PROK IDLERS MEDIUM TO HEAVYDUTY.pdf

description

Transcript of PROK IDLERS MEDIUM TO HEAVYDUTY.pdf

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 00

PULLEYS, IDLERS AND MATERIALS HANDLING SYSTEMS

Sandvik Materials Handling

CATALOGUE MEDIUM TO HEAVY DUTY IDLER

ISSUE 1

IMPORTANT NOTE FOR ALL DESIGNERS AND DRAFTSPERSONS

The information contained in this catalogue is dimensional only

To ensure any product selection performed provides the end users with the lowest

total cost of ownership we have provided at page 24 of this catalogue a design

submission sheet. If you require Prok to design/select equipment please complete the

submission sheet and forward to your nearest Prok office. This selection process may

result in some dimensions of the selected equipment differing from those stated in

this catalogue.

INDEX

3 ROLL INLINE CARRY & IMPACT PAGE 3

3 ROLL INLINE PLAIN P/A TRAINER PAGE 5

SINGLE ROLL FLAT CARRY & IMPACT PAGE 7

SINGLE ROLL PLAIN & DISC FLAT RETURN PAGE 9

SINGLE ROLL PLAIN P/A RETURN TRAINER PAGE 11

2 ROLL PLAIN & DISC VEE RETURN PAGE 13

2 ROLL PLAIN SUSPENDED VEE RETURN PAGE 15

3 ROLL SUSPENDED CARRY & IMPACT PAGE 17

ACCESSORIES PAGE 19

WEIGH IDLERS PAGE 22

ORDERING INFORMATION PAGE 23

PROK IDLER SELECTION DATA SHEET PAGE 24

PAGE 1 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

Total Indicator Runout (T.I.R.)This is a very important tolerance on all conveyor rolls. Excessive T.I.R. causes noisy belt flap,structural vibrations, roll imbalance and reduced bearing life. Prok roll shells are checked regularly during manufacture to ensure they comply with quality standards established by Prok Group.

Prok standard rolls are designed on sound engineering principles with particular attention toachieving:

• better balance• increased bearing life• less shell wear• reduced power consumption• lower vibration levels• and quieter running

The high level of balance achieved by Prok begins with the quality of the electric resistance welded high speed conveyor tube used in all Prok rolls.

BalanceDestructive vibration can arise from imbalance of rollers producing fluctuating loads on the idlerand supporting structure.

Excessive imbalance can cause hammer on the bearings and loosening of bearing and seal fits.

The degree of outer balance is controlled on Prok rolls during manufacture.

Every roll is test run after final assembly at an equivalent belt speed of nine (9) metres per second.

DragA key issue in roll performance is drag. Roll drag is important as it can increase power consumption, starting tensions and in some cases, can affect the life of the roll shell. The latterbeing due to belt drag over the top of the roll thereby causing flat spots on the shall face. Prokhas a unique seal design which helps to minimise drag.

BearingsAll conveyor idler rolls require the bearing and shaft assembly to operate under deflection conditions. The shaft is only supported at each end and therefore must accept the load from theshell to the bearings at each end. This results in shaft bending and angular deflection at the bearings.

Prok chose Single Row Deep Groove Precision Ball Bearings because they:

• Satisfy deflection criteria without unreasonable increases in shaft diameters between thebearings.

• Will accept the axial thrust component of the load generated by conveyor belt movement across the roller face or where rollers are inclined in the wing position.

• Permit practical shaft diameters which satisfy bearing deflection criteria and allow manufacturers to use normal dynamic capacity ratings to assess B10 bearing life.

• Retain grease at the bearing faces thus permitting an extended period of operation withouthaving to relubricate the roll.

• If the angular deflection limits are exceeded, the effect on ball bearings is less critical than for other bearing types.

Shell EndsProk Shell ends are manufactured on our premises from heavy gauge steel coil strip. They areconcentric and correctly sized to suit the selected bearings

TubeProk conveyor tube is produced to Prok specification AS 1165. The tube is carefully rolled andelectric resistance welded and drawn to ensure concentricity and that the weld is flush inside andout. Steel grade is minimum C250. Alternative grades can be supplied for special applications.Consult your Prok representative for further information.

Shell to End Cap WeldShell ends are attached to the tube by specially designed welding machines. These special purpose machines ensure that the shell tubing is clamped at the ends at all times duringthe welding process. Thereby ensuring that only minimum run-out high balance quality rolls areproduced.

