SERVICE INSTRUCTIONS “PVWJ” B-FRAME PUMPS -025/-034/ …

Transcript of SERVICE INSTRUCTIONS “PVWJ” B-FRAME PUMPS -025/-034/ …

Bulletin 947637

SERVICE INSTRUCTIONS“PVWJ” B-FRAME PUMPS -025/-034/-046

FOR TYPE “P-1NN/F/J/K” AND “P-LNN/F/J/K” LOAD SENSING CONTROLS

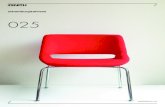

Figure 1. Typical Oilgear Type “P-1NN/F/J/K” and “P-LNN/F/J/K” Load Sensor Controls for “PVWJ” B-Frame Pump (shown with and without optional adapter and maximum volume stop)

PURPOSE OF INSTRUCTIONSThese instructions will simplify the installation,operation, troubleshooting and maintenance ofOilgear type “P-1NN/F/J/K” and “P-LNN/F/J/K”controlled units.

This material will inform you about the basicconstruction, principle of operation and serviceparts listings. Some controls may be modified forspecific applications from those described in thisbulletin and other changes may be made withoutnotice.

REFERENCE MATERIAL

Fluid Recommendations....................................................................................................... Bulletin 90000Contamination Evaluation Guide.......................................................................................... Bulletin 90004Filtration Recommendations................................................................................................. Bulletin 90007Piping Information ................................................................................................................ Bulletin 90011Proper Installation of Vertical Pumps ................................................................................... Bulletin 90014Alternate Remote Compensating of Single/Multiple Load Sense Pumps ............................... DS-47974-APVWJ Open Loop Pumps, Application Guidelines............................................................. Bulletin 847085PVWJ Open Loop Pumps (All Frame Sizes) Service Instructions ..................................... Bulletin 947085PVWJ Open Loop Pumps, Sales ......................................................................................... Bulletin 47085

PVWJ PUMP INSTALLATIONS

PVWJ B Frame (PVWJ-025/-034/-046) w/ Rear Ports ................................................................DS-47483PVWJ B Frame (PVWJ-025/-034/-046) w/ Side Ports.................................................................DS-47484PVWJ B Frame (PVWJ-025/-034/-046) w/ Side Ports & Thru Shaft ...........................................DS-47485

PVWJ PUMP CONTROL INSTALLATIONS

“P-1NN/F/J/K” and “P-LNN/F/J/K” Pressure Compensator w/ Load Sense for PVWJ-025/-034/-046...................................................................................................................DS-47988

OILG0258

THE OILGEAR COMPANY2300 South 51st Street

Milwaukee, Wisconsin 53219

Bulletin 947637 THE OILGEAR COMPANY 1Issued: August 2006www.oilgear.comBulletin 947637

Safety First

Read and understand this entire instruction sheetbefore repairing, or adjusting your Oilgear product.

Those who use and maintain this equipment mustbe thoroughly trained and familiar with the product.If incorrectly used or maintained, this product andits equipment can cause severe injury.

SAFETY SYMBOLSThe following signal words are used in thisinstruction sheet to identify areas of concern whereyour safety may be involved. Carefully read the textand observe any instructions provided to ensureyour safety.

THIS SIGNAL WORD INDICATES AN IMMI-NENTLY HAZARDOUS SITUATION WHICH,IF NOT AVOIDED, WILL RESULT IN DEATHOR SERIOUS INJURY.

This signal word indicates a potentiallyhazardous situation which, if not avoided,could result in death or serious injury.

This signal word indicates that a potentiallyhazardous situation exists which, if notavoided, may result in damage toequipment or minor personal injury.

While not directly relevant to the topic beingdiscussed, the NOTE is used to emphasizeinformation provided, or provide additionalinformation which may be of benefit.

This service information is designed forthe maintenance of your Oilgear product.It contains the information on the correctprocedures determined by Oilgear for thesafe manner of servicing. Always keepthis instruction sheet in a location where itis readily available for the persons whouse and maintain the product. Additionalcopies of this instruction sheet areavailable through the Oilgear Company.Contact us at 414-327-1700 or visit ourwebsite: www.oilgear.com. Please contactus if you have any questions regarding theinformation in this instruction bulletin.

