of functions designed to help users such as having real-time access to our current product line, viewing technical product information as well as account information, tracking orders, monitoring account balance, managing documents, and viewing and printing sales documents and volume reports in demand. The online tool departs from the conventional ways of transacting with Shell via fax, email or placing manual calls to Customer Service,” adds Chavez. Transactions are immediately posted and documents are easily downloadable, making Shell eServe a one-stop shop for all users serving their needs. Unlike the conventional order taking, eServe does all the work for the users with

minimal input requirements.

Chavez adds that the online ordering tool is very secure since it provides specific identification and password for log-on, as well as flexibility and security that can grant access to multiple users in a single organisation. In addition, Shell eServe is free with no IT cost per customer. Since its launch, the latest release of Shell eServe is a step up from the original version, with more functionality and more user-friendly features that simplify everyday tasks for customers. “After the introduction of Shell eServe to customers in 2009, the usage of the system for placing orders has doubled in 2010, from 13% to 25%. As of August 2011, touchless uptake in the Philippines for all combined channels went up to 81%.” Through different incentive programmes for customers and account managers, as well as holding classroom-type training, Chavez is continuing to drive uptake of eServe among Shell customers. “With our customers at the heart of our business, we are strengthening our delivery promise to them through efficient technology. This ensures our support to drive business efficiency and add value to their business operation,” Chavez concludes. SWP

eHaulierLubricants Supply Chain (LSC) similarly employs an internet-based system called eHaulier for its packed and bulk hauliers. It is a cost-effective solution designed to give third party hauliers access to delivery information such as viewing of the shipment and delivery notes. “With this, hauliers are able to allocate trucks more efficiently as they are able to view the products’ quantity and destination of deliveries,” says Logistics Supervisor for Lubricants Joan Co.

The system likewise allows hauliers to input the correct information based on the delivery that needs to be met. The eHaulier system ensures accountability on the part of the haulier in ensuring proper and careful handling of the overall delivery process.

“Using Shell eServe is more convenient than manual ordering with the Customer Service Centre via telephone. It is user-friendly and fast, and it has a system update notification.”- Cherry Alonzo-Flores, Secretary, Diamond Motors/Mitsubishi

“With the use of Shell eServe, we are able to process our orders faster and more accurately. From my experience, using Shell eServe is very beneficial as it provides all the necessary information a customer needs. Everything is already there, but if it can still be improved, that would be great!”- Tony Abarquez, Parts Supervisor – Micah /Chevrolet

“The advantage of Shell eServe for us is we get a confirmation right after placing our orders. We don’t need to call Customer Service to confirm if our order was processed and to ask for the delivery date as the system provides this immediately.”- Agnes Andal, Materials Planner, Toyota Motor Philippines Corporation

“When it comes to using the Shell online system, the process is quick. When it comes to our invoices, for example, these can be readily downloaded and printed through Shell eServe.”- Ian Cerda, Parts Supervisor – PORSCHE

What customers are saying about Shell eServe

Rina conducts eServe training for Shell customers

To lead is to share:

A winner’s perspective

24 SHELL WORLD PHILIPPINES

THE MAN AT THE HELM OF AGC FLAT GLASS, A LONGTIME BUSINESS PARTNER OF SHELL COMMERCIAL FUELS, IS EMMANUEL “NOEL” GO, RECIPIENT OF THIS YEAR’S

PRESTIGIOUS CEO EXCEL AWARD FOR MANUFACTURING. NOEL WAS RECOGNISED BOTH FOR DISPLAYING MANAGEMENT COMPETENCE AND EXCELLENCE IN

COMMUNICATION. HE NARRATES HIS JOURNEY TO THE TOP OF THE ORGANISATION, HIS LEADERSHIP STYLE AND PERSONAL ADVOCACIES. IN SHARING ALL THESE, HE EMPHASISES THE IMPORTANCE OF INSPIRING WORK EXCELLENCE AND EFFECTIVE

COMMUNICATION AS KEYS TO A STRONG LEADERSHIP.