Prok Breather HoleProk developed the unique breather hole system which still features in our heavy duty range ofconveyor rolls.

Each roller has a breather device through which cyclic induction and expulsion of air caused bytemperature change can take place, thus removing the opportunity for contaminants to enter thegrease reservoir and bearing assembly.

This unique feature ensures that the absolute minimum maintenance is required, and continuous roller re-lubricaton is a thing of the past.

These rolls are fitted with internal seals to ensure no foreign matter can enter the bearing cavityfrom the rear.

THE BENEFITS OF PROK CONVEYOR IDLERS

It was in 1958 that Prok Engineers saw the need to improve the design of materials handling equipment so as to be capable of handling large tonnages at higher speeds required bymining companies and operators throughout the world to achieve economies in their operation.From this sprang the realisation that much of the hardware available, in particular, idlers and pulleys, were simply not of the standard necessary to make this aim possible.

Thus, the challenge was met by a revolutionary design for conveyor idlers which incorporated the many features found in Prok idlers ever since. These features were uniquethroughout the world at that time and many remain so even today. From that time Prok have continued their research and development work and this has culminated in idlers which have allthe following predominant features.

SealingAll Prok rollers incorporate multi-labyrinth sealing and while the details vary between idlers series,the basic principles of the system adopted by Prok and the attributes of the system are commonto all rolls.

The grease filled multi-labyrinth seal prevents the ingress of contaminants in to the bearing cavity. In addition to the labyrinth seal, the outer seal has minimal clearance where theseal meets the shaft. This seal is further protected by an external weather seal.

An important point to look for in a labyrinth seal is its ability to prevent the ingress of foreign particles into the bearing area. Prok have successfully achieved this.

Prok seal components are manufactured from precision rolled steel coil. To ensure long life andresistance to corrosion all Prok rolls are assembled with galvanised outer seals.

The grease used is specially formulated for its lubricating and sealing properties.

A range of special greases are also available for extreme hot or cold climatic conditions.

The Prok multi-labyrinth seal has been continuously refined to become the most effective seal inthe business.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 2

IMPORTANT POINTS TO CONSIDER WHEN SELECTING IDLER ROLLERS

• Shaft diameters must be large enough to limit angular deflection at bearings to withinbearing supplier recommendations.

• Design of seals must prevent ingress of dirt and water vapour to the bearing cavity.

• Utilise rollers with the minimum external seal gap.

• Choose rollers with large grease cavity.

• Select the roller with a low mass of rotating parts.

• Choose rollers where shell ends are integral with the shell and are pocket-free.

• Maximum performance is achieved where the roller load capacities of shells, shell ends,and bearings are balanced.

• Ensure minimum run-out to prevent vibration transmission to belt.

• Provided for vibration-free running and future capacity increases by selecting highbalance rollers.

• Belt protection is enhanced by selecting rollers with well-rounded corners.

• All components of the idler are expected to run for millions of revolutions and should beprecision made to closest possible tolerances.

• Utilise precision ball bearings to retain grease and give long maintenance free life.

• Rollers requiring frequent regreasing through grease nipples are subject to ingress of dirtand water to the bearing.

• Rollers with internal rubbing seals such as sealed-for-life bearings with felt or neoprenerubbing seals are subject to wear and eventual bearing failure.

• Rollers should be tightly fitted to a rigid base designed to shed dirt by minimising materialbuildup.

• Rollers operating in the open or subject to hosing down during inhouse housekeepingshould be fitted with weather seals.

• Select rolls in which labyrinth sealing has a minimum grease shear area.

PROK IDLER STANDARD DATA

Unless otherwise agreed PROK idlers will be supplied to the standards listed below. Thesestandards have been developed over 40 years of research and experience in conveyor design tosuit customer requirements. The resulting product is technically and commercially sound, and isdesigned to virtually eliminate the need for maintenance. Quality controls and systems are in placein accordance with AS/NZS I.S.O. 9001 - 1994. Our certification body is BUREAU VERITASQUALITY INTERNATIONAL, who are recognized throughout the world, in the field of quality andsafety standards.

