Retail Programme – Food Waste. Final Report Evaluating the

Transcript of Retail Programme – Food Waste. Final Report Evaluating the

Retail Programme – Food Waste. Final Report

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage

An investigation the potential of LLS Smart Technology to extend shelf-life and quality of fresh produce in the UK, and hence reduce both supply chain and household food waste

Project code: INN3-027 Research date: January 2006 – March 2008 Date: September 2008

WRAP helps individuals, businesses and local authorities to reduce waste and recycle more, making better use of resources and helping to tackle climate change.

Written by: Dr Chris Bishop Long Life Solutions Ltd Writtle College

Front cover photography: Diagram of Modified Interactive Packaging WRAP and Writtle College believe the content of this report to be correct as at the date of writing. However, factors such as prices, levels of recycled content and regulatory requirements are subject to change and users of the report should check with their suppliers to confirm the current situation. In addition, care should be taken in using any of the cost information provided as it is based upon numerous project-specific assumptions (such as scale, location, tender context, etc.). The report does not claim to be exhaustive, nor does it claim to cover all relevant products and specifications available on the market. While steps have been taken to ensure accuracy, WRAP cannot accept responsibility or be held liable to any person for any loss or damage arising out of or in connection with this information being inaccurate, incomplete or misleading. It is the responsibility of the potential user of a material or product to consult with the supplier or manufacturer and ascertain whether a particular product will satisfy their specific requirements. The listing or featuring of a particular product or company does not constitute an endorsement by WRAP and WRAP cannot guarantee the performance of individual products or materials. This material is copyrighted. It may be reproduced free of charge subject to the material being accurate and not used in a misleading context. The source of the material must be identified and the copyright status acknowledged. This material must not be used to endorse or used to suggest WRAP’s endorsement of a commercial product or service. For more detail, please refer to WRAP’s Terms & Conditions on its web site: www.wrap.org.uk

Executive summary The amount of food waste generated within the UK, together with the financial and environmental implications, has received considerable attention recently. It is estimated that between 18 – 20 million tonnes of food waste in total are produced (see http://www.wrap.org.uk/retail/food_waste/nonhousehold_food.html), with households being responsible for the single largest fraction (6.7 million tonnes). WRAP launched its consumer facing Love Food Hate Waste campaign in November 2007, with the objectives of raising awareness of this issue, and bringing about behavioural change. However there is also the need for technical innovation which can help reduce both household and supply chain food waste. Fresh fruit and vegetables have been shown to make up almost 40% by weight of household food waste (The Food We Waste, 2008; WRAP), and are believed to be a significant proportion of retailer back of store waste. Long Life Solution’s (LLS) Smart Technology creates a modified interactive packaging (MIP), as opposed to a modified atmosphere packaging (MAP) commonly employed to extend the shelf life of fresh produce. The films, both flexible (SmartLiners and SmartBags) and rigid (SmartPunnet), effectively manage gas exchange (oxygen, carbon dioxide, ethylene) in and through the package, creating high Relative Humidity (RH), extending fresh food shelf-life naturally and it inhibiting dehydration. WRAP agreed to fund a project to investigate the potential of LLS Smart Technology to extend shelf-life and quality of fresh produce in the UK, and hence reduce both supply chain and household food waste. Several retailers took part in these trials, over the course of two years. Retailers have the power to positively influence the reduction of food waste at home by choosing packaging that extends the shelf life of the product. This is most relevant to fresh produce which has a relatively short shelf life. The project was formulated to evaluate the wastage reduction through the use of LLS MIP or Smart Technology in the supply chain from harvest to the consumers refrigerator. Four products were chosen for the trials - lettuce, carrots, strawberries and broccoli. This was to be achieved by monitoring the crop all the way from the field through to the retailer regional distribution centre (RDC) and then through a number of simulated temperature scenarios at Writtle College (to mimic household storage). The intention was that information gained from pilot trials would inform commercial trials using initially one or two RDC’s and their corresponding supermarkets for a period of approximately one month, and then rolling out the use of Smart Technology for these products to the whole retailer group. In the case of lettuce the reduction in weight loss achieved through the use of Smartbags was statistically significant but the overall weight loss was minimal (< 2% in the control samples) and therefore not commercially significant. The reduced rate of water vapour transmission demonstrated through the use of the SmartBags and SmartLiners is an advantage to reduce product dehydration but can also be a disadvantage if the crop is harvested wet, such as after rain or with a heavy dew, or when the package is enclosed and rapidly cooled. The resulting high levels of free water can encourage disease as well as producing condensation which also is visually unattractive. This was most apparent in lettuce where the current practice involves packing in the field, meaning that the product can be packed wet, resulting in trapped free water and consequently encouraging the development of disease. Lettuce packed in Smartbags under these conditions showed an increased potential for disease, leading to higher levels of product rejection. As it was not possible to change the commercial packing arrangements, i.e. to reduce free water levels around the product, it was decided not to proceed with commercial trials as part of the WRAP project. Trials with the SmartLiner on UK grown carrots again revealed a statistically significant reduction in product weight loss, however as there was little weight loss in the existing carrot supply chain the commercial benefit was limited. From the overall data, comprising weight loss, colour changes, firmness and decay during the two trials, it was concluded that carrots stored in SmartLiners were of similar quality to the control. As there was no significant commercial benefits it was decided not continue with further trials within the WRAP programme. However where there is an increased risk of disease it would be worth reconsidering the use of the SmartLiner, as there was an indication that its use could reduce the incidence of “crown disease” and the associated losses.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 1

