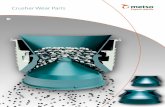

Roller Crusher

Click here to load reader

Transcript of Roller Crusher

Application

Roller crushers are used mainly for crushingeasily fractured materials such as soft lime-stone, chalk, and clay.

In the cement industry, roller crushers areemployed for primary and secondary crush-ing. Depending on the hardness of the materialconcerned, lumps are reduced to between athird and a fifth of their original size. Size reduc-tion is effected by tearing and crushing thematerial between rollers.

The FLS Roller Crusher Type E consists oftwo rollers with cast bosses. One of the rollershafts is adjustable while the other has a fixedposition and is provided with a flywheel. Thegap between the two rollers can be varied ac-cording to the degree of crushing required.Both rollers have scrapers to remove any mate-rial sticking to the surface.

The machinery is overload-protected by aplate punching device connected to the bear-ing of the adjustable roller, combined with amotor safety switch. If an extremely hard ob-ject is jammed between the rollers, the punch-ing device is activated and the crusher andfeed are stopped.

Design and operation

The motor power is transmitted through a gear-drive and two cardan shafts to permit theadjustment of the space between the rollers.

The frame structure of the roller crushercomprises welded and cast steel parts whichare bolted together. The rollers are providedwith grease-lubricated roller bearings. Thetoothed wheels on the gear-drive are oil-im-mersed with grease lubricated shaft bearings.

FLS roller crushers are very reliable in op-eration and require little maintenance and lubri-cation.

The FLS Roller Crusher Type TS, designedfor soft chalk and clay, is fitted with toothed rollersections for tearing large blocks of material be-fore they are crushed in a subsequent process.

Roller crusher performances vary accordingto the degree of crushing required and the con-sistency of the material.

The FLS roller crusher type designationsindicate: E = single-step roller crusher, TS =roller crusher with toothed sections, followed bye.g. 120 x 150 = roller diameter x roller length incm.

Dimensioning

Data in this brochure series is only intended for preliminary project planning. Manufacturer reserves the right to modify equipment details and/or specifications without notice.

DENMARK: F. L. Smidth & Co. A/S. Vigerslev Allé 77, DK-2500 Valby Copenhagen • UNITED KINGDOM: F. L. Smidth & Co., Ltd. 17, Lansdowne Road, Croydon, GB-CR9 2JT • FRANCE:F. L. Smidth & Cie - France, 55, Rue Ampére, F-75017 Paris • FEDERAL REPUBLIC OF GERMANY: F. L. Smidth & Co. GmbH, D-2400 Lübeck, Geniner Strasse 133-135 • ITALY:F. L. Smidth & C. Italiana, S.r.l., Via Lucilio, 25,1-00136 Rome • SPAIN: F. L. Smidth & Cia. Española, S.A., Calle de Jorge Juan, 46, Madrid 1 • CANADA: F. L. Smidth & Co. of Canada,Limited, 1500 De Mainsonneuve Blvd. West, Montreal, Quebec, Canada H3G 1H1 • U.S.A.: F. L. Smidth & Co., 300 Knickerbocker Road, Cresskill, New Jersey 07626 • MEXICO:F. L. Smidth & Cia., S.A. de C.V., Ave, Campos Eliseos, 385, 5° piso, Torre B, Polanco. Mexico City 5, D.F. • BRAZIL: F. L. Smidth, S.A. Comércio e indústria, Rua Nebraska, 459, BrooklinPaulista - CEP-04560, Caixa Postal 3506, 01000 Sao Paulo - SP • JAPAN: F. L. Smidth & Co. (Japan) Ltd., Togeki Building 1-1, Tsukiji 4-chome, Kyobashi P.O. Box 78, Chuo-ku, Tokyo 104.

Example :Clay to be crushed to outlet size 75 mm with athroughput of 400 t/h.

Solution :FLS Roller Crusher, Type ESize 120 x 150Weight 35,000 kg.

Type

E

Dimensions (mm) Weight

(t)

Motor size(kW)

from* to **

100 x 100 3420 1625 850 968 2590 3095 905 1230 611 430 650 3000 1730 19.1 45 - 90

100 x 120 3420 1825 850 1168 2790 3095 935 1230 611 430 680 3040 1730 20.5 75 - 150

120 x 150 4065 2220 1150 1470 3415 3000 1340 1503 741 402 1020 3355 1975 35.0 150 - 250

150 x 150 4620 2320 1350 1470 3585 2885 1520 1810 900 442 1040 4000 2310 52.0 220 - 400

150 x 200 4620 2820 1350 1970 4085 2885 1590 1810 900 442 1110 4000 2310 59.0 280 - 500

A B C D E F G H1 H2 H3 K L M

*) Lowest motor rating for coarse crushing **) Highest motor rating for fine crushing.