005-001-004-004 Royal Geographical Society - Gap Planning Toolkit

Rev 0 to report 42074-R-004, 'Seismic Verification of ...

Transcript of Rev 0 to report 42074-R-004, 'Seismic Verification of ...

Report No. 42074-R-004

SEISMIC VERIFICATION OF BATTERY CHARGER 21 AT INDIAN POINT UNIT 2

September 23, 1991

Revision 0

Prepared for:

CONSOLIDATED EDISON

EQE ENGINEERING

42074-R-004 Revision 0 September 23, 1991 Page 1 of 21

SEISMIC VERIFICATION OF BATTERY CHARGER 21 AT INDIAN POINT UNIT 2

September 23, 1991

Revision 0

Prepared for:

CONSOLIDATED EDISON 4 Irving Place

New York, NY 10003

EQE Project Number: 42074.03

EQE ENGINEERING

42074-R-004 Revision 0 September 23, 1991 Page 2 of 21

01991 by EQE Incorporated ALL RIGHTS RESERVED

The information contained in this document is confidential and proprietary data. No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from EQE Incorporated.

CONED/R740-TORMEE

42074-R-004 Revision 0 September 23, 1991 Page 3 of 21

APPROVAL COVER SHEET

Seismic Verification of Battery Charger 21 at Indian Point Unit 2

REPORT NUNMBER:

CLIENT:

PROJECT NO.:

42074-R-004

Consolidated Edison

42074.03

REVISION RECORD

REV. NO. DATE PREPARED REVIEWED APPROVED

0 9/23/91

forms/repomt/cvr-sht/1 2-13-89

CONED/R740-TOR

TITLE:

42074-R-004 Revision 0 September 23, 1991 Page 4 of 21

TABLE OF REVISIONS

Description of Revision

Initial Issue

Date Approved

September 23, 1991

Revision No.

0

CONED/R740-TOR

42074-R-004 Revision 0 September 23, 1991 Page 5 of 21

SUMMARY

This report documents the seismic verification of Battery Charger 21 located in

the Control Building of Indian Point Unit 2. The seismic verification is based on

the performance of similar components in past strong-motion earthquakes. The

evaluation consists of design response spectra comparison, similarity comparison

of equipment with the experience data base equipment, investigation of specific

qualification caveats, and walkdowns to document field conditions. The results of

the walkdown and evaluation show that the battery charger will remain functional

following a Safe Shutdown Earthquake (SSE) at the Indian Point site.

To ensure the applicability of this conclusion, the anchor bolts must be tightness

checked during the future A-46 walkdowns.

CONED/R740-SUM

42074-R-004 Revision 0 September 23, 1991 Page 6 of 21

TABLE OF CONTENTS

Page SUM MARY ........................................................................................... 5

1. INTRODUCTION AND BACKGROUND ....................................... 8

1.1 Introduction ...................................................................... 8

1.2 Background of Seismic Experience Methods .................... 8

2. SCOPE ........................................................................................ 10

3. M ETHODOLOGY ......................................................................... 11

3.1 Seismic Qualification Utility Group Methodology ............... 11

3.2 Spectrum Com parison ..................................................... 12

3.3 W alkdown ......................................................................... 12

3.3.1 Unit Anchorage ....................................................... 13

3.3.2 Relay Review ........................................................... 13

3.3.3 Seism ic Spatial System s Interaction ........................ 14

3.3.4 Internal Com ponent Com parison ........................... 14

3.3.5 Transform er Location ............................................... 14

3.3.6 Base Assem bly Stiffness .......................................... 14

3.4. Outlier Evaluation .............................................................. 14

4. RESULTS .................................................................................... 16

4.1 Spectrum Com parison ...................................................... 16

4.2 W alkdown ......................................................................... 16

4.2.1 Unit Anchorage ....................................................... 16

4.2.2 Relay Review ........................................................... 17

4.2.3 Seism ic Spatial System s Interaction ........................ 17

4.2.4 Internal Com ponent Com parison ........................... 17

4.2.5 Transform er Location .............................................. 17

4.2.6 Base Assem bly Stiffness ......................................... 17

4.3 Outlier Evaluation .............................................................. 17

5. CONCLUSIONS ........................................................................... 19

6. REFERENCES ............................................................................. 20

CONED/R740-TOC

42074-R-004 Revision 0 September 23, 1991 Page 7 of 21

APPENDICES

Page A. Summary of the Seismic Experience Data Base ...................... A-1 to A-13

B. Generic Equipment Class of Battery Chargers ........................ B-1 to B-26

C. Completed Screening and Evaluation Worksheets .................. C-1 to C-5

D. Battery Charger Anchorage Evaluation ................................... D-1 to D-34

E. Battery Charger 21 Phetos ...................................................... E-1 to E-4

"FIGURES

3-1 SSRAP Generic Bounding Spectrum ....................................... 15

4-1 Comparison of Indian Point Unit 2 ground spectrum with

the Generic Bounding Spectrum .............................................. 18

CONED/R740-TOC

42074-R-004 Revision 0 September 23, 1991 Page 8 of 21

1. INTRODUCTION AND BACKGROUND

1.1 Introduction

This report documents the seismic evaluation of Battery Charger 21 installed on

Elevation 33'-0" of the Control Building at the Indian Point Unit 2 Station. The

methods used for the evaluation are those developed for the Seismic Qualification

Utility Group (SQUG), based on a seismic experience data base of the perform

ance of similar components in past strong-motion earthquakes. These methods

have been developed for different generic equipment categories and are detailed

in the Senior Seismic Review and Advisory Panel (SSRAP) Report (Reference 2)

and EQE's Twenty Classes of Equipment Report (Reference 3). The use of

seismic experience data has been endorsed by the United States Nuclear

Regulatory Commission (USNRC) as a reasonable and cost effective method to

verify the seismic adequacy of components in operating nuclear power plants

(Reference 1).

The SSRAP recommendations, as stated in Reference 2, are used as the tech

nical basis for the work performed on this project. SSRAP is an independent

review board consisting of a five-member panel of seismic experts whose

members were jointly selected by SQUG and the USNRC.

1.2 Background of Seismic Experience Methods

In 1982, the SQUG was formed to address USNRC Unresolved Safety Issue (USI)

A-46, "Seismic Qualification of Equipment in Operating Nuclear Power Plants."

The goal of the SQUG was to develop a reasonable and cost effective resolution

to this issue, which could be applied generically to all of its member utilities. The

generic resolution to USI A-46 is based primarily on the use of seismic experience

data, lessons learned from earthquakes. In 1988, the SQUG produced a Generic

Implementation Procedure (Reference 4) describing the procedure to be used for

resolving USI A-46 for its member utilities. The GIP was endorsed by the NRC in

1988 (Reference 5).

CONED/R740-CH1

42074-R-004 Revision 0 September 23, 1991 Page 9 of 21

Battery chargers and inverters are included in the USI A-46 program by the SQUG. The SQUG review procedures are founded primarily on a data base of experience of similar equipment which have been subjected to earthquakes comparable to or stronger than the design Safe Shutdown Earthquakes (SSE) for typical nuclear plants in the eastern United States. The review procedures

developed by the SQUG, with approval from the USNRC, focus on demonstrated sources of seismic vulnerability in power plant equipment. The SQUG program and its supporting experience data base are described in detail in References 2 and 3. Appendix A provides a brief summary of the seismic experience data

base.

The experience data base has demonstrated that battery chargers and inverters are not susceptible to damage in earthquakes comparable to the SSE for nuclear plants in the eastern United States (earthquakes with a peak ground acceleration less than about 0.30g). This conclusion is based upon the experience data base which is founded on studies of over 100 facilities located in the strong motion

areas of 18 earthquakes that have occurred in the United States and throughout the world since 1971. Of this inventory, there are no examples of seismicallyinduced damage to properly anchored battery chargers or inverters that resulted

in loss of function or structural integrity.

CONED/R740-CH1

42074-R-004 Revision 0 September 23, 1991 Page 10 of 21

2. SCOPE

The workscope for this project is the seismic verification of Battery Charger 21

installed on the floor at Elevation 33'-0" of the Control Building at the Indian Point

Unit 2 Station. The project consists of evaluations and inspections to verify the

seismic adequacy of the equipment. This includes an in-plant inspection, seismic

spectrum comparison, and calculations to verify anchorage adequacy.

The operability requirements for this battery charger is that it must remain

functional following a SSE and must remain structurally intact and in place during

and after a SSE.

All work performed under this scope is in accordance with the latest revision of

EQE's Quality Assurance Program Manual.

CONED/R740-CH2

42074-R-004 Revision 0 September 23, 1991 Page 11 of 21

3. METHODOLOGY

3.1 Seismic Qualification Utility Group (SQUG) Methodology

The methodology employed for the seismic verification of equipment in this report was developed as part of the SQUG program to address USI A-46. A Generic

Implementation Procedure has been developed (Reference 4) and endorsed by

the NRC (Reference 5). The development of this methodology is based on the

information included in References 1 through 6.