The performance of the SmartPunnet was assessed in a trial involving UK strawberries, where the impact on shelf life, maintaining quality in terms of colour, and calyx condition, minimising weight loss and providing antimicrobial protection under various temperature regimes was monitored. The use of SmartPunnets reduced the amount of punnets that would need to be either marked down or thrown away before the ‘Best Before’ date. The differences were greater in the case of the premium variety Jubilee which seemed to be more susceptible to disease and fruit darkening. Owing to difficulties in punnet manufacture there was not time to carry out full trials with the SmartPunnet, However the initial trials did give improved results for both weight loss and disease control. Subsequent to the WRAP project a robust supply chain for the manufacture and delivery of SmartPunnets was established. Trials with broccoli from Spain and the UK, packed using the SmartLiner revealed significant benefits. The SmartLiners worked well in reducing weight loss and preserving firmness and colour. Unfortunately it was not possible to complete successful commercial trials during the course of the WRAP project, but it is hoped to complete a commercial trial in the near future. Overall the trial results showed that Smart Technology resulted in the reduction of weight loss throughout the supply chain for all four products, and this was commercially significant for strawberries and broccoli. There were also benefits in terms of texture and colour preservation and prevention of disease. It is regrettable that full scale commercial trials were not possible within this project, which prevented the impact of Smart Technology on food and packaging waste to be assessed or quantified. However LLS Smart Technology has been commercialised in a number of applications around the world (see http://www.longlifesolutions.com/index.html for details). For example trials on bunched carrots did show a large advantage and the product is now commercially packed in SmartLiners for a large UK retailer. The Co-op has also replaced the shrink-wrap film in whole cucumbers with SmartLiners. These latter projects have been successful and the feedback from all parties (i.e. customers, suppliers, in-store managers) has been very positive. Scope of Project This project aims to improve the quality of produce, decreasing product loss in the supply-chain and improving product life-span in the household through the use of interactive packaging. The project:

carried out pilot trials to demonstrate the feasibility of using interactive packaging for the supply of lettuce

from Spain and the UK to Somerfield stores;

carried out pilot trials to demonstrate the feasibility of using interactive packaging for the supply of carrots

from the UK to Somerfield stores;

carried out pilot trials to demonstrate the feasibility of using interactive packaging for the supply of

strawberries from the UK to UK stores, in cooperation with Berry Gardens; and

carried out pilot trials to demonstrate the feasibility of using interactive packaging for the supply of broccoli

from Spain and the UK to Somerfield and Morrisons stores.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 2

Contents 1.0 Introduction ............................................................................................................................. 4

1.1 Fresh Produce Packaging .......................................................................................................4 1.2 Modified Atmosphere Packaging (MAP) ...................................................................................4 1.3 LongLifeSolutions Modified Interactive Packaging (MIP) ...........................................................5

2.0 LongLifeSolution Trials ............................................................................................................ 6 2.1 Proposed Trial Objectives.......................................................................................................6 2.2 Lettuce Trials ........................................................................................................................6 2.3 Carrot Trials ........................................................................................................................10 2.4 Strawberry Trials .................................................................................................................13 2.5 Broccoli Trials......................................................................................................................16

3.0 Summary & Conclusions......................................................................................................... 20 Figures

Figure 1 Modified Interactive Packaging ..............................................................................................5 Figure 2 Temperature traces for 6 of the data loggers in the initial lettuce trial from Spain, illustrating the

level of consistency achieved within each treatment ...............................................................7 Figure 3 Impact of control and LLS SmartBags on lettuce weight loss (trial 1 was still in transit from Spain

on day 2) .............................................................................................................................8 Figure 4 Impact of control and LLS SmartBags on the colour of lettuce butt ends ...................................8 Figure 5 Lettuce at time of harvest, note the wine butt end ..................................................................9 Figure 6 Lettuce from control and SmartBags on day 8. Note disease in particular on top left and bottom

right of the lettuce packed in SmartBags ................................................................................9 Figure 7 Impact of control and LLS SmartLiners on carrot weight loss .................................................10 Figure 8 Impact of control and LLS SmartLiners on carrot apperence and early indication of infection....11 Figure 9 Impact of control and LLS SmartLiners on carrot firmness .....................................................11 Figure 10 Impact of control and LLS SmartLiners on carrot colour ........................................................12 Figure 11 Impact of control and LLS SmartLiners on bunched carrot weight loss (10% and 12% indicate

the % use of particles within the packaging material: DAP=days after packaging) ..................12 Figure 12 Impact of control and LLS SmartPunnets on strawberry weight loss (Elsanta variety) ..............14 Figure 13 Impact of control and LLS SmartPunnets on strawberry weight loss (Jubilee variety) ..............14 Figure 14 Comparison between strawberryies (Jubilee variety) in control punnets and SmartPunnets (3

days after packing; including temperature abuse treatment 4)) .............................................15 Figure 15 Impact of control and LLS SmartLiners on broccoli weight loss (10% and 12% indicate the %

use of particles within the packaging material ......................................................................17 Figure 16 Impact of control and LLS SmartLiners on broccoli flesh temperature post harvest .................17 Figure 17 Impact of control and LLS SmartLiners on broccoli firmness ..................................................18 Figure 18 Impact of control and LLS SmartLiners on broccoli respiration rates .......................................18 Figure 19 Impact of SmartLiners on broccoli appearance (10% and 12% indicate the % use of particles

within the packaging material; treatment 1,12 days after harvest ..........................................19 Tables

