Return Request: LRAFB Bldg. 214 Pro Insulation Various ...

Transcript of Return Request: LRAFB Bldg. 214 Pro Insulation Various ...

Comfort Systems USA (Arkansas), Inc. P.O. Box 16620

Little Rock, AR 72231 Phone 501-834-3320

Fax 501-834-5416

4806 Rixey Road No. Little Rock, AR 72117

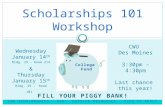

Date: 10/8/2020 Return Request: 10/22/2020 Project: LRAFB Bldg. 214 - Air Traffic Control Tower HVAC Supplier: Pro Insulation Manufacturer: Various Submittal: Piping Insulation Submittal Number: 23 07 19-01 Spec Section: 23 07 19, 2.01-2.03 Drawing # and Installation: Mechanical Drawings ARCHITECT ENGINEER Clements & Associates Energy Engineering Consultants, Inc. 507 Main Street 10 Corporate Hill Drive, Suite 100 North Little Rock, AR 72114 Little Rock, AR 72205 501-375-3380 501-244-0511 GENERAL CONTRACTOR MECHANICAL SUBCONTRACTOR HGL Construction Comfort Systems USA (Arkansas), Inc. 2000 S. Douglas Blvd. 4806 Rixey Road Midwest City, OK 73130 North Little Rock, AR 72117 405-869-4995 501-834-3320 Notes:

Pro Insulation 4414 South 16th Street Ft. Smith, AR 72901

Ph. 479-646-5644 Fax 479-646-5654

September 28, 2020 Comfort Systems USA, Inc. P.O. Box 16620 Little Rock, AR 72231 Mr. Tad Hankins Re: Mechanical Insulation Submittals for LRAFB B214, Jacksonville, Arkansas. No Spec Section. The following items will be insulated with Knauf Earthwool pipe insulation with ASJ + vapor barrier jacket. All fittings will have an additional PVC fitting cover. Item #1 Chilled Water---------------------------------------------------------------- 2” Thick

----Exterior will receive an additional .016 Smooth Aluminum Jacket------

Item #2 Heating Water---------------------------------------------------------------- 2” Thick ----Exterior will receive an additional .016 Smooth Aluminum Jacket------

Thank You, Chad Bartlett

Earthwool® 1000° Pipe Insulationwith ECOSE® Technology

DATA SHEET

DOING MORE FOR THE WORLD WE LIVE IN.

Knauf Insulation products with ECOSE® Technology are

made using our patented, bio-based binder - a smarter

alternative to the phenol/formaldehyde (PF) binder

traditionally used in fiberglass products. The bio-based

binder holds our product together and gives the product

its unique appearance.

All of our products are formaldehyde-free and made from

sustainable resources, such as recycled glass and sand.

And we’re proud to be putting glass bottles back to work

rather than into landfills. Our products are made with a

minimum of 50% recycled glass—totaling an average of

26 million bottles each month.

CONTRACTOR: ______________________________________

JOB: _______________________________________________

DATE: ______________________________________________

TECHNICAL DATA

Property (Unit) Test Performance

Corrosiveness ASTM C665 Does not accelerate corrosion of steel

Corrosion ASTM C1617 Pass

Maximum Service Temperature ASTM C411 + ASTM C447 1000° F (538° C)

Water Vapor Permeance ASTM E96, Procedure A 0.01 perms or less

Water Vapor Sorption (by weight) ASTM C1104 Less than 5%

Shrinkage ASTM C356 Negligible

Mold Growth ASTM C1338 Pass

Surface Burning Characteristics(flame spread/smoke developed)

ASTM E84, UL 723, CAN/ULC S102 UL/ULC Classified FHC 25/50

DESCRIPTION

Earthwool 1000° Pipe Insulation is a molded, one-piece

insulation made from highly resilient, inorganic glass fibers

bonded with ECOSE Technology.

APPLICATION

• Iron, copper, stainless steel, PVC, and CPVC piping

• Hot, cold, concealed and exposed piping systems operating

at temperatures 0° F-1000° F (-18° C to 538° C)

• Additional weather protection is needed for outdoors use

SPECIFICATION COMPLIANCE

U.S.

• ASTM C547; Type I, Type IV

• ASTM C585

• ASTM C1136 (jacket); Type I, II, III, IV, VII, VIII, X

• NFPA 90A and 90B

• Conformity for fit Marine Equipment IMO 1408

• MIL-DTL-32585; Type 1, Form 4, Facing A and D

• USCG 164.109/4/1

• UL/ULC Classified

• ASTM C795, MIL-I-24244, NRC Reg. Guide 1.36

(Certification needs to be specified at time of order)

Canada

• CAN/ULC S102

• CGSB 51-GP-9M

• CGSB 51-GP-52M (jacket)

• CAN/CGSB-51.9 (obsolete, replaced by ASTM C547)

INDOOR AIR QUALITY

• UL Environment

• GREENGUARD Certified

• GREENGUARD Gold Certified

• Validated to be Formaldehyde-Free

• Does not contain polybrominated diphenyl ethers (PBDE)

such as: Penta–BDE, Octa–BDE or Deca–BDE

• EUCEB Certified

• IgCC Section 806.6 compliant

PRODUCT FORMS AND SIZES

• Produced in 3' (914 mm) sections

• For iron pipe ½" – 24" (15 mm – 610 mm) nominal pipe

size

• For copper tube 5⁄8" – 61⁄8" (16 mm – 156 mm)

• All insulation inner and outer diameters comply with

ASTM C585.

• Wall thicknesses from ½" to 6" (13 mm to 152 mm) in

single layer for most sizes

• With or without a white, factory-applied jacket, ASJ+ (all-

service jacket) is composed of aluminum foil, reinforced

with a glass scrim bonded to a kraft paper interleaving with

an outer flim layer leaving no paper exposed.

• A matching ASJ+ butt strip is supplied for each section

• The longitudinal lap of the jacket has the SSL+ self-sealing

lap that creates a strong and lasting bond

Packaging

• Four carton sizes for easy ordering, inventory tracking

and storage

• Reinforced carton handles for strength and easy lifting

• Bar-coded cartons for accurate shipments and tracking

• Full product range stocked at distributors for fast availability

THERMAL CONDUCTIVITY | ASTM C335

Mean Temperature k k (SI)0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0.101

0.087

0.072

0.058

0.043

0.029

0.014

0 100 200 300 400 600 (° F)

-18 38 93 149 204

500

260 316 (° C)

MEAN TEMPERATURE

THER

MA

L C

ON

DU

CTI

VIT

Y(B

TU •

IN

/HR

• F

T² •

°F)

THER

MA

L C

ON

DU

CTI

VIT

Y(S

I U

NIT

S)

(W/M

• °

C)75° F (24° C) 0.23 0.033

100° F (38° C) 0.24 0.035

200° F (93° C) 0.28 0.040

300° F (149° C) 0.34 0.049

400° F (204° C) 0.42 0.061

500° F (260° C) 0.51 0.074

600° F (316° C) 0.62 0.089

ASHRAE 90.1-2016 REQUIREMENTS

MINIMUM PIPE INSULATION THICKNESS

Fluid Operating Temperature Range

and Usage

Insulation Conductivity Nominal Pipe or Tube Size

Conductivity Range BTU-in./(hr ∙ ft² ∙ °F)

Mean Temperature Rating

<1" 1"–<1½" 1½"–<4" 4"–<8" ≥8"

Heating and Hot Water Systems (Steam, Steam Condensate, Hot-Water Heating and Domestic Water Systems)a, b, c, d

Above 350° F 0.32–0.34 250° F 4½" 5" 5" 5" 5"

251–350° F 0.29–0.31 200° F 3" 4" 4½" 4½" 4½"

201–250° F 0.27–0.30 150° F 2½" 2½" 2½" 3" 3"

141–200° F 0.25–0.29 125° F 1½" 1½" 2" 2" 2"

105–140° F 0.22–0.28 100° F 1" 1" 1½" 1½" 1½"

Cooling Systems (Chilled Water, Brine, Refrigerant) a, b, c, d

40–60° F 0.21–0.27 75° F ½" ½" 1" 1" 1"

Below 40° F 0.20–0.26 50° F ½" 1" 1" 1" 1½"

a. For insulation outside the stated conductivity range, the minimum thickness (T) shall be determined as follows: T=r{(1+t/r)K/k-1}, where T=minimum insulation thickness (in.), r=actual outside radius of pipe (in.), t=insulation thickness listed in this table for applicable fluid temperature and pipe size, K=conductivity of alternate material at mean rating temperature indicated for the applicable fluid temperature {Btu ∙ in.(h ∙ ft² ∙ °F)}; and k=the upper value of the conductivity range listed in this table for the applicable fluid temperature. b. These thicknesses are based on energy efficiency considerations only. c. For piping smaller than 1½" and located in partitions within conditioned spaces, reduction of these thicknesses by 1" shall be permitted (before thickness adjustment required in footnote a) but not to thicknesses below 1". These thicknesses are based on energy efficiency considerations only. Issues such as water vapor permeability or surface condensation sometimes require vapor retarders or additional insulation. d. The table is based on steel pipe. Non-metallic pipes schedule 80 thickness or less shall use the table values. For other non-metallic pipes having thermal resistance greater than that of steel pipe, reduced insulation thicknesses are permitted if documentation is provided showing that the pipe with the proposed insulation has no more heat transfer per foot than a steel pipe of the same size with the insulation thickness shown on the table.

