Review of Canadian Enclosure Studies Involving Field...

-

Upload

truonghanh -

Category

Documents

-

view

214 -

download

1

Transcript of Review of Canadian Enclosure Studies Involving Field...

Review of Canadian Enclosure Studies Involving Field Exposure

Chris Schumacher and John Straube

1 Introduction

Wood-frame house construction in Canada has evolved over many decades. Part of thisevolution has come about in response to problems encountered with existing buildings. Buildersattempting to understand and repair problems likely conducted the earliest studies involving fieldexposure. Scientific Canadian studies involving field exposure of wood-frame housing havebeen undertaken for almost a century -- a test house was built at the University of Saskatchewanbefore 1920. The National Research Council's Division of Building Research made extensiveuse of field monitoring of roof assemblies at their Outdoor Test Facility in Saskatoon (since atleast the 1950's), of walls in test huts in Ottawa, and of cladding in Halifax. Since then,published enclosure performance studies involving field exposure have become more common.

In 1992, Canada Mortgage and Housing Corporation (CMHC) commissioned a review ofmoisture related problems, research and construction practice in Canadian wood-frame houseconstruction between 1975 and 1991 [1]. This report focuses on the connections betweenmoisture problems, research and evolution of construction practice. Little has been done,however, to summarize Canadian studies involving field exposure of wood frame buildingenclosures.

This paper reviews these moisture-related field studies of wood frame buildings conducted inCanada since 1975, presents a synopsis of the results, and examines the methods used. Therelationships between objectives, resources, monitoring protocol and study results are discussed.This summary of experience should be useful for the design of future field studies.

2 Field Exposure Studies

Field exposure experiments are only one part of a more comprehensive research program.Laboratory studies on both full-scale and fractional-scale assemblies and materials are a criticalfirst step in most physical research programs. Lab work acts to fill the gap between theoreticalstudies or computer models and full-scale field exposure experiments. Field surveys of largenumbers of existing buildings complete the spectrum of research by providing information of theeffects of in-service exposure on real buildings delivered via the normal construction process.

Studies employing field exposures have several advantages and disadvantages relative tolaboratory and numerical studies. The primary advantage of field studies is that thehygrothermal and structural loads can be applied with realistic frequency, magnitude andoccurrence. Hence, the loading itself does not need to be understood or predictable. While this isnot much of an advantage for, as an example, temperature exposure, it is significant for wind,solar, and rain loads. The physics and material properties are also not modeled in an approximatemanner as they are in numerical models. Specimens also tend to be built more realistically forfield studies because they are built in the field, as most enclosure systems still are.

One scientific disadvantage of field studies is the poor control of all of the loadings. Thevariation and combination of loads can only be measured, not controlled, and hence cause andeffect are sometimes difficult to understand. Two other practical disadvantages must also berecognized -- field exposure experiments and studies tend to more expensive and take longerthan equivalent laboratory experiments.

The approach to a field study depends on the objectives, resources and intended use of theresults. Past Canadian studies can be grouped under three broad categories: field surveys, fieldmonitoring, and test houses. A description of each category follows.

2.1 Field Survey

The objective of a field survey is to document the state of a sample set of buildings. Fieldsurveys are often used to characterize a perceived problem, establish its extent, and perhaps toestablish its cause. The sample set of buildings almost always comprises buildings built byindustry, not those built for a specific experimental purpose.

The advantage of field surveys is that they deliver results collected from a range of buildings,i.e., they are felt to accurately represent the average of the building population being studied. Itis rare to have sufficient resources to investigate a statistically significant number of buildings,since the population size is often in the tens of thousands, and the number of influencingvariables is often in the hundreds. Detailed field studies in Canada have typically involved lessthan 100 buildings. Field surveys require a relatively short time commitment (e.g., a few monthsto less than one year) but require effort to identify representative buildings, gain the agreement ofowners and occupants, and significant manpower to carry out. Field surveys also usually do notinvolve intrusive disassembly of enclosures, and hence cannot provide information about thecondition of hidden elements.

