SCR Power Controls Provide Reliable Industrial Electric ... · PDF filecontrolling...

Transcript of SCR Power Controls Provide Reliable Industrial Electric ... · PDF filecontrolling...

reprinted from Industrial Heating october 2002

p r o c e s s c o n t r o l & i n s t r u m e n t a t i o n

Equipment manufac-turers and mainte-nance engineersneed a reliable, flex-ible approach to

controlling electric-heatingprocesses in today’s competi-tive, cost-conscious industrialenvironment. SCR (silicon con-trolled rectifier) power controloffers advantages includingprecise control of the heatingprocess, extended heater life,improved product quality atfaster production speeds andreduced maintenance costs.Proper selection of an SCRpower control can result inmany years of reliable service.

Comparing power controls

A silicon controlled rectifieris a solid state switching devicethat can provide fast, infinitelyvariable proportional controlof electric power; an SCR cancycle as fast as 0.08 secondson a 60-Hz power line. Withproper selection and use, anSCR power control can cycleon and off 1,000,000,000times without any problems.

Unlike a mechanical relay orcontactor, an SCR power con-trol has no mechanical parts towear out. An SCR power con-trol will not arc and is notaffected by dirty contacts. Bycomparison, a mechanical

relay must be replaced after acertain number of cycles. Dueto the slow cycle time (30 sec-onds minimum) inherent inmechanical relays, control ispoor, the heating process maybe inaccurate and heater lifecould be shortened due tothermal shock.

A mercury displacementrelay (MDR) cycles fasterthan a mechanical relay.However, overheating therelay due to excessively fastcycling or overloading willcause it to explode, a situa-tion which creates a haz-ardous-materials problem. Inaddition, shipping and dis-posing of MDRs is becomingincreasingly more difficultdue to more stringent federalenvironmental regulations.

A solid-state relay (SSR) is a

popular alternative to mechan-ical power control. However,solid-state relays are not sup-plied with lugs that make asolid electrical connection forhigher power levels, and theyare not always supplied withheat sinks, voltage protectionor the fuses needed to protect

and safely operate the device.A common characteristic of allsolid-state devices (includingSSRs) is that they generateheat that needs to removed.Solid-state relays generatemore heat than SCRs.

Another consideration ofsolid-state relays is their rat-ing, which could cause a prob-lem. Almost all solid-staterelays are rated for maximumoutput at a temperature of25°C (77°F). However, in realworld operating conditions

where temperatures insideelectrical enclosures exceed40°C (104°F), a solid-staterelay will fail if used at fulloutput. Most manufacturershave a de-rating chart for theirproduct to compensate for thisdiscrepancy. Unfortunately,many plant personnel use theadvertised maximum ratingwhen selecting a solid-staterelay. It is important to under-stand the manufacturer’s databefore determining whichsolid-state relay will work bestfor a specific process.

Most SCR power controlsare rated for ambient operat-ing temperatures of around50°C (122°F) at full powerratings. Also, SCR power con-trols usually are supplied withfuses, heat sinks, voltage pro-tection and power lugs.

SCR selection and careThree factors that will

destroy all solid-state powercontrols are over-temperature,short circuits and transientvoltage spikes. Protectionagainst over-temperature, volt-age spikes and short circuitsshould be taken into account atthe outset of a system design.

All solid-state power de-vices (that is, thyristors suchas SCRs TRIACs and SSRs)generate heat. Voltage drops,which can be anywhere from

SCR Power Controls Provide ReliableIndustrial Electric Heating Paul Evalds, Avatar Instruments, Broomall, Pa.

By following the few simple steps provided here, an SCR power control can givesuperior performance with minimal maintenance costs for many years.

SCR power controls have been used since the late 1950s. Today, SCR power con-trols are smaller, safer, versatile and very reliable.

p r o c e s s c o n t r o l & i n s t r u m e n t a t i o n

1 to 2 volts depending on thedevice across a power device,generate heat. The more cur-rent (amps) put through thedevice, the higher the wattagethe device will generate in theform of heat, which must beremoved or the device willfail. Almost all semiconduc-tors are destroyed at an inter-nal junction temperature of125°C (260°F).

The higher the amperageoutput, the greater the heatthat is generated. The sim-plest, most common way toremove heat is to use a heatsink. Many manufacturersuse fans to remove excessheat from their high-outputSCR power controls. Onsome superhigh-output SCRpower controls (over 1000A), water-cooled heat sinksare used. If a properly sizedheat sink is used, an SCR canoperate at its full rating at anambient temperature of50°C (122°F).