Table 1 Treatment regemes for second lettuce trial (*indicates days on which full quality assessments were taken ...........................................................................................................................6

Table 2 Number of punnets that were still saleable by the “best before” date per treatment ...............13 Table 3 Treatment regemes for broccoli trials ...................................................................................16

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 3

1.0 Introduction The amount of food waste generated within the UK, together with the financial and environmental implications, has received considerable attention recently. It is estimated that between 18 – 20 million tonnes of food waste in total are produced (see http://www.wrap.org.uk/retail/food_waste/nonhousehold_food.html), with households being responsible for the single largest fraction (6.7 million tonnes). WRAP launched its consumer facing Love Food Hate Waste campaign in November 2007, with the objectives of raising awareness of this issue, and bringing about behavioural change. However there is also the need for technical innovation which can help reduce both household and supply chain food waste. Fresh fruit and vegetables have been shown to make up almost 40% by weight of household food waste (The Food We Waste, 2008, WRAP), and are believed to be a significant proportion of retailer back of store waste. Long Life Solution’s (LLS) Smart Technology creates a modified interactive packaging (MIP), as opposed to a modified atmosphere packaging (MAP) commonly employed to extend the shelf life of fresh produce. The films, both flexible (SmartLiners and SmartBags) and rigid (SmartPunnet), effectively manage gas exchange (O2 CO2

C2H4 ) in and through the package, creating high Relative Humidity (RH), extending fresh food shelf-life naturally and it inhibiting dehydration. WRAP agreed to fund a project to investigate the potential of LLS Smart Technology to extend shelf-life and quality of fresh produce in the UK, and hence reduce both supply chain and household food waste. Several retailers took part in these trials, over the course of two years. Retailers have the power to positively influence the reduction of food waste at home by choosing packaging that extends the shelf life of the product. This is most relevant to fresh produce which has a relatively short shelf life. 1.1 Fresh Produce Packaging The packaging of fresh produce performs a number of functions, among which are:

physical protection from damage;

product identity and defining unit size;

providing an ability to stack the product; and

prolonging the life after harvest, often referred to as the shelf life.

This project focused on the final of these packaging functions. 1.2 Modified Atmosphere Packaging (MAP) The introduction of modified atmosphere packaging (MAP) for fresh produce in the late 1980’s revolutionised the fresh produce industry by giving an extension of shelf life over the traditional loose product. The prolonging of shelf life was achieved by reducing the oxygen availability within the package by having a package wall of limited gas permeability. The low level of oxygen was either achieved by the respiration of the product consuming oxygen and giving out carbon dioxide (passive) or by filling the package with a specific gas concentration at the time of filling (active). A further benefit of MAP was that the increased level of carbon dioxide has a fungistatic effect and so reduces (not eliminates) disease levels. The permeability of the package wall (or film) and the temperature are crucial parts of the success of this form of packaging. If the temperature is too high or low in respect to the target temperature the respiration rate of the product changes and so therefore does the internal atmosphere. As the respiration rate doubles with an increase in temperature of 10oC it can be seen that small fluctuations of more than + 1oC can alter the atmosphere and hence the life of the product. These temperature fluctuations can also result in condensation occurring which can be visually unattractive and also provide the available water (aw) to assist in disease development. In addition as different products have greatly differing respiration rates the optimum permeability of the package wall (or film) is specific to the crop and the quantity within the package. This can result in waste of product and/or waste of packaging materials as many different types of packaging are required and if there are temperature fluctuations in the supply chain these can result in temperature abused product.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 4