BY JUN JAY G. JIMENEZ

SHELL WORLD PHILIPPINES 25

Without the skill of effective communication, a leader is nothing. This is what

CEO Noel Go firmly believes.

”A leader of any organisation must be a communicator. He must share his ideas to effectively lead his people,” states the current President of AGC Flat Glass. He practices transparency in dealing with his people and openly declares his objectives and goals. But to be a truly effective leader, Noel believes one must walk the talk, or lead by example. Savvy in conducting business and adept in communicating his ideas, Noel is one of the recipients of the 2011 Communication Excellence in Organisations (CEO) Excel Award given by the International Association of Business Communicators (IABC) Philippines, a leading association for business communication professionals committed to inspiring, establishing, and supporting the highest professional standards of quality and innovation in organisational communication. With this honour, he joins the select group of outstanding national and industry leaders who epitomise management competence and excellence in communication at a strategic level.

His decades of prolific experience have shaped him to become one of the prime movers in the glass manufacturing industry. Joining hands with other industry leaders, Noel has championed outstanding programmes that earned recognition from prestigious institutions and organisations in the country. With his able leadership, he successfully ushered AGC Flat Glass to become one of the leading companies in the manufacturing industry today.

Making things happenHis peers and colleagues in the industry know his dedication and passion for his advocacies. Noel is the type who moves mountains to succeed in his projects. In all that he does, he always makes a plan. On working with projects, Noel can be relied upon with his brilliant foresight and quality of leadership.

Just like a teacher, Noel is generous in sharing his knowledge with his employees. His awareness of the power of communication in leading his people towards realising corporate goals is remarkable. “People in the organisation may resist change. Communicating to them the benefits of change and explaining to them how to attain the objectives are the best way to convince them.

Communication is a tool to overcome barriers towards reaching goals,” Noel explains. His style of leadership is practical, making sure that every step leads to the desired results. “I see to it that my goals are clear, and the ways of doing things must be practical for everyone to follow.” According to Noel, understanding that people have varying capabilities and setbacks can help a leader in designating his people on tasks that best fit with their abilities and empower them to deliver the desired outcome. Throughout these years, Noel has never gotten tired of pursuing programmes that benefit a large number of people. “It is best to come up with objectives that benefit not only yourself, but everyone.” He explained that cooperative effort is a requisite in attaining objectives that are beneficial to many people. “Knowing the interest and background of the people you are tapping for a project will help in winning them by your side. First, you have to get their attention with a convincing presentation of your project. Second, you have to persuade them to commit in order to sustain a project and realise objectives.” When it comes to encouraging people to agree with a plan, it is not always a bed of roses. But Noel shares that the best way to enable collaboration is to approach the situation with an open mind. “One must give others a chance to present their ideas. You may not agree with their ideas, but there should always be a desire to find the middle ground.”

While being a leader is a challenge by itself, Noel is always ready to embrace the challenges that come his way. Managing a large number of people at AGC Flat Glass has equipped him with skills that make him an effective leader. “My several years of leading our company have taught me methodologies in dealing with different situations at the workplace. But my guiding principle Noel together with his family

during the awards night

26 SHELL WORLD PHILIPPINES

is the readiness to accept change. Knowing the nature of your business and the external environment that influences your business will give you the edge in making decisions and taking action.” In the face of challenges, Noel is one hard nut to crack. His many years of leading people have shaped him to be resilient. His mettle had been put to test through the challenging situations he has dealt with. Looking back, Noel is happy to share that he, together with his team, surpassed the challenges. Today, they are all proud of what has become of AGC Flat Glass. Their dedication and teamwork finally paid off.