The cleanliness of working on this pump orthe hydraulic system is extremelyimportant to the safety and reliability of thepump and the system. Always make surethe fittings are clean on the outside beforeremoving them from their connections, arecapped and plugged when removed andplaced in a clean rag or container until theyare reinstalled.

Some service operations may requirespecial tools or equipment. If you requireinformation on these items, please contactOilgear before attempting these repairsand service operations.

Read, understand and follow the safetyguidelines, dangers and warningscontained in this instruction sheet topromote reliable operation and preventserious personal injury.

DO NOT attempt to service this machineryin an environment where safety regulationsare not established and in place.

DO NOT operate the hydraulic system if aleak is present. Serious injury may result.

Hydraulic systems operate under very highpressure. Hydraulic fluid escaping from apressurized system can penetrateunprotected body tissue. DO NOT inspectfor hydraulic leaks with bare hands or otherexposed body parts. As a minimum, wearleather gloves prior to inspecting for leaksand use cardboard or wood. If leaks arepresent, relieve pressure and allow systemto cool prior to servicing. If injured byescaping hydraulic oil, contact a physicianimmediately. Serious complications mayarise if not treated immediately. If you havequestions regarding inspecting forhydraulic leaks, please contact Oilgearprior to servicing.

DANGER! !

! WARNING

CAUTION

NOTE

! WARNING

NOTE

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

2 THE OILGEAR COMPANY Bulletin 947637© 2006 THE OILGEAR COMPANY - ALL RIGHTS RESERVED

Safety First

Hydraulic hoses and tubing must beinspected on a daily basis for leaks, cuts,abrasions, damage and improperclearance along any mounting frame forhidden damage before the unit is put intoservice. Replace damaged hoses or hosesyou suspect are damaged before thesystem is returned to service! Hoses mustbe replaced every two years. Failure toproperly inspect and maintain the systemmay result in serious injury.

Hydraulic systems are hot. DO NOTTOUCH! Serious personal injury mayresult from hot oil. When you havecompleted working on the hydraulicsystem, thoroughly clean any spilled oilfrom the equipment. Do not spill anyhydraulic fluids on the ground. Clean anyhydraulic fluids from your skin as soon asyou have completed maintenance andrepairs. Dispose of used oil and systemfilters as required by law.

Use correct hoses, fittings, and adapterswith the correct SAE rating whenreplacing hoses to prevent possibleserious injury. Always replace hoses,fittings, and adapters with replacementsthat have a proper, suitable, workingpressure rating. Replacement hoses mustbe of the correct length and must complywith the hose manufacturer’s andOilgear’s installation guidelines andrecommendations.

Hydraulic hoses have the SAE ratingsmarked on the hose to assist you inselecting the correct hose. The samemanufacturer must supply any replacementhydraulic hoses and fitting assemblies. Asan example: Brand “X” hose and brand “Y”fitting will not normally be compatible. No“Twist” is allowed in the hydraulic hoses.“Twist” may result in premature hosefailure. This can cause serious injury.Please contact Oilgear for assistance whenrequired.

Hydraulic cylinders can be holding afunction in a certain position when thepump is OFF. An example of this is afunction being held in the lift or partial liftposition by the cylinders. If a hydraulicline is removed or the hydraulic circuits orcontrols are being worked on, gravity mayallow the function being held in position todrop. All workers and personnel mustremain clear of these areas when workingon or operating the hydraulic system.Block and secure all devices andfunctions which apply before beginningwork or operation. Failure to comply withthis can result in serious injury or death.

Any hydraulic pipe which is replaced mustconform to SAE J1065 specifications. Ifincorrect hydraulic pipe is installed, thehydraulic system may fail, causingserious injury. Damaged or leakingfittings, pipes or hoses must be replacedbefore the system is returned to service.

DO NOT heat hydraulic pipe. The carboncontent of this steel tube is such that ifheated for bending, and either water or airquenched, the pipe may lose its ductilityand thereby be subject to failure underhigh pressure conditions. Serious injurycan result. Damaged or leaking pipes mustbe replaced before the system is returnedto service. Please contact Oilgear if yourequire assistance or have questions.

All hydraulic pressure must be relievedfrom the hydraulic system prior to removingany components from the system. Torelieve the hydraulic pressure from thehydraulic system, turn off the motor andoperate the control panel with the key in theON position. Failure to comply can result inserious injury. If you have any questionsconcerning relieving the hydraulic pressurefrom the system, please contact Oilgear.

