Rosefield Pipeline Company, LLC The Woodlands, Texas 77381 ... · Rosefield Pipeline Company, LLC...

Transcript of Rosefield Pipeline Company, LLC The Woodlands, Texas 77381 ... · Rosefield Pipeline Company, LLC...

Rosefield Pipeline Company, L L C 4200 Research Forest Drive, Suite 230

The Woodlands, Texas 77381

March 15, 2019

U.S. Department of the Interior Bureau of Safety and Environmental Enforcement 1201 Elmwood Park Boulevard New Orleans, Louisiana 70123-2394

Attention: Phillip Smith Pipeline Section

RE: Application for Modification to Existing 14-Inch Oil Right-of-Way Pipeline (ROW OCS-G 29378/Segment No. 19785) Originating at Eugene Island Block 297 Capped End and Terminating at Ship Shoal Block 28 A Platform, OCS Federal Waters, Gulf of Mexico

Mr. Smith:

As required by Section 5(e) o f the Outer Continental ShelfLands Act (67 Stat.462) (43 U.S.C. 1331), as amended (92 Sta. 629), and in accordance wi th federal regulations contained in Title 30 CFR Part 250.1007; Rosefield Pipeline Company, LLC (Rosefield) is filing this application in quadruplicate for a proposed modification which addresses our proposed installation of a hot-tap on the existing pipeline.

The proposed modification wil l allow for the subsea tie-in of a proposed 6-inch tie-in spool piece to Renaissance Pipeline Seg. No. 7954.

Rosefield expressly agrees that i f any site, structure, or object of historical or archaeological significance should be discovered during the conduct of any operations associated within the permitted right-of-way, we shall report immediately such findings to the Director, Gulf of Mexico Region, and make every reasonable effort to preserve and protect the cultural resource from damage unt i l said Director has given directions as to its preservation.

Rosefield agrees to be bound by the aforementioned regulations and further agrees to comply wi th the applicable stipulations set forth i n Title 30 CFR Part 250, Subpart J.

Installation of the proposed hot tap assembly to the existing pipeline wil l be accomplished by utilizing a dive support vessel. Sand bags wi l l be utilized to stabilize and support the hot tap and subsea assembly.

Contingent upon receiving regulatory approval and scheduling of personnel and equipment, Rosefield anticipates commencing installation on approximately May 15, 2019 wi th an overall completion of project being estimated at 7 days.

Bureau of Safety and Environmental Enforcement AppUcation for Modification to Existing 14-Inch Oil Right-of-Way PipeUne Eugne Island 297 Capped End to Ship Shoal Block 28 A Platform March 15, 2019 Page 2

In support of our application, and for your review and use, the following supporting documentation is enclosed and made a part of this application letter:

Document Rev. No. Dated Pipeline Modification Permit 85 Calculations A 3/8/2019

Procedure for Mechanical Hot Tap Installation N/A

N/A Proposed Tie-In Spool Piece and Location Details N/A 3/5/2019 PSN 19785 Safety Flow Diagram 6 3/8/2019 Anchor Plat N/A 2/20/2019 Mattress Cover Plan 0 3/8/2019 Formatted ASCII CD of Application and .txt files N/A 3/13/2019 Pay Gov Receipt NA 3/13/2019

For any comments, questions or requests for additional data, please contact the below:

Aimee Deady Arena Offshore, LP 4200 Research Forest Drive, Suite 230 The Woodlands, Texas 77381 281-210-0180 (Phone) aimeeii v̂ ar e n g o ffsho re. com

Sincerely,

Rosefield Pipeline Company, LLC

Michael E. McCauley Operations General Manager

MEM/KMG Enclosures

Kathleen Gamiotea

From: Sent: To: Subject:

[email protected] Friday, March 15, 2019 9:13 AM Kathleen Gamiotea Pay.gov Payment Confirmation: BSEE Pipeline ROW Modification Application - BY

An official email ofthe United States government

Your payment has been submitted to Pay.gov and the details are below. Ifyou have any questions regarding this payment, please contact Brenda Dickerson at (703) 787-1617 or [email protected].