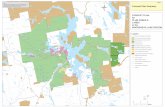

1.3 LongLifeSolutions Modified Interactive Packaging (MIP) Long Life Solution’s Smart Technology creates modified interactive packaging (MIP) as opposed to a modified atmosphere packaging (MAP). The film, both flexible (SmartLiners and SmartBags) and rigid (SmartPunnet), is a product that effectively manages gas exchange (oxygen, carbon dioxide, ethylene) in and through the package, creates high Relative Humidity (RH), extends fresh food shelf-life naturally and inhibits dehydration. This is made possible due to the very high permeability of the film to oxygen and other gases (44,000-45,000 OTR [oxygen transfer rates],) but not to moisture. The substrate (clay particles) that has been incorporated into the film creates micro cracks which allow the exchange of gases. These micro cracks respond to the environment within the pack. For instance if the temperature rises slightly the respiration rate of the product goes up and so more gas and vapour are produced. this produces a slight pressure differential causing the film to expand and the cracks to increase in size and hence increase permeability. The internal pressure will reduce, and again form an equilibrium. This response to adverse circumstances means that more uniform conditions are maintained within the pack, and if there is uniformity and less stress the product will last longer. The substrate is normally added in the film at a 10% rate, however, films with a 12% substrate have been formulated in order to be used in situations where a film with greater breathability would be beneficial. Smart Technology can also incorporate a controlled release, food approved antioxidant preservative (active ingredient) that protects the contents and internal surroundings from early mycotoxin forming fungi, premature deterioration and microbial instability within the package. This active ingredient is completely safe and has been used extensively for the preservation of many food products. It provides an early stage inhibition of a wide range of micro-organisms including, fungi, bacteria and yeasts. Within this (WRAP) project only the SmartPunnet contained the active ingredient, however SmartLiners and SmartBags can also be formulated to contain the active ingredient.

Figure 1: Modified Interactive Packaging

Unlike other barrier-like films, MIP can tolerate temperature fluctuations in the range of ±40C for the reasons explained above. The introduction of MIP offers the potential for further reduction of food waste as it allows the retailer extra sale time and the householder increased best-before time. As well reducing food and packaging waste the same product can be used for many more types of fresh produce. In addition the LLS bags are approximately 35% thinner (the thickness of LLS material ranged between 19 and 24 microns), than the normal bags used by Somerfield and Morrisons (mean of 19 different bag types used at the time of the project was 15-58 microns).

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 5

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 6

2.0 LongLifeSolution Trials 2.1 Proposed Trial Objectives The trials were all initiated from the field in the case of lettuce, strawberries and broccoli and from arrival at the pack house for carrots. A variety of measures were taken to assess the impact of Smart Technology, including:

Colour.

“Quality” of produce (visual appearance).

Weight Loss.

Disease levels.

Firmness (shore).

Firmness (lbs or kg/cm2).

The other objectives of the trials were:

to determine the benefits of the packaging in terms of extended product life;

to quantify packaging savings; and

to quantify reduced product waste levels, in the supply chain, in-store and at home.

2.2 Lettuce Trials These trials were undertaken with the support of Somerfield, and evaluated the impact of Smartbags on lettuce quality and shelf-life. Iceberg lettuce were harvested and put straight into LLS bags in the field and then packed, transported, vacuum cooled as per normal practice, but under the supervision of trial staff. In the case of the first trial from Spain the lettuce were transported to the UK (with some difficulties in maintaining the cool chain) and then collected on arrival and taken to Writtle College where the combination of temperature treatments and quality assessments were carried out. In the case of the UK harvested crop after the vacuum cooling the crop was loaded into a refrigerated truck and taken directly to Writtle College. The temperature regimes were similar for the two trials and the summary for the second trial is given below.

Table 1. Treatment regimes for second lettuce trial (* indicates days on which full quality assessments were taken) DAY 0 1* 2 4* 6 8* 10 12* 14 Harvest Vac cool

Taken To Writtle RDC regime

In store regime Domestic regime

Treatment 1 Harvest early eg 08.00 hrs

3oC 3oC 8oC 8oC 8oC 3oC 3oC 3oC 3oC

Treatment 2 Harvest mid eg 12.00 hrs

3oC 3oC 8oC 8oC 8oC 3oC 3oC 3oC 3oC

Treatment 3 Harvest late eg 16.00 hrs

3oC 3oC 8oC 8oC 8oC 3oC 3oC 3oC 3oC

Treatment 4 Harvest as 2, temperature abuse from day 6

3oC 3oC 8oC 8oC 25oC 20oC 20oC 20oC 20oC

Treatment 5 Harvest as 2

3oC 3oC 8oC 8oC 8oC 3oC 3oC 3oC 3oC

Treatment 6 Harvest as 2, temperature abuse from day 8

3oC 3oC 8oC 8oC 8oC 20oC 20oC 20oC 20oC

At the time of packing in the field temperature loggers with sensors in the crop flesh itself were installed (12 in total per trial). Results from the first trial of six sensors are shown below.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 7

Figure 2. Temperature traces for 6 of the data loggers in the initial lettuce trial from Spain, illustrating the level of consistency achieved within each treatment.

The weight loss figures were slightly different for the two trials as can be seen below, but these small differences are not commercially important as the total loss was always below 2% (the weight loss in SmartBags was almost 0% for the duration of the trial).

Figure 3. Impact of control and LLS Smart Bags on lettuce weight loss (Trial 1 was still in transit from Spain on day 2)

Weight Loss of Whole Head Lettuce

0.00%

0.20%

0.40%

0.60%

0.80%

1.00%

1.20%

1.40%

1.60%

1.80%

2.00%

2.00 6.00 9.00 13.00

Days After Harvest

% L

oss

Trial 1 ControlTrial 1 LLSTrial 2 ControlTrial 2 LLS

One of the “indications” of freshness used by consumers is the browness or otherwise of the butt end of the lettuce. There was no measurable difference in the colour of the butt end as indicated in Figure 3.