In summary, very few components of nuclear plant systems are unique to nuclear

facilities. Nuclear plant systems include battery chargers and inverters, water chillers, compressors, heat exchangers, piping and piping components (e.g.,

valves, strainers), control panels, ducts, and many other items that are common

components of conventional power plants and industrial facilities. The seismic

experience data base was developed to address the problem of equipment qualification in nuclear plants for equipment which was purchased and/or installed as

commercial grade. By reviewing the performance of facilities that contain equipment similar to that found in nuclear plants, conclusions can be drawn about the

performance of nuclear plant equipment during and after a safe shutdown earth

quake. A pilot program to demonstrate the feasibility of using earthquake

experience in lieu of formal seismic qualification of equipment was performed in 1982 (Reference 6). This program demonstrated that selected types of equip

ment in data base facilities are similar to equipment in operating nuclear plants. It

further demonstrated that explicit seismic qualification of those equipment types

should not be required in view of their performance in strong earthquakes. The

last conclusion is currently supported by the program data base for nuclear sites

with ground PGA less than about 0.30g.

During the evaluation and walkdown, four areas should be considered. These

areas are:

", Equipment seismic capacity vs. seismic demand (see Section 3.2)

", Applicability of seismic experience data to plant specific equipment (see Section 3.3)

CONED\R740-CH3

42074-R-004 Revision 0 September 23, 1991 Page 12 of 21

"Equipment anchorage (see Section 3.3.1)

"* Seismic interaction (see Section 3.3.3)

3.2 Spectrum Comparison

A Generic Bounding Spectrum (Figure 3-1) was developed to compare the potential seismic exposure of equipment in a nuclear power plant with the estimated ground motion that similar equipment experienced (resisted) in earthquakes described in the data base.

"The comparison of the seismic bound with design horizontal ground response spectrum is judged to be acceptable for equipment mounted less than about 40 feet above grade (top of the ground surrounding the building) and for reasonably stiff structures. For equipment mounted more than about 40 feet above grade, comparison of 1.5 times the Bounding Spectrum with horizontal in-structure

spectra is necessary" (Reference 2).

3.3. Walkdown

A walkdown inspection of the battery charger was performed on September 4, 1991. This walkdown was in accordance with the SQUG GIP (Reference 4).

The EQE walkdown addressed the following issues:

,, Determination of whether equipment lies within the limitations of the caveats and similarity exclusion rules defined in the documentation (References 2, 3 and 4).

,, Judgmental evaluation of any factor that might affect the seismic performance of the equipment.

,, Flagging of any unusual or nontypical conditions, such as major modifications to standard equipment or equipment that is unique, for special review.

• , Assessment of the adequacy of equipment anchorage.

,, Assessment of seismic spatial systems interactions.

* Documentation of the walkdown.

CONED\R740-CH3

42074-R-004 Revision 0 September 23, 1991 Page 13 of 21

"The exercise of considerable judgment and experience is necessary during a seismic walkdown" (Reference 2). In accordance with the SQUG methodology, knowledgeable and practical individuals were selected to participate in the

walkdown as part of the Seismic Review Team (SRT). All engineers shall have knowledge of the failure modes and performance of components during strongmotion earthquakes in heavy industrial process plants and fossil fuel power plants and have knowledge of nuclear design standards and seismic design practices for nuclear power plants. Therefore, these engineers will have the ability and experience to perform seismic capability evaluations, including structural/ mechanical analysis, as needed.

The detailed evaluation methodology used by EQE and Con Edison during the walkdown is described in the Generic Implementation Procedure (Reference 4). The walkdown results were documented on Screening and Evaluation Work

Sheets (Attachment D).

3.3.1 Unit Anchorage. The presence of properly engineered anchorage is perhaps the most important single item which affects the seismic performance of equipment. Earthquakes have repeatedly demonstrated that equipment will slide, overturn, or move excessively when it lacks positive anchorage or when it does not have proper engineered anchorage. Anchored equipment failures in the earthquake experience data base include expansion bolts with very short embedments, friction clips (steel plates anchored to the concrete base which extend over the flange or base of the equipment without a positive connection), and base anchorage details with significant eccentricities which allow the equipment base to bend or tear or which generate large prying forces. Adequate anchorage is determined to be that which provides both adequate strength and stiffness. Adequate strength and stiffness of equipment anchorage can be determined by any one of many commonly accepted analysis methods.

3.3.2 Relay Review. Relays within the unit should be evaluated to determine possible effects of seismically induced vibration in accordance with the guidelines given in Reference 2, Section 5.

CONED\R740-CH3

42074-R-004 Revision 0 September 23, 1991 Page 14 of 21

3.3.3 Seismic Spatial Systems Interaction. In accordance with the SQUG methodology, an assessment of potential seismic spatial system interaction hazards shall be performed. The scope of this assessment is limited to an interaction review in the area surrounding the battery charger. The seismic interaction assessment considers examples of poor housekeeping, inadequately supported HVAC ducts, cable trays, conduit, piping, and instrument tubing. The SRT will also review the area for possible hazardous interactions with building structural members (e.g., columns, beams, bracing) or with architectural items (e.g., fire separation walls, stairways). This review will be performed to verify that impacts during a seismic event which rn-ight cause damage are precluded. The specific methodology to be used by EQE and Con Edison for performing the seismic spatial systems interaction review (including details on the basis for engineering judgment of the items reviewed) is presented in Section 4.5 of the GIP (Refer

ence 4).

3.3.4 Internal Component Composition. The battery charger or static inverter should be a solid-state type. The solid-state electrical construction is the primary type included in the earthquake experience database. The concern is that electronics which are not of the solid state variety (glass tubes, etc.) are vulnerable to earthquake damage.

3.3.5 Transformer Location. For the floor-mounted units, the transformer, which is the heaviest component of this equipment, should be positively anchored and mounted near the base of the cabinet. If not mounted near the base, then the load path should be evaluated.

3.3.6 Base Assembly Stiffness. The base assembly of floor-mounted units shall be properly braced or stiffened such that lateral forces in any direction do not rely on weak-way bending of sheet metal or thin webs of structural steel shapes. If such unbraced or stiffened steel webs exist in the nuclear plant, they shall be investigated and justified by the walkdown engineer by other means for adequacy of strength and stiffness.

3.4 Outlier Evaluation

Items that cannot be qualified by use of the SQUG methods as described above are considered "outliers". Outliers can be seismically verified either by further review of the seismic experience data base or by standard analysis techniques.

CONED\R740-CH3

2 6 10 14 18 22 26 30 34

FREQUENCY (Hz)

Figure 3-1: Generic Bounding Spectrum

CONED\R7T40-CH3

42074-R-004 Revision 0 September 23, 1991 Page 15 of 21

1.4

1.3

1.2

1.1

1

0.9

0.8

0.7S 0

0 0.6

0.5

0.4

0.3

0.2

0.1

0

M

42074-R-004 Revision 0 September 23, 1991 Page 16 of 21

4. RESULTS

This section presents the results of the seismic evaluation of Battery Charger 21 using the SQUG methodology summarized in Section 3.

4.1 Spectrum Comparison

The equipment location is on the floor at Elevation 33'-0" of the Control Building. This elevation is less than about 40 feet above grade (grade is Elevation 18'). Consequently, the IP2 site horizontal SSE free-field response spectrum was compared with the Generic Bounding Spectrum from Reference 2 in EQE calculation 41008.01-C-003 (Reference 9). This calculation shows the Generic Bounding Spectrum envelopes the IP2:SSE spectrum over the entire frequency range (Figure 4-1). This verifies the use of experience data for the seismic qualification of the battery charger.

4.2 Walkdown

Two different walkdowns of the battery charger were performed. One was by Con Edison and EQE personnel during which access to the internals of Battery Charger 21 was not possible. A walkdown of a similar unit which was accessible on the turbine floor deck was performed. This walkdown evaluated all SQUG GIP caveats except anchorage. The anchorage of Battery Charger 21 was walked down and evaluated at an earlier date by Con Edison personnel.

A number of key areas were addressed by the Seismic Review Teams including the caveats for battery chargers as outlined in Section 11 of Reference 2. These included unit anchorage, relays, seismic spatial systems interaction, internal construction, transformer location, and base assembly stiffness.

4.2.1 Unit Anchorage. The battery charger is secured to the floor by (4) 1/2" diameter shell anchors. This anchorage was evaluated by EQE in Reference No. 10 and was found to be adequate for the IP2 SSE event. This finding is contingent upon the anchor bolts being successfully tightness tested during the

future A-46 walkdowns.