A vision for sustainability and progressWhether in business or hobbies, Noel engages in activities where he can excel. Overseeing the operations of AGC Flat Glass is like a smooth sail with Noel steering the wheel. Considering the diverse composition of its workforce, the leadership and involvement of Noel in various Human Resource activities are profound. The company’s recent employee satisfaction survey showed encouraging results, with more employees satisfied with the pro-active management action in improving work-life balance - which yielded higher productivity, lower wastage and lesser customer complaints. The company received various recognitions for promoting productivity, quality and safety in all aspects of its operations. AGC received a“Kapatid Award” from the Employees Confederation of the Philippines, which is a prestigious award judged by the Labour Secretary, the International Labour Organisation, and the Workers Association.

Noel also spearheaded operational excellence and environmental programmes that manifested his vision for environment-friendly and sustainable operations in pursuit of long-term productivity. As AGC Flat Glass’s operation is anchored on the productivity of its furnace, Noel

and his team rolled out a repair and capacity expansion project that yielded savings and minimal operational downtime. The project utilised lower fuel and oil consumption, which led to energy efficiency and savings, and resulted to better product quality, thereby contributing to the overall growth of the business. His team also received a Safety Achievement Award, Gawad Kaligtasan at Kalusugan (GKK) from the Safety Organisation of the Philippines for the attainment of 7.2 million no lost time work hours. On environmental initiatives which resulted to improved corporate performance, AGC Flat Glass was awarded with Excellence in Ecology and Economy by the Philippine Chamber of Commerce and Industry, including two awards from the Philippine Economic Zone Authority (PEZA).

Noel’s vision goes beyond the confines of the AGC Flat Glass business. He is also determined to direct the course of the glass manufacturing industry to continuous progress. As a member of the Federation of Philippine Industries (FPI), Noel lobbied and advocated for the availability of natural gas for Philippine industries as a competitive enhancing measure with the relevant government agencies, the Department of Trade and Industry (DTI) and the Department of Energy (DOE). As a result, the DOE and other private groups gave a positive response to carry out this programme.

Constantly looking for opportunities for growth for his company, the industry, and for the country, Noel and his team embarked on a search for local silica sand as raw material and other indigenous materials like feldspar and dolomite. With current glass manufacturing operations dependent on raw material importations from

Australia, Vietnam and China, Noel predicts that raw materials will be locally sourced in the very near future, thus, tempering threats of emerging protectionism of supplying nations on their own resources.

He also launched campaigns on anti-smuggling and prohibition of sub-standard products in collaboration with the FPI and some government agencies. Dialogues with the government and the private sector enabled the strong pursuit to eradicate smuggling and entry of sub-standard products in the country.

As he continues to churn up noteworthy programmes for AGC Flat Glass and the industry, Noel enthuses that he will continue searching for possible ways to improve himself in his chosen field. “I see myself as a big jar. My enthusiasm for learning will be until I am still capable of learning. I will feed my mind with knowledge to prepare for the future,” he resolutely shares.

Noel says that it gives him a different kind of high when he is presented with opportunities to share his knowledge with colleagues and subordinates. “Sharing generously the knowledge I gained through the years is the best part of being a leader.” The way this CEO Excel awardee generously imparts his wisdom is a source of inspiration, not only for his workers but for all those who aspire to be effective leaders of their organisation. SWP

Noel leads his team in celebrating AGC Flat Glass' outstanding safety record

SHELL LORRY DRIVER WALTER FLORES SHARES THE DETAILS OF HIS JOURNEY AS A PROFESSIONAL DRIVER AND HIS APPRECIATION OF SHELL’S LIFE-SAVING RULES (LSR) AS HE TRAVELS THE ROAD EACH DAY.

SHELL WORLD PHILIPPINES 27

Living with LSR: The Walter Flores story

Gone are the days when he lived a perilous life. Today, Walter Flores

embraces safety.

Walter admits that in the past, he has done some actions that he considers reckless. But his views on safety changed when he joined Shell as a lorry driver. At the age of 15, Walter already learned the basics of driving since he worked as a truck helper in the province. He recalls having to take on odd jobs as a teenager to help support his siblings after his parents got retrenched from their jobs as plantation workers. Walter also shares that he had to put off his plans of pursuing a college education when he started to work as a truck driver at the age of 20.