MANUFACTURING TOLERANCES.Nominal O.D. of Roll - Steel Shell +/- 0.3 mm Rubber Disc +/- 0.8 mmThickness of Steel shell: +/- 0.5 mmRoll face length: +/- 1.5 mmCenter roll height above base line +/- 2.0 mmTransverse hole centers: +/- 2.0 mmLongitudinal hole centers: +/- 2.0 mmReturn bracket drop height: +/- 2.0 mmTrough angle: +/- 1°

Roll corner radius: 3.0 mm minimumCorner weld penetration: 80% minimumTotal Indicator Reading (T.I.R.) Runout max.

Over steel shell: Up to 750 mm long: 0.50 mmAbove 750 mm long: 0.0007 x length

Out of balance: Standard rolls - 0.056 NmWeighing rolls - 0.014 Nm

Angular deflection at bearing under full load 10 min.

IDLER MOUNTING CENTERSTo generally conform with ISO 1535 and accepted Australian practice, the mounting hole centerslisted in the dimensional tables are based on:-

BELT WIDTH + 250 mm for belts up to and including 1200 mm.BELT WIDTH + 300 mm for belts over 1200 mm up to and including 1500 mm.BELT WIDTH + 400 mm for belts 1600 mm and over.

Mounting foot slots are sized throughout the range to suit M 12 bolts.We also recommend the use of M12 flat washers for attachment to the structure.

BASIC PROK ROLL CHARACTERISTICSProk Series Roll Dia. Bearing Bearing Dynamic C.E.M.A. Rating

Designation Capacity05 114 6205 14.0 kN C4 1/210 102 6204 12.7 kN C411 114 6204 12.7 kN C4 1/212 127 6204 12.7 kN C515 127 6205 14.0 kN C520 152 6205 14.0 kN C625 127 6305 22.5 kN C530 152 6305 22.5 kN C635 152 6306 28.1 kN E640 178 6306 28.1 kN E745 152 6307 33.2 kN E6 plus50 178 6307 33.2 kN E7 plus54 152 6308 41.0 kN super 655 152 6309 52.7 kN super 6+59 178 6308 41.0 kN super 760 178 6309 52.7 kN super 7+

ShaftsA main cause of bearing failure is excessive shaft deflection.

All Prok rolls are designed to limit the extent of deflection to within the allowable limits of thebearing.

Shaft diameters are selected for the idler assembly under full load operating conditions.

LubricationProk rolls are Factory greased to ensure correct quantity. Large greaseways provided to minimisegreasing pressure. Various types of grease are available to suit extreme temperatures.

Provision for regreasing is available if required, but is not recommended.

FinishProk standard paint finishes include solvent washed and spray painted alkyd yellow enamel onrolls and structural members dip painted with DUAL-COAT dipping enamel.

A wide variety of alternate finishes are available. The most common alternative is hot dip galvanising to AS 1650, which can be applied to frames and rollers.

Alternative MaterialsProk rolls are available in a variety of materials to suit particularly arduous applications, materialssuch as Aluminium, and high chromium alloys are available. Please contact your nearest ProkOffice for further details on our products to solve your really difficult problems.

Low NoiseNoise generation is becoming an increasing issue with new Government Legislation. Prok Grouphave developed a range of alternative rolls to address this issue. Each application will be different and may require different roll solutions. Please contact your nearest Prok Office for further details.

Aluminium RollsProk have developed a range of standard aluminium rolls.

These are ideally suited for use in salt applications or other highly corrosive materials handling systems.

Aluminium rolls offer less resistance to belt acceleration.

Provides less resistance on the conveyor normal running state, as a result of reduced mass ofrotating parts.

These standard aluminium rolls are fitted with special seals which are corrosion resistant.

Use of these rolls will significantly reduce supporting structures, particularly on mobile stackingand loading installations.

Consult your nearest PROK office for recommendations.

Features of the Prok Base FrameIdler bases are designed to provide a minimum gap between rollers, and give added protection to the conveyor belt.Frame outer slopers are designed to prevent material build uparound the shell end thereby avoiding premature shell wear due to roll jamming.

Base frame cross members are designed for optimum strength weight ratio whilst providing adequate support for the rolls under load conditions.

Self CleaningThe inverted angle base frame has a self cleaning action by virtue of its sloping upper surfaces. This feature eliminates the possibility of rolls jamming due to material build up.

WeldingJig welding of the base frames ensures slotted mounting brackets are accurately aligned. Thishas the effect of reducing installation costs and belt wear. All roll supports are welded to provide smooth weld surfaces for the application of protective coatings. Welds arecleaned prior to surface treatment.