CONED/R740-CH4

42074-R-004 Revision 0 September 23, 1991 Page 17 of 21

4.2.2 Relay Review.

The Battery Charger is only required to function following a SSE event at IP2. As

such, the relays can chatter during a SSE event but must be able to function properly following the earthquake. To satisfy this requirement, a comparison was made between the installed relays and those which have been found to be so

seismically sensitive that they could be damaged during an earthquake. This

comparison is shown in Appendix C.

It was found that the IP2 relays are not on the seismic "bad actors" list and as

such are adequate to function following a seismic event at IP2.

4.2.3 Seismic Spatial Systems Interaction. The interaction review was performed

during the EQE walkdown and was in accordance with the guidelines of Reference 4. The walkdown investigated the area in the vicinity of the Battery Charger

and did not find any possibility of unacceptable interactions.

4.2.4 Internal Component Composition. The internals of the battery chargers were reviewed during the walkdown and found to be composed entirely of solid

state devices.

4.2.5 Transformer Location. The transformer was found to be mounted on a

metal shelf 3'-2" above the battery charger base. The transformer is secured to

the 1/8" thick shelf with (4) 1/4" A307 bolts. This shelf is in turn bolted to the

battery charger internal framing by (8) 1/4" bolts.

This mounting and associated load path was reviewed by the Seismic Review Team and was judged to be adequate to ensure position retention of the

transformer during and following an SSE event.

4.2.6 Base Assembly Stiffness. The base was found to be comprised of small, welded steel channels. These were judged to be adequate to transfer the seismic loads of the battery charger to the anchor bolts.

4.3 Outlier Evaluation

No outliers were identified during the walkdowns.

CONED/R740-CH4

42074-R-004 Revision 0 September 23, 1991 Page 18 of 21

6 10 14 18 22 26 30 34

FREQUENCY (Hz)

Figure 4-1: Comparison of the Indian Point Unit 2 Free Field SSE response spectrum with the Generic Bounding Spectrum.

CONED/R740-CH4

1.4

1.3

1.2

1

I 0

0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

5% DAMPING]

1.0 TIMES SOUG BOUNDING SPECTRUM

IP2 SSE GROUND RESPONSE SPECTRUM

I I I I

2

K'ý ý EE

42074-R-004 Revision 0 September 23, 1991 Page 19 of 21

5. CONCLUSIONS

Battery Charger 21 installed on Elev. 33'-0" of the Control Building at Indian Point Unit 2 has been evaluated using the seismic experience data in accordance with References 2, 3 and 4. The conclusion of this evaluation is that the battery charger is seismically rugged and will remain functional following a SSE event at IP2.

This evaluation did not include an anchor bolt tightness check which must be performed during the future A-46 walkdowns.

CONED/R740-CH5

42074-R-004 Revision 0 September 23, 1991 Page 20 of 21

6. REFERENCES

1. USNRC. February 1987. NUREG 1211. Status Report, Unresolved Safety

Issue A-46. "Seismic Qualification of Equipment in Operating Plants."

2. Senior Seismic Review and Advisory Panel. February 28, 1991. "Use of

Seismic Experience and Test Data to Show Ruggedness of Equipment in

Nuclear Power Plants." Prepared for the Seismic Qualification Utility Group.

3. EQE Engineering. February 1989. "Summary of the Seismic Adequacy of

Twenty Classes of Equipment Required for the Safe Shutdown of Nuclear Plants." Draft. Prepared for the Seismic Qualification Utility Group.

4. Bishop, Cook, Purcell and Reynolds; EQE Incorporated; MPR Associates,

Inc.; Stevensons and Associates; and URS/John A. Blume and Associates,

Engineers. September 21, 1990. "Generic Implementation Procedure (GIP)

for Seismic Verification of Nuclear Plant Equipment." Revision 2. Prepared for the Seismic Qualification Utility Group.

5. USNRC. July 29, 1988. Generic Safety Evaluation Report on SQUG Generic

Implementation Procedure.

6. EQE Engineering. 1982. "Pilot Program Report, Program for the Development

of an Alternative Approach to Seismic Equipment Qualification." Prepared for the Seismic Qualification Utility Group.

7. EQE Incorporated. August 11, 1986. Revision 1. "Quality Assurance

Manual."

8. URS Corporation/John A. Blume & Associates, Engineers, "Seismic Verifica

tion of Nuclear Plant Equipment Anchorage, Volume 2: Anchorage Inspection

Workbook." May 1987.

9. EQE Engineering Calculation Number 41008.01 -C-003, "Spectrum Com

parison." Revision 0 dated December 29, 1988.

42074-R-004 Revision 0 September 23, 1991 Page 21 of 21

10. EQE Engineering Calculation Number 42074-C-004, "Battery Charger #21 Anchorage Evaluation." Revision 0 dated September 23, 1991.

11. Yanev, Peter I. and Sam W. Swan. September 1982. "Program for the

Development of an Alternative Approach to Seismic Equipment Qualification",

2 volumes. San Francisco, CA. EQE Incorporated.

42074-R-004 Revision 0 September 23, 1991 Page A-1 of 13

APPENDIX A

SUMMARY OF SEISMIC EXPERIENCE DATA BASE

CONED/R740-ATA

42074-R-004 Revision 0 September 23, 1991 Page A-2 of 13

SUMMARY OF THE EARTHQUAKE EXPERIENCE DATA BASE

Strong-motion earthquakes frequently occur in California and Latin American countries, where power plants or industrial facilities are included in the affected areas. By studying the performance of these earthquake-affected (or data base) facilities, a large inventory of various types of equipment installations can be compiled that have experienced substantial seismic motion.

The primary purposes of the seismic experience data base are summarized as follows:

"* To determine the most Common sources of seismic damage, or adverse effects, on equipment installations typical of industrial facilities.

"* To determine the thresholds of seismic motion corresponding to various types of seismic damage.

", To determine the performance of equipment during earthquakes, regardless of the levels of seismic motion.

"* To determine minimum standards in equipment construction and installation, based on past experience, to assure the ability to withstand anticipated seismic loads.

To summarize, the primary assumption in compiling an experience data base is that the actual seismic hazard to industrial installations is best demonstrated by the performance of similar installations in past earthquakes.

FACILITIES SURVEYED IN COMPILING THE DATA BASE. The seismic experience data base is founded on studies of over 100 facilities located in the strong motion areas of 18 earthquakes that have occurred in California and Latin America since 1971. The earthquakes and facilities included in the data base are summarized in Table 1.

The data base was compiled through surveys of the following types of facilities:

", Fossil-fueled power plants

", Hydroelectric power plants

"* Electrical distribution substations

"a Oil processing and refining facilities

"* Water treatment and pumping stations

", Natural gas processing and pumping stations

"* Manufacturing facilities

"* Large commercial facilities (focusing on their HVAC plants)

CONED/R740-ATA

42074-R-004 Revision 0 September 23, 1991 Page A-4 of 13

Standard procedures used in surveying data base facilities focus on collecting all information on damage or adverse effects of any kind caused by the earthquake. For a large majority of the facilities surveyed in the data base, this is not a lengthy task. Except for sites that experienced very high seismic motion (in excess of 0.50g peak ground acceleration), seismic damage to well-engineered facilities is normally limited to only a few items.

CONED/R740-ATA

Table 1

SUMMARY OF SITES REVIEWED IN COMPILING THE SEISMIC EXPERIENCE DATA BASEC) 0 Z m

Earthquake (Magnitude)

San Fernando, CA Earthquake 1971 (M6.5)

Point Mugu, CA Earthquake 1973 (M5.7)

Facility

Sylmar Converter Station

Rinaldi Receiving Station

Valley Steam Plant

Burbank Power Plant

Glendale Power Plant

Pasadena Power Plant

Ormond Beach Power Plant

Type of Facility

Large electrical sub

station

Large electrical substation

Four-unit gas-fired power plant

Six-unit gas-fired power plant

Five-unit gas-fired power plant

Five-unit gas-fired power plant

Large two-unit oilfired power plant

Estimated Peak Ground Acceleration

(a00)**

0.50-0.75

0.50-0.;5

0.40

0.30

0.30

0.20

0.20

Primary Seismic Damage

Extensive damage to station equipment, shut down for several months

Damage to switchyard components

Minor yielding in boiler, structure, tripped electrical relays

Moderate damage to piping, tripped electrical relays

Minor damage, plant remained on line during earthquake

Minor damage, plant remained on line during earthquake

Moderate damage (buckled hydraulic snubber), one unit trilppn. ,. . 0 off line during earthquake D0

CD 0o

S * Ground acceleration measured by an instrument at the site

** Average of two horizontal components

Earthquake (Magnitude)

Ferndale, CA Earthquake 1975 (M5.5)

Santa Barbara, CA Earthquake 1978 (M5.7)

Imperial Valley, CA Earthquake 1979 (M6.6)

Humboldt, CA Earthquake 1980 (M7.0)