Application Name: BSEE Pipeline ROW Modification Application - BY Pay.gov Tracking ID: 26G3VAGH Agency Tracking ID: 75703082224 Transaction Type: Sale Transaction Date: 03/15/2019 10:12:30 AM EDT Account Holder Name: Kathi Gamiotea Transaction Amount: $4,169.00 Card Type: Visa Card Number: ************ 9793

Region : Gulf of Mexico Contact: Kathi Gamiotea 281-210-0540 Company Name/No: Rosefield Pipeline Company, LLC, 03542 Pipeline Segment No.: 19785

THIS IS AN AUTOMATED MESSAGE. PLEASE DO NOT REPLY.

Pay.gov is a program ofthe U.S. Department ofthe Treasury, Bureau ofthe Fiscal Service

PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION ISSUED FOR

Permit, MOC PSN19785-2019-02-19

By App'd

JobNo: 19041

Client: Arena Offshore, LP

Project: PSN 19785 Mod.

By/Date: CJM/3-7-19

Doc No: 19041-PLEN-TP-0003

Spec No:

Page: 1 of

PIPELINE MODIFICATION PERMIT

PROPOSED 14" X 6" HOT TAP MODIFICATION

ON

ARENA OFFSHORE, LP 14" OIL PIPELINE

PSN 19785

FOR

RENAISSANCE OFFSHORE, LLC 6" OIL PIPELINE SUBSEA TIE-IN (EUGENE ISLAND BLOCK 213)

PSN 7954

GULF of MEXICO FEDERAL WATERS, OFFSHORE LOUISIANA

Prepared By: ARENA OFFSHORE, LP

MARCH 2019

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

0* PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION e Client: Project:

Arena Offshore, LP PSN 19785 Mod.

Job No:

19041

Rev: Date:

3/8/19

Issued For:

Permit, MOC PSN19785-2019-02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

2ofE

GENERAL INFORMATION

Pipeline Tag No.

Pipeline Name

Pipeline Size

Pipeline Length, ft

Average Water Depth, ft

Design Pressure, Psig

Design Temperature, °F

Operating Pressure, Psig

Operating Temperature, °F

PSN 19785

14" X 6" HOT TAP MODIFICATION

Six-inch

10.47

100

1,480

100

500

100

Flowrates:

Gas, mmscfd

Oil/Condensate, bpd

Water, bpd

Specific Gravities:

Specific Gravity-Gas

Specific Gravity-Oil/Condensate

Specific Gravity-Water

0 4,100

0

0.65

0.85

1.05

(!) DESCRIPTION OF THE CATHODIC PROTECTION SYSTEM

Pipeline Anodes with the following characteristics will be used for cathodic protection of the pipeline.

Anode Type:

Size:

Weight (net):

Number:

Spacing (Max):

Life Expectancy:

Calculations

Number of Anodes Required (N)

N = Length of Route (ft)

N=

Anode Spacing (Max)

10

Tapered, Semi-Cylindrical Aluminum Bracelet, Galvalum

Six-inch

32

1 500 2,230.8 years

Life Expectancy (L)

3 . 8 2 x l 0 , x W o

L =

Where: DxIxR

500

N= 1

Anode tntervat (t)

!_ Length of Route (ft)

1=

Number of Anodes

10

1

1= 11 ft

L = Life of Cathodic Protection System (years)

W 0 = Weight of unit anodes (Ibs)

D = Outside Diameter of pipe (inches)

I = Interval length of pipe (ftytotal no. of anodes

R = Rate of consumption (Ibs/amp-year) - The value

of R for Galvalum III (aluminum-zinc-indium) as

obtained from Table 1 .B of NACE Standard

RP0176-83 is 8.4 to 7.4; use 7.9.