As for all research programs, the intent of the field survey must be well defined before the surveyis designed or the results may not be useful. Often field surveys are used to define the extent andsignificance of a perceived problem and to help develop a more detailed study. They can rarelybe used to aid in the understanding of how or precisely why problems developed.

2.2 Field Monitoring

Field monitoring of an existing building is sometimes used to confirm a design approach, or todemonstrate product/system performance under realistic loadings, installation quality, and aging.Field monitoring might also be used to confirm numerical/analytical estimates of performanceand to demonstrate that laboratory studies are representative of real performance.

Field monitoring typically requires at least one year to complete simply because each seasonimposes different loadings. Ideally, field monitoring need only continue long enough to matchpredicted performance, and the predictive method used to extrapolate the measured data. Inreality, the aging structure, simple performance models, and limited instrumentation results inlong monitoring periods.

Installing sensors within an enclosure is intrusive, and requires committed owners and co-operative occupants to achieve. Such studies are usually relatively expensive or limited in scope,and require a high level of expertise in experimental / instrumentation work to completesuccessfully.

2.3 Field Exposure Test Houses

The objectives of field exposures in test houses are typically similar to those of field monitoringexisting buildings. The difference is that the interior conditions can be more carefully controlled,owners and occupants need not be involved, and the considerable overhead of data acquisitionand weather monitoring can be shared between projects. Since the loadings on a test house canbe reasonably similar over each face, parametric studies between panels on the same face canprovide strong evidence of performance difference. Modifications to the enclosure element canbe made in the midst of an experiment if necessary. The control of the interior environment, thelimited range of exposures provided by typically one-storey test houses, and the more controlledmode of specimen construction offsets some of these advantages.

Provided that interior and exterior boundary conditions are carefully measured, the resultsgenerated by this form of study are almost as accurate as those provided by a full-scalelaboratory test. Hence, test houses can be profitably used to confirm and develop theory andnumerical models.

3 Selected Studies

The studies that are discussed below have been selected from a range of publicly availablestudies available to the authors. The objectives, methodologies and results are summarized.

3.1 Field Survey of Building Envelope Failures in British Columbia [2]

In November 1996, Morrison Hershfield Limited completed a CMHC sponsored survey ofbuilding envelope failures in coastal British Columbia. The survey was structured to identify therelationships between building envelope problems, sources of moisture and design andconstruction features in low-rise multi-unit wood frame buildings.

The study focused on 3 and 4 story buildings that were less than 8 years old and located within30 km of the Strait of Georgia. A total of 46 buildings were surveyed: 37 “problem” buildingsthat had a history of moisture problems which had resulted in damage of more than$10,000/building and 9 “control” buildings that did not have any history of problems. The wallsof the buildings chosen included both OSB and exterior grade plywood sheathings and asphalt-impregnated building papers and housewraps. The cladding systems included stucco, woodsiding and vinyl siding but excluded masonry and EIFS.

Since the data were collected by four different organizations, it was important that all membersof the survey team use the same procedure, definitions and framework for analyzing the causesof problems and describing the quality of construction. Information about the survey buildingswas entered using five standard forms: one to describe the building, two to describe buildingassemblies and details, one to describe problem symptoms and one to describe failure

mechanisms. The data were then transferred from the forms to a database program for analysisof the correlations. Evaluators were asked to attribute responsibility for each problem to design,construction, maintenance or operating procedure. Problems were assigned to design orconstruction for 100 out of 193 cases. Materials, maintenance and operation were not identifiedas areas for improvement.

The most common wall system reported was composed of stucco, building paper, OSB and 2x4stud with batt insulation. One of the interesting results of this study was the impact of overhangs.Although the sample size is small, the effect of large overhangs appeared to be significant. Otherimportant conclusions included the fact there were more problems and higher repair cost forstucco and wood than for vinyl. It should be noted that vinyl walls were, however, used inconjunction with the largest overhangs.