Coalinga, CA Earthquake 1983 (M6.7)

Estimated Peak Ground Acceleration

(Cl)**- -Facility

Humboldt Bay Power Plant

Goleta Substation

El Centro Steam Plant

Drop IV Hydro. Plant

Humbolt Bay Power Plant

Main Oil Pumping Plant

Union Oil Butane Plant

Shell Water Treatment Plant

S* Ground acceleration measured by an instrument at the site

** Average of two horizontal components

Type of Facility

Two gas-fired units, one nuclear unit

Electrical substation

Four-unit gas-fired power plant

Two-unit hydroelectric plant

Two gas-fired units one nuclear unit

Pumping station feeding oil pipe-line from Coalinga area

Petrochemical facility to extract butane and propane from well waste gas

Petrochemical facility to demimeralize water prior to steam injection Into oil wells

0.30*

0.26*

0.42*

0.30

0.25

0.60

0.60

0.60

Primary Seismic Damage

Damage to air preheater seismic stops, units tripped off line during earthquake

No damage, station remained on-line during earthquake

Moderate damage to piping and equipment, two units tripped off line during earthquake

Minor damage, plant remained online during earthquake

Moderate damage to piping, two units tripped off-line during earthquake

Extensive damage to equipment anchorages, plant shut down during earthquake

Moderate damage to structures and tanks, plant shut down during W Mo 33 *0< 0

earthquake (0'0

Moderate damage to equipment O 0

anchorage, plant shut down _during earthquake

(0

Estimated Peak Ground Acceleration

(.. a)** -Type of Facility Primary Seismic Damage

Morgan Hill, CA Earthquake 1984 (M6.2)

Coalinga Water Treatment

Coalinga Substation No. 2

Shell tank Farm No. 29

Pleasant Valley

f

San Luis Canal Pumping Stations (29)

Gates Substation

Kettleman Compressor Station

United Tech. Chemical Plant

IBM/Santa Teresa Facility

Potable water purification facility

Electrical Substation

Oil storage tank farm

Pumping station to supply Pumping Plant water from the San Luis Canal to the Coalinga Canal

Agricultural pumping stations taking water from the San Luis Canal

Large electrical substation

Natural gas pipeline booster station

Large research facility for missile systems development

Large computer facility for software development

0.60

0.60

0.60

0.56'"

0.20-0.60

0.25

0.20

0.50

0.37*

Minor damage to equipment anchorage, plant shut down during earthquake

Extensive structural damage to control house, station remained operable during earthquake

Extensive damage to 60% of tanks associated equipment not damaged

Minor damage, plant shut down during earthquake

Minor damage, power temporarily lost during earthquake

Minor damage

Minor damage, plant operated through earthquake

Moderate damage to cable trays an4(D M p, ducts, power lost during earthquakqe -, <

.. n 0 Minor damage, facility operated -ro

through earthquake W

CD• Co3

Ir••I * Ground acceleration measured by an Instrument at the site

** Average of two horizontal components

Earthquake (Magnitude) Facilit

Estimated Peak Ground Acceleration

(g)•**--Facilit

San Martin Winery

Witron Electronics Plant

Metcalf Substation

Evergreen Community College

Mirassou Winery

Bata Shoe Factory

San Isidro Substation

Uolieo Water Pumping Plant

Terquim Tank Farm

Vicuna Hospital

Ground acceleration measured by an instrument at the site

** Average of two horizontal components

Type of Facility

Winery

Electronics manufacturing facility

Large electrical substation

Large college complex with self-contained HVAC power plant

Winery

Four-building factory and tannery

Electrical substation

Water pumping station

Oil/acetate/acid storage tank farm

Four-story hospital

0.35

0.35

0.40

0.20

0.20

0.64

0.58*

0.55

0.55

0.55

Primary Seismic Damage

Extensive tank damage

Moderate damage to equipment anchorage and ducts, facility not in operation at time of earthquake

Moderate switchyard damage, power lost during earthquake

Minor damage to architectural features

Moderate tank damage

Extensive structural and equipment damage power lost during

Moderate switchyard and equipment damage, power lost during earthquake

Moderate piping and equipment damage, power lost during earthquake

0(DV M

Extensive tank damage D _..p,

>30 O0 n

Moderate damage to piping and r P. equipment anchorage hospital CAP

closed following earthquake -L

Earthquake NMagnitudej

Chile Earthquake 1985 earthquake (M7.8)

Facility

Rapel Hydroelectric Plant

San Sebastian Substation

Concon Petroleum Refinery

Oxiquim Chemical Plant

Concon Water Pumping Station

Type of Facility

Five-unit hydroelectric plant

Electrical substation

Petrochemical facility producing fuel oil, asphalt, gasoline, and other petroleum products

Chemical facility producing various chemicals, including feed stock for paint ingredients

Water pumping station

Estimated Peak Ground Acceleration

(g)I±

0,40*

0.35

0.30

0.30

0.30

Primary Seismic Damaae

Moderate damage to equipment, relays, and switchyard equipment, plant not on-line during earthquake

No damage

Moderate equipment and tank damage, relay actuation tripped plant off line

Moderate damage to tanks and piping, power lost during earthquake

Moderate damage to piping and equipment anchorages, power lost during earthquake

Renca Power Plant

Laguna Verde Power Plant

Las Ventanas Copper Refinery

Las Ventanas Power Plant

Ground acceleration measured by an instrument at the site

** Averaoe of two horizontal components

Two-unit coal-fired peaking power plant

Two-unit coal-fired peaking plant

Copper refinery/foundry/ power plant

Two-unit gas-fired power plant

0.30

0.25

0.25

0.25*

Minor damage to structure and equipment anchorage plant not on-line during earthquake

Moderate damage to structural and piping, plant not online during earthquake W (D D

n-'O < 0J Extensive structural damage, plant > 3

taken off-line during earthquake b rr = ,- D C)

0. 0

Moderate damage to structure and c equipment, one line tripped unit

off-during earthquake

Earthquake (Maanitude)

Type of Facility

Estimated Peak Ground Acceleration

(cl)*_*... Primary Seismic Damage

San Cristobal Substation

Las Condes Hospital

Mexico Earthquake 1985 (M8.1)

InflernIllo Dam

La Villita Power Plant

SICARTSA Steel Mill

Fertimex Fertilizer Plant

Adak, Alaska Earthquake 1986 (M7.5)

North Palm Springs, CA Earthquake 1986 (M6.0)

Adak Naval Base

Devers Substation

Whitewater Hydro. Plant

Electrical substation

Four-story hospital

Six-unit hydroelectric plant

Four-unit hydroelectric

plant

Large, modern steel mill

Fertilizer plant

Diesel-electric power plants, electrical substations, sewage lift stations, water treatment plant, steam plants

Large electrical distribution substation

Small hydroelectric power plant

0.25

0.20

0.15

0.14

0.25-0.50

0.25-0.50

0.25

0.85*

0.50

Moderate structural and switchyard damage, power was lost during earthquake

Minor damage, hospital operated through earthquake

No damage

No damage

Extensive damage to equipment and structures, facility shut down following earthquake

Extensive damage to equipment and structures, facility shut down following earthquake

Minor structural and equipment damage, facilities remained online during earthquake

Extensive switchyard damage, plant lost power during earthquake

Minor equipment damage

"1D0 M " bi, 0 < 0

>E30' ,_

Q)(D 06 ~'0

C.o (0 CA)

* Ground acceleration measured by an Instrument at the site

Earthquake (Magnitude) Faculty

0 0 Z m

Earthquake (Magnitudel

Chalfant Valley, CA Earthquake 1986 (M6.0)

controller,

San Salvador Earthquake 1986 (M5.4)

Cerro Prieto, Mexico Earthquake 1987 (M5.4)

Bay of Plenty, New Zealand 1987 (M6.25)

Caxton Paper Mill

Kawerau Substation

Whakatane Board Mill

* Ground acceleration measured by an instrument at the site

' Average of two horizontal components

Facilly

Control Gorge Hydro Plant

Hi-Head Hydro

Plant

Soyapango Substation

San Antonio substation

Power Plant 1

Power Plant 3

Edgecumbe Substation

New Zealand Distillery

Estimated Peak Ground Acceleration

0.25

0.25

Type of Facility

Two-unit hydroelectric plant

Small one-unit unmanned

hydroelectric plant

Electric substation

Electrical substation

Geothermal power plant

Geothermal power plant

230/115 kV substation

Liquor distillery

Paper and pulp mill

230/115 kV substation

Paper mill producing cardboard

Primary Seismic Damage

Minor switchyard damage, plant lost power during earthquake

Damage to programmable

plant lost power during earthquake

Moderate switchyard and equipment damage tripped electrical relays

Minor switchyard damage, plant lost

power during earthquake

No damage, both plants tripped by actuation of sudden pressure relays

Extensive switchyard damage, plant lost power during earthquake

Extensive tank damage, plant lost power during earthquake

0.50

0.40

0.20-0.30

0.20-0.30

0.50-1.0

0.50-1.0

0.40-0.55

0.40-0.55

0.30

Moderate equipment and duct damage plant lost power during -0 C/ X earthquake .) CD (