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

Bulletin 947637 THE OILGEAR COMPANY 3

Safety First

Hydraulic components can be heavy. Usecaution while lifting these components.Serious personal injury can be avoidedwith proper handling of the components.

Please contact Oilgear if you requireassistance. When performing hydraulictest procedures, use the proper hydraulicgauges. Installing an incorrect test gaugecould result in serious injury if the gaugefails. Use properly rated hydraulic hosesto allow the test gauge to be read awayfrom moving parts and functions.

Increasing hydraulic pressure beyond therecommendations may result in seriousdamage to the pump and system orserious personal injury and may void theOilgear Warranty. If you have questionsconcerning hydraulic pressures or testingprocedures, please contact Oilgear beforeattempting the test procedures or makingadjustments.

An Oilgear pump or pump control mustnot be modified in any way withoutauthorization from Oilgear. Modificationsmay not comply with safety standards,including ANSI safety standards, and mayresult in serious personal injury. Pleasecontact Oilgear if you require assistance.

DO NOT enter under hydraulic supportedequipment unless they are fully supportedor blocked. Failure to follow this procedurecan result in serious injury or death.

Any Oilgear pump safety decals must bereplaced anytime they are damaged,missing, or cannot be read clearly. Failureto have proper decals in place can resultin serious injury or death. (If you requiresafety decals, please contact Oilgear forreplacement safety decals, at no charge.)

Be sure everyone is clear of the areaaround the hydraulic system beforeoperating after servicing. Remain attentiveat all times when operating to check yourwork until you are completely sure it issafe to return to service. Failure to heedthis warning may result in seriouspersonal injury or death.

Wear the proper protective clothing whenoperating, servicing or maintaining thehydraulic system or the Oilgear pump. Wearthe correct protective gear, safety glasses,gloves and safety shoes. Serious injury canresult without proper protective gear.

Make sure to keep hands, feet and otherparts of your body clear of revolving ormoving parts. Failure to comply can causeserious injury.

DO NOT wear watches, rings or jewelrywhile working with electrical and mechani-cal equipment. These items can be hazard-ous and can cause serious and painfulinjuries if they come into contact with elec-trical wires, moving parts or hydraulicequipment.

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

4 THE OILGEAR COMPANY Bulletin 947637

Figure 2. ASA Diagram for “P-1NN/F/J/K” or “P-LNN/F/J/K” Controls Shown with Typical Pump

Figure 3. Curve Indicating Flow Versus Pressure for “P-1NN/F/J/K” or “P-LNN/F/J/K” Type Control

B

A

RP

LS

OILG0259

OILG0260A

1500 psi(103.4 bar)

“P-LNN/F”RANGE

PRESSURE

“P-1NN/F”RANGE

250 psi(17.2 bar)

750 psi(51.7 bar)

Bulletin 947637 THE OILGEAR COMPANY 5

TROUBLESHOOTINGPROBLEM CAUSES REMEDY

Unresponsive or Unstable Control

Swashblock bearing surface and/or saddle bearings worn or damaged.

See appropriate pump service bulletin.Control pin and/or hole in swashblock worn significantly.Saddle bearing locating pins broken.Fluid is contaminated. Inspect and clean if necessary. See bulletin 90007.Control piston orifice (732) plugged. Inspect and clean if necessary.Contamination trapped between control piston (702) and piston bore is not allowing piston to move smoothly.

Inspect and clean if necessary. Replace scored or damaged parts.

Contamination trapped between control spool (706) and spool bore is not allowing spool to move smoothly.Contamination trapped between control spool (725) and spool bore is not allowing spool to move smoothly.Faulty remote pressure compensator circuit components. Inspect and replace if necessary.Hydraulic line between remote pressure compensator components and RP port of control is too long.

Shorten line length.

Insufficient control flow. Increase size of control piston orifice (732).

Insufficient Outlet Volume

Swashblock not stroking to desired displacement.

See appropriate pump service bulletin.

Low input drive speed.Worn or grooved cylinder barrel and/or valve plate mating surfaces.Failed driveshaft.Worn or damaged piston shoes or swashblock.Worn pistons and/or piston bores.Control piston stuck off stroke. Inspect and replace if necessary.