Figure 4. Impact of control and LLS Smart Bags on the colour of lettuce butt ends

Browning of butt end in different treatments all taken on day 10

0

2

4

6

8

10

12

1 2 3 4 5 6 Mean Treatment

"a"

valu

e

Smartbag Control

Evaluating the potential of Long Life Solutions – Smart Technology to reduce

fresh produce wastage 8

There were no real differences in other parameters such as the colour of the butt end or colour of the heads. However the crop in Spain was harvested under wet conditions and the early morning harvest in the UK was harvested with a dew. When vacuum cooled there were high levels of free water on the LLS packed lettuce which were high enough to increase the potential for disease and the levels of rots. This normally manifested itself initially in brown ribbing leading to an unacceptably high level of reject lettuce. After two trials it was decided to discontinue further work with lettuce within the WRAP programme.

Figure 5. Lettuce at time of harvest, note the white butt end

Figure 6. Lettuce from control and SmartBags on day 8. Note disease in particular on top left and bottom right of the lettuce packed in Smartbags

Control SmartBag

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 9

2.3 Carrot Trials These trials were undertaken with the support of Somerfield, and evaluated the impact of Smartliners on carrot quality and shelf-life. The typical processes that took place during processing of carrots during the trials were monitored and the observations are summarised below: Process for carrot packing involves: 1 Carrots are transported for processing straight from the field for packing at the packhouse (Packhouse runs

at ambient ~ 200C) 2 Washing and rough grading 3 “Hydro-cooling” is used to reduce field temperature (water temperatures recorded at 3.1 - 4.70C) 4 Carrots are packed in bags or cartons and temperature loggers inserted into the flesh of the carrot 5 Carrots were transported to Writtle College in a refrigerated van set at 8oC and stored in a cold store that

runs at 30C. This was to replicate commercial practice, storage during the cool chain and distribution network.

As the carrots had been washed and not subsequently dried a fair amount of surface moisture was observed in carrots after processing. The carrots used in Trial 1 were old season carrots left in the ground until February and the carrots in Trail 2 were new season carrots which were harvested as mature. Looking at the weight loss and observed water in the bags, higher condensation levels were been observed in the control liner. This could typically encourage the development of bacterial disease such as Erwinia carotova. On closer inspection of the graphed data, it can be seen that the SmartLiner reduced the weight loss consistently below 0.05% throughout the 10 day trial, while the standard liners had weight loss 6 times higher at 0.3% after day 7.

Figure 7. Impact of control and LLS SmartLiners on carrot weight loss

Weight Loss of Carrots

-0.05

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

2 or 3 5 7 9 or 10

Days After Harvest

% L

oss Trial 1 Control

Trial 1 SL

Trial 2 ControlTrial 2 SL

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 10

During the second trial there were a few isolated cases of disease forming around the crown of the carrots from the standard bag. The bacterial origin of this disease is not known, but the higher condensation levels may have encouraged its development to the stage where it was noted (as pictured in Figure 7).

Figure 8. Impact of control and LLS SmartLiners on carrot appearance and early indications of infection

Control SmartLiner

8 DAYS AFTERHARVEST

10 DAYS AFTERHARVEST

Control SmartLiner

8 DAYS AFTERHARVEST

10 DAYS AFTERHARVEST

The root cause of infection may have been due to wounding in the field (pest or harvest damage), but it is assumed that as the carrots were of identical sourcing, the same background factors were present in both packaging treatments. Therefore the SmartLiner may have the potential to provide a small reduction of “quality losses” due to crown disease at retail display. The firmness of the carrots were measured using a industry standard Fruit Texture Analyser (FTA), measuring the puncture force of the flesh in lbs (Figure 8).

Figure 9. Impact of control and LLS SmartLiners on carrot firmness

Firmness of Carrots

10

11

12

13 14

15

16

17

0 5 10 15Days After Harvest

lbs

forc

e Trial 1 ControlTrial 1 LLSTrial 2 ControlTrial 2 LLS

The graph above shows that there was a significant difference in the carrot flesh firmness between the two trials. Despite this variation, in both cases firmness increased during the trials except where the Smartliner was used in Trial 1. This increase in firmness is due to water loss and associated “crisping” of the flesh. However there appears to be no significant difference between the samples within each trial (once allowance has been given for scientific error), and therefore the use of the SmartLiner (despite giving a clear advantage on weight loss and possible disease reduction), is unlikely to have an affect on the “mouth-feel” of the product.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 11

The surface colour of the carrots was measured by a colorimeter, and the results are shown in Figure 9.