Extensive switchyard damage, plant> 3 o_-" lost power during earthquake "• : M

Moderate equipment damage, plant 'o.5 lost power during earthquake C.0

Co

Facility

Matahina Dam

Olinda Substation

SCE Dispatch Headquarters

SCE Headquarters

California Federal Bank Facility

Ticor Facility

Sanwa Bank Facility

Alhambra Pacific Bell Station

Rosemead Pacific Bell Station

Pacific Bell Central Station

Wells Fargo Bank Facility

Center Substation

Earthquake (MaanitudeI

Estimated Peak Ground Acceleration

(g)**

0.26*

0.65*

0.56*

Primary Selsmic Damage

Moderate switchyard damage, plant

lost power during earthquake

Minor switchyard damage, plant lost power during earthquake

Minor damage, facility operated through earthquake

0 0 z m

Type of Facility

Two-unIt hydroelectric plant

Electrical substation

Data Processing Center

Large office complex

Data processing facility

Data processing facility

Data processing facility

Three-story concreteframe building

Two-story steelframe building

Three steel-frame highrise buildings

Data processing facility

Electrical Substation

0.15

0.30

0.30

Extensive structural, equipment, and and piping damage, facility lost power during earthquake

Extensive damage, power lost during earthquake

Moderate equipment damage, plant lost power during earthquake

Moderate cable tray damge, facility retained power during earthquake

Moderate structural damage, plant lost power during earthquake

Moderate structural damage, facility retained power during earthquake .V CO ,,

Q3 D CD < Moderate equipment damage, CD ̀ _.. facility tripped off-line > 0

K)CD 06 Moderate switchyard damage, o 41'

-'hC facility retained power during " 2 earthquake C "

CD .,D=

* Ground acceleration measured by an instrument at the site

** Average of two horizontal components

0.42*

0.42

0.42

0.40

0.30

0.30

Whittier, CA Earthquake 1987 (M5.9)

Type of Facility

Estimated Peak Ground Acceleration

(g)** Primary Seismic Damage

Superstition Hills (El Centro), CA 1987 (M6.3)

Del Amo Substation

Lightpe Substation

Commerce Refuseto-Energy Plant

Puente Hills Landfill Gas & Energy Recovery Plant

Mesquite Lake Resource Recovery Plant

El Centro Steam Plant

Electrical Substation

Electrical Substation

One-unit gas-fired power plant

One-unit gas-fired power plant

16 MW gas-fired power plant

Four-unit gas-fired power plant

0.20

0.26*

0.30

0.20

Minor switchyard damage, facility retained power during earthquake

Minor switchyard damage, facility retained power during earthquake

Minor damage, facility retained power during earthquake

No damage, facility retained power during earthquake

Moderate equipment damage, plant not on-line before earthquake

Minor structural and piping damage, facility retained power plant during earthquake

0.30

0.25*

* Ground acceleration measured by an Instrument at the site

** -- ,nf tx,-, ý rmnonenfiý

Earthquake (Magnitude) Facility

D -0 < 0

->3 0

W00 (0

C) r " 'p_L CO• C'a I,

42074-R-004 Revision 0 September 23, 1991 Page B-1 of 26

APPENDIX B

GENERIC EQUIPMENT CLASS

OF BATTERY CHARGERS

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-2 of 26

SECTION 16

BATTERY CHARGERS AND INVERTERS

SUMMARY OF SEISMIC ADEQUACY

This class of equipment includes solid-state battery chargers and

inverters. Battery chargers and inverters perform similar functions,

contain similar components, and are packaged-in similar cabinets. IEEE

Standard 650-1979 groups these two components together for Class 1E

qualification purposes due to their inherent similarity. Although

inverters and battery chargers-perform electrically inverse functions,

they are physically very similar and will be treated in the same class.

16.1 DEFINITION OF EQUIPMENT-CLASS

Battery chargers are assemblies of electronic components whose function

is to convert ac input into dc output. Inverters are assemblies of

similar electronic components whose function is to convert dc input into

ac output. Battery chargers and inverters are normally housed in floor

or wall-mounted cabinets.

Battery Chargers

The primary electrical function of a battery charger (i.e., production

of direct current by means of an alternating voltage) is accomplished

using a rectifier. Traditionally, many kinds of rectifiers have been

used for battery charging, including rotary converters, mercury-arc

rectifiers, and thermionic valves. Most modern battery chargers are

based on solid-state rectifiers consisting of semiconductors of

selenium, germanium, or silicon diodes. Solid-state battery chargers

have substantial representation in the data base and are the focus of

this equipment class. Rotary type chargers and inverters are

represented in the equipment class of Motor Generators.

The primary components of battery chargers include solid-state diodes,

transformer coils, capacitors, electronic filters, and resistors. In

addition, the primary components are usually protected from electrical

896/20c04c16/3 16-1 1 -

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-3 of 26

faults by molded case circuit breakers and fuses. The internal

components are normally bolted either to the rear panel or walls of the

cabinet, or to interior panels or steel frames mounted within the

cabinet. The front panel of the cabinet typically contains

instrumentation and controls, including ammeters, voltmeters, switches,

alarms, and control relays. Figure 16-1 shows the arrangement of

components within a typical wall-mounted battery charger.

Inverters

Inverters perform the Qpposite function of battery chargers; they change

dc into ac power. The primary components of an inverter are similar to

those of a battery charger except that inverters use a solid-state

thyristor (or silicon-controlled rectifier) instead of a diode, and have

a commutation control circuit which activates the thyristor in

converting dc voltage into positive and negative half-cycles. Virtually

all inverters used in power plant applications are designed using solid

state components. Figure 16-2 shows a typical arrangement of components

in an inverter.

Battery Charger and Inverter Characteristics

Battery chargers and inverters are typically mounted in separate

cabinets. For applications sized for the same power system, the overall

dimensions and weight of chargers and inverters are usually similar.

Some manufacturers supply the battery charger and inverter as an

assembly of two adjoining cabinets.

Battery chargers and inverters cover a range of sizes and capacities.

The smallest units are wall-mounted or rack-mounted with typical

dimensions of 10 to 20 inches in height, width, and depth, and typical

weights of 50 to 200 pounds. Typical wall-mounted and rack-mounted

units are shown in Figure 16-5 (lower photograph) and Figure 16-4 (lower

photograph), respectively. Most power plant applications require

larger, floor-mounted units, as shown in Figure 16-5 (upper photograph)

and Figure 16-7. Typical cabinet dimensions are 20 to 40 inches in

width and depth, and 60 to 80 inches in height. The weights of the

896/20c04c16/3 16-2

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-4 of 26

floor-mounted chargers and inverters range from several hundred to

several thousand pounds, depending on the power requirements of the

system they serve.

Typical ac voltages to battery chargers and from inverters range from

120 to 480 volts. Voltages in dc power typically range from 24 to 240

volts.

Industry standards are maintained for the construction of cabinets by

Underwriter's Laboratory Standard (e.g., UL-1236 1984) and the National

Electrical Manufacturer's Association (e.g., NEMA Standard ICS-6 1978).

These standards determine the minimum structural framing and sheet metal

thickness for charger and inverter cabinetry as a function of size.

Equipment Anchorage

Floor-mounted cabinets typically rest on base channels. Holes are

normally provided in the bottom flange of the base channel for embedded

bolts or expansion anchors into the concrete floor. Alternately, the

cabinet may be welded to embedded steel, either by puddle welds through

the bolt holes or tack welds along the periphery of the base channels.

Wall- or rack-mounted units are normally anchored by bolts through the 'rear panel of the cabinet. If the unit is attached directly to a

concrete wall, expansion anchors are normally used. Rack-mounted units are typically anchored by threaded connections such as the

manufacturer's standard spring-supported nut into a Unistrut member.

Data Base Applications

The most common applications for both battery chargers and inverters are as components of an uninterruptible power supply (UPS). UPS systems are

used extensively to supply high quality power to equipment such as

programmable control systems or computers. A typical UPS consists of a

solid-state inverter, a battery charger, a set of lead-acid storage

batteries, and an automatic transfer switch. These components

effectively isolate critical loads from all types of power

896/20c04c16/3 16-3 r; 7ý-

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-5 of 26

perturbations, including line transients, voltage fluctuations, and loss

of normal offsite power.