BlastingAll frames and brackets are shot blasted prior to surface treatment. This process removes millscale and any oil and grease to ensure good coverage and adhesion of the surface coatings.

Shot blasting is to AS 1627, Part 4-1989, class 2.

InspectionAll frames are inspected prior to commencing the welding run to confirm accuracy of majordimensions. Selected frames are removed from the productions run at intervals and subjected to full dimension checks and weld quality inspection.

55 x 55 x 5EA

65 x 65 x 5EA

75 x 75 x 6EA

90 x 90 x 6EA

100 x 100 x 8EA

125 x 125 x 8EA

150 x 150 x 10EA

PAGE 3 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

25113-0750-00 280 1000 305 862 347 808 368 776 403 707 140 205 10.5 26.0

25113-0800-00 296 1050 317 908 362 852 384 818 422 746 150 212 10.8 27.8

25113-0900-00 333 1150 330 1015 381 953 405 915 448 835 150 212 11.7 30.1

25113-1000-00 360 1250 348 1092 403 1026 430 987 476 900 165 221 12.6 34.9

25113-1050-00 385 1300 357 1164 416 1095 444 1053 494 960 165 221 13.2 37.8

25113-1200-00 438 1450 386 1317 453 1240 485 1192 542 1088 180 232 14.7 43.7

25113-1350-00 490 1650 404 1467 479 1382 515 1330 579 1214 180 232 16.2 48.1

25113-1400-00 496 1700 414 1484 490 1398 527 1345 591 1228 200 240 16.2 56.1

25113-1500-00 543 1800 430 1619 514 1526 554 1469 624 1342 200 240 17.7 61.8

25113-1600-00 563 2000 457 1677 544 1581 585 1522 658 1390 240 260 18.0 75.4

25113-1800-00 627 2200 479 1861 576 1756 622 1691 704 1545 240 260 19.8 82.0

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

35113-0750-00 286 1000 335 879 378 817 397 782 432 718 140 230 17.1 38.3

35113-0800-00 300 1050 346 919 392 856 412 819 449 751 150 237 17.7 40.4

35113-0900-00 339 1150 360 1031 411 962 435 922 477 845 150 237 19.5 43.6

35113-1000-00 366 1250 378 1109 434 1036 459 993 505 911 165 246 20.7 49.1

35113-1050-00 391 1300 386 1181 446 1104 473 1059 522 971 165 246 21.9 51.1

35113-1200-00 444 1450 416 1333 484 1249 515 1199 571 1099 180 257 24.3 58.3

35113-1350-00 496 1650 433 1483 510 1391 545 1336 608 1225 180 257 26.4 63.7

35113-1400-00 502 1700 443 1500 521 1407 556 1352 620 1239 200 265 26.7 71.8

35113-1500-00 549 1800 459 1636 544 1536 583 1476 653 1352 200 265 28.8 78.7

35113-1600-00 569 2000 486 1693 574 1590 615 1528 687 1401 240 285 29.7 90.7

35113-1800-00 633 2200 508 1878 606 1765 651 1697 733 1555 240 285 32.4 101.8

35113-2000-00 708 2400 553 2094 663 1970 713 1895 805 1736 280 304 35.7 130.7

35113-2200-00 787 2600 580 2321 702 2186 759 2103 861 1927 280 304 39.0 145.3

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

30113-0750-00 283 1000 317 856 359 798 379 764 413 691 140 218 16.8 32.3

30113-0800-00 299 1050 330 902 374 842 395 806 431 730 150 225 17.4 34.4

30113-0900-00 336 1150 342 1009 393 943 416 904 458 819 150 225 18.9 37.3

30113-1000-00 363 1250 361 1087 415 1017 441 975 486 885 165 234 20.1 43.9

30113-1050-00 388 1300 369 1159 428 1085 455 1041 503 945 165 234 21.3 45.9

30113-1200-00 441 1450 398 1311 465 1230 497 1181 552 1073 180 245 23.7 52.7

30113-1350-00 493 1650 416 1461 491 1372 526 1318 589 1198 180 245 25.8 57.7

30113-1400-00 499 1700 426 1478 502 1388 538 1334 601 1213 200 253 26.1 65.7

30113-1500-00 546 1800 442 1614 526 1516 565 1458 634 1326 200 253 28.2 72.3