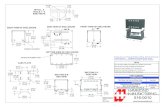

Figure 1: Impact of Overhang Width on Damage

3.1.1 Discussion

Recommendations from the report included:

1. Clarity in design strategies was lacking. There is a need to educate designers – theymust understand basic principles of water management.

2. Clarity of details for communication of design intent to construction trades waslacking.

3. Key problem areas such as windows, saddle flashings (railing – wall intersection) andthe perimeter of decks require resolution and the creation of a best practice guide.

4. Details must be re-evaluated after the job is tendered so that the specific materials tobe used are considered instead of the generic materials shown on tender drawings.

5. Systems and details must reflect logical sequencing of trades and materials.

6. Site mockups should be used to identify issues related to construction of proposeddetails and to communicate design concepts to construction trades.

7. The need for a quality management process for the construction of the buildingenvelope was identified.

3.2 Drying of Walls in Atlantic Canada [3]

In 1984, CMHC issued a Technical Builders Bulletin that required the use of furring strips undersiding for all Atlantic Canadian housing insured or funded under the National Housing Act.After the Canadian Home Builders Association (CHBA) raised questions about the necessity forthis requirement, CMHC agreed to reassess the matter.

Under the direction of a CMHC/CHBA joint task force, ADI Limited and Oboe EngineeringLimited designed a research study to develop an understanding of the drying mechanisms actingin furred and non-furred walls clad with vinyl siding. In 1985, three test huts, each 8 by 11meters, were constructed in Halifax, Fredericton and St. John’s to identify the effect of anyclimatic differences.

In March of 1986, sixteen 1.22 m wide x 2.44 m vinyl clad walls were installed in each test hut:eight on the North side and eight on the South side (Figure 2). The test panels were built withand without furring strips and different types of insulation.

The wood framing was chosen to contain a high built-in moisture load (all wood was over 30%moisture content by weight, but the MC was not standardized between panels), to provide themoisture source for the study. The vinyl siding was installed continuous across all panels, e.g.,the cavity formed by the siding was continuous across all panels. The furred air spaces wereblocked at the top to create a vented but non-ventilated cavity.

Temperature and relative humidity were measured at mid-height in the center of each furredcavity. Temperature was also measured on back of vinyl siding at mid-height, at the center ofthe North and South walls. Temperature and condensation were measured on the back of thesheathing. Moisture content was also measured in the wood sheathing where used. One of thecenter studs in each panel was instrumented with temperature, moisture content and

condensation gauges at 150 mm above the bottom of the panels, at 150 mm below the top of thepanel and at mid height. . The final stud MC measurements were averaged for each panel typeand orientation. MC readings above 30% were corrected using the equation:

• Reading < 30% à corrected MC = 6.1 + 0.93 (reading)

• Reading > 30% à corrected MC = -30.8 + 2.2 (reading)

Temperature and relative humidity were measured inside the test hut while temperature, relativehumidity and wind speed & direction were measured at three meters above the test hut (7.4 mabove grade). Data was collected by a computerized data acquisition system at 20 minuteintervals and saved as hourly averages.

The interior of the test house was maintained at about 20 C and 50 to 60%RH.

Figure 2: Atlantic Test House Design

3.2.1 Significant Results

In most cases, the moisture content of the North-facing panels remained higher than South.Some mould growth was observed in all panels. The panels insulated with sprayed cellulosewere the wettest, but the borate chemicals used to treat the cellulose acted as an anti-fungal agentfor the entire panel.

Since as many of six panels of each type were tested, comparisons could be made between Northand South facing panels and between similar panels in the three different climates. For example,the slowest drying of the #5 panels started at 88% MC and dried in less time than the slowest ofthe #6 panels, which started at over 120%MC (Figure 3). The fastest drying of the #5 panelsstarted at 44% and did not dry as quickly as the fastest drying #6 panel, which started at 40%MC. Obviously, the starting moisture content was an important variable in these results. Asanother example, Panel #4 exhibited the shortest drying time (only 9 weeks to drop to 19% MC),however, it also started with a very low MC. Panel #6 was constructed in the same manner aspanel #5, but with furring strips.