PRECAUTIONS

Hot Pipe

• May be installed while the system is in operation, at all

temperatures up to 1000° F (538° C).

• Knauf Insulation recommends, for insulation thicknesses

greater than 6" (152 mm), the temperature must be

increased from 500° F (260° C) to maximum temperature at

a rate not exceeding 100° F (37.8° C) per hour.

• During initial heat-up to operating temperatures above

350° F (177° C), a slight odor and some smoke may be

given off as a portion of the bonding material used in the

insulation begins to undergo a controlled decomposition.

• If natural convection is not adequate in confined areas,

forced ventilation should be provided in order to protect

against any harmful fumes and vapors that might

be generated.

• Care must also be taken when using sealants, solvents or

flammable adhesive during installation.

• A maximum of 6" (152 mm) wall thickness

is recommended.

Cold Pipe

• Use a continuous vapor retarder on piping operating below

ambient temperatures.

• Seal all joints, surfaces, seams and fittings to

prevent condensation.

• On below freezing applications, and in high-abuse areas, the

ASJ+ jacket shall be protected with a PVC vapor retarding

outer jacket. In addition, exposed ends of insulation shall

be sealed with vapor barrier mastic installed per the mastic

manufacturer’s instructions. Vapor seals at butt joints

shall be applied at 12' to 21' intervals; at the Engineer’s

discretion and at each fitting to isolate any water incursion.

• On chilled water systems operating in high humidity

conditions, it is recommended that the same guidelines be

followed as listed above for below freezing applications.

• Exterior hanger supports are recommended.

Outside Application

• Do not expose pipe insulation to weather. It must be

covered with appropriate jacketing, mastic or vapor

retardant coatings.

• All exposed surfaces must be protected. Proto® Indoor/

Outdoor PVC Jacketing is recommended. See Knauf

Insulation Guide Specifications for recommended PVC

jacketing application guidelines.

• Apply jacketing, mastics or vapor retardant adhesives per

manufacturer’s instructions.

• For metallic jackets, factory-applied moisture retarders are

recommended.

ASJ+ SSL+

• Keep adhesive and contact surfaces free from dirt and

water. Seal immediately once adhesive is exposed.

• Apply when ambient and insulation temperatures are

between 20° F and 130° F (-6.7° C and 54° C).

• If stored below 20° F or above 130° F, allow insulation

cartons to stand within recommended temperature range for

24 hours prior to application.

• Do not store product below -20° F (-29° C) or above

150° F (66° C).

• When using Knauf Insulation’s SSL+ Advanced Closure

System, make sure the longitudinal and circumferential

joints are properly sealed by rubbing the closure firmly with

a squeegee. Use of staples is not recommended.

• When using Earthwool® 1000° pipe insulation, the surface

temperature of the ASJ+ facing should not exceed 150° F

(66° C).

Fittings and Hangers

• Use Proto 25/50 Rated (ASTM E84) PVC Fitting Covers,

applying PVC fittings per Proto’s Data Sheet.

• Fittings should be insulated to same thickness as the

adjoining insulation.

• Apply fittings per manufacturer’s instructions.

• When required by specification, a hard insert of

sufficient length should be used to avoid compression of

the insulation.

APPLICATION GUIDELINES

Storage

• Protect insulation from water damage or other abuse,

welding sparks and open flame.

• Cartons are not designed for outside storage.

Preparation

• Apply only on clean, dry surfaces

• Pipe or vessel should be tested and released before

insulation is applied.

General Guidelines

• All sections should be firmly butted.

• Seal circumferential joint with a minimum 3" (76 mm) wide

butt strip.

• Jackets, coating and adhesives should have a comparable

F.H.C. rating.

• ASJ+ may be painted. As with traditional ASJ, Knauf

Insulation does not encourage the painting of ASJ+ because

the application of any paint may change the surface burning

characteristics and will void the UL Classification and Knauf

Insulation Limited Warranty.

Insulation Limited Warranty

• Where painting is necessary, use common water, oil,

or solvent-based paints. All paints should be tested for

compatibility and adhesion before use.

• All piping should have continuous insulation.

• Position longitudinal lap downward to avoid dirt and

moisture infiltration.

• Do not expose pipe insulation to excessive vibration or

physical abuse.

• Faced insulation should not have a facing temperature

above 150° F (66° C).

SSL+ Installation Instructions:

• To install SSL+, first remove the kraft release liner to

expose adhesive.

• Carefully align the jacketing. Starting in the center of the

insulation section, begin initial SSL+ tack using pressure

in the direction of the overlap. Again, starting in the center

of the insulation section, with a plastic squeegee begin to

apply firm pressure to the bonded lap area swiping from the

center of the insulation section toward each end.

• Note: After initial SSL+ adhesive tack, it is critical that

the closure is not re-opened and repositioned on the

facing. Doing so will delaminate the jacket and adhesive,

diminishing the bond strength.

Butt Strip Installation Instructions:

• To install Butt Strips, remove the kraft release liner by

separating the butt strip from the kraft using the convenient,

easy release kiss cut.

• Simply wrap the butt strip, centered around the joint, and

apply firm pressure with a squeegee.

• Note: After initial Butt Strip adhesive tack, it is critical

that the closure is not re-opened and repositioned on the

facing. Doing so will weaken the adhesive and diminish

bond strength.

Recommended Thicknesses (ASHRAE 90.1-2016)

The minimum thicknesses are based on ASHRAE 90.1-2016

standards and do not necessarily represent the Economic

Thickness of Insulation or the thickness required for proper

condensation control. Rather, they serve as minimum

recommendations for commercial applications. For recommended

Economic Thickness, install according to Knauf Insulation or

NAIMA 3E Plus programs or as specified.

FIBERGLASS AND MOLD

Fiberglass insulation will not sustain mold growth. However,

mold can grow on almost any material when it becomes wet

and contaminated. Carefully inspect any insulation that has

been exposed to water. If it shows any sign of mold it must be

discarded. If the material is wet but shows no evidence of mold, it

should be dried rapidly and thoroughly. If it shows signs of facing

degradation from wetting, it should be replaced.

CERTIFICATIONS

KNAUF INSULATION, INC.One Knauf Drive

Shelbyville, IN 46176

Technical Support(317) 398-4434 ext. 8727

01-20

© 2020 Knauf Insulation, Inc.

Check with your Knauf Insulation Territory Manager to ensure information is current.

The chemical and physical properties of this product represent average values determined in accordance with accepted test methods. The data is subject to normal manufacturing variations. The data is supplied as a technical service and is subject to change without notice. References to numerical flame spread ratings are not intended to reflect hazards presented by these or any other materials under actual fire conditions.

This product is covered by one or more U.S. and/or other patents. See patent www.knaufnorthamerica.com/patents

Visit knaufnorthamerica.com to learn more.

FEATURES: BENEFITS:

• •

• •

• •

• •

• •

• •

•

CONSTRUCTION:

Carrier:

Foil Laminate

Adhesive:

COLD TOUGH™ Acrylic

Liner:

Densified Kraft

LEED® Point Contributor

Flame Spread 20

Smoke Developed 10

722S

UL 723 Recognition under File No. BVYS.R7078 Made in the USA

UL ULC S102 Recognition under File No.