30113-1600-00 566 2000 469 1671 556 1571 596 1510 668 1375 240 273 29.1 86.2

30113-1800-00 630 2200 491 1856 588 1746 633 1679 714 1529 240 273 31.8 94.0

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

40113-0750-00 286 1000 347 870 389 804 408 767 441 699 140 243 20.7 41.6

40113-0800-00 300 1050 359 910 403 843 423 804 458 733 150 250 21.3 44.0

40113-0900-00 339 1150 372 1022 425 949 445 907 486 827 150 250 23.4 47.5

40113-1000-00 366 1250 390 1100 445 1023 470 978 514 892 165 259 24.9 53.0

40113-1050-00 391 1300 399 1172 458 1091 484 1044 532 953 165 259 26.1 55.3

40113-1200-00 444 1450 428 1325 495 1236 525 1184 580 1081 180 270 28.8 62.8

40113-1350-00 496 1650 446 1474 521 1378 555 1321 617 1206 180 270 31.5 68.8

40113-1400-00 502 1700 456 1492 532 1394 567 1337 629 1221 200 278 31.8 76.9

40113-1500-00 549 1800 472 1627 556 1523 594 1461 662 1334 200 278 34.2 84.1

40113-1600-00 569 2000 499 1685 586 1577 625 1513 697 1382 240 298 35.4 96.4

40113-1800-00 633 2200 520 1869 618 1752 662 1682 742 1537 240 298 38.7 107.8

40113-2000-00 708 2400 565 2085 674 1957 724 1880 814 1718 280 317 42.3 140.6

40113-2200-00 787 2600 592 2312 714 2173 769 2089 870 1909 280 317 46.5 152.5

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

45113-0750-00 284 1000 334 877 377 816 397 780 432 716 140 230 17.4 41.3

45113-0800-00 298 1050 346 917 391 854 412 817 448 750 150 237 18.0 43.4

45113-0900-00 337 1150 359 1029 411 960 434 920 476 844 150 237 19.8 47.2

45113-1000-00 364 1250 378 1107 433 1034 459 991 504 909 165 246 21.0 53.0

45113-1050-00 389 1300 386 1179 446 1102 473 1057 522 970 165 246 22.2 55.3

45113-1200-00 442 1450 415 1332 483 1247 514 1197 570 1098 180 257 24.3 62.8

45113-1350-00 494 1650 433 1481 509 1389 544 1334 607 1223 180 257 26.7 68.5

45113-1400-00 500 1700 443 1499 520 1406 556 1350 619 1238 200 265 27.0 76.9

45113-1500-00 547 1800 459 1634 544 1534 582 1474 653 1351 200 265 29.1 81.7

45113-1600-00 567 2000 486 1692 574 1589 614 1527 687 1399 240 285 30.0 94.0

45113-1800-00 631 2200 508 1876 606 1764 651 1696 732 1554 240 285 32.7 105.1

45113-2000-00 706 2400 553 2092 662 1969 713 1893 804 1735 280 304 36.0 134.6

45113-2200-00 785 2600 580 2319 702 2184 758 2102 860 1926 280 304 39.6 145.9

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

50113-0750-00 284 1000 346 868 389 803 407 765 441 698 140 243 30.3 54.2

50113-0800-00 298 1050 358 908 403 841 422 802 458 732 150 250 31.5 56.9

50113-0900-00 337 1150 372 1020 422 947 445 905 485 826 150 250 34.2 61.9

50113-1000-00 364 1250 390 1098 445 1021 469 976 513 891 165 259 36.3 68.3

50113-1050-00 389 1300 398 1170 457 1089 484 1042 531 951 165 259 38.4 71.5

50113-1200-00 442 1450 427 1323 495 1234 525 1182 579 1079 180 270 42.3 80.5

50113-1350-00 494 1650 445 1472 521 1376 555 1319 616 1205 180 270 46.2 88.3

50113-1400-00 500 1700 455 1490 532 1393 566 1335 628 1219 200 278 46.8 96.7

50113-1500-00 547 1800 471 1625 555 1521 593 1459 662 1333 200 278 50.4 103.0

50113-1600-00 567 2000 498 1683 585 1576 625 1512 696 1381 240 298 51.9 115.9

50113-1800-00 631 2200 520 1867 617 1751 661 1681 741 1535 240 298 56.7 129.4

50113-2000-00 706 2400 565 2083 674 1956 723 1879 813 1717 280 317 62.7 161.0

50113-2200-00 785 2600 592 2310 713 2171 769 2087 869 1907 280 317 68.7 175.0