38,200 x 32 L=

6.625x 11 ftx 7.9

L= 2,230.8 years LIFE EXPECTANCY

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

^^RATEGY PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP

MODIFICATION e Client:

Arena Offshore, LP

Project:

PSN 19785 Mod.

Job No:

19041

Rev:

A

Date:

3/8/19

Issued For: Permit, MOC PSN19785-2019-

02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

3 of 8

(11) DESCRIPTION OF EXTERNAL PIPE COATING SYSTEM

Line Pipe:

Coating Type: Fusion bonded epoxy coating, 1 4 - 1 6 mils thick

Risers: There are no risers

Above Splash Zone: Three Coat Offshore Paint System

Splash Zone: Neoprene rubber base coating (Splashtron), thick, 20 feet long, vulcanized to pipe

Below Splash Zone: Fusion bonded epoxy coating, 1 4 - 1 6 mils thick

(iii) DESCRIPTION O F INTERNAL PROTECTIVE MEASURES

No internal coating is provided. The analysis of the transported products will be monitored and preventive

measures such as inhibiting will be employed as necessary.

(iv) SPECIF IC GRAVITY O F EMPTY PIPELINE PIPE

Specific gravity of No Line Pipe Permitted, empty pipe = 1.87

Weight o f Bare Pipe in air ( W p )

W p = Volume of steel x Density of steel

w = 7i(Do2-Di2) x 12 f t 3

P 4 1728 in 3 Xpp

(6.625 A 2-5.761 A 2) Wp =

W 0 = 28.59 lb/ft3

Weight of Pipe Coating (WJ

12

1728 x 489.6

Weight of Coated Pipe in air (W)

W= W p + W c

W= 28.59 + 0.00

W= 28.59 lb/ft3

Weight of Displaced Seawater (Ws)

Ws = Volume of sea water x Density of sea water

n{Do)2 12 f t 3

1728 in 3 ' x Pwater

wc =

wr =

12 f t 3 7i((Do+2Tc) 2-Do 2)

4 ' 1728 in 3

TI ((0.00+2(0.00))A2 - 0.00 A2)

Xpc

12 f t 3

1728 in' - xO.O

W S - " ( 6 - 6 2 5 ) ) A 2 x

W s = 15.32 lb/ft3

12

1728 x 6 4

W c = 0.00 lb/ft3

Specific Gravity (SG)

Weight of Pipe in Air

SG=

Weight of Displaced Sea Water

28.59 lb/ft3

15.32 lb/ft3

SG= 1.87

PIPE SPECIF IC GRAVITY

(v) MAXIMUM S O U R C E P R E S S U R E (MSP)

MSP (psig): = 2,150

Based on: Pipeline pumps installed on Renaissance Platforms SS-198H and SS-1981

Protection: Platform pipeline pumps PSVs and PSHs. PSVs to be reset to 1000 psig.

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION

Client: Project:

Arena Offshore, LP PSN 19785 Mod.

Job No:

19041

Rev: Date:

3/8/19

Issued For:

Permit, MOC PSN19785-2019-02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

4ofE

(vl) MAXIMUM ALLOWABLE OPERATING PRESSURE (MAOP) AND CALCULATIONS

Pipeline MAOP: Limiting Component:

1,000 psig @ 100 0 F Existing MAOP of PSN 19785.

Design Pressure & Component Summary

ComDonents Material or Ratina Nominal Size Desian Pressure

Line Pipe No Line Pipe Permitted -Line Pipe Bends - No Line Pipe Bends Permitted -Riser Pipe - No Riser Permited

Riser Pipe Bends - No Riser Bend Permited -Flanges ANSI 900 6" Nominal 2,220 psig

Subsea Tie-in Assembly API 5L Gr.B 6.625" x 0.432" wt 3,286 psig

Subsea Valves ANSI 900 6" Nominal 2,220 psig

Formulas

Internal Design Pressure

From: Title 30 CFR, Chapter II, Subchapter B, Part 250, Subpart J, §250.1002

p _2(S)( t ) (FETS) Do

Where: P = Internal design pressure in pounds per square inch (psig).