In the normal mode, a UPS battery charger is powered from an offsite ac

power line. It provides regulated dc output to the inverter, while

simultaneously float-charging the battery. This system acts as a buffer

to critical systems, isolating them from voltage transients and

frequency fluctuations. The inverter then supplies a steady flow of ac

power to critical loads. In the event of a loss of offsite power, the

critical load continues to be supplied by the UPS inverter, which

obtains power from the standby batteries. The UPS batteries will

continue to supply ac power through the inverter until the emergency

generators come on-line or commercial offsite ac power is restored.

Application in Nuclear Plants

In nuclear plants, chargers serve the station batteries which provide a

dc power source to controls, instrumentation and switchgear. A portion

of the dc power from the batteries is routed through inverters which

provide a source of ac power to critical equipment. Inverters and

battery chargers in nuclear plants are, in general, the same type, size,

and construction as those found in the data base, as illustrated in the

examples from nuclear plants shown in Figure 16-3.

16.2 DATA BASE REPRESENTATION FOR BATTERY CHARGERS AND INVERTERS

Figures 16-4 through 16-15 present examples of battery chargers and

inverters within the data base. The data base inventory of

inverters/chargers includes about 90 examples, representing 36 sites and

14 of the earthquakes studied in compiling the data base. Of this

inventory, there is one instance of seismically-induced loss of function

to an inverter.

Figure 16-16 presents a bar chart that illustrates the inventory of

battery chargers/inverters at various data base sites as a function of

their estimated PGA.

896/20c04c16/3 16-4

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-6 of 26

The general bounds of the data base representation for the equipment class of battery chargers and inverters are summarized below.

Solid-state inverters and battery chargers are represented in freestanding, rack-mounted, and wall-mounted configurations. Floor or wall anchorage of cabinets includes bolts (typically 3/8- or 1/2-inch), welds, or friction clips.

Data base representation includes the following components:

"* The sheet metal enclosure and all internal components

"* Junction boxes attached to the cabinet

"* Attached cable or conduit between the unit and the nearest building anchor point

Basis for the Generic Bounding Spectrum

The Svlmar Converter Station is one of the major power facilities reviewed in the SQUG pilot program. The station, located near the fault rupture of the 1971 San Fernando Earthquake, is estimated to have experienced at least O.50g peak ground acceleration, with about ten seconds of strong motion.

The station control building is a three-story steel-frame structure. The basement of the station contains two battery chargers, which are bolted to steel angle frames (Figure 16-4, lower photograph). The chargers were manufactured by Powertronic Equipment Limited, of Ontario, Canada. The frame is bolted to the concrete floor with four 1-inch anchor bolts. The battery chargers were undamaged by the earthquake.

The Union Oil Butane Plant experienced a peak ground acceleration of approximately O.60g, with strong motion occurring for a duration of about 15 seconds, during the 1983 Coalinga Earthquake. This PGA is a conservative estimate, based on the nearest ground motion record of 0.56g (an average of the horizontal components) recorded at the Pleasant Valley Plant much further from the fault.

896/20c04c16/3 16-5

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-7 of 26

The plant contains three small battery chargers wall-mounted into the

rear of sheet metal cabinets (Figure 16-5, lower photograph). They are

manufactured by Nife Corporation of Rhode Island and operate at 240

volts, 20 amps dc. All battery chargers were undamaged by the

earthquake.

The Main Oil Pumoino Plant is located near the epicenter of the initial

shock in the 1983 Coalinga sequence of earthquakes. The ground motion

spectrum recorded at the Pleasant Valley Plant is applicable to the

nearby Main Oil Pumping Plant site.

The plant contains one wall-mounted battery charger and a floor-mounted

inverter. The charger, manufactured by Power Conversion Products,

operates at 120 volts, 5 amps. The inverter was manufactured by Exide Power Systems, and operates at 105/140 volts dc input, 120 volts ac

output (Figure 16-5, upper photograph). The inverter was not anchored

during the earthquake and slid several inches. Both units were

undamaged by the earthquake.

The Pleasant Valley Pumping Plant recorded ground motion closest to the

epicenter of the 1983 Coalinga sequence of earthquakes. Strong motion

monitors are located in the station switchyard, as well as in the

basement, operating floor, and on the roof of the station building. The

monitor located in the switchyard (free-field) recorded an average

horizontal peak ground acceleration of 0.56g, with a duration of strong

motion of about 15 seconds.

The station includes two floor-mounted battery chargers. The chargers,

manufactured by Exide, are anchored with four 1/2-inch bolts in the corners of the cabinets. The units were undamaged by the earthquakes,

but there was evidence of impact with the adjacent wall.

The Devers Substation recorded an average horizontal PGA of 0.85g with a

duration of about six seconds, during the 1986 North Palm Springs

Earthquake. The site experienced from two to five times more motion

than its design basis, resulting in extensive damage to switchyard

equipment.

896/20c04c16/3 16-6 fE..

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-8 of 26

The substation control building is a one-story reinforced concrete-block

structure with a wood diaphragm roof. The station includes two battery

chargers and one inverter (Figure 16-6). The units were undamaged by

the earthquake and operated for two hours following the event.

Eventually, the batteries serving the inverter were exhausted and the

system switched off.

16.3 INSTANCES OF SEISMIC EFFECTS AND DAMAGE

The experience data base includes one instance of seismic damage to an

inverter that resulted in a loss of function and several instances of

seismic effects which did not dffect functionality.

At the Wells Fargo Data Processing Center, which experienced an

estimated PGA in excess of O.-3Og during the 1987 Whittier Earthquake,

one Uninterruptible Power Supply (UPS) unit sustained five blown fuses

following the earthquake (Figure 16-12). The blown fuses in the unit

caused a loss of emergency power to the facility.

The UPS is an Emerson "Acu-Power" which regulates incoming. ac power and

supplies emergency power to the facility. The system requires three

units in order to maintain full power. If less than three units are

available, overload breakers will actuate, and all UPS systems will

disconnect. At the time of the earthquake, one of the four UPS units

was down for maintenance; the remaining three units were operating to

supply ac power to the facility.

Approximately 4-1/2 hours following the earthquake, system problems in

the power grid caused a loss of offsite power. When power was lost to

the facility, one of the operating UPS units sustained five blown fuses.

The facility engineer and the manufacturer suggested threeý possible

explanations for the damage. When offsite power is lost, emergency dc

power is supplied by batteries. If one of the cells is not functional,

certain fuses within the UPS will blow in order to protect the more

valuable subcomponents. Another potential explanation is that power

surges occurred prior to the loss of offsite power, which could blow

896/20c04c16/3 16-7

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-9 of 26

fuses in the unit. A third and equally plausible explanation is that the UPS unit contained faulty fuses or other subcomponents.

At the Del Amo Substation, which experienced an estimated PGA of O.20g during the 1987 Whittier Earthquake, a battery charger was tripped by the actuation of a molded case, branch circuit breaker in the associated distribution panel (Figure 16-13). The distribution panel is a 110/220 volt dead front switchboard, manufactured by Square 0. The distribution panel is anchored with 1/2-inch bolts in the corners of the cabinet, and the adjacent cabinets in the assembly are bolted together. There is about a 1/2-inch clearance between the panel and the adjacent wall. The breaker actuation appears to be the result of impact of the panel with the wall.

At the California Federal Bank Data Processing Facility, an Emerson "Acu-Power" Uninterruptible Power Supply (UPS) pulled or sheared all of its anchor bolts (Figure 16-15). The unit was anchored with 3/8-inch shell type expansion anchors. The UPS was not damaged, in spite of a PGA in excess of 0.40g measured nearby.

At the Sanwa Bank Computer Facility, which experienced an estimated PGA of 0.40g during the 1987 Whittier Earthquake, two UPS units sheared their anchorage and slid about 12 inches during the earthquake. The cabinets were observed to have poor anchorage-concrete pad edge distance. The units remained functional.

No additional instances of seismically-induced damage to inverters and battery chargers were found in an extensive literature search/telephone

survey.

16.4 SOURCES OF SEISMIC DAMAGE

The seismic experience data base indicates that static inverters and battery chargers possess characteristics which generally preclude damage in earthquakes. With the exception of units with poorly designed

anchorage, the experience data base demonstrates no tendency for seismic

damage to static inverters and battery chargers.

896/20c04c16/3 16-8 F%

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-10 of 26

16.5 BIBLIOGRAPHY

1. "IEEE Standard for Qualification of Class 1E Static Battery

Chargers and Inverters for Nuclear Power Generating Stations."

n.d. IEEE Standard 650-1979.

2. Underwriters Laboratory Standard UL-1236. August 1978. "Electric

Battery Chargers." Northbrook, IL.

3. National Electrical Manufacturer's Association (NEMA) Standard

ICS-6. April 1980. "Enclosures for Industrial Controls and

Systems." Washington, DC

4. Ratelco Inc. June 1985. "Emergency AC Power: Count on It, with

Ratelco on Charge!" Power Systems Division.

5. Emerson Electric Co. April 1987. "AP300 Series 60 Hz

Uninterruptible Power System." Santa Ana, CA.