Differential pressure setting is too low.Adjust load sense setting CW or add shim to increase differential pressure.

Maximum volume stop adjusted incorrectly.Adjust maximum volume stop CCW to increase outlet flow.

Pressure compensator is set too close to operating pressure.Adjust pressure compensator setting CW to increase setting.

Destrokes at low pressure

Pressure compensator adjustment not set correctly.Adjust pressure compensator setting CW to increase setting and retorque jam nut (715).

Load sense line is vented.Check pressure in load sense line (at load sense port) to assure it is same as system pressure.

Flow control valve is closed or blocked. Inspect and service if necessary.Control piston orifice (732) plugged. Inspect and clean if necessary.Severely worn load sense control spool (725) and/or spool bore.

Inspect and replace if necessary.

Damaged or fractured control spring (items 708, 709 and/or 726).Severely worn pressure compensator control spool (706) and/or spool bore.Damaged or fractured control piston spring (item 703).Faulty remote pressure compensator circuit components.

Excessive peak pressure

Pressure compensator is set too high.Adjust pressure compensator setting CCW to decrease setting.

Minimum volume stop is set too high.Adjust minimum volume stop CCW to decrease outlet flow.

Fluid is contaminated. Inspect and clean if necessary. See bulletin 90007.Swashblock bearing surface and/or saddle bearings worn or damaged.

See appropriate pump service bulletin.

Contamination trapped between control piston (702) and piston bore is not allowing piston to move smoothly. Inspect and clean if necessary. Replace scored or

damaged parts.Contamination trapped between control spool (706) and spool bore is not allowing spool to move smoothly.Faulty remote pressure compensator circuit components. Inspect and replace if necessary.Restriction in drilled passages between pump outlet port and control spool.

Inspect and clean if necessary.

6 THE OILGEAR COMPANY Bulletin 947637

PRINCIPLE OF OPERATION“P-1NN/F/J/K” and “P-LNN/F/J/K” load sensingcontrolled pumps match flow and pressure to loaddemand. As the load on the system increases,pump pressure will also increase, but flow (volume)will remain constant. The control senses andmaintains a constant pressure differential acrossan orifice (flow control valve) in the delivery lineand pump flow becomes a function of valveposition. For a given flow control valve setting, thepump will maintain a constant flow regardless ofchanges in the pump input speed and/or working

pressure. The flow compensator has no tank porttherefore, the pressure compensator valve takespriority and short strokes the pump when thecompensator setting is reached. As load pressurefalls below the compensator setting, the loadsensing function automatically resumes. “P-1NN/F/J/K” controls can be adjusted from 750psi (51,7 bar) working pressure up to a maximumpressure rating of the applicable pump. “P-LNN/F/J/K” controls can be adjusted from 250psi (17,2 bar) up to a maximum of 1500 psi (103,4 bar).

Figure 4. Swashblock at Full Delivery and “P-1NN/F/J/K” or “P-LNN/F/J/K” Controls at Maximum Volume Stop

OILG0291

Bulletin 947637 THE OILGEAR COMPANY 7

LINE MOUNTED REMOTE PRESSURE CONTROL FOR TYPE “P-1NN/F/J/K” AND “P-LNN/F/J/K” PUMP CONTROLSRemote operation of “P-1NN/F/J/K” and “P-LNN/F/J/K” controls can be accomplished byinstalling a remote compensator valve at thelocation shown in the control circuit.

The compensator setting on the pumpcontrol must be set at least 200 psi (13,8bar) higher than the required pressuresetting of the remote compensator moduleto prevent the pump compensator controlfrom interacting with the remotecompensator module.

Figure 5. “P-1NN/F/J/K” and “P-LNN/F/J/K” Control Circuit with Remote Pressure Control

NOTE

B

A

REMOTECOMPENSATOR

VALVE

TO SYSTEM

RP

LS

INSTALL Ø.030 ORIFICEPLUG IN TEE FITTING

OILG0307

8 THE OILGEAR COMPANY Bulletin 947637

ALTERNATEREMOTE COMPENSATING SINGLE/MULTIPLE PVWJ PUMPS REMOTE ADJUSTMENT

Figure 6. Remote Adjustment by Incorporating a Single Remote Valve

Minimum system pressure will bedetermined by the control piston spring inthe load sense control. Pump outlets mustbe isolated with check valves.