S = Specified minimum yield strength, in psi, will be stipulated in the specification under which the pipe will be

purchased from the manufacturer. S=35,000 psi for API 5L Gr. B

D = Nominal outside diameter of the pipe in inches,

t = Nominal wall thickness of the pipe in inches.

F = Construction design factor of 0.72 for submerged components and 0.60 for riser pipe.

E = Longitudinal joint factor, 1.00 for API 5L seamless (SMLS) and electric resistance welded (ERW) pipe as

obtained from Table 841.115A of ANSI B31.8.

T = Temperature derating factor, 1.00 for temperatures 250°F or less as obtained from Table 841.116A of ANSI

B31.8.

Pipe Thinning on the Outside Bend Radius of Hot Bends:

From: International Pipe Association's Voluntary Standard for Induction Bending of Pipe (IPA-VIBS-86)

R (D) of Bend=

Dn

Where: R = Center Line Radius of Bend, in inches.

Dn = Nominal pipe Diameter, in inches.

Anticipated wall thinning, in percent, is obtained from Table 1-1 of IPA-VIBS.

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION

Client: Project:

Arena Offshore, LP PSN 19785 Mod.

Job No: Rev: Date: Issued For: Permit, MOC PSN19785-2019-

02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

(vl) MAXIMUM ALLOWABLE OPERATING PRESSURE (MAOP) AND CALCULATIONS - Cont'd

Calculations

Une Pipe Internal Des/gn Pressure

Nominal Pipe Size (in):

Pipe Outside Diameter (Do) (in)

Pipe Schedule

Pipe Inside Diameter (Di) (in)

Wall Thickness (t) (in)

Material:

Minimum Yield Strength (S) (psi)

Construction Type - Line Pipe:

Construction Factor (F):

Temperature Selection:

Temperature Derating Factor (T):

Longitudinal Joint Factor (E):

Line Pipe Bend Intemal Design Pressure

Nominal Pipe Size (in):

Pipe Outside Diameter (Do) (in)

Pipe Schedule

Pipe Inside Diameter (Di) (in)

Wall Thickness (t) (in)

Material:

Minimum Yield Strength (S) (psi)

Construction Type - Line Pipe:

Construction Factor (F):

Temperature Derating Factor (T):

Longitudinal Joint Factor (E):

(D) of Bend (R/D):

Wall Thinning (%):

Riser Pipe Intemal Design Pressure

Nominal Pipe Size (in):

Pipe Outside Diameter (Do) (in)

Pipe Schedule

Pipe Inside Diameter (Di) (in)

Wall Thickness (t) (in)

Material:

Minimum Yield Strength (S) (psi)

Construction Type - Line Pipe:

Construction Factor (F):

Temperature Selection:

Temperature Derating Factor (T):

Longitudinal Joint Factor (E):

6

6.625

Sch. 80

5.761

0.432

API 5L Gr.B

35,000

A

0.72

1

1.00

1.00

6

6.625

Sch. 80

5.761

0.432

API 5L Gr.B

35,000

A

0.72

1.0

1.0

5

8

0 There is no Riser

P=-

P=-

2(S)(t)(FET)

Do

2(35,000)(0.432)(0.72)(1.00)(1.00)

6.625

P= No Line Pipe

LINE PIPE

t(post bend)- W a i r (thinning % x ^ 3 1 , ,

W e n d f 0.432-(8/100)(0.432)

(post bendf 0 - 3 9 7 into

P=-2(S)(t)(FET)

Do

r _ 2(35,000)(0.397)(0.72)( 1.00)( 1.00)

6.625

P= No Line Pipe Bends

LINE PIPE BENDS

P=-

P=-

2( S)( t)( F E T) Do

2(0)(0.000)(0.00)(0.00)(0.00)

0.000

P= No Riser

RISER PIPE

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

0- PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION

Client: Project:

Arena Offshore, LP PSN 19785 Mod.