One problem with someSCRs and solid-state relaycontrols is packaging. In aneffort to reduce the size of theheat sink, the fin area is notadequate to remove excessheat. DIN rail-mounted heatsinks can save panel spaceand installation time. How-ever, with many controlsmounted close together on aDIN rail, the power density(W/area) inside the enclosureis increased. At the sametime, airflow to the heat sinksis decreased or blocked. Ifsuch an arrangement is used,it is important that the manu-facturer has not asked thatthe DIN rail heat sink be fancooled or mounted with theheat sink fins outside the cab-inet. It also is important tocheck the de-rating curve forthe device at the power levelat which it will be used.

Even at low power (such as25 A), each controlled leg ofan SSR will generate close to

50 W of heat. Therefore, if 20DIN rail mount SSR powercontrols are used in a smallenclosure, it is necessary toremove 1000 W of heat.

To determine the properspacing for power controls, arule of thumb is to use twicethe footprint of the devicewhen mounting. For exam-ple, if the SCR power controlhas a 12 in. × 12 in. (305 ×305 mm) footprint, use a 24in. × 24 in. (610 × 610 mm)area for mounting.

Proper ventilation of theelectrical enclosure is criticalto keep an SCR power con-trol functioning. Even apower control having an ade-quate heat sink will fail if theheat cannot escape from theenclosure. When venting anenclosure, the basic formulais to use 10 in.2 (64.5 cm2) ofinlet and outlet area for every50 A per controlled leg. Ventholes should be at the top andbottom of the enclosure.

Wattage and airflowThe heat (as watts generat-

ed) generated by each con-trolled leg (C) of an SCR con-troller is equal to 1.5 timesthe amperage load (I). Fancooling is an efficient way tokeep the enclosure at safeoperating temperatures. Thesize of the fan required can bedetermined by multiplyingthe watts generated by 3.16and dividing by the tempera-ture rise (10°F) above ambi-ent. The resulting value issimply taken as the fan vol-ume size in ft3/min (cfm).

For example: To limit theheat rise in an enclosure to10°F above ambient tempera-ture, with 1000 W of generat-ted heat, you have:

Plastic enclosures functionas thermal insulators. AnSCR power control most

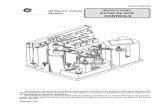

Properly designed SCR power control built with fan cooled heat sink, MOV voltagespike protection and I2T fusing.

To prevent premature power control failure, the SCR power control containsthermostats to provide an alarm if ambient temperature is too high, fans havefailed, or air supply is interrupted.

1000 (3.16) = 3160 = 316-cfm fan10 10

likely will be destroyed ifinstalled inside a plasticenclosure. The only reliableway to use a plastic enclosureis to have a “through-holemount” heat sink, with theheat-sink fins on the outsideof the enclosure.

Short-circuit protectionand fusing

Semiconductors are destroy-ed by a short circuit. One ofthe simplest ways to protectan SCR power control isproper fusing. While an SCRis a robust, reliable device,semiconductor, subcycle, andI2T current-limiting fusingmust be used to ensure maxi-mum performance and serv-ice life. Nearly all SCRpower-control manufacturersincorporate these fuses ontheir controls. I2T fuses willclear within 2 millisecondsand limit the current as theyclear. They are reliable andeasy to replace.

Not using a semiconductorfuse is penny wise and dollarfoolish. If there is no fuseprotection, an SCR can bedamaged when it need not bedamaged. A fuse is the easiestcomponent to replace if thereis a heater short. It is impor-tant to clear the shortedheater or wiring beforeinstalling a new fuse.

Note that 99.9% of fusefailures are due to shortedheaters, loose connections,incorrect (too large) loadmatching and miswiring ofthe SCR power control. Withhigh inrush loads (such aswith tungsten heaters, trans-former primary drivers,molybdenum heaters andshortwave heaters), use ofanything other than a softstart, phase-angle fired SCR

control will blow fuses.Never switch on a cold inrushheater bank after the softstart has been activated.Changing taps on a trans-former while in use also mayblow fuses.

It is necessary to size anSCR power control to theheater load. Because heatersand power lines have somefluctuation, an SCR powercontrol with a rating of atleast 110% of the maximumheater load potential shouldbe used to be safe.

Transient voltagesOver-voltage spikes affect

almost all electronic devices.

Transient-voltage spikes cancause an SCR to misfire orcan even permanently dam-age an SCR.

The simplest protectivedevice for over-voltage is ametal-oxide varistor (MOV),which is wired in across theSCR. By using an MOV hav-ing a voltage rating higherthan the line voltage, butlower than the SCR peakvoltage rating, the MOVbecomes an effective guardagainst voltage spikes. If atransient voltage spike goesover the rating of the MOV,the MOV will block thespike. If the spike is powerfulenough, the MOV will

explode, protecting the SCR.The use of a DV/DT sup-

pression board is the nextstep in power-line noise andvoltage-spike protection.With a network of powerresistors, high-voltage capaci-tors and MOVs, the SCR hasgreater protection from linenoise and voltage spikes. Thenetwork helps eliminate dam-age to the SCR, as well asSCR misfiring.