igure 10. Impact of control and LLS SmartLiners on carrot colour

F

The graph above shows that the colour was variable in some cases, but ge

Colour of Carrots

15

17

19

21

23

27

0 5 10 15Days After Harvest

a* re

adin

g Trial 1 ControlTrial 1 LLSTrial 2 ControlTrial 2 LLS

nerally did not show any significant 0

rom the overall data, comprising weight loss, colour changes, firmness and decay during the two trials, it was

e

ubsequent to the above trial some work was carried out on the storage of bunched carrots (with their green

s

igure 11. Impact of control and LLS SmartLiners on bunched carrot weight loss (10% and 12%

variance in the a* spectrum (an indication of colour on a red to green scale), with a close correlation around +2to +25 throughout the trial. The variation seen is likely to have been due to sampling errors (variation between samples), combined with differences in the surface “finish” / surface moisture giving adverse reflectance which affected the “measured colour spectrums”. From observations it was found that SmartLiner-stored carrots appeared to be brighter in colour until the last quality control check. Fconcluded that carrots stored in SmartLiners were of similar quality to the control. As there was no significant commercial benefit it was decided not continue with further trials within the WRAP programme. However wherthere is an increased risk of disease it would be worth reconsidering the use of the SmartLiner. Stops). Comparisons were made in appearance, disease and weight loss between the use of a Returnable PlasticCrate (RPC) with SmartLiner and without. In all cases there was less weight loss and fresher appearance with those using the SmartLiner resulting in a five day increase in shelf life. As a result of this spin off trial ASDA hanow adopted the use of Smart Technology for bunched carrots. The individual sleeves have been removed and the bunched carrots are being sold loose within a SmartLiner.

Findicate the % use of particles within the packaging material; DAP = days after packaging)

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

14 DAP 17 DAP 21 DAPTreatments

Wei

ght L

oss

(g)

Control Non Hydrocooled 12% SL Hydrocooled 10% SL Hydrocooled 12% SL

Weight Loss of stored Bunched Carrots

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 12

2.4 Strawberry Trials The objectives of this trial were to test the performance of the SmartPunnet in increstrawberries, maintaining quality in terms of colour, and calyx condition, minimising antimicrobial protection under various temperature regimes. The trial was undertakCollege facilities and assistance. The fruit were sourced from Berry Gardens. All strawberries tested in this trial were harvested on the same day and they wereJubilee and Elsanta. The harvesting, packing and transportation operations that wbelow:

Field packing in punnets and in to trays.

Transporting trays \ container in a refrigerated van to the pack house .

Cooling down of the produce using vacuum cooling. The temperature befo

Sorting, grading and putting lids on.

Pulp temperature data loggers were used for the duration of the trial.

asing the shelf life of weight loss and providing

en by LLS using Writtle

of two different varieties, ere followed are described

re sorting and lidding was 3-40C.

Strawberries were subjected to 4 temperature regimes: 1 Chilled throughout (0-3oC) 2 Ambient throughout (20oC) 3 Chilled followed by ambient storage (0-3oC; 20oC) 4 Chilled-abuse-chilled (300C for 4 hours, remainder of the time at 0-3oC) From the following table it is clear that the use of SmartPunnets reduced the amount of punnets that would need to be either marked down or thrown away before the ‘Best Before’ date. The differences were greater in the case of the premium variety Jubilee which seemed to be more susceptible to disease and fruit darkening.

Table 2. Number of punnets that were still saleable by the “best before” date per treatment. Temperature Treatment

1 2 3 4

SmartPunnet 3/3 0/3 3/3 3/3

Jubilee

Control 2/3 0/3 0/3 0/3

SmartPunnet 2/3 0/3 2/3 3/3

Elsanta

Control 1/3 0/3 2/3 2/3

The difference in weight loss of strawberries stored under three different temperature regimes can be seen in the two following figures. For both varieties, the weight loss of SmartPunnets was less than 0.5% whilst that of the control punnets ranged from 1.1 to 2.2% for the Jubilee variety and from 1.5 to 3.8% for the Elsanta variety.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 13

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 14

on strawberry weight loss (Elsanta variety) Figure 12. Impact of control and LLS SmartPunnets

Figure 13. Impact of control and LLS SmartPunnets on strawberry weight loss (Jubilee variety)

wing to difficulties in the manufacturing of the punnets there was not time to carry out full trials with the OSmartPunnet. However the initial trials did give improved results for both weight loss and disease control.

nt to the WRAP project a robust supply chain for the manufacture and delivery of SmartPunnets was Subsequeestablished.

Weight loss of Strawberries (var. Elsanta) during storage under three different temperature regimes

0.0%

0.5%

1.5%

4.0%

chille + ambient chilled + abuse

1.0%

2.0%

2.5% We

loss

3.0% ight

(%

) 3.5%

4.5%

chilled d

Temperature Treatment

SmartPunnet Control

Weight loss of Strawberries (var. Jubilee) during storage under three different temperature regimes

0%

1%

2%

3%

chilled chilled + ambient chilled + abuse

Wei

ght l

oss

(

1%

2%

%)

Temperature treatment

SmartPunnet Control

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 15

Jubilee variety) in control punnets and Smar nnets (3 days after packing; including temperature abuse (treatment 4) Figure 14. Comparison of strawberries ( tPu

3 days SmartPunnet 3 days Control

3 Da ys Controlys SmartPunnet 3 Da

2 Broccoli Trials In total three trials were carried out on broccoli, two from Spain (one with a Somerfield supplier and one with a

.5

Morrisons supplier) and one from the UK. As with lettuce a number of different temperature regimes were evaluated which are given below.

The first Treatment (1) was to simulate what should happen with a good cool chain right through the system, the second and third were to simulate what happens if the produce is not kept in cool conditions either in the store or the home.