Job No:

19041

Rev: Date:

3/8/19

Issued For: Permit, MOC PSN19785-2019-

02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

6ofE

(vl) MAXIMUM ALLOWABLE OPERATING PRESSURE (MAOP) AND CALCULATIONS - Cont'd

Riser Pipe Bend Internal Design Pressure

Nominal Pipe Size (in):

Pipe Outside Diameter (Do) (in)

Pipe Schedule

Pipe Inside Diameter (Di) (in)

Wall Thickness (t) (in)

Material:

Minimum Yield Strength (S) (psi)

Construction Type - Line Pipe:

Construction Factor (F):

Temperature Derating Factor (T):

Longitudinal Joint Factor (E):

(D) of Bend (R/D):

Wall Thinning (%):

Subsea Assembly Piping

Nominal Pipe Size (in):

Pipe Outside Diameter (Do) (in)

Pipe Schedule

Pipe Inside Diameter (Di) (in)

Wall Thickness (t) (in)

Material:

Minimum Yield Strength (S) (psi)

Construction Type - Line Pipe:

Construction Factor (F):

Temperature Selection:

Temperature Derating Factor (T):

Longitudinal Joint Factor (E):

Flanges

ANSI Class

From: ANSI B16.5, Table 2

Temperature =

Flange Sizes

Flange Sizes, Additional

Subsea Valves

ANSI Class

From: API 6D, Table 2.1

Valve Size

tjpost bendf '(initial)" ( th inn ing % X imtial))

'(post bendf 0 . 0 0 0 - ( 8 / 1 0 0 ) ( 0 . 0 0 0 )

t(post bendf 0 .000 in.

P = -

P = -

gMFET) Do

2(0)(0.000)(0.00)(0.00)(0.00)

0.000

P= No Riser Bends

RISER PIPE BENDS

5

8

• There is nc Subsea Assembly

6

6.625

Sch. 80

5.761

0.432

API 5L Gr.B

35,000

A

0.72

1

1.00

1.00

ANSI 900

-20 to 100 °F

P=-

P=-

gMEEI) Do

2(35,000)(0.432)(0.72)(1.00)(1.00)

6.625

P= 3,286 psig

SUBSEA ASSEMBLY PIPING

P= 2,220 psig

FLANGES

ANSI 900 P= 2,220 psig

SUBSEA VALVES

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP MODIFICATION

Client: Project:

Arena Offshore, LP PSN 19785 Mod.

Job No:

19041

Rev: Date:

3/8/19

Issued For:

Permit, MOC PSN19785-2019-02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

7ofE

(vll) HYDROSTATIC TEST PRESSURE (HTP), TEST MEDIUM, AND PERIOD OF TIME

Hydrostatic test pressure for the pipeline: 1,250 psig

Test Medium: Sea Water

Test Period: 8 Hours

Calculation

Minimum Hydrostatic Test Pressure (HTP) for the pipeline:

HTP= 1.25 x MAOP

HTP= 1.25 x 1,000 psig |HTP= 1,250 psig

HYDRO TEST PRESSURE

Sfress at Hydrotest Pressure

Where:

Limiting pipeline SMYS Component:

SMYS of Limiting Component:

Outside Diameter (Do):

Wall Thickness (t):

Subsea Assembly 35,000

6.625

0.432

S=

8=

(HTP)(Do)E

2(t)

1,250(6.625)(1.00)

2(0.432) S= 9,585 psi

Stress Ra(/o (SR)

SR=-Stress at Hydrotest Pressure

SMYS Limit

SR=-9,585

35,000

SR= 27%

Condusion

The hydrotest will be performed at a pressure that is 27% of the SMYS of the pipeline (based on the wall thickness of the 6.625-inch Subsea Assembly).