The potential for condensation on the back of the siding was calculated using the relativehumidity and temperature measured in the space behind the siding, and the temperaturemeasured on the back of the siding. There was a potential for condensation to occur up to 80%of the time during the winter months – even after the panel had dried out for one year. Thepotential was higher on the north side (Figure 4). This may be a concern with wood basedsidings.

The report concluded that:

1. The use of low-permeance sheathings restricts outward drying

2. the measured moisture content was approximately the same for furred and non-furred walls;

3. solar effects on the south-facing panels are important;

4. climatic differences between the three sites did not have significant impact on the final MCmeasurements; and

5. the dominant drying mechanism was “suspected” to be condensation on the back of thesheathing followed by drainage down and out of the studspace.

Figure 3: Moisture content versus time for Atlantic Test House studies(Panel #5 Unfurred, Panel #6 Furred)

Figure 4: Occurrence of Ventilation Cavity Condensation In Halifax Test Panels

3.2.2 Discussion

These early test houses had some methodological limitations. For example, siding was installedin such a manner that the airspace behind the cladding was continuous across all eight panels on

the north and south sides. This created a path for air and moisture to communicate between thepanels. The thermal isolation between the test panels was very poor. This created unrealisticthermal gradients at the interface between two dissimilar panels. Similarly, the corner panelswere significantly more exposed to wind flow, cooling, sun and rain.

The wood moisture content pins were installed across the grain (not recommended) and along theexpected moisture gradients. That is, a gradient is likely to form between the inside and theoutside of the stud, so moisture pins should be installed perpendicular to that gradient. Themoisture content were measured with commercial Delmhorst equipment, but the results were notcorrected for temperature and were crudely corrected for species. The results demonstrated theimpact of daily temperature swings on the wood moisture contents. Many of the panelsexhibited very high moisture content readings (e.g., over 60%MC), a region in which resistancemeters are not very accurate. The exact depth and location of the moisture pins was notidentified in the report. It appears that the pins were installed about midway on the face of thestud. The depth of the pins is unknown.

Although no difference between furred and unfurred panels was found, it should be noted thatthe furred walls did not have vent openings in the top of the wall, and hence little or noventilation flow could be expected. The range in measured performance between panels of thesame type indicated that factors not included in the experimental design were having asignificant impact on the results.

Another concern is the fact that each of the panels started with different moisture contents. Sinceit is known that the moisture transfer rate varies with the moisture content of the wood materialsit is difficult to compare drying rates in such an experiment.

3.3 Wood Siding Monitoring St. John’s, Newfoundland [4]

The wall assemblies tested in the Atlantic Canadian wall-drying study (discussed in Section 3.2)were all clad with vinyl siding. As a result of this study, it was suggested that an air gapprovided behind wood based sidings could receive water vapour from the siding and reduce thelikelihood of damage to wood wall sheathings. To test this hypothesis, CMHC asked OboeEngineering Limited to set up a second field study in the test hut in St. John’s, Newfoundland.

Sixteen new walls were installed in the St John’s test house in August of 1987. Half of the wallswere constructed with furring behind the wood siding and half without. Four of the eight furredwalls and four of the eight non-furred walls were constructed with a polyethylene air/vapourbarrier between the sheathing and the siding. This was done to prevent air and vapour frommoving between the framed inner wall and the outer airspace and siding, thus decoupling thesiding from the remainder of the wall. This was done to isolate the effects of the furring on thedrying of the wood siding.

In the previous vinyl-only study, wet framing (approx. 30%-80% MC) was used to construct thewall panels. Dry wood framing was used in the construction of the wall panels for this secondstudy. The shiplap wood siding was installed continuously over the sheathing and furred cavitiesand two coats of paint were applied to the exterior surface. The interior surface of the siding was

left unpainted. Whereas the top of the furred cavity was closed in the previous set of tests, bothtop and bottom were left open to promote ventilation in the second set of tests.