Procedure for setting up the remote compensatoron multiple PVWJ pumps with adjustable loadsense controls. A pressure gauge should beinstalled at the outlet of each pump.

1. Remove the load sense line from each pumpand plug the load sense line.

2. Start pumps and set each standby setting at300 psi (20,7 bar), then turn off the pumps.

3. Reinstall load sense lines.

4. Set the remote compensator relief valve at itsmaximum pressure setting.

If possible, start each pump individually for the remainder of the set-up procedure.

5. Start the pump and set the compensatoradjustment at 200 psi (13,8 bar) above whatthe maximum (system) remote setting wouldbe, i.e. if the remote psi was to be 3000 (206,8bar) set the pump at 3200 psi (220,6 bar).

6. Repeat step 5 for each pump.

7. Start all pumps and observe the pressures ateach unit as the pressure is varied at theremote compensator valve.

Supply orifice size may vary based onapplication.

Orifice

Load Sense Port Load Sense PortLoad Sense Port

RemoteCompensator Valve

LS AdjusterLS Adjuster LS Adjuster

To System

OILG0292

NOTE

NOTE

Bulletin 947637 THE OILGEAR COMPANY 9

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

SCREW AND PLUG TORQUES FOR CONTROLS

CONTROL O-RING SEALS

Item Number Description Head Type & Size Tightening Torque

601 SAE #2 Plug 1/8" Internal Hex 45 in.-lbs (5 N·m)

603 SAE #4 Plug 3/16" Internal Hex 120 in.-lbs (14 N·m)

605 SAE #6 Plug 1/4" Internal Hex 200 in.-lbs (23 N·m)

606 SAE #8 Plug 5/16" Internal Hex 45 ft-lbs (61 N·m)

711 PC Adjuster Screw LHCS 3/32" Internal Hex 57 in.-lbs (6 N·m)

714 Adjuster Plate Screw 5/32" Internal Hex 80 in.-lbs (9 N·m)

720 Max. or Min. Volume Stop Housing

7/8" External Hex 50 ft-lbs (68 N·m)

722 End Cap Screws 3/16" Internal Hex 120 in.-lbs (14 N·m)

723 Control Body Screws 1/4" Internal Hex 30 ft-lbs (41 N·m)

730 Load Sense Module Screws 5/32" Internal Hex 80 in.-lbs (9 N·m)

732 Control Piston Orifice 3/32" Internal Hex 20 in.-lbs (2.3 N·m)

733 Load Sense Module Adapter Screws

5/32" Internal Hex 80 in.-lbs (9 N·m)

738 Load Sense Adjustment Housing 7/8" External Hex 50 ft-lbs (68 N·m)

Item Number ARP 568 Uniform Size Number Shore A Durometer

1009 009 90

1010 010 90

1011 011 90

1014 014 90

1113 113 90

1125 125 90

1237 237 70

1902 902 90

1904 904 90

1906 906 90

1908 908 90

10 THE OILGEAR COMPANY Bulletin 947637

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

PARTS LISTParts used in these assemblies are per Oilgearspecifications. Use only Oilgear parts to ensurecompatibility with assembly requirements. Whenordering replacement parts, be sure to includepump type and serial number, bulletin number anditem number. Specify type of hydraulic fluid toensure seal and packing compatibility.

Parts drawings may not be identical toOilgear drawings referenced.

PVWJ CONTROL PART LISTB-FRAME FOR 025, 034 & 046LOAD SENSE WITH PRESSURE COMPENSATOR CONTROL

Item Description

COMMON PARTS GROUP601 SAE#2 Plug603 SAE#4 Plug605 SAE#6 Plug606 SAE#8 Plug640 Plug701 Control Block702 Control Piston703 Control Piston Spring704 Piston Stop705 End Cap706 Pressure Compensator Control Spool707 Spring Seat708 Pressure Compensator Spring (Outer)709* Pressure Compensator Spring (Inner)710 Control Plug711 Screw712 Shims713 Adjuster Plate714 Screw715 Jam Nut716 Pressure Compensator Adjustment Screw717 Minimum Volume Stop Stem718 Maximum Volume Stop Stem719 Jam Nut720 Volume Stop Housing721 Control Pin722 Screw, End Cap723 Screw, Control Body724 Load Sense Control Module725 Load Sense Control Spool726 Load Sense Spring727 Shims728 Solid Shim729 Locating Pin730 Screw731 Adapter Block732 Orifice733 Screw737 Stem

NOTE

738 Bonnet739 Jam Nut

1009 O-Ring1010 O-Ring1011 O-Ring1012 O-Ring1014 O-Ring1113 O-Ring1125 O-Ring1237 O-Ring1805 Back-Up Ring1902 O-Ring1904 O-Ring1906 O-Ring1908 O-Ring

*Only used in P-1 Control.