BVYS7.R7078

UL 723

* Contributes to Energy Atmosphere (SA) Credit 1

* Contributes to Indoor Environmental Quality (IEC) Credit 4.1

General Use Tape Surface Burning

Characteristcs to

Meets ASTM C-1136 Type I, Type II, Type III and Type IV Foil laminate facing (30J) is decaBDE free

PSA complies with South Coast Air Quality

Management District's (SCAQMD) Rule 1168.

Excellent initial tack and long-term adhesion

High strength reinforced facestock. All weather acrylic insulation sealant tape

Application temperature as low as 0º F

FASSON® 0838

Closure system tape with Lamtec ASJ 30J insulation facing

Specially formulated antimicrobial, extreme weather,

COLD TOUGH™ acrylic adhesive

Excellent bond to Lamtec ASJ 30J insulation facing

Excellent adhesion and quick stick

Adhesive Properties:

Thickness Test Method(s): PSTC-133

Liner:

Adhesive:

Carrier:

Total Caliper:

PEEL ADHESION Test Method(s): PSTC-101, ASTM D-3330, STD-10

Product 180º 12" min

Substrate

SS

LOOP TACK Test Method(s): PSTC-16, STD-7

Product 180º 20" / min

Substrate

SS

TENSILE Test Method(s): PSTC-131, ASTM D-882, STD-3A,B,C

Product

Substrate

Product

ELONGATION Test Method(s): PSTC-131, ASTM D-882, STD-3A,B,C

Product

Substrate

Product

TLMI RELEASE Test Method(s): PSTC-4, STD-8

Product 90º 300" / min

Substrate

VOC CONTENT

Product

Substrate

Product

TEMPERATURES

Min Application Temp

Max Continuous Operating Temp

Max Intermittent Operating Temp

APPLICATION TECHNIQUES

• It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied be clean, dry, and free of grease or oil

• Bond strength is dependent upon the amount of adhesive-to-surface contact developed

• Note that different pressure, time and temperature on different (film / rigid) surface achieves different performance

STORAGE / SHELF LIFE

• One year when stored at 64-72ºF (18-22ºC) / 30-70% relative humidity, out of direct sunlight and in original packaging.

Phone: +86 512 57155001

Fax: +86 512 57155059

CD

FASSON® 0838

Typical Values

Lbf / In N / MeterUS Oz / In

CD

-17 º C

8755

1

%

US Oz / In N / Meter

Lbf / In

º F

North America

© 2016 Avery Dennison Corporation. All rights reserved. Avery Dennison® is a registered trademark of Avery Dennison Corporation. All other Avery Dennison

brands, product names, antenna designs and codes or service programs are trademarks of Avery Dennison Corporation.

Gf / 2 In w

Initial 50.0

MD

44077 USA

Please refer to Tapes.AveryDennison.com for complete terms and conditions, including warranty terms, relating to this product. You should periodically review

the site as terms and conditions are subject to change without notice.

4.8 77 840

50.0 800

9631

Lbf / In

Asia Pacific

135 º C

Painesville, Ohio

0 º F

200 º F

275 º F

g / L

< 15

Fax: +1 888-358-4469

Kunshan, China, 250 Chester Street

NO. 618 Nanhe Road

Kunshan Economic &

Technological Zone

China, 215335

Phone: +1 866-462-8379

Initial

96

THE LISTED VALUES ARE TYPICAL AND NOT INTENDED TO SERVE AS PRODUCT SPECIFICATIONS

N / Meter

6.0 1051

1

93 º C

MD 55.0 880

Initial

º C

US Oz / In

0.36

US Mils

3.6

1.7

9.0

14.3

Microns (µm)

91

43

228

363

MM's

0.09

0.04

0.23

Europe

Tieblokkenlaan 1

B-2300 Turnhout

Belgium

Phone: +32 (0)14 40 48 11

Fax: +32 (0)14 40 48 55

25/50 Smoke-Safe™ PVC specification data

Cleveland: 1 800 551 9759 | Greensboro: 1 800 551 9760 Stockton: 1 800 833 4500 | La Porte: 713 670 9700www.speedlinepvc.com

ApplicationsSpeedline® Smoke Safe™ PVC Insulated Fitting Covers and Jacketing are designed for indoor and outdoor* applications in commercial, institutional and industrial facilities.

■ Speedline® Smoke Safe™ PVC Fitting Covers are designed to cover pipe fittings and other mechanical equipment with an outside diameter of 1-5/8” up to 24” in accordance with ASTM C-585. For outdoor use and in high abuse areas, .030 is recommended. For straight runs of piping, expansion joints should always be used to prevent product failure.

■ Speedline® Smoke Safe™ PVC jacketing is suitable for covering all flat and round surfaces such as ductwork, tanks and other mechanical equipment. On vessels larger than 24" OD a minimum of .040 Jacketing should be used. For OD's larger than 48", Speedline flat jacketing is not recommended. Due to the expansion and contraction of tanks and vessels, expansion joints should always be used to prevent product failure.

■ The Speedline® Smoke Safe™ PVC Jacketing System has an application temperature range of -35°F to 500°F (-37°C to 260°C). The PVC surface should remain below 150°F (66°C) through the installation of sufficient insulation on higher temperature applications.

The Speedline® Smoke Safe™ PVC Insulated Fitting Covering System consists of preformed gloss white outdoor weatherable and gloss colored insulated covers for piping fittings. Their unique shapes fit screwed, Victaulic®, welded and flanged elbows, tees, valves, couplings, laterals, reducers and endcaps.

The Speedline® Smoke Safe™ PVC Jacketing System consists of gloss white outdoor weatherable and colored PVC sheet in either bulk rolls or precurled cut-to-fit pipe sizes. The White Jacketing is available in .010”, .015”, .020”, and .030” thicknesses.

The Jacketing and Fitting Covering Systems include solvent weld adhesives, stainless steel tack fasteners, silicone caulking and adhesive tapes. A die-cut multi-temperature fiberglass insulation insert is available and sized for a full insulation over the exposed pipe fitting and under the overlay of the PVC Fitting Cover.

Specification ComplianceASTM D 1784, Cell Class 16354, Federal Specification HH-I-558, Form B, Type 1 Class B (Insert Insulation) USDA and FDA for use in food processing, beverage, and pharmaceutical facilities Military Spec LP-1035A, Type II Grade GU Military Spec LP-535E, Type II Grade GU New York City MEA 402-07-M, Agriculture Canada, Canada: CGSB 51.53-95

■ Easy Installation - the unique shapes make an easy seal over an entire mechanical system

■ Clean, neat and attractive appearance due to the high gloss PVC surface

■ Low maintenance

■ Corrosion resistance

■ Outdoor weatherability* (UV stable)

■ The 25/50 fire class of all Speedline® Smoke Safe™ products provides greater universal building code acceptance

■ Provides a natural barrier to moisture, bacteria and mold

* Colored fitting covers and jacketing are NOT recommended for outdoor use.

Chemical ResistanceInorganic AcidsSulfuric, nitric, hydrochloric, hydrofluoric (diluted or concentrated):

Excellent

Organic AcidsFormic, acetic and propionic Poor

AlkaliesSodium and potassium hydroxides ExcellentAmmonium hydroxide ExcellentCaustic Soda ExcellentSoda Ash Excellent

Miscellaneous Corrosive ChemicalsPhenol, resorcinol and creosol PoorIodine, crystals FairIodine, tincture ExcellentChlorine and bromine water ExcellentPotassium dichromate ExcellentSilver nitrate ExcellentTannic acid Excellent

Solvent and DilutentsAlcohol and polyalcohols, including ethyl methanol, butanol and isopropyl alcohol

Excellent

KetonesLower boiling ketones DissolvesHigher boiling ketones Swells

EthersEthyl SoftensDichlorethyl ether SwellsDiethyl cellosolve SwellsDioxane DissolvesPropylene oxide Dissolves

HydrocarbonsAromatics as gasoline, kerosene and petroleum oils

Excellent

Oils, Fats and WaxesAnimal, mineral and vegetable Excellent

25/50 Smoke-Safe™ PVC specification data

Physical Properties

Property Test Method Value

Speedline® Smoke Safe™ PVC

Flame Spread ASTM E84 25 or less

Smoke Developed ASTM E84 50 or less

Specific Gravity ASTM 792 1.46

Tensile Strength @ yield lb./in.2 ASTM D638 7,000

Tensile Modulus PSI ASTM D638 400,000

Izod Impact- ft.lb./in. ASTM D256 15.0

Permeance @ .030”WVTR @ .030"

ASTM E96ASTM E96

.03

.014

Permeance @ .020”WVTR @ .020"

ASTM E96ASTM E96

.05

.021

Electrical Conductance ASTM D257 None

Fiberglass Insulation

Flame Spread ASTM E84 25 or less

Smoke Developed ASTM E84 50 or less

Thermal Conductivity (75°F/24°C) ASTM C177 0.26

Specification Data Hot SystemsAll piping fittings shall be insulated by filling the total void over all fittings, between straight runs of pipe insulation, with Speedline® die-cut fiberglass insulation, forming a uniform insulation thickness equal to or exceeding the adjacent pipe insulation. Finish all insulated pipe fittings by applying Speedline® Smoke Safe™ PVC Fitting Covers overlapping the adjacent pipe insulation outer covering. Secure the Speedline® Fitting Covers with Speedline® Stainless Steel Tack Fasteners, Speedline® PVC Tape or by welding PVC overlaps with Speedline® Solvent Weld Adhesive. Caution should be exercised to be sure that the insulation surface temperature is maintained below 150°F (66°C) through the application of sufficient insulation under all PVC Covering.