Temperature, moisture content and condensation were measured on the back of the wood sidingat 150 mm above the bottom of the panels and at 150 mm below the top of the panel. Thetemperature was also measured on back of wood siding at mid-height, at the center of the Northand South walls. Temperature and relative humidity were measured at mid-height in the centerof each furred cavity. Finally, temperature and relative humidity were measured inside the testhut while temperature, relative humidity and air speed & direction were measured at three metersabove the test hut. Data was collected by a computerized data acquisition system at 20 minuteintervals and saved as hourly averages.

In addition to the data collected through the data acquisition system, the top and bottom sidingboards were removed, weighed, and replaced on a monthly basis. This allowed for an accurategravimetric moisture content measurement.

3.3.1 Significant Results

The team concluded that vented cavities formed by furring strips were useful for keeping wallsand siding dry. The walls that coupled the siding with the remainder of the wall (i.e., normalconstruction) exhibited significantly lower siding moisture contents than the walls withpolyethylene over the sheathing. In fact, the moisture content of the siding in the furred wallswas consistently and significantly higher for the decoupled case, and lower in the coupled case.

3.3.2 Discussion

This study suffered from some of the methodological problems of the first study (lack of panelisolation, moisture content reading) but offered some improvements. It also appears that that themeasurements of wood siding may have been influenced by excessive rain wetting of some ofthe panels.

The installation of a truly ventilated space behind the siding was shown to be of measurablebenefit. However, it is unclear if the reason the vinyl siding in the previous study did not benefitfrom furring was 1. ventilation was blocked in the vinyl study, 2. the hygroscopic nature of woodrequires ventilation, or 3. vinyl siding is better ventilated than wood siding even in the unfurredcase.

3.4 The Prairie Wall Drying Project [5]

Following the Maritime drying study, a Prairie Wall Drying study was launched. A 2.4 m wideby 12.2 m long test house was built in Ellerslie Alberta (south of Edmonton), in 1989. Theinterior of the hut was maintained at 20 C and 40%RH. Six panels faced North and six pairedpanels faced South. The panels in this study represented the common wall types in this region.Three of the six panels were clad in vinyl and three in stucco. One of the stucco walls was wellvented. Some of the walls used 2x4 framing with exterior insulated sheathing and others used2x6 framing with wood sheathing.

The sensors in this study were more extensive. An array of moisture content pins was installedon the face of a stud to capture gradients. The moisture content was measured at or near thesurface of the stud. Upper and lower plate moisture contents were also measured in addition tothe vertical stud. The relative humidity within the stud space was measured, and nocondensation gauges were used.

3.4.1 Results

This study found that the panels dried very quickly in the cold and dry Prairie winter. Themechanism was assumed to be by vapour diffusion, with some assistance from ventilation behindthose claddings that were ventilated. The ventilated stucco rainscreen panel (veniltaed behindthe wood sheathing) dried very quickly, within weeks.

Significant differences were found between upper and lower plate moisture contents. Thebottom plate (likely artificially cold because of the hut design) remained wet the longest in mostof the panels

3.5 The Ontario Wall Drying Project [6]

To complete the range of wall drying studies, CMHC commissioned the Building EngineeringGroup at University of Waterloo to conduct a similar study for the Ontario region. This projectwas an extension of the Maritime and Prairie wall drying projects. With funding from a numberof industry partners, a larger test house, which allowed 7 panels to be installed facing each of thefour cardinal directions (not just North and South), was built (Figure 5). Experience gained fromthe Maritime and Prairie test houses was incorporated into the design and instrumentation. Moremoisture pins, better moisture content species and temperature correction formulas, better windmeasurement, and extensive horizontal panel isolation were incorporated. Moisture pins wereinstalled in the top and bottom plates, the upper, mid-height and lower studs.