Table 3. Treatment regimes for broccoli trials

arvest direct on harvester into returnable plastic crates (RPCs).

emperature loggers inserted in the broccoli heads.

PC’s transported on pallets to trailer which then takes produce to cold store.

ime to load the truck (typical 45mins).

roccoli being transported to the pack house (~15-20mins, 10C).

roccoli stays in the cold store overnight in order to remove the field heat by forced air cooling (temperature

f cold store 3-40C, with no mist.

fter being kept for 20 hours in the cold store (3-40C) broccoli core temperatures were 3.5-4.50C, probably

epending on the position in the cold store.

Broccoli was then moved to a 30C cold store RDC. The postharvest procedure in Spain was as follows:

arvest in field into Dolavs (bulk bins of normally one tonne).

emperature loggers inserted in the broccoli heads.

olavs transported on pallets to trailer which then takes produce to cold store.

ime to load the truck (typical 45mins).

roccoli being transported to the pack house (~15-20mins, 10C).

roccoli stays in the cold store overnight in order to ove the field heat by forced air cooling (temperat

f cold store 3-40C, with no mist ) in Dolavs and the cked into cartons.

roccoli then moved from Spain to the UK importer ossibly RDC. In the case of the trial with the

omerfield supplier the broccoli was transported dry t in the case of the Morrisons supplier the crates o

ontrol produce were covered with crushed ice as per normal packhouse procedures. The crates of lined

roduce were left without ice.

In all trials the weight loss, texture (firmness) and colour of butt end and florets were monitored on a regular basis approximately every two days. The results below are summaries of the trials from Spain and the UK. The graphs presented in this section are examples and refer to trial 2 from Spain and trial 3 from the UK.

The postharvest procedure in the UK was as follows;

H

T

R

T

B

B

o

A

d

H

T

D

T

B

B

o

B

S

c

p

rem ure

n pa

or p

, bu f

Cold Store

0 1 2 34 30C 30C 30C 30C

30C 30C 30C 30C

30C 30C 30C 30C

SHIPMENT TO THE UK

Treatment 1 c

Trea

Trea

tment 2

tment 3

RDC

4

WC

and

30C

ov

erni

ght

5 6 7 8 9 10 11 12 13

30C 30C 30C 30C 30C 30C 30C 30C 30C

200C 200C 200C 30C 30C 30C 30C 30C 30C

30C 30C 30C 200C 200C 200C 200C 200C 200C

IN STORE DOMESTIC

3oC

over

Evaluating the potential of Long Life Solutions – Smart Technology to reduce

fresh produce wastage 16

Figure 15. Impact of control and LLS SmartLiners on broccoli weight loss (10% and 12% indicate the % use of particles within the packaging material)

e nsistently significantly greater than that of r all simulated temperature regimes. By 7

box nder 2%. There did not appear to be any difference in weight loss for

se the rate of cooling was slower for the liner folded over at har

igure 16. Impact of control and LLS SmartLiners on broccoli flesh temperature post harvest

Weight Loss of Whole Head Broccoli

16.00%

18.00%

Th weight loss of broccoli heads stored in cartons with no liner was cobroccoli kept in cartons lined with SmartLiner. This was observed undedays broccoli heads kept in unlined boxes had lost between 6 – 11% of their weight per head while those kept in

es lined with SmartLiner had lost uthose where the liner was folded over in the field as opposed to those which were folded over later. It can be

en from the cooling curve below that although vest there was still a quick cooling.

F

s reflect those of moisture content (Figure 17). Where SmartLiners were sed the broccoli butts were found to be firmer.

As expected measurements of firmnesu

-2.00% 3.00 5.00 7.00 9.00

0.00%

2.00%

6.00%

8.00%

10.00%

12.00%

14.00%

12.00

est

% L

oss

Trial 2 Control Trial 2 LLS 10%

Trial 2 LLS 12%

Trial 3 Control Trial 3 LLS

4.00%

Days After Harv

---- Temperature trace of broccoli flesh in RPC (lesh in RP

control) C with SmartLiner folded over after cooling

n RPC with SmartLiner folded over at harvest ---- Temperature trace with broccoli f----- Temperature trace of broccoli flesh i

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 17

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 18

Respiration measurements were made of the broccoli stored as normal or in the SmartLiners subjected to Treatment 1 conditions. The results are shown in Figure 18 and as there was so little difference, it was decided not to replicate these measurements.

Figure 18. Impact of control and LLS SmartLiners on broccoli respiration rates

Figure 17. Impact of control and LLS SmartLiners on broccoli firmness

helped to preserve the colour of the broccoli heads.

repeat these trials within the WRAP project.