Cold SystemsAll piping fittings shall be insulated by filling the total void over all pipe fittings between straight runs of pipe insulation with Speedline® die-cut fiberglass insulation, forming a uniform insulation thickness equal to, or exceeding, the adjacent pipe insulation. Finish all insulated pipe fittings by applying Speedline® Smoke Safe™ PVC Fitting Covers overlapping the adjacent pipe insulation outer covering. The overlap of the throat of the PVC Fitting Cover and the ends of the Fitting Cover overlapping the adjacent pipe insulation vapor barrier jacketing shall be vapor sealed with compatible vapor barrier mastic. The ends of the PVC Fitting Cover overlapping the adjacent pipe insulation shall be further sealed by an outer wrapping of Speedline® PVC Tape extending over the adjacent pipe insulation vapor barrier jacketing and overlapping its own circumferential juncture by at least two inches in the downward direction on the downward side.

Cleveland: 1 800 551 9759 | Greensboro: 1 800 551 9760 Stockton: 1 800 833 4500 | La Porte: 713 670 9700www.speedlinepvc.com

LoSmoke® PVC Jacketing and Fittings Submittal Sheet

DESCRIPTION The Proto Fitting Cover System consists of one or two piece pre-molded high impact, UV resistant, LoSmoke® PVC fitting covers with or without formaldehyde free fiberglass inserts and accessories. This product line is designed to cover all standard and specialty fittings; which include elbows, tee/valves, end caps, mechanical line couplings, and many more. When combined with our PVC jacketing and solvent welding adhesive or tape, our PVC fitting covers form a completely sealed system that may be used for below ambient applications. Colored PVC is manufactured from a LoSmoke® formula that is suitable for indoor use only.

AVAILABLE FORMS Thickness: Standard and Heavy Duty

Fitting Covers: 45° and 90° small and long radius, tees, valves, flanges, reducers, end caps, traps, mechanical groove - fittings and many more

Jacketing: PVC rolls and cut and curl are available in thickness ranging from 10 to 40 mil at a 35 1/2” and 48” width

OPERATING TEMPERATUREPVC: -20° F (-29° C) to 150° F (66° C) (exposed surface)Inserts: - 20° F (-29° C) to 1000° F (538° C)

PHYSICAL PROPERTIESSpecific Gravity (ASTMD-792) 1.41

Tensile Modulus, PSI (ASTMD-638) 361,000 (25,380kg/cm2)

Tensile Strength, PSI (ASTMD-638) 6,011

Flexural Strength, PSI (ASTMD-790) 9,396

IZOD Impact (1/4”) ft. lb./in(ASTMD-256) 3.7Heat Deflection Temp. (ASTMD-648)

@ 264 PSI (8.95 kg/cm2)157° F (70° C)

VICAT Softening Temp. (ASTMD-1525) 198° F (92° C)

Permeance (WVTR) 0.015” thick ≤0.058

ASTM E E96 0.020” thick ≤0.047

Procedure A Perm, (grains/hr-ft2in Hg) 0.030” thick ≤0.027 Tested over code compliant

Vapor barrier* 0.02” thick ≤0.02

*ASTM C1136@ ≤ 0.02 perm

ASTM E 84 and CAN/ULC S102 Flame ≤25

Surface Burning Characteristics Smoke ≤50

Puncture Resistance (ASTMD781) 0.006” thick 178 Beach Units

0.015” thick 221 Beach Units

Electrical resistance Non-conductor

ASTM E84 Surface burning characteristics

ASTM E136 Non-combustibility (insert only)

ASTM C-585 Standard dimensions for pipe

ASTM 1784 Specification for rigid PVC

ASTM C1338 Fungi test

ASTM G21 & G22 Fungi and bacteria test Federal Specification

LP-1035A Federal standard PVC - Type II Grade GU

LP-535E US Army standard PVC - Type II Grade GU

USDA United States Department of Agriculture

New York City MEA Toxicity

Canada

CAN/CGSB – 51.53.95 PVC Jacketing

CAN/ULC S102 Surface burning characteristics

Agriculture Canada

ICC International code council

IBC International building code

IMC International mechanical code

Manufacturing Location Clearwater, FL

Recycled Content Pre 55+%

CA 1350 - VOC Pass office and School

Berkeley Analytical Cert NO 160504 – 10

LEED Credits per V4Contributes EA, MR, EQ(See Proto LEED credit guide)

RoHS Heavy metal compliant

DecaBDE ≤0.01% Pass State of Oregon

Rigid PVC No plasticizers or phthalates

SPECIFICATION COMPLIANCE

GREEN BUILDING ATTRIBUTES

Revised 5/19PTB04

protocorporation.com

INSERTS Formaldehyde free precut fiber glass inserts save time and labor and are an integral part of our LoSmoke PVC fitting system. This 1000° F rated, 1 pcf dense, insulation classified as noncombustible, meets all fungi and corrosion resistance criteria and design requirements of ASHRAE 90.1-10. The product is designed to be installed using one insert per each inch of installed pipe insulation thickness.

Specification compliance:ASTM C553, ASTM C547, C665, C1338, C1617, C795, ASTM E84,

ASTM E136

ASHRAE 90.1

ASTM E84 & CAN ULC S102

GREENGUARD: Gold

Recycled content: 53% pre and post

consumer content

Decabrom free

F° C° BTU in/sq ft hr F W/M C

75 24 0.23 0.033

150 66 0.27 0.039

300 40 0.4 0.058

Mean Temperature K value

INSERT COMPRESSED THERMAL CONDUCTIVITY

Storage:Protect cartons from water damage or other abuse. Proto cartons are not designed for outside storage.

Preparation:Proto fitting covers and inserts should be applied on a clean, dry surface.

Above ambient – General installation:A Proto fiberglass insert shall be wrapped completely around the metal fitting leaving no voids or open spaces. A loose wrapping of twine or tape may be helpful to hold insulation in place. The Proto Fitting Cover shall then be applied over the insert, and secured by using serrated stainless steel tacks or by taping.

Cold pipe:Fitting systems below ambient temperature must have a continuous vapor retarder or vapor retardant mastic as specified by the engineer. When using Proto PVC Tape, a 2” (51mm) minimum downward overlap is recommended for optimum performance. Care should be taken not to stretch the last 2” (51mm) of Proto PVC Tape, to avoid stretching or creeping.

Hot system:Use proper insulation thickness to ensure PVC covers are kept below 150°F (66°C). PVC jackets and fitting covers should be kept away from direct contact or exposure to radiated heat. For conditions where operating temperatures exceed 250°F (121°C) or where pipe insulation thickness is greater than 1” (25.4mm), two

or more layers of insulation inserts are required beneath the fitting cover.

Refrigerant Systems and/or Cold Systems In Severe Ambient Conditions:An intermediate layer of low perm facing or vapor-compatible mastic with PVC is required to completely seal the insulation prior to installing the PVC fitting cover. Vapor barrier mastic should be applied between the pipe insulation and the insert, fitting cover, throat of the fitting cover, and overlap seam.