3.5.1 Results

Although the base detail of the test panels had been improved over the previous test huts,problems were still encountered achieving thermal isolation from the slab foundation (which wasinsulated on the exterior with 38 mm of foam). The more detailed measurements indicated thatthis was causing the base plate to be cooler.

All of the framing in all of the 10 wall systems tested dried down below 20%MC within 3months, and reached equilibrium with 5 to 6 months. The fastest drying wall system was a 2x4wall with vapour permeable glass fiber insulated sheathing, and the slowest was the wall systemwith foil-faced polyisocyanurate insulated sheathing. Figure 6 provides a plot of some of theresults, showing how quickly some of the walls dried. No signs of mould were found after thewalls were opened after one year.

Figure 5: The BEGHUT Test Facility with Driving Rain Gauges, Weather Station

3.5.2 Discussion

It should be noted that all of these studies started the drying process at a different time of theyear – March, August, and December for the two Maritime and Ontario wall drying studiesrespectively. The Ontario study found relatively fast drying. This is partly due to the differentclimate, but it was recognized at the end of this study that the best time for drying is in the coldperiods of the year (when the vapour pressure between the framing lumber and the exterior is thehighest). Hence, results are not strictly comparable between the four drying studies, evenallowing for the different types of walls and the different climate. Inward drying was not allowedin any of the studies because of the installation of a polyethylene vapour barrier.

Although improvements were made from the early to later studies, the starting moisture contentof panels was still quite variable. Hence, it was sometime difficult to assess the relativeperformance of test panels. The initial moisture contents of the last two studies was sufficientlyuniform to allow for stronger conclusions to be made about the fastest and slowest drying panels,but not to differentiate between intermediate drying rate panels.

0

10

20

30

40

50

0 7 14 21 28Days

Moi

stur

e C

onte

nt (

%)

0

1 0

2 0

3 0

4 0

5 0

0 7 1 4 2 1 2 8D a y s

Moi

stur

e C

onte

nt (

%)

Figure 6: Wood Framing Moisture Content During Drying Experiment

3.6 The Zero-Cavity and DPV Wall Project [7]

The practical difficulty of ensuring a clean cavity which freely drains water and encouragesventilation has also been found to be a major problem in brick veneer walls. To explore theseissues CMHC and Dow Chemical funded a project to study two different approaches to ensuringa clear cavity. The objective was to demonstrate and investigate the effect of filling the air spacebehind brick veneers with untreated glass fibre insulation or special grooved foam insulation.The impact on drainage and pressure moderation was specifically of interest.

The experimental program involved the construction, testing, and field monitoring of the threepairs of test panels and the evaluation of their performance. The Building Engineering Group atUniversity of Waterloo conducted this work over the period 1992-1994 using the same test houseas for the Ontario Wall Drying study.

Extruded polystyrene sheathing, Brick Veneer

Fibreglass sheathing, Brick Veneer

The same type of equipment was used to measure hygrothermal performance as in previousprojects. Improvements made in the test program included the use of less intrusive RH sensors,and use of more representative amounts of wood framing in each panel. Drainage behind thecladding was intercepted at weep holes and measured in the test house.

3.6.1 Results

The fibrous cavity fill did not restrict drainage, nor did it seriously reduce pressure moderationperformance. However, some small amount of moisture was retained in the glass-fibre fill, and itwas hypothesized that ventilation flow was restricted in the filled cavities. The results were largeand frequent solar-driven inward vapour drives that caused excessive wetting and decay of theframing in the filled cavity wall. The walls sheathed with grooved extruded polystyrene (XPS)performance very well. Drainage was excellent, and inward vapour drives were completelycontrolled. Inspection of the wall panels after 18 months of exposure showed extensive rot andmold in the panels with glass fibre sheathing, and pristine wood in the walls with XPS.

0

2000

4000

6000

1 4 7 10 13 16 19 22

Hour

Vap

our

Pre

ssur

e (P

a)

Interior

Batt/Studspace

Cavity

Exterior

Saturation Pressure @ vapour retarder(calc.)