Item Description

Bulletin 947637 THE OILGEAR COMPANY 11

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

SERVICE KITSPVWJ Service KitsReference 519975-202 and 519975-203SERVICE KIT, Figures 7 through 10

Document Number: 519975-SK2

Revision: New

Description Kit No.Design Series Items Included (quantity is 1 unless noted)

Main Control Body KitsPVWJ-025 K50432-101 A1 701, 706PVWJ-034/-046 K50432-201 A1 701, 706

Control Piston KitAll Models K50484 A1 702, 732

Pressure Compensator Spools PVWJ-025 50015-100 A1 706 PVWJ-034/-046 50015-200 A1 706

Control Spring KitsP-LNN/F, P-LNN/J, & P-LNN/K (All Models) K50036-104 A1 703, 708PVWJ-025 P-1NN/F, P-1NN/J, & P-1NN/K K50036-107 A1 703, 708PVWJ-034/-046 P-1NN/F, P-1NN/J, & P-1NN/K

K50036-110 A1 703, 708, 709

Load Sense Differential = 100-220 psid (All Models)

K50036-200 A1 726, 727(5), 728

Load Sense Differential = 225-350 psid (All Models)

K50036-202 A1 726, 727(5), 728

Control PinAll Models 51339-5 A1 721

Volume Stop Kits Maximum Volume Stop (All Models) K50590 A1 718, 719, 720, 1011, 1908 Minimum Volume Stop (All Models) K50590-200 A1 705, 717, 719, 720, 1011, 1020, 1908

Pressure Compensator Adjuster KitAll Models K50660-200 A1 710, 711, 712, 713, 715, 716, 1113

Load Sense Module KitsFixed Load Sense Module Assembly, 170 psid

K51141-170 A1605, 606, 724, 725, 726, 727, 728, 730, 1009, 1014, 1906, 1908

Adjustable Load Sense Module Assembly, 100 -220 psid

K51141-900 A1605, 606, 724, 725, 726, 729, 730, 737, 738, 739, 1009, 1012, 1014, 1805, 1906, 1908

Adjustable Load Sense Module Assembly, 225 -350 psid

K51141-901 A1605, 606, 724, 725, 726, 729, 730, 737, 738, 739, 1009, 1012, 1014, 1805, 1906, 1908

Load Sense Adjuster Kit L51792-2 A1 737, 738, 739, 1012, 1805, 1908Load Sense Adapter Kit K51141-903 A1 729, 731, 733(4), 1010(2)

Control Seal Kits

P-1NN/F & P-LNN/F (All Models) K50824-201 A11009, 1010(2), 1011, 1014, 1113, 1125, 1237, 1902, 1904, 1906, 1908

P-1NN/J, P-LNN/J, P-1NN/K, & P-LNN/K (All Models)

K50824-202 A11009, 1010(2), 1011, 1012, 1014, 1113, 1125, 1237, 1805, 1902, 1904, 1906, 1908(2)

12 THE OILGEAR COMPANY Bulletin 947637

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

Figure 7. Parts Drawing of Standard Configuration for “P-1NN/FNN” and “P-LNN/FNN” Control (519975-202 sheet 1)

601 1902

730 724

705703

715713710 711708709

702

716

1908

606 1908STANDARD CONFIGURATIONFOR P-1NN/FNN & P-LNN/FNN

SEE DETAIL C

732

OPTIONAL MINIMUMVOLUME STOP

FOR P-1NN/FSA & P-LNN/FSA

1125 1908 705 1011 720 719 717

DETAIL C

640

1014

1009

.000 TO .040

712

1125

1113

704

725

1906

605

727

726

728

606

701 707706

OILG0275

Bulletin 947637 THE OILGEAR COMPANY 13

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

Figure 8. Exploded Parts Drawing for “P-1NN/FNN” and “P-LNN/FNN” Control (519975-202 sheet 2)