6. KW Control Systems, Inc. n.d. "Introduction to the Uniblock UPS

System." Middletown, NY.

7. Atlas Energy Systems. n.d. "The Atlas UPC/Unterruptible Power

Conditioner."

8. RTE DELTEC Corporation. 1985. "Uninterruptible Power Systems."

San Diego, CA.

9. Square D Company. November 1984. "DC to AC Sine Wave Inverters

Especially for Telecommunications Systems."

10. T. B. Wood's Sons Company. January 1986. "E-TRAC AC Inverter."

Chambersburg, PA.

11. Zenith Controls, Inc. n.d. "Zenith ZTS Transfer Switches."

Chicago, IL.

896/20c04c16/3 16-9

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-11 of 26

Li1 CHOKE

I( zlý

TIMER OR

MANUAL FLOAT EQUALIZE

SWITCH

GROUND DETECTION

SWITCH

FLOAT __1 VOLTAGE-CONTROL T

POWER TRANSFORMERV EQUALIZE VOLTAGE CONTROL

Courtesy Gould Incorporated

Figure 16-1: Typical wall-mounted solid-state battery charger.

896/20c04c16/3 16-10

U_

ooned/R740-ATB

lab

42074-R-004 Revision 0 September 23, 1991 Page B-12 of 26

fronsfer-Z- erfer con-ro-sed-ion

Figure 16-2:

896/20c04c16/3

Typical inverter.

16-11

Input filter /ocotin

Ac output filter

powertion

coned/R740-AT8

42074-R-004 Revision 0 September 23, 1991 Page B-13 of 26

Figure 16-3: Static inverters (upper photograph) and battery chargers (lower photograph ) in nuclear plant applications.

896/20c04c16/3 16-i2

coned/R740-ATB

A wall-mounted PR Industries battery charger Station.

Figure 16-4: Battery chargers Earthquake.

896/20c04c16/3

42074-R-004 Revision 0 September 23, 1991 Page B-14 of 26

at the Rinaldi Receiving

At the Sylmar Converter Station, Powertronic battery chargers are bolted to a steel frame that is bolted into the concrete floor.

at sites affected by the 1971 San Fernando

16-13

coned/R740-AT8

42074-R-004 Revision 0 September 23, 1991 Page B-1 5 of 26

This Exide inverter at the Main Oil Pumping Plant was unanchored at the time of the earthquake. It slid several inches without damage.

This small wall-mounted battery charger is bolted to the rear of a sheet metal cabinet at the Union Oil Plant.

Figure 16-5:

896/20c04c16/3

Battery chargers and inverters at near-field sites affected by the Coalinga sequence of earthquakes of 1983.

16-14

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-16 of 26

A) 4

... ..

Figure 16-6:

896/20c04c16/3

The Devers Substation includes an Elgar Inverter that was undamaged by the 1986 North Palm Springs Earthquake.

16-15

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 P•,B-17 of 26

S,4r,

The Rapel Hydroelectric Plant has approximately five AEG battery chargers and five AEI inverters, each anchored with four 3/8-inch anchor bolts.

I

Las Ventanas Power Plant contains at least two inverters manufactured by Solid-state Controls, Inc., each anchored with four 3/8-inch anchor bolts.

Figure 16-7:

896/20c04c16/3

Battery chargers and Chile Earthquake.

inverters at sites affected by the 198E

16-16

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991

S926

The battery charger at the Burbank Power Plant is bolted to steel channels that are anchored to the concrete floor with 1/2inch (est.) bolts.

SCI Inverter located in the basement at the Glendale Power Plant.

Figure 16-8:

896/20c04c16/3

Battery chargers and inverters at sites affected by the 1971 San Fernando Earthquake.

16-17

coned/R74M-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-19 of 26

This Elgar inverter, located at the Ormond Beach Power Plant, is bolted to steel angles that are anchored to the concrete floor with 5/8-inch bolts.

This C&D AutoReg battery charger is wall-mounted in Unit 3 (nuclear) of the Humboldt Bay Power Plant.

Figure 16-9: Battery chargers and inverters at sites affected by the 1973 Point Mugu Earthquake (upper photograph) and the 1975/1980 Humboldt earthquakes (lower photograph).

896/20c04c16/3 16-18

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991

These Exide battery chargers at the Metcalf Substation are anchored with four 1/2-inch bolts.

AIR battery charger at the Renca Power Plant.

Figure 16-10:

895/20c04ci6/3

Battery chargers at sites affected by the 1984 Morgan Hill Earthquake (upper photograph) and the 1985 Chile Earthquake (lower photograph).

16-19

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-21 of 26

Figure 16-11: Single enclosure UPS systems at Adak Naval Station. No units were damaged in the 1986 Adak, Alaska Earthquake.

896/20c04c16/3 16-20

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-22 of 26

The Wells Fargo Bank Computer Facility experienced an estimated average horizontal PGA in excess of O.30g during the 1987 Whittier Earthquake. There are four Emerson Acu-Power UPS units located on the fourth floor of the facility. One of the UPS systems sustained five blown fuses Following the earthquake.

896/20c04c16/3 16-21

ure 16-12:

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-23 of 26

Figure 16-13: At the Del Amo Substation, affected by the 1987 Whittier Earthquake, a battery charger (lower photograph) was tripped by the actuation of a molded case circuit breaker in the associated distribution panel (upper photograph). The breaker actuation was apparently the result of the panel impacting the adjacent wall.

896/20c04c16/3

coned/R740-ATB

16-22

S• •i•:•

42074-R-004 Revision 0 September 23, 1991 Page B-24 of 26

re 16-14: Examples of large capacity inverters, serving the UPS systems of the data processing centers, are found in the Emerson "Acu-Power" units at the Southern California Edison Dispatch Center, affected by the 1987 Whittier Earthquake.

896/20c04c16/3 16-23

coned/R740-ATB

42074-R-004 Revision 0 September 23, 1991 Page B-25 of 26

Figure 16-15: Anchorage failed on one of the Emerson "Acu-Power" inverters at the California Federal Savings Data Processing Center, during the 1987 Whittier Earthquake. The inverter slid about 2 inches, but was undamaged. The lower photograph shows anchor brackets, at thE base of the inverters, that were added immediately following the earthquake as a precaution against aftershocks. The remains of the original 3/8-inch expansion anchors are visible adjacent to the brackets.

896/20c04c15/3 16-24

coned/R740-ATB

CC

4. .4

C)i I LC uk

•0 - ýI.. • 1: .. ) C

Co . - . _ • C. ?•C ,r

•" .. ....... r ' ..

(Reference 4,Dawn o.921OF2X1)0

-~~~~~ -- ... . • ••o-- 00

"-0

•4 ' " .... LAM C"' ". .

:• :i.. "• - ' , . . . .

Figure 1. PAB Plan Views • (Reference 4, Drawing No. 9321-F-25 10) •

54 N

C

8

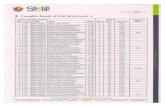

H go

* At th Well Faroo Bark Coute C or, a LkPS sygtem wtstakied &qe blown Iuhxa.

lndlaltaa A dmmoged uniA.

0

C)

0

(-4

I•

0W

Co

0

cc tu

ItJ

cc

0

cc 0

c4 C > X

cc

z

0 0.20g

400C 40 94 t4.4-0 C*0 f

al0.8Og

Figure 16-16: Selected inventory of static inverters and battery chargers within the seismic experience data base as a function of ground motion. All instances resulting in loss of function are indicated.

(gJn`

0.40g O.50g 0.60g

PEAK GROUND ACCELERATION (AVERAGE HORIZONTAL)

0.30g

Lfl

0.90g

M(0

(D 0 CD 4ý

03 ZI:0

1V-Ot1,L8/p0Uoo

£/9 tV0D0Z/962

Cr

CL0

*CD

"I

e- '

CD

LA -.,

-0

o M

(I

e-.

'* 0,

-4==

0.

=0~

= 0

S(0D

U

S0

o0

0

(0

mi

0 a z

0 0

-I"

z in

rn

0

0 z -'1

3-

0

0

0

0 (0=

0 .o 0

0

9Z .o 9Z-8 Ge~d L66tL '63 jeqwejdes

0 UOIS!A9eE tO0-1d-VLZOti,

NUMBER OF CHARGERS OR INVERTERS0

Adak Naval Station Las Ventanas Power Pant Renca Power Plant

Gates Substation Goleta Substation

::I: :: Glendale Power Plant Shurno•Bay Power Piant

Burbank Power Plant Mesquite Lake Facilty

Mesa Substation >& Metcalf Substation

Valley Steam Paant

Wels Fargo Computer Center*

n Substation .Rrnald Receivkig Station

SSylmar Converter Station Whitewater Hydroelectric Plant

7 SCE Dispatch Center J Pleasant Valley Pumping Plant

.Union XMain C~tzping Plants ~jSan Wdro Substation

F7 Ofinda Substation I C)

.z..1Devers Substation

SZ-91

42074-R-004 Revision 0 September 23, 1991 Page C- 1 of 5

APPENDIX C

COMPLETED SCREENING AND EVALUATION WORKSHEETS

coned/R740-ATC

42074-R-004 Revision 0 September 23, 1991 Page C-2 of 5

Revision 2 Status Y N U

SCREENING EVALUATION WORK SHEET (SEWS) Sheet 1 of 3

Equip. ID No. 2- Equip. Class 16 - Battery Charcers & inverters

Equipment Description BlqY/ve: y C •hg,Location: Bldg. F-• 7L. Floor El. 3 ' Room, Row/Col

Manufacturer, Model, Etc.