Because continuous over-voltage will destroy an SCR,it is necessary that the SCRsused on the power control arerated with a voltage highenough to withstand industri-al voltage peaks. The higherthe peak voltage rating of theSCR, the safer it will be. Theminimum SCR voltage rat-ings for the power line onwhich it will be used areshown in Table 1.

Selecting an SCR power control

Three ways an SCR powercontrol can deliver electricalpower to heaters are: phase-angle fired, zero-voltageswitched and on/off control.

Phase angle-fired controlsproportionally turn on a per-centage of each power linehalf cycle, which givessmooth, infinitely variableapplication of power to theheaters. It is the most precisemethod of control. Phase-

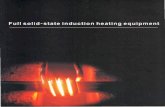

SCR power control safety design features. The SCRs have I2T fusing and MOV volt-age protection, and heat sinks are spaced at a safe distance from each other forefficient cooling. Door mounted fan and vents in top of enclosure provide sufficientcooling for all components. Courtesy of Radiant Energy Systems.

Table 1 SCR voltage rating vs. line voltage

Line Minimum SCR repetitivevoltage peak reverse voltage rating

120 200

240 400

380 600

480 800

600 1,000

p r o c e s s c o n t r o l & i n s t r u m e n t a t i o n

angle firing can increaseheater life up to seven timesdepending on heater type, andalso allows options such assoft start, voltage limit andcurrent limit. These optionsare not available using anyother methods of control.

Zero voltage-switchingcontrols proportionally turnon and off each power linefull cycle. The SCR providespower to the heaters by vary-ing the number of ac powerline cycles. With a variabletime base, the optimum num-ber of cycles turned on/off isachieved. This method pro-duces less RFI line noise thanphase angle-fired SCRs.

On/Off controls function inthe same way as a mechanicalor mercury relay, but with theadvantage of much fastercycle times.

Table 2 shows SCR powercontrol matching for typicalapplications. The use of anSCR power control offers themost precise means of control-

ling electric heaters. Heaterlife is extended, production isincreased and product qualityis improved. SCR power con-trols are an environmentallyfriendly alternative to mercuryrelays. The flexibility of SCRpower controls provides solu-tions to power-handling needsunavailable using any otherdevice. IH

For more information:Paul Evalds is Vice PresidentSales, Avatar Instruments,577 Abbott Dr., Broomall,PA 19008; tel: 610-543-5155; fax: 610-543-5255; e-mail: [email protected]; Internet; www.avatarinstruments.com

Table 2 Power control selection chartHeater/load type Heater/load characteristics Control type Typical applications

Constant resistant elements Slow response On/off, zero-voltage switched Large-tank heating and mechanical-Immersion heaters relay replacement

Medium-wave infrared, ceramic, Faster response; constant-resistance Zero-voltage switched Thermoforming, textiles, industrial

cartridge, duct, strip and band heaters heaters only furnaces and ovens, chemical-process

Platens heating and fast water heat

Open-coil/wire heaters Fastest, most precise response Phase-angle fired Paper and pulp drying, packaging

Medium-wave infrared quartz machines, pharmaceutical processes,

Infrared panels infrared ovens and dryers

Silicon-carbide heaters Load changes in resistance with Phase-angle fired with current-limit High-temperature ovens and furnaces,Graphite heaters age; high-temperature elements option glass, ceramics & high-temperature alloys

Tungsten (T-3) lamps and heaters High inrush currents Phase-angle fired with soft-start option High-speed paper & ink dryers, high-

Short-wave infrared elements High hot/cold resistance ratio temperature infrared heating and high-

Molybdenum heaters Tungsten 14:1 Molybdenum 20:1 temperature materials processing

Transformer-couples loads. Inductive loads Phase-angle fired with soft-start option Used with transformer-coupled loads

Primary driving to drive low-voltage elements

Inductive heater loads

Additional productinformation can

be found onwww.scrpower.com

Avatar Instrumentsoffers you the advantage of over 40years of industrialcontrol experience.Our engineering staffhas over a dozenpatents to their credit. Why not putthis advantage towork for you?

• ApplicationsAssistance

• Next Day Delivery• Competitive Pricing• 10-600 Amp

12-600 Volts• 5 Year Warranty

SCR POWER CONTROLS

Phase Angle Fired

Zero Voltage Switched

AVATAR INSTRUMENTS: PERFORMANCE - NOT BUZZWORDS.

Broomall, PA 19008Phone: (610) 543-5155

Fax: (610) 543-5255email: [email protected]

Web: www.avatarinstruments.com