Figure 7: Hourly Vapour Pressure Plots Measured During Summer (CondensationOccurring Due to Inward Vapour Drives)

Pressure response of the panels was extensively measured at high rates. The results showed thatinstantaneous pressure equalization did not occur, and that pressure equalization has little impacton rain penetration. The brick veneer exhibited high rates of water penetration when tested, butvery little water was collected during field exposure. The amount of rain deposition thattypically occurred was stored in the brickwork.

Brick veneer over glass fibre insulation – no airspace

3.6.2 Discussion

It is interesting to note that the same type of wall panel that exhibited the fastest drying in thewintertime Wall Drying study was, with the air space removed, the wall system that exhibiteddamaging wetting, for almost the same reasons – very high outboard vapour permeance. Theprovision of a well vented and clear air space in the previous study apparently prevented summerwetting problems in the Wall Drying study.

3.7 The URIF Project [8]

The CMHC-sponsored research work on filled cavities prompted interest from industry. Aconsortium of partners and the Ontario government joined with the Building Engineering Groupat University of Waterloo to launch a more comprehensive and ambitious study. The objectiveof the experimental work was compare and investigate several different types of wall systems,including vinyl- EIFS- and Brick-clad, steel and wood stud. The ventilation drying, pressuremoderation, filled cavities, and rain control characteristics were extensively studied. The wallswere installed in 1995, and monitored for two years.

Significant improvements were made in miniaturizing RH and temperature sensors, pressure tapswere refined, and driving rain gauges were developed.

3.7.1 Results

Filled cavity walls using hydrophobically treated insulation did not retain liquid moisture, but didstop ventilation flow. Inward vapour drives were found to be a performance problem in almostall walls with absorbent claddings, little or no ventilation, and vapour permeable exteriorassemblies. Insulated foam sheathing was confirmed to be a powerful means of reducing bothwinter-time condensation from diffusion and air leakage and summer-time inward-drivecondensation. High levels of instantaneous pressure equalization were found to be difficult toachieve in practice. All of the brick veneers allowed significant amounts of water to penetrateonce the cladding was saturated.

Extensive information on the nature of driving rain deposition, temperature loads on differentcladdings, and methods of measuring and analyzing pressure moderation was also developed.

3.8 Field Monitoring Studies Presently Underway

The US Department of Energy recently sponsored the field monitoring of crawlspaces in a hot-humid climate. Oak Ridge National Labs and the authors were commissioned to design andinstall the field monitoring experiment. A data logger connected to approximately 70 woodmoisture, relative humidity and temperature sensors was installed in two homes. A small weatherstation was also installed. Both homes have a good ground cover, one home has a ventedcrawlspace and the other has an insulated unvented crawlspace. Initial results indicate that thetheoretical predictions for unvented and insulated crawlspaces are correct.

RDH Engineering is also monitoring the performance of the repair/retrofit of a three-storey woodframe apartment in the Vancouver area. The authors helped design the wood monitoring

equipment for this study. Results will be presented elsewhere in these proceedings. RDH hasalso recently completed a comprehensive and scientifically-designed field survey of high-risebuildings, which should soon be available from CMHC.

The American Society of Heating Refrigeration and Air-Conditioning Engineers has sponsored afield exposure experiment at the University of Waterloo's test house. This study will examinethe role of housewrap selection and ventilation on the drying capabilities of wood framed walls.Both vinyl siding and brick veneer are being studied.

4 Discussion and Recommendations for Future Studies

The research reviewed above leads to several important conclusions. Design and workmanshipcan cause serious predictable problems – scientific knowledge must be transferred to the tradesand professional designers. Moisture that is retained within walls will cause mold growth withinabout 3 months. Walls can dry outward in winter even with relatively vapour impermeable XPSsheathing because of the elevated vapour pressures in the studspace. Drying is slower in wetclimates than cold dry climates. Inward vapour drives occur, and can cause wetting in walls withvapour permeable sheathing and rain absorbing cladding exposed to the sun.