SEISMIC CAPACITY VS DEMAND 1. Elevation where equipment receves seismic input 2. Elevation of seismic input below about 40' from grade 3. Equipment has fundamental frequency above about 8 Hz 4. Capacity based on: Existing Documentation

Bounding :Spectrum GERS

5. Demand based on: Ground Spectra Amplified (Floor) Spectra

Does capacity exceed demand?

CAVEATS - BOUNDING SPECTRUM I. Equipment is included in earthquake experience

data base 2. Solid state type 3. For floor-mounted, transformer positively

anchored and mounted near base, or load path is U"' evaluated

4. Base assembly of floor-mounted unit properly braced or stiffened for lateral forces

5. For wall-mounted, transformer supports and bracing provide adequate load path to the rear cabinet wall

6. All latches and fasteners in doors secured 7. Anchorage adequate 8. Relays mounted on equipment evaluated -se.•. 9. No other concerns

Are the caveats met for Bounding Spectrum?

CAVEATS - GERS 1. Equipment is included in generic seismic test

data base 2. Meets all Bounding Spectrum caveats 3. Silicon-Controlled Rectifier (SCR) power controls;

wall- or floor-mounted NEMA-type enclosure

-3-3 1

) U N/A

AFS

O9N U

N/A N/A

N/A

U N/A

Y N 6ý) N If -)N

N N

U U U U U

7A) N/A N/A N/A

QDN U N/A

Y N U Y N U (ZA;

coned/R740-ATC

'j . " O'.J•

4.2074-R-004 Revision 0 September 23, 1991 Page C-4 of 5

Revision 2 SCREENING EVALUATTON WORK SHEET (SEWS) Sheet 3 of 3

Equip. 10 No. 3.~ Z Equip. Class 16 - Battery Charqers &-Inverters

Equipment Description &ý7T--gy

INTERACTION EFFECTIS (Cont'd) 4. No collapse of overhead equipment or

di stribution systems N U N/A 5. No other concerns N U N/A

Is equipment free of interaction effects? ON U

IS EQUIPMENT SEISMICALLY ADEQUATE? )N U

COM~MENTS

7-11e- 6J4 '9r ::ýr-rew I.S ýO~ raijoireeJ 40 ývc-c 4l-o.

7 I e s- 4 re, a )rsj no4 e i- tU 5 occ L)

7¾1- re- 5*..'s r a l it5. czr4te- n 4-t a i A A,,- 6- CLCC-1'6+ "' (/-~e-) 4 )E C"~

);jU wel 4 a -1 +L- 4xvo S'C-revi ar ,jk+4vJ 50i~;. C' "I hý .jJIM P4

Evaluated by: _____________________ at: ______

~KAO. Date:

coned/R74G-ATC

42074-R-004 Revision 0 September 23, 1991 Page C-5 of 5

Table 3-1

Unacceptable Relays (Appendix E of SQUG Relay Evaluation Procedure, MPR 1987)

Relay Operating Mode* References

GE CFD All

GE CFVB

GE CEH

GE CPD

GE IJD+ (none IE)

GE PVDII and PVD21

GE RAV11

GE HGA

W HLF

W HU (non 1E)

W ITH

W ARMLA W PMQ

W SG

ASEA ARMX-1

English Electric YCG+

Mercury Switches

Sudden Pressure Switches

Al I All

Al 1

All

All

All

(DE, NC)

All

All

All

All

All

(DE, NC)

All

All

All

1 (81-14/313, 82-26/348, 86-13/ 293),2, 3, 4, 5 (IN 85-82), 6

2, 3, 6

2, 6

2, 6

2

1 (84-20/352), 3, 4 (GE)

4 (GE)

1 (84-18/331, 86-15/269, 87-11/ 250), 4, 5 (IN 88-14)

2, 6

3, 6

1 (81-44/346 and 81-37/346)

5 (IN 82-55)

1 (85-16/247)

4 (ANCO)

1 (88-06/387)

2

1 (86-25/249), 2

2

REFERENCES:

1 LERS 2 Earthquake Experience Data 3 SAFEGUARDS Data 4 IEEE 501 Test Data 5 Notices, Bulletins, etc. 6 Induction Cup or Induction Cylinder Design * DE = DE-energized

E - Energized NC - Normally Closed Contact NO - Normally Open ALL - All Modes

+ Susceptible to damage; damage has occurred to this relay in an earthquake and it must be assumed that it will be inoperable following an SSE level earthquake.

960nb/chatch3 3-5

coned/R740-ATC

42074-R-004 Revision 0 September 23, 1991 Page D-1 of 34

ATTACHMENT D

BATTERY CHARGER ANCHORAGE EVALUATION

CONED/R740-ATD

42074-R-004 Revision 0 September 23, 1991 Page D-2 of 34

CALCULATION NO.:

PROJECT NUMBER/NAM

CALCULATION TITLE:

REFERENCES:

ATTACHMENTS:

TOTAL NUMBER

PREPARED BY:

CHECKED BY:

REVIEWED BY:

APPROVED BY:

CALCULATION COVER SHEET

4io74- c- oo4

IE: 47.7 P ~lc

A -925ll Z- A~io4RAtj- ýýVLUA 701,)

A I- A?! -3

OF PAGES (INCLUDING COVER SHEET)"

DATE: ,,, :- 3-9-i

DATE: -2- -1'!

DATE:

DATE: , 2-3-ri

DESCRIPTION REV. NO. DATE OF REVISION BY

923/calcov

CHECK REVIEW APPROVED

~i- -E:

CONED/R740-ATD

42074-R-004 Revision 0 September 23, 1991 Page D-3 of 34

EQE ENGINEEM1NG

CLIENT CX 6 z SUB&ECT 7~/¶2 ~ -~ /L

-74

+ 5, �CF�<c�Jczo5

SH~EET NO. z___

8y DATE _____,24

CHK'D WT- DATE 1-23-f)

3

3

(a

7

14- cm C tier- c Aec)Ja

A 7rA 6) jr4&1, T ::1 -7z ~ zO/ ~~~ 5L. 3 3

` %

CONED/R740-ATD

(2-i SY75

13 sb-15

42074-R-004 Revision 0 September 23, 1991

1______ Page D-4 of 34

EQEEIGNERNGSHEET;NO. ___

JOB NO.Z07 -:C8 P 5 ,5r~1.5mi V~zir1/::-r1QAj1s DATE____3

CLUENT S&ET y2 AI ý'~6~ CHK- Di:3 DATE ±3

(AL~ 44D n4 Y-c

I.JL c4e- 4); 0-/ý1 evaýuJ 4 -2 ;4J,10- ý-lr/

-4 f '

~ 2~~~~ZA -- ~~/(~7 'sLzJ6 7 ' 5/Cf

CONED/R740-ATO

C.

42074-R-004 Revision 0 September 23, 1991 Page D-5 of 34

EQE ENG~NEEP1NG

JOB NO -7___ JOB ,cai~~ /~~7 CLIENT !C-IA fc SUBJECT ~A6~2-) !A~~~AL

SHEET \4c.___

CHK'D ý/JblA- DATE LU

c - CA ý-C- u'

Sý4 Az I Lc0l/h aZS 4)W5

-F~-cM pjý- Ao l

Qt4$S

____ ___ ~ e 5-c

-305

(45",

-r�-�--� �.

3 60~ 4

-74-S

>105

-~~~, -2,~ 0~ (.) 4 ,/4, ±1,.~4

Pý 'ýIlja c e /?-rlýl Iy-4

4ý 3 0 0_

i~'a7- 2-~v Z j/ 7~~ -7f))

4-u Z L~

CONED/R740-ATO

/

7b

loc-r--leS ýý44Z-f-k/ ,me-Lr-

EQE ENGiNEERING

2CB NO.______ J08 2Y- 7ic:Vr/c72, CUJENT 6Pt>\ SUBJECT EA 77/ A~CZ-A5 AL,

(,ifx #-,'42ýD74- Oc4-0 L

F,- 7ý4/, -ýRclý ) 4,