Totally Sealed Systems (USDA): 20 mil (0.5 mm) minimum LoSmoke PVC jacketing should be applied to pipe insulation in conjunction with LoSmoke PVC fitting covers. Circumferential and longitudinal jacketing and fitting cover seams should be sealed with solvent welding adhesive. Circumferential seams should be a minimum of 1 ½” - 2” (38mm to 51mm) overlap and longitudinal seams should be 11⁄2”- 2” (38mm to 51mm) overlap (with 6-8 inches for expansion joints). All seams should visually be checked for seal and, if necessary, repaired. Slip joints will be required between fixed supports and on continuous long runs of straight piping.

Outdoors (for white only):Proto PVC Jacketing thickness for outdoor applications should be a minimum of 0.030” (0.8 mm) and 0.040”(1.0 mm) for any O.D. over 15”. The PVC Jacketing shall be overlapped a minimum of 2” (51 mm) on the down side so as to shed water. All longitudinal and circumferential joints shall be completely weather sealed with caulk adhesive. Additionally, a slip type expansion joint of 8” (202 mm) minimum width shall be applied at least every 25 lineal feet (6.1 lineal meters) and between fittings.

APPLICATION FOR USE

The physical and chemical properties of Proto Corp. PVC represent typical average values obtained in accordance with accepted test methods and are subject to normal manufacturing variations. They are supplied as a technical service and are subject to change without notice. Numerical flame spread rating is not intended to reflect hazards presented by this or any other materials under actual fire conditions. Check with Proto Corp. office to assure current information. Purchaser will be responsible to determine suitability of this product for purchaser’s use. Proto Corp. liability will be limited to the purchase price of the material. No person is authorized to alter this without a Proto Corp. officer’s written approval.

Revised 5/19PTB04

10500 47th Street North, Clearwater, FL 33762-5017Toll Free: (800) 875-7768 | Office (727) 573-4665 | Fax: (727) 572-6823 | www.Protocorporation.com

©2015 ITW Insulation Systems 800-231-1024 ACCS-0915 Pabco / Childers Metal www.itwinsulation.com Supercedes ACCS-0513

*Trademark of DuPont 2.10

ALUMINUM ROLL JACKETING

(cladding)

DESCRIPTION ITW Pabco/Childers Aluminum Jacketing is the premier protective outer surface for mechanical insulation systems including pipe, vessels, and equipment. It protects the insulation and underlying pipe/vessel from physical damage, UV exposure, corrosive atmospheres, and water. ITW Aluminum jacketing (also called cladding) is available in smooth, stucco embossed, and 3/16 corrugated (cross-crimped) finishes. For larger surfaces, box-rib and deep corrugated sheets are also available. ITW Aluminum Jacketing has a bare outer surface and comes standard with a 3-mil thick polyfilm moisture barrier heat-laminated to the interior surface to help prevent corrosion of the jacketing and the underlying metal pipe, vessel, or equipment. COMPOSITION Commercially pure aluminum is relatively soft and less suited for use in this application. Its strength can be greatly improved by alloying with small percentages of one or more other elements such as manganese, silicon, copper, zinc, and magnesium. Additional strength can be achieved by cold working. ITW Insulation Systems carefully screens all potential aluminum coil suppliers to assure our products have the highest quality, are corrosion resistant, and comply with all relevant standards. ITW Aluminum Jacketing is typically manufactured using alloys 3105 or 3003 which have very similar composition and performance and are considered interchangeable for use as insulation jacketing. ITW reserves the right to ship whichever alloy is in stock at the time of order placement. One of these two specific alloys or an alternative alloy can be specified by purchaser at time of order placement but this may affect minimum quantity, lead-time, and price. Composition Differences in Aluminum Alloys (%)

Alloy Cu Mn Mg Zn 3105 ≤ 0.3 0.3-0.8 0.2-0.8 ≤ 0.4 3003 0.05-0.2 1-1.5 --- ≤ 0.1

COMPLIANCE TO STANDARDS All bare and polyfilm lined Aluminum Jacketing from ITW Insulation Systems complies with the requirements of ASTM C1729 (Aluminum Jacketing

Material Standard) which includes the strength and chemical composition requirements for compliance to ASTM B209 (Aluminum Alloy Standard). RECOMMENDED USES Aluminum Jacketing is recommended for use in all of the following insulation system applications:

• Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks

• Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired

LIMITATIONS ON USE Aluminum Jacketing is not appropriate for the following applications:

• For vertical tank insulation system applications where the outer diameter is larger than 8 ft, ITW deep corrugated aluminum sheets should be used

• Where increased emissivity is desired, painted aluminum jacketing should be considered

• For applications where a maximum resistance to fire is required, stainless steel jacketing should be used

• For applications where additional resistance to corrosion from the external environment is required, ITW painted aluminum jacketing may be used. Where maximum resistance to corrosion is required, ITW stainless steel jacketing (T304 or T316) should be used.

POLYFILM MOISTURE BARRIER Polyfilm Moisture Barrier (PFMB) is an engineered three layer coextruded film of polyethylene and Surlyn* polymers with a total film thickness of 3 mils (76 µm) that is heat laminated in the factory to the interior surface of aluminum jacketing. ITW recommends the use of PFMB on all aluminum jacketing to help prevent pitting, crevice, and galvanic corrosion of the interior surface of the metal jacketing and the insulated pipe, tank, or equipment. Due to its superior performance characteristics, PFMB replaces the old moisture barrier technology of 1 to 3 mil thick polykraft

©2015 ITW Insulation Systems 800-231-1024 ACCS-0915Pabco / Childers Metal www.itwinsulation.com Supercedes ACCS-0513

*Trademark of DuPont 2.10

ALUMINUM ROLL JACKETING

(cladding) RECOMMENDED THICKNESS ITW recommends that the thickness of aluminum jacketing used vary based on the outer diameter of the insulation system per the requirements of ASTM C1729. This recommended thickness is shown in the table below. EMITTANCE ITW Aluminum Jacketing has an outer surface emittance per ASTM C1371 and specified by ASTM C1729 of:

• Bare aluminum (oxidized in service ) = 0.1 SURFACE FINISHES Each of the three surface finishes available for ITW Aluminum Jacketing (smooth, stucco embossed, and 3/16” corrugated has applications where it is recommended. All of these can be supplied with a painted exterior. For more information on this, consult the ITW data sheet on painted aluminum jacketing. Smooth (Plain Mill) Finish This is a very popular finish and is the “default” for the many end-users/specifiers who prefer the clean look of this finish. This finish sheds rain water the best. However, this smooth surface readily shows damage such as from hail or other physical abuse. It is also shows the dirt more than the other finishes due to its smoothness. Lastly, it is highly reflective of sunlight and when located near roadways, some specifiers see this reflection as a possible safety hazard.

Stucco Embossed Finish This is another popular finish used for aluminum jacketing. The stucco-like surface texture hides small imperfections and scratches caused by physical damage during or after installation. This finish also reduces reflectivity while still looking very professional. Lastly, the use of stucco embossed finish provides a small increase to the rigidity and strength of the aluminum jacketing. 3/16” Corrugated (Cross-Crimped) Finish This finish consists of parallel grooves or crimps about 3/16” apart running in the length direction of the pipe. This finish also hides small damage and scratches to the jacketing and reduces sunlight reflection. In addition, the nature of this finish gives the aluminum jacket more ability to expand and contract to adapt to insulation movement caused by pipe or ambient temperature changes. Lastly, the rigidity and strength of 3/16” corrugated finish is substantially increased making it ideal for use as jacketing on large diameter pipe and vessels up to 8 ft diameter. This finish is available in a maximum thickness of 0.024 inches. FLAMMABILITY ITW Aluminum Jacketing with a 3 mil polysurlyn moisture barrier has been tested for flammability using the industry standard ASTM E84 test method. The results were: ASTM E84 Flame Spread Index = 0 ASTM E84 Smoke Developed Index = 5 (Tested with exterior metal surface exposed to the flame)

Outer Insulation

Diameter (in)

Minimum Aluminum Jacket Thickness, inches (mm)

Rigid Insulation Non-Rigid Insulation

≤ 8 0.016 (0.41) 0.016 (0.41)

Over 8 thru 11 0.016 (0.41) 0.020 (0.51)

Over 11 thru 24 0.016 (0.41) 0.024 (0.61)

Over 24 thru 36 0.020 (0.51) 0.032 (0.81)

>36 0.024 (0.61) 0.040 (1.01)

©2016 ITW Insulation Systems 800-231-1024 PAEC-0716 Pabco / Childers Metal www.itwinsulation.com Supersedes PAEC-0915

11.10

Alloy Si + Fe Cu Mn Zn

1100 0.95 0.05-0.20 0.05 0.1

DESCRIPTION

ITW Insulation Systems’ Polyfilm lined Aluminum Elbow

Covers are made in two precision formed matching halves to cover and weatherproof insulated 45° and 90° pipe elbows.