Field surveys can be successfully used to define the scope and significance of a problem. Theyshould also be used to confirm performance of new systems once deployed and after numerical,laboratory, and test house studies have been complete. The key points required to accomplish asuccessful survey are: 1. a carefully selected (i.e. representative of the target population),sufficiently large sample set, 2. a uniform set of definitions and instructions for the surveyors,and 3. informed and consistent surveyors.

Much has been learned about how to conduct and interpret field studies. For example, exposureconditions of the test enclosures must be clearly defined, and preferably measured (e.g., measuredriving rain deposition, solar radiation, etc). These exposure conditions should be measured insuch a way that they represent normal national weather data, e.g., wind speed and directionshould be measured at 10 m. Interior temperature and humidity should be measured for all fieldmonitoring exercises. Measurement of the airtightness of the enclosure is also advisable. Thetime-scale of moisture movement is often on the order of hours (with respect to solar drivenmoisture redistribution and night-sky radiation condensation) although the results require weeksto manifest themselves. Hence, one needs to measure RH and temperature as well as woodmoisture content.

The legacy of the extensive test house drying studies is not a ranking of which wall dries mostquickly. Instead, it was learned that hygrothermal performance of wood framed walls is quitecomplex. The effect of exterior climate and interior conditions are profound, and hence the needfor understanding the physics are critical if one is to extend the results of the field tests tobuildings in general. Results of moisture content, temperature, and humidity are interesting, butshould be tied to the predicted performance. This may require more work in the form ofmaterial-specific tests, etc. Test panels must be carefully isolated from one another, andunintentional communication eliminated. For maximum benefit studies should begin, as much asis practical, with different panels at the same temperature and moisture condition.

Research involving field exposure of wood framed enclosures continues to play an importantrole in building research. Our understanding of the true complexities of the varying boundaryconditions, the highly variable and interdependent material properties, and the reality of site-builtenclosures can only be properly assessed and confirmed by field exposure studies.

5 References

[1] Morrison Hershfield Limited Consulting Engineers. Moisture in Canadian Wood-FrameHouse Construction: Problems, Research & Practice From 1975 to 1991. Prepared forthe Research Division, Canada Mortgage and Housing Corporation. Principal consultant:Grant Wilson. Ottawa, 1992.

[2] Morrison Hershfield Limited Consulting Engineers. Survey of Building EnvelopeFailures in the Coastal Climate of British Columbia. Prepared for Canada Mortgage andHousing Corporation. Principal consultants: David R. Ricketts, John E. Lovatt. Ottawa,1996.

[3] Oboe Engineering Ltd. Final Report on the Drying of Walls – Atlantic Canada.Prepared for: Project Implementation Division, Canada Mortgage and HousingCorporation. Ottawa, 1987.

[4] Oboe Engineering Ltd. Wood Siding Moisture Monitoring – St. John’s, Newfoundland.Prepared for: Project Implementation Division, Canada Mortgage and HousingCorporation. Ottawa, 1987.

[5] Forest, T., and Walker, I., Drying of Walls Prairie Region. Department of MechanicalEngineering, University of Alberta, Alberta, Prepared for: Project ImplementationDivision, Canada Mortgage and Housing Corporation. Ottawa, 1990.

[6] Burnett, E.F.P., Amanda J. Reynolds, The Ontario Wall Drying Report. Final Report forCanada Mortgage and Housing Corporation by the Building Engineering Group,University of Waterloo, July 1991, 128 pages + appendices.

[7] Straube, J.F. and Burnett, E.F.P., The Zero-Cavity and DPV Wall Project. Final Reportfor Canada Mortgage and Housing Corporation by the Building Engineering Group,University of Waterloo, December, 1995, 130 pages + appendices.

[8] Straube, J.F., and Burnett, E.F.P., In-Service Performance of Enclosure Walls: SummaryFinal Report. Building Engineering Group report for URIF corporate partners,December, 1997, 125 pages + appendices.