713

714

730

1125

1125

705

722

1011

717

720

1908

719

1113

603

1904

732

712

710

703

1014

605

1906

728

606

1908

716

722

701

708

709

707

601

1902

702

723

705

1237

1010

711

721

715

704

606

1908

725

729

727

726

640

1009

706

724

OIL

G02

76

“RP

” PO

RT

737

1012

1805

738

1908

739

14 THE OILGEAR COMPANY Bulletin 947637

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

Figure 9. Parts Drawing of Standard Configuration for “P-1NN/FSN” and “P-LNN/FSN” Control (519975-203 sheet 1)

MAXIMUM AND MINIMUM VOLUME STOPThe maximum volume stop can be adjusted toattain a maximum volume from full to 25% of fullflow. The pump can be de-stroked from full to 25%flow with 11 turns of the volume stop. One turnclockwise will decrease maximum pump outlet flow7%.

The minimum volume stop can be adjusted toattain a minimum volume from zero to full flow. Theadjustment requires 14 turns to go from zero to fullflow. One turn clockwise will increase minimumpump outlet flow 7%.

601 1902 705703

715713710 711708709

702

720

716

719 1908

STANDARD CONFIGURATIONFOR P-1NN/FSN & P-LNN/FSN

B

SEE DETAIL C

OPTIONAL MINIMUMVOLUME STOP

FOR P-1NN/FSA & P-LNN/FSA

1125 1908 705 1011 720 719 717

SECTION B-B 731 733

1010

1906

605

725

726

727

728

1908

606

730 724

DETAIL C

640

1014

1009

.000 TO .040

712

1125

1113

1011

704

701 707706

718

B

732

OILG0277

Bulletin 947637 THE OILGEAR COMPANY 15

B-Frame PVWJ -025/-034/-046 “P-1NN/F/J/K” and “P-LNN/F/J/K”

Figure 10. Exploded Parts Drawing for “P-1NN/FSN” and “P-LNN/FSN” Control (519975-203 sheet 2) Optional Adapter and Maximum Volume Stop Shown

Sho

wn

for

Orie

ntat

ion

only

Max

imum

Vol

ume

Sto

p

Ada

pter

OIL

G02

78

1908

606 72

8

727

726

725

729

724

730

605

1906

733

650

1010

650

731

719

720

1908

718

718

73710

12180573

819

0 8

739

16 THE OILGEAR COMPANY Bulletin 947637

NOTES_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

Bulletin 947637 THE OILGEAR COMPANY 17

NOTES_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

18 THE OILGEAR COMPANY Bulletin 947637

NOTES_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

Bulletin 947637 THE OILGEAR COMPANY 19

AFTER SALES SERVICESAt Oilgear we build products to last. It is the natureof this type of machinery to require propermaintenance regardless of the care we put intomanufacturing. Oilgear has several serviceprograms in place to help you.

STAY-ON-STREAM SERVICE

By signing up for Oilgear's Stay-On-Streamprogram, you can prepare for problems before theyhappen. Certain field tests such as fluid testing,slip testing and electronic profile recordingcomparisons can be performed by our field servicepeople or your own factory trained personnel.These tests can indicate problems before theybecome “down-time” difficulties.

SERVICE SCHOOLS

Oilgear conducts training to train your maintenancepersonnel. “General” hydraulic or electronictraining is conducted at our Milwaukee, Wisconsinplant on a regular basis. “Custom” training,specifically addressing your particular hydraulicand electro-hydraulic equipment, can be conductedat your facilities.

SPARE PARTS AVAILABILITY

Prepare for your future needs by stocking Oilgearoriginal factory parts. Having the correct parts andnecessary skills “in-plant” enables you to minimize“down-time.” Oilgear has developed parts kits tocover likely future needs. Oilgear Field ServiceTechnicians are also ready to assist you and yourmaintenance people in troubleshooting andrepairing equipment.

THE OILGEAR COMPANY2300 South 51st Street

Milwaukee, Wisconsin 53219

20 THE OILGEAR COMPANY Bulletin 947637Issued: August 2006www.oilgear.com