(viii) MAOP OF TIE-IN PIPING

The MAOP of the tie-in piping is 1000 PSIG (PSN 19785).

(ix) PROPOSED DATE FOR COMMENCING INSTALLATION AND ESTIMATED TIME FOR CONSTRUCTION

Commence Construction Date:

Estimated Construction Time:

June 2019

7 days

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

0** rear PIPELINE PERMIT & CALCULATIONS - PSN 19785, 14" X 6" HOT TAP

MODIFICATION e Client:

Arena Offshore, LP

Project:

PSN 19785 Mod.

Job No: Rev: Date: Issued For: KermiT, IVIUU Kt.mb/OD-^u-|b-

02-19

Spec No: Doc No:

19041-PLEN-TP-0003

Page:

(x) TYPE OF PROTECTION TO THE AFFORDED CROSSING PIPELINES, SUBSEA VALVES, TAPS AND MANIFOLD ASSEMBLIES

Pipeline Burial

The proposed pipeline will be buried to a minimum depth of three feet below natural bottom.

Pipeline Crossings

The proposed pipeline does not cross any existing pipelines.

Subsea Valves, Taps, and Manifold Assemblies

The proposed subsea components (valves, taps or assemblies) will be covered to a minimum of three feet using sand bags.

Riser Protection

There is no pipeline riser.

(xi) ADDITIONAL DESIGN PRECAUTIONS

Additional design precautions will not be required to enable the pipeline to withstand the effects of water currents, storm or ice scouring, soft bottoms, mudslides, earthquakes, perfafrost or other environmental factors.

19041-PLEN-TP-0003, RA - ROW Pipeline Permit Strategy Engineering and Consulting, LLC.

Arena Offshore, LP Eugene Island Block 213 Subsea Hot Tap Installation Procedure on 14-Inch ROW OCS-G 29378/Segment No. 19785

Hot Tap Size: 14" x 6" Fitting Manufacturer: Oceaneering Construction Code: API 1104 Pipe Type: Carbon Streel Water Depth: 110' Flange Configuration: RTJ ANSI Rating: 900 Pipe Diameter: 14-Inch Pipe Wall Thickness: 0.350" MAOP: 1000 psi

Max. Allowable Operating Temperature: 100oF

Notes:

• Hot Tap Contractor to provide a copy of machinery pressure test certification report.

• Pre-fabricated UWTI assembly has been hydrostatically tested onshore to 1.25 x MAOP for a minimum duration of 4 hours.

• The existing 14-Inch pipeline (Segment No. 19785] is flowing Oil from Eugene Island Block 341 to Ship Shoal Block 28, Current Operating Pressures are less than 400 psig

Procedure: 1. Company will mobilize a Dive Boat with a Saturation Dive Spread. 2. Upon arrival Dive Boat will set anchors. All anchors will be a minimum of 500' from

foreign pipelines and the Arena and Renaissance pipelines, the anchor lines will not cross any pipeline except the 6" Renaissance pipeline being connected and the 14" Arena Pipeline being Hot Tapped for the connection. Once in position the anchors will be 1000' in the direction of pull from the anchors to the pipelines.

3. Divers will remove concrete and somastic with water blaster and hydraulic chipper. 4. Utilizing hydraulic grinders with Z pads, divers will clean the 14" pipe to bare metal

at the 14"x6" Hot Tap Clamp Location. 5. Divers will confirm the longitudinal weld seem is located outside of the hot tap

cutter area, using an Ultrasonic probe. 6. Divers will take UT readings at the 14"x6" Hot tap location as per Installation

Contractors and Hot Tap Technicians instructions at every clock position to verify wall thickness.