These elbow covers are called Ell-Jacs™ Plus by ITW

Insulation Systems.

Like ITW Aluminum Jacketing, Ell-Jacs™ Plus are a premier

protective outer surface for insulation systems on pipe and are

an excellent performing and critical accessory to complement

the aluminum jacketing. Ell-Jacs™ Plus protect the insulation

and underlying pipe from physical damage, UV exposure,

corrosive atmospheres, and water. They also reduce the time

and labor needed to install the metal jacketing system.

Ell-Jacs™ Plus have a 3 mil (76 micron) three-layer Polyfilm

Moisture Barrier (PFMB) that is factory heat laminated to the

interior surface. When coupled with the ultrapure 1100 alloy

used in these elbows, this moisture barrier reduces

pitting/crevice and galvanic corrosion potential of the interior

surface of the elbow cover and the underlying pipe.

Ell-Jacs™ Plus have a factory applied and baked on finish of

highly durable hard film clear acrylic or polyester paint on the

exterior surface to help resist external corrosion and to raise the

emittance. The special paint used on the exterior surface of Ell-

Jacs™ Plus is chalk and fade resistant. It exhibits better

resistance to oxidation and to the effects of various corrosive

environments than bare aluminum jacketing. This painted surface

also resists water, scratching, and fingerprint staining.

See the ITW Polyfilm Technical Data Sheet for more

information on this material.

ADVANTAGES

Ell-Jacs™ Plus provide key advantages over aluminum

elbows with a painted moisture barrier:

• PFMB on the interior surface reduces corrosion

propensity – three layers of film in the PFMB

eliminate pinholes

• Allows for the presence of PFMB on all parts of the

metal jacketing system

• Increased spacing between fingers/ribs, for easier

banding in the middle of the elbow

• PFMB has a very low water vapor transmission rate,

further reducing corrosion potential

• Tough and strong PFMB film to resist damage during

handling and installation. Painted moisture barrier is

more easily scratched

Clear exterior coating helps resist unsightly metal

scratches

ELL-JACS™ PLUS

POLYFILM LINED

ALUMINUM ELBOW

COVERS

INNOVATIVE PRODUCT

Using ITW’s innovation process, our team has developed an

improved product that will enhance the performance of the

overall insulation system.

Ell-Jacs™ Plus will benefit the facility owner and specifier, as

the optimum performing PFMB is now available for the first

time as a complete system without having to utilize gore

sections on the elbows.

COMPOSITION

Ell-Jacs™ Plus are made from the commercially pure

(>99% aluminum) and highly corrosion resistant 1100

aluminum alloy.

The performance of even commercially pure aluminum can

be improved by alloying with small percentages of one or

more other elements such as silicon, iron, copper,

manganese, and zinc. ITW Insulation Systems carefully

screens all potential aluminum coil suppliers to assure our

products have the highest quality, are corrosion resistant, and

comply with all relevant standards. Composition of Aluminum 1100 Alloy (max %)

See the ITW PFMB vs. Polykraft or Paint Data Sheet

for more detailed information regarding key

benefits of PFMB compared to painted moisture

barrier.

©2016 ITW Insulation Systems 800-231-1024 PAEC-0716 Pabco / Childers Metal www.itwinsulation.com Supersedes PAEC-0915

11.10

ELL-JACS™ PLUS

POLYFILM LINED

ALUMINUM

ELBOW COVERS

SIZE SELECTION AND INSTALLATION

For details on Ell-Jacs™ Plus sizes, their fit on insulation,

and installation, see the ITW data sheet on Aluminum

Elbow Sizes and Installation.

FIT

Ell-Jacs™ Plus are available to fit:

• 45° and 90° pipe elbows

• Long and short radius pipe elbows

• Butt weld, socket weld, and screwed elbows

• Insulated pipe from ½” to 12” NPS1

1Ell-Jacs™ Plus are available as quad sections for some

insulation thicknesses at NPS > 12”. Not all combinations

of NPS and insulation thickness are available. See your

ITW sales representative for details.

THICKNESS

Ell-Jacs™ Plus are 0.024” (0.6 mm) in thickness to allow the

elbows to be formed in the press. This thickness has proven

acceptable in a vast number of installations and is adequate

since elbows do not get the same abuse as straight jacketing

and do not get walked on or ladders leaned on them.

RECOMMENDED USES

Ell-Jacs™ Plus are recommended for use anywhere

aluminum jacketing is used on the associated straight

sections of pipe but are especially critical when the straight

pipe aluminum jacketing uses PFMB.

LIMITATIONS ON USE

Ell-Jacs™ Plus are not appropriate for the following

applications:

• For applications where a maximum resistance to fire

is required, ITW stainless steel elbow covers should

be used

• Where maximum resistance to exterior surface

corrosion is required, ITW stainless steel elbow covers

should be used

EMITTANCE OF ALUMINUM ELBOWS

Ell-Jacs™ Plus have an outer surface emittance as measured

by ASTM C1371 and specified by ASTM C1729 of:

Standard clear coated = 0.5

Bare aluminum (oxidized in service) for comparison

= 0.1

FLAMMABILITY

Ell-Jacs™ Plus have been tested for flammability via the

commonly used ASTM E84 test method. The results are

shown below.

ASTM E84 Flame Spread Index = 0

ASTM E84 Smoke Developed Index = 5

(Tested with exterior metal surface exposed to the flame)

SURFACE FINISHES

Due to the pressing process during elbow formation,

Ell-Jacs™ Plus have a smooth (mill) finish.

COMPLIANCE TO STANDARDS

Ell-Jacs™ Plus from ITW Insulation Systems comply with the

applicable requirements of ASTM C1729 (Aluminum Jacketing

Material Standard), Type III, Grade 3, Class A, which includes

the strength and chemical composition requirements for

compliance to ASTM B209 (Aluminum Alloy Standard).

SEALING OF JOINTS

For best insulation system performance and resistance to

water infiltration, ITW recommends that all joints in Ell-

Jacs™ Plus be sealed with an appropriate joint sealant. This

should be applied between the overlapping pieces of metal in

the joint and not as a caulking bead on the exterior lip of the

joint.

Pro Insulation 4144 S. 16th Street

Fort Smith, AR 72901 Phone: 479-646-5644

Fax: 479-646-5654

September 28, 2020 Comfort Systems USA, Inc. P.O. Box 16620 Little Rock, AR 72231 Mr. Tad Hankins Re: Mechanical Insulation Submittals for LRAFB B214, Jacksonville, Arkansas. No Spec Section. The following items will be insulated with Foamglas Pipe Cover. All fittings will be mitered segments of pipe covering. Will receive an additional Pitt Wrap vapor barrier, protective jacket. Item #1 Buried Chilled Water ---------------------------------------------------------- 2” Thick Item #2 Buried Heating Water --------------------------------------------------------- 2” Thick Thank You, Chad Bartlett

Pittsburgh Corning

FOAMGLAS® insulation is manufactured by Pittsburgh Corning in a basic block form. Blocks are fabricated into a wide range of shapes, thicknesses and sizes to satisfy industrial insulation requirements.

ASTM EN ISO PHYSICAL PROPERTIES

SI ENGLISH Method Method

0.2% 0.2% C 240 EN 1609 EN 12087 Absorption of Moisture

(Water % by Volume) Only moisture retained is that adhering to surface cells after immersion

Water-Vapor Permeability 0.00 perm-cm 0.00 perm-in E96

Wet Cup Procedure B

EN 12086 EN ISO 10456

Acid Resistance Impervious to common acids and their fumes except hydrofluoric acid

Capillarity None

Combustibility & Reaction to Fire

Noncombustible - will not burn Flame Spread 0

Smoke Development 0

E 136 E84

EN ISO 1182 (Class A1)

Composition Soda-lime silicate glass – inorganic with no fibers or binders 620 kPa 90 psi

Compressive Strength, Block Strength for flat surfaces capped with hot asphalt.