(Figure 18) clearly show the use of SmartLiners have Photographs taken after 12 days storage within trial 1

Initial commercial trials were undertaken in the UK, but due to poor weather conditions and logistical difficultiesthese were not successful. It was not possible to

Respiration rate of Broccoli stored in cartons with no liner and

0

20

40

60

80

100

120

6 7 8 9 10 11 12 13 Days after Harvest

ml C

O2

/kg/

h

SmartLiner media

r

SmartLiner Control

Firmness (Shore) of Butt of Whole Head Broccoli

10.00

12.00

14.00

16.00

18.00

20.00

22.00

3.00 5.00 7.00 9.00

Days After Harvest

"Sho

re"

Trial 3 LLS

Trial 3 Control Trial 2 LLS 12%

Trial 2 LLS 10%

Trial 2 Control

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 19

Fi 9 ct of SmartLiners on broccoli appearance (10% and 12% of particles within the packaging material; treatment 1, 12 days

10%

gure 1 . Impa indicate the % use

)nero li

a rv

Control (n

12% est) fter ha

3.0 Summary & Conclusions This project was formulated to evaluate the wastage reduction through the use of LLS MIP or Smart Technology in the supply chain from harvest to the consumers refrigerator. Four products were chosen for the trials - lettuce, carrots, strawberries and broccoli. This was to be achieved by monitoring the crop all the way from the field through to the retailer regional distribution centre (RDC) and then through a number of simulated temperature scenarios at Writtle College (to mimic household storage). The intention was that using information from pilot trials, various commercial trials could be set up using initially one or two RDC’s and their corresponding supermarkets for a period of approximately one month and then rolling out the use of Smart Technology for these products to the whole retailer group. The results from the trials highlighted various difficulties and potential benefits. In the case of lettuce the reduction in weight loss achieved through the use of Smartbags was statistically significant but the overall weight loss levels were minimal (< 2% in the control samples) and therefore not commercially significant. The reduced rate of water vapour transmission demonstrated through the use of the SmartBags and SmartLiners is an advantage to reduce product dehydration but can also be a disadvantage if the crop is harvested wet such as after rain or with a heavy dew, or when the package is enclosed and rapidly cooled. The resulting high levels of free water (water activity, Aw) can encourage disease as well as producing condensation which also is visually unattractive. This was most apparent in lettuce where the current practice involves packing in the field, which means that the product can be packed wet, resulting in trapped free water and consequently encouraging the development of disease. Lettuce packed in Smartbags under these conditions showed an increased potential for disease, leading to higher levels of product rejection. As it was not possible to change the commercial packing arrangements, i.e. to reduce free water levels around the product, it was decided not to proceed with commercial trials as part of the WRAP project. Trials with the SmartLiner on UK grown carrots again revealed a statistically significant reduction in product weight loss, however as there was little weight loss in the existing supply chain with carrots the commercial benefit was limited. From the overall data, comprising weight loss, colour changes, firmness and decay during the two trials, it was concluded that carrots stored in SmartLiners were of similar quality to the control. As there was no significant commercial benefits it was decided not continue with further trials within the WRAP programme. However where there is an increased risk of disease it would be worth reconsidering the use of the SmartLiner, as there was an indication that its use could reduce the incidence of “crown disease” and the associated losses. The performance of the SmartPunnet was assessed in a trial involving UK strawberries, where the impact on shelf life, maintaining quality in terms of colour, and calyx condition, minimising weight loss and providing antimicrobial protection under various temperature regimes was monitored. The use of SmartPunnets reduced the amount of punnets that would need to be either marked down or thrown away before the ‘Best Before’ date. The differences were greater in the case of the premium variety Jubilee which seemed to be more susceptible to disease and fruit darkening. Owing to difficulties in manufacturing was not time to carry out full trials with the SmartPunnet, However the initial trials did give improved results for both weight loss and disease control. Subsequent to the WRAP project a robust supply chain for the manufacture and delivery of SmartPunnets was established. Trials with broccoli from Spain and the UK, packed using the SmartLiner revealed significant benefits. The SmartLiners worked well in reducing weight loss and preserving firmness and colour. Unfortunately it was not possible to complete successful commercial trials during the course of the WRAP project, but it is hoped to complete a commercial trial in the near future. Overall the trial results showed that Smart Technology resulted in the reduction of weight loss throughout the supply chain for all four products, and this was commercially significant for strawberries and broccoli. There were also benefits in terms of texture and colour preservation and prevention of disease. It is regrettable that full scale commercial trials were not possible within this project, which prevented the impact of Smart Technology on food and packaging waste to be assessed or quantified.

Evaluating the potential of Long Life Solutions – Smart Technology to reduce

fresh produce wastage 20

H ever LLS Smart Technology has been commercialised in a number of applications around the world (see http://www.longlifesolutions.com/index.html

ow for details). For example trials on bunched carrots did show a large

advantage and the product is now commercially packed in SmartLiners for a large UK retailer. The Co-op has also

and the f

urther trials on broccoli from UK growers and full supermarket commercial evaluation of food and packaging

avings.

urther trials on UK and non-UK strawberries, at pilot and commercial scale, and evaluation of food and

acka vings. Other berry fruit including raspberries should be also considered.

replaced the shrink-wrap film in whole cucumbers with SmartLiners. These latter projects have been successful eedback from all parties (i.e. customers, suppliers, in-store managers) has been very positive.

Recommendations for future work:

F

s

F

p ging sa

Evaluating the potential of Long Life Solutions – Smart Technology to reduce fresh produce wastage 21

www.wrap.org.uk/retail