7. Utilizing an ovality gauge, divers will verify proper roundness of the 14" pipe at the hot tap location as per Installation Contractor and Technicians Instructions.

8. Divers will take CP reading on the 14" pipeline at the Hot Tap Location. 9. Assemble and check hydraulics on the deck. 10. Testing and recording hot tap travel: Attach crank handle to the hot tap machine

and turning clockwise, count and record the number of turns it takes to advance the pilot to where it will make contact with the outer edge of the pipe.

Arena Offshore, LP Eugene Island Block 213 Subsea Hot Tap Installation Procedure on 14-Inch ROW OCS-G 29378/Segment No. 19785

11. Crank the handle clockwise and advance the cutter until it has gone the required distance to complete the cutout. Count and record these turns. Using the crank handle, turning counter-clockwise, retract the boring bar to where the pilot is withdrawn past the edge of the pipe and is within two [2] turns from the original location of the outer edge of the pipe.

12. Take the crank handle and tie off to the hot tap machine. 13. The pre-assembled hot tap clamp, 6" ball valve, and tapping machine will be

launched overboard and lowered to the 14" Pipeline for installation as per Installation Contractor and Hot Tap Technicians Procedures

14. All bolts on the 14"x6" Hot Tap Clamp shall be tensioned as per the Installation Contractor and Hot Tap Technicians Procedures.

15. The Hot Tap Assembly will be pressure tested as per the Installation Contractor and Hot Tap Technicians Procedures to ensure a proper seal and verify no leaks.

16. Upon a successful test, divers will coat any remaining bare pipe with SeaShield 525 Epoxy and support the Hot Tap clamp with 3:1 sand/cement bags.

17. When the hot tap assembly has been placed on the pipeline and the hoses and fitting have been pressure tested (test pressure = 1000 psi], send down hydraulic hoses and attach to the hot tap assembly.

18. With crank handle attached, advance the boring bar to where the pilot hits the outer edge of the pipe.

19. Turn crank handle counter-clockwise one (1] full turn and then push the engagement handle. Verify engagement and remove crank handle. Start tap and check cutter travel every 15 minutes.

20. Shut off hydraulics and using crank handle, disengage machine;, then turning clockwise, advance boring bar two (2] turns, ensuring cut is complete. Turn crank handle counter-clockwise to retract the boring bar. Close the valve on the hot tap assembly. Vent pressure and remove machine

21. Lower UWTV assembly to depth and install gaskets and bolts to make up flange. 22. Torque bolts with hydraulic torque wrench to values specified by Contractor. 23. Install 3:1 sand/cement bags to support UWTV assembly. 24. Check hydrostatic test hose to 1250 psi and equipment for leaks. 25. Deploy Vz" hose and connect to Vz" connection on blind flange on UWTV. 26. Perform 1 hour leak test for UWTV assembly to Hot Tap Valve, pressure to 1250 psi 27. Disconnect test hose and cover UWTV and Hot Tap assembly with sand only bags.

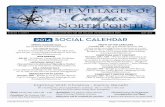

KAH-9000 D DP n n D D

MAX DISCHARGE PRESSURE: 2510 PSIG SIZE: 14" O.D. IAOP: 1000 PSIG

-< (X) CXI

m

D D r J

SIZE: 14" O.D. IAOP: 1000 PSIG

SIZE: 20"x14'

PROM LACT/ CHARGE PUMP SKID

PSV^ SET @ 1000 PSIG

SE" 1000 PSIG

PSHI /

! PSV \

B31.3

B31.4

PSHI

00

J

14 OIL PIPELINE TERMINATION POINT PSN 19785

8.625" O.D. OIL PIPEI EROM EI-2521 APPROX. 23,362.96 F (4.99 MULES) PSN 19901

ca i

(O.O.S.)