C 165 C 240 C 552

EN 826 Method A

Density 120 kg/m3 7.5 lb/ft3 C 303 EN 1602

Dimensional Stability Excellent—does not shrink, swell or warp EN 1604

(DS 70/90)

Flexural Strength, Block 480 kPa 70 psi C 203 C 240

EN 12089 (BS450)

Hygroscopicity No increase in weight at 90% relative humidity Linear Coefficient of Thermal Expansion

9.0 x 10-6/K 25ºC to 300ºC

5.0 x 10-6/°F 75°F to 575°F

E 228 EN 13471

Maximum Service Temperature 482˚ C 900˚ F

Modulus of Elasticity, Approx. 900 MPa 1.3 x 105 psi C 623 EN 826

Method A1

Thermal Conductivity W/mK

0.040 @ 10°C 0.042 @ 24°C

Btu-in/hr.ft2.°F 0.28 @ 50°F 0.29 @ 75°F

C 177 C 518

EN 12667 EN 12939

( D (90/90) 0.041 W/mK @ 10˚ C) Specific Heat 0.84 kJ/kg.K 0.18 Btu/lb.°F Thermal Diffusivity 4.2 x 10-7 m2/sec 0.016 ft2/hr

Note: FOAMGLAS® ONE™ is manufactured to meet or exceed the minimum requirements of ASTM C552-07 Standard Specification for Cellular Glass Insulation (or most recent revision). Unless otherwise specified, measurements were collected using ASTM guidelines at 24°C (75ºF) and are average or typical values recommended for design purposes and not intended as specification or limit values. Values under EN ISO are declared as limit values under the specific set of standard test conditions. Properties may vary with temperature. Where testing method or reporting values differ between ASTM and EN ISO methodologies, values are denoted within parentheses in the EN ISO column.

PHYSICAL AND THERMAL PROPERTIES OF FOAMGLAS® ONE™ INSULATION

INDUSTRIAL PIPING, DUCTS AND EQUIPMENTFOAMGLAS® insulation is a lightweight, rigid material composed of millions of completely sealed glass cells. Each cell is an insulating entity. FOAMGLAS® insulation’s all-glass, closed-cell structure provides the following benefits:

•ConstantInsulatingEfficiency

•ZeroWaterVaporPermeability

•MoistureResistance

•FireProtection

•CorrosionResistance

•Long-TermDimensional Stability

•VerminResistance

•CFCandHCFCFree

These benefits result in FOAMGLAS® Insulation Systems that are long-lasting, require little maintenance and are ideal for:

•Lowtemperaturepipe, equipment, tanks and vessels

•Mediumandhightemperature pipes and equipment

•Hotoilandhotasphalt storage tanks

•Heattransferfluidsystems

•Hydrocarbonprocessing systems

•Chemicalprocessingsystems

•Abovegroundand underground steam and chilled water piping

•Commercialpipingand ductwork

Manufactured to comply with ASTM C 552

Protect ing Companies and TheirPeopleWorldwide

FOAMGLAS® ONE™ INSULATION SYSTEMS FOR INDUSTRIAL APPLICATIONSPittsburgh Corning has developed insulation systems for a wide range of piping and equipment applications—above ground or underground, indoors or outdoors—at operating temperatures from -450°F to +900°F (-268°C to +482°C).

WiththepatentedStrataFab® System, blocks of FOAMGLAS® insulation are laminated into billets using a special high temperature adhesive. These billets are fabricated into the desired shapes and sizes for pipe, tank, vessels, flanges and valves—practically any industrial insulation application.

Printed in U.S.A.

STANDARDS, CERTIFICATIONS* ANDAPPROVALS

FOAMGLAS® insulation can be certified to conform to the requirements of:

•ASTMC552“Specificationfor Cellular Glass Thermal Insulation”

•ASTMC1639“StandardSpecification for Fabrication of Cellular Glass Piping and Tubing Insulation”

•MilitarySpecificationMIL-I-24244C, “InsulationMaterials,Thermal, with Special Corrosion and Chloride Requirement”

•NuclearRegulatoryGuide1.36,ASTM C795,C692,C871

•FlameSpread5,SmokeDeveloped0 (UL723,ASTME84),ULR2844;also classified by UL of Canada

•ISO9001:2008

•UL1709

•ForalistingofULThrough Penetration Fire Stop Approved Systems please search the UL Database at http://www.ul.com/ Once on this page click on CERTIFICATIONS on the left hand side. Under General Search click on UL FILE NUMBER and type in R15207andthenSEARCH

•BoardofSteamshipInspection (Canada) Certificate of Approval No.100/F1-98

•GeneralServicesAdministration,PBS (PCD):15250,PublicBuildingService GuideSpecification,“Thermal Insulation (Mechanical)”

•NewYorkCityDept.ofBldgs.,MEA #138-81-MFOAMGLAS® insulation for piping, equipment, walls and ceilings

•NewYorkStateUniformFire Prevention and Building Code Dept. ofState(DOS)07200-890201-2013

•CityofLosAngelesGeneralApproval RR22534

FOAMGLAS® insulation is identified by Federal Supply Code for Manufacturers (FSCM 08869)

*Written request for certificate of compliance must accompany order.

FG-3Rev.7/09(ReplacesRev.1/09)

The information contained herein is accurate and reliable to the best of our knowledge. But, because Pittsburgh Corning Corporation has no control overinstallationworksmanship,accessorymaterialsorconditionsofapplication,NOEXPRESSEDORIMPLIEDWARRANTYOFANYKIND,INCLUDINGTHOSEOFMERCHANTABILITYORFITNESSFORAPARTICULARPURPOSE,ISMADEastotheperformanceofaninstallationcontainingPittsburghCorning products. In no event shall Pittsburgh Corning be liable for any damages arising because of product failure, whether incidental, special, consequential or punitive, regardless of the theory of liability upon which any such damages are claimed. Pittsburgh Corning Corporation provides written warranties for many of its products, and such warranties take precedence over the statements contained herein.

www.GreenSpec.com

BCCA ISO 9001:2008

For complete data on FOAMGLAS® Insulation Systems, please visit our Web site at www.foamglas.com, or contact Pittsburgh Corning at any of the following locations:

Pittsburgh Corning USA(CorporateHeadquarters)800 Presque Isle DrivePittsburgh,PA15239Tel:1-724-327-6100Fax:1-724-387-3807

Pittsburgh Corning Corporation Asia(AsiaHeadquarters)Pittsburgh Corning Corporation3-7-4-304HikarigaokaNerima-ku,Tokyo,Japan179-0072Tel&Fax:01181-3-5997-0248

PittsburghCorningEuropeNV(Europe / Middle East Africa Headquarters)Albertkade,1B-3980TessenderloBelgiumTel:+32-13-66-17-21Fax:+32-13-66-78-54

Totally ImpermeableLong Term PerformanceBecause it consists of closed glass cells, FOAMGLAS® insulation resists moisture in both liquid and vapor forms.WhentestedinaccordancewithASTME96,ithasapermeabilityratingof0.00perm-in.

NoncombustibleFOAMGLAS®insulationis100%glassandcontainsnobindersorfillers—itcannotburn.FOAMGLAS® insulationwillnotabsorbflammableliquidsorvapors.Ifafiredoesoccur,FOAMGLAS® insulation can help to contain or supress it.

Corrosion-ResistantAll-glass FOAMGLAS® insulation is unaffected by common chemicals and by most corrosive plant atmospheres. It does not promote metal corrosion and its moisture resistance will help keep water from reaching equipment and piping.

Dimensionally StableFOAMGLAS® insulation is unaffected by temperature differentials and humidity. It will not swell, warp, shrink or otherwise distort. The insulation system’s integrity remains intact.

High Compressive StrengthFOAMGLAS® insulation can withstand loads which crush most other insulating materials. In a properly designed piping system, FOAMGLAS® insulation eliminates the need for special treatment at pipe cradles. Italsoprovidesafirmbaseforroofmembranes,jacketingorvaporretarders,prolongingtheirlife.

Technical ServicePittsburgh Corning’s Technical Service Staff provides product, application and materials testing— standardizedandcustomizedspecifications—on-sitecustomerassistanceandinstallationguidance.

FOAMGLAS® and StrataFab® are federally registered trademarks owned by Pittsburgh Corning Corporation.

© 2009 Pittsburgh Corning Corporation

PITTSBURGH CORNING

FOAMGLAS INSULATION ACCESSORIES 800 Presque Isle DrivePittsburgh, Pennsylvania 15239-2799 IMPORTANT: MATERIAL SAFETY DATA SHEETS ARE Tel: 724/327-6100 • 800/359-8433 AVAILABLE AND SHOULD BE READ BEFORE USING Fax: 724/327-5890 THIS PRODUCT.www.foamglasinsulation.com

PITTWRAP® JACKETINGPRODUCT DATA SHEET

DESCRIPTION:PITTWRAP® jacketing is a heat sealable, multiplylaminate for protecting underground FOAMGLAS®insulation systems for outer surface temperatures below190°F.

PITTWRAP® jacketing consists of three layers of apolymer modified bituminous compound separated byglass fabric reinforcement and aluminum foil. An outerlayer of polyester film is laminated to the bituminouscompound. An outer layer of polyester film is laminatedto the bituminous compound. A release paper preventssticking in the roll before use.

*TYPICAL PROPERTIESColor: BlackThickness, mils (mm): 125 (3)Weight.ft2, lbs (kg/m2): 0.66-.69 (3.2-3.4)Width, inches (cm): 23 3/8 (59.4)Roll Length, ft, (m): 50 (15.24)Sq.Ft/Roll, (m2) 100 (9.3)Roll Weight, lbs, (kg): 66-69 (29.9-31.3)Tensile Strength, lbs/in: @ 78°F, 105

@ 20°F, 165Application Temperature, min °F (°C): 20 (-7)Service Temperature, °F:20 to 190 (°C): (-7 to 88)Butt Strips: Width, inches (cm): 4 (10.2) Roll Length, ft (m): 50 (15.24)Permeability, ASTM E96 Perm inches: 0.002Perms @ 125mils: 0.02

RESISTANCE:Water: goodAlkalies: goodAcids: goodPetroleum Solvents: poorFire: Combustible

This is a guide. Since conditions vary, consult PittsburghCorning if in doubt about chemical resistance.

MATERIAL APPLICATION:Store PITTWRAP® jacketing in a cool area out of directsun in hot weather. In cold weather, store in warm areaprior to use to facilitate application.

APPLICATION:PITTWRAP® jacketing may be shop or field-applied. Inboth cases, a cigarette-wrap application is used aroundFOAMGLAS® insulation with butt strips over the endjoints. (See back page.)

All underground insulation systems must be designedwith proper engineering details to control expansion/contraction, anchoring, etc. A qualified engineer shouldbe consulted for design.

FITTINGS OR CHANGES IN THICKNESS:With any jacketing or coating, any change in insulationthickness, such as screwed ell covers, pipe stepdowns,etc., should be field-tapered to make a smooth transition.Fittings may be covered with jacketing cut in shapes tofit, or with PITTCOTE® 300 finish (FI-120) and PC®Fabric 79 (FI-159). When finish is used, stop the last fullsection of jacketing 4” (10cm) short of the change inthickness or beginning of curvature. The polyethylenefilm on the PITTWRAP® jacketing must be flashed off aminimum of 2”. Over the bituminous surface, apply atack coat of PITTCOTE® 300 finish 2-3 gallons/100 ft2

(0.8-1.2 l/m2) and embed PC® Fabric 79, lappingjacketing a minimum of 2” (5cm). After one hour, apply asecond coat of finish 2-3 gallons/100 ft2 and a secondlayer of fabric. Apply a top coat of finish 2-3 gallons/100ft2 so that no fabric is visible when dry. Total wetthickness should be _” minimum. If backfilling takesplace less than 24 hours after PITTWRAP® 300 finish isapplied, roofing felt shall be placed over the coating.

The second and succeeding sections are placed in thesame manner, tightly butting the edges. All longitudinaljoints should be started on the same line to facilitate laterplacement of butt strips.

LIMITATIONS:DO NOT use over combustible insulations or installwhere open flames are not permitted.

Do not use above ground without a metal jacket.

Do not use in areas where jacketing will be exposed totemperatures in excess of 190°F (88°C).

Do not use where jacketing will be exposed to solventsthat will dissolve asphalt.

Observe practical precautions when backfilling so not topuncture jacket.

This material is designed for application only forprofessional, trained personnel using proper equipmentand is not intended for sale to the general public.

STORAGE:Store in a heated area for cold weather application.

SHIPPING:DOT Hazard Class: None

CAUTION:This material is intended to be used only withFOAMGLAS® insulation and in conformity withPittsburgh Corning’s standard instructions. Be sureyou have read and understand all instructions andMaterial Safety Data Sheets before using. MaterialSafety Data Sheets should be considered part of thisproduct data sheet.

WARNING:THIS PRODUCT CONTAINS A MATERIAL THAT HASBEEN CLASSIFIED AS CARCINOGENIC TO HUMANS BYTHE INTERNATIONAL AGENCY FOR RESEARCH ONCANCER (IARC) AS GROUP 1.

INGREDIENTS: CAS#Asphalt 8052-42-4Heavy Parafinic Distillant Solvent Extract 64742-04-7

IRRITANT:Repeated or prolonged contact may irritate skin. Weargloves. If heated, fumes are irritants to eyes, nasal andrespiratory tract.

HARMFUL OR FATAL IF SWALLOWED.

COMBUSTIBLE:Store in a cool area. Keep away from open flame or ignitionsources.

FIRE HAZARD CLASSIFICATION:Health: 1 Fire: 1 Reactivity: 1

Use torch with caution. Hot asphalt can cause burns. Wearsuitable gloves, long sleeves, and goggles, if workingoverhead. Avoid breathing asphalt fumes.

Store and handle fuel tanks in accordance with existingregulations.

If metal bands are used directly over jacketing, place anextra strip of jacketing beneath the band and take care notto puncture jacketing.

KEEP OUT OF REACH OF CHILDREN

EQUIPMENT:LPG Torch, regulator: Goss Kit KP118 with BP-5TE tipand EX128 extension.

LPG Tank: LP-20

LPG Hose: Goss HEF-25

Additional equipment: Gloves. pointed trowel, shears.

The information contained herein is accurate and reliable to the bestof our knowledge. But, because Pittsburgh Corning Corporationhas no control over installation workmanship, accessory materialsor conditions of application, NO EXPRESS OR IMPLIEDWARRANTY OF ANY KIND, INCLUDING THOSE OFMERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE, IS MADE as to the performance of an installationcontaining Pittsburgh Corning products. In no event shallPittsburgh Corning be liable for any damages arising because ofproduct failure, whether incidental, special, consequential orpunitive, regardless of the theory of liability upon which any suchdamages are claimed. Pittsburgh Corning Corporation provideswritten warranties for many of its products, and such warrantiestake precedence over the statements contained herein.

FOAMGLAS® , PITTWRAP®, and PC® are federallyregistered trademarks owned by Pittsburgh Corning Corporation.

PITTWRAP® JACKETINGFI-209 Rev. 9/01

1FOAMGLAS® Insulation installedwith chalk line at three o’clockposition. 2

Starting at edge of PITTWRAP®

jacketing lap seal, apply butt striphalf way around, lapping two inch-es on each side of butt joint.

3 Heat leading edge and halfof PITTWRAP® jacketing. 4

Starting on the chalk line, press PITTWRAP® jacketing half wayaround FOAMGLAS® Insulation.

5Burn off polyester film at lapseal for distance of 3” backPITTWRAP® jacketing. 6

Heat remaining half of PITTWRAP®

jacketing, pull jacketing around,and make lap seal.

7Remove release paper from PITTWRAP® jacketing butt strip. 8

Burn off polyester film fordistance of 2” on each sideof PITTWRAP® jacketing.

9Heat leading edge and halfof PITTWRAP® jacketing. 10

Starting at edge of PITTWRAP®

jacketing lap seal, apply butt striphalf way around, lapping twoinches on each side of butt joint

11Burn off polyester film for distanceof 2” back at butt lap seal. 12 Heat remaining half of butt strip,

pull it around, and make lap seal.

13Heat-seal PITTWRAP® jacketing lapedges and butt strip edges aroundcircumference until PITTWRAP®

jacketing softens and flows together.

Step-by-Step Instructions for Applying PITTWRAP® Jacketing

NOTE: Lap is closed with openingfacing upward to allow softenedcoating to flow into open seam,providing a positive seal. This tech-nique is the opposite of that forconventional jacketing materials.