14" SSTI EI-253 SEGMENT NO. 19785

PSN 5422

cc 00

SSTI EI-3-

4" ELANGES 1 4 " A N S I 9 0 0 L B

ANSI 900 E N D CONNECTOR

xl4 SMART TAP ANSI 900 LB

a i 4 " x l

8"xl4"

"HE PROPOSED PIPELINE

GENERAL NOTES:

1. THE DESIGN CHARACTERISTICS OE THE PROPOSED PIPELINE EQUALS OR EXCEEDS THE REQUIREMENTS OE DOI TITLE 30 CER, PART 250 SUBPART J.

2. SEE SECTION VI OE THE RIGHT OE WAY PIPELINE APPLICATION EOR SPECIEIC DESIGN CHARACTERISTICS OE 3. 14.00" PIPELINE WILL TRANSPORT OIL.

4. PLATEORM PRESSURE PILOT SENSORS AT EI-341A, EI-215B-PR0D, EI-2521 AND SS-28A WILL BE SET AS POLLOWS: HI SENSOR: 15% OVER NORMAL OPERATING PRESSURE RANGE, NOT TO EXCEED THE MAOP OE THE SEGMENT THEY ARE PROTEC"

OPERATING PRESSURE RANGE

PROPOSED HOT TAP PITTING:

LO SENSOR: 15% UNDER

5. EXISTING 14" LINE PIPE:

O.D. - 14.00 IN W.T. = 0.375 IN WEIGHT = 54.62 LB/ET API 5L X52 TYPE = SMLS DESIGN - 2006 PSIG

14.00" PIPELINE MAOP IS 1000 PSIG.

GLASS ANSI 900 SIZE - 14" x 6" DESIGN = 2220 PSIG

CLASS = ANSI 900 SIZE - 6" SPEC API 6D DESIGN - 2220 PSIG

625 O.D. OIL PIPELINE EROM EI-215B-PR0D. APPROX 22,628.11 E

4.29 MULES PSN 19950

4"x8" HOT-TAP ASSEMB

(IN EI-232

RENAISSANCE OEESHORE, LLC PSN 7954

'28 PSIG

EROM SS419

7. CODES

VALVES EITTINGS PIPELINE PLATEORM PIPING

SPEOIEIGATIONS:

API 6D ANSI B16.5 30 CER 250, B31.4 ANSI B31.3

PSN 7954 MAOP 1728 PSIG

ARENA O F F S H O R E , L P

NOTES:

COVERED UNDER SEPARATE LETTER/DWG. 6 SLEEPING TURTLE MOOIEICATION, MOC PSN 1 9785-201 9 - 0 2 - 1 9 YNY MAC CJM 03/08/19 VN 03/08/19

5 ADDED 10" SUBSEA ASSEMBLY, MOC SS28A-201 7 - 1 1-28 YNY MDS CJM 11/08/18 SRF 11/08/18

4 COMBINE PSN 19943 WITH 19785, MOC SS28A-201 7 - 1 1-28 RMB CJM LW 10/09/18 SRF 10/09/18

3 ADDED PROPOSED 8.625" OIL P/L FROM EI-215B-PR0D. Sc GBB MDS CJM 07/05/18 RC 07/05/18

PROPOSED 14" OIL P/L FROM FI-341A, MOC S S 2 8 A - 2 0 1 7 - 1 1 - 2 8

No. DESCRIPTION BY CHKD APPVD. DATE ARENA APPVD. DATE

REVISION

SEAL CONTRACTOR

^^TRATECY

Texas Registered Engineermg Firm F-l 1658

N A S Y

~ 1— ____ BY DATL ARENA DATE PRELIMINARY

FOR APPROVAC

ISSUED AS NOTED

ISSUED FOR CONSTRUCTION

DESIGNED

DRAWN RMB 12/04/17 CHECKED

P OIL PIPELINE SEGMENT 19785 PIPELINE SAPETY ELOW DIAGRAM [ INCH OIL PIPELINE MOOIEICATION

SCALE: NTS

DWG. No.: 430 REV. 6