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

54113-0750-00 286 1000 335 879 378 817 397 782 432 718 140 230 18.3 44.0

54113-0800-00 300 1050 346 919 392 856 412 819 449 751 150 237 18.9 46.4

54113-0900-00 339 1150 360 1031 411 962 435 922 477 845 150 237 20.7 50.2

54113-1000-00 366 1250 378 1109 434 1036 459 993 505 911 165 246 21.9 56.0

54113-1050-00 391 1300 386 1181 446 1104 473 1059 522 971 165 246 22.8 58.3

54113-1200-00 444 1450 416 1333 484 1249 515 1199 571 1099 180 257 25.2 66.1

54113-1350-00 496 1650 433 1483 510 1391 545 1336 608 1225 180 257 27.6 72.1

54113-1400-00 502 1700 443 1500 521 1407 556 1352 620 1239 200 265 27.6 80.0

54113-1500-00 549 1800 459 1636 544 1536 583 1476 653 1352 200 265 29.7 85.6

54113-1600-00 569 2000 486 1693 574 1590 615 1528 687 1401 240 285 30.6 97.9

54113-1800-00 633 2200 508 1877 606 1765 651 1697 733 1555 240 285 33.6 109.3

54113-2000-00 708 2400 553 2094 663 1970 713 1895 805 1736 280 304 36.9 139.1

54113-2200-00 787 2600 580 2321 702 2186 759 2103 860 1927 280 304 40.2 150.7

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

55113-1200-00 444 1450 416 1333 484 1249 515 1199 571 1099 180 257 25.8 72.1

55113-1350-00 496 1650 433 1483 510 1391 545 1336 608 1225 180 257 28.2 78.7

55113-1400-00 502 1700 443 1500 521 1407 556 1352 620 1239 200 265 28.5 87.1

55113-1500-00 549 1800 459 1636 544 1536 583 1476 653 1352 200 265 30.3 92.5

55113-1600-00 569 2000 486 1693 574 1590 615 1528 687 1401 240 285 31.2 105.1

55113-1800-00 633 2200 508 1878 606 1765 651 1697 733 1555 240 285 34.2 117.4

55113-2000-00 708 2400 553 2094 663 1970 713 1895 805 1736 280 304 37.2 147.8

55113-2200-00 787 2600 580 2321 702 2186 759 2103 861 1927 280 304 40.8 160.3

55113-2400-00 848 2800 641 2497 773 2353 834 2264 944 2074 350 344 43.5 222.1

55113-2500-00 873 2900 649 2569 785 2421 848 2330 961 2135 350 344 44.7 228.5

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

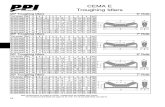

3 ROLL INLINE CARRY & IMPACT

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

25 30 35,45,54 & 55 40,50

ANGLE SERIES

Nominated E and F dimensions are based on standard base angle sizes. These dimensions will vary with a in base angle size as tabulated below.

E

140

150

165

180

200

240

-

F

205

212

221

232

240

260

-

E

140

150

165

180

200

240

-

F

218

225

234

245

253

273

-

E

140

150

165

180

200

240

280

F

230

237

246

257

265

285

304

E

140

150

165

180

200

240

280

F

243

250

259

270

278

298

317

E

140

150

165

180

200

240

280

F

243

250

259

270

278

298

317

Nominated E and F dimensions are based on standard base angle sizes. These dimensions will vary with a in base angle size as tabulated below.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 4

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

59113-0750-00 286 1000 347 870 389 804 408 767 441 699 140 243 31.2 56.9

59113-0800-00 300 1050 359 910 403 843 423 804 458 733 150 250 32.1 59.6

59113-0900-00 339 1150 372 1022 423 949 445 907 486 827 150 250 35.1 64.6

59113-1000-00 366 1250 390 1100 445 1023 470 978 514 892 165 259 37.2 71.3

59113-1050-00 391 1300 399 1172 458 1091 484 1044 532 953 165 259 39.0 74.5

59113-1200-00 444 1450 428 1325 495 1236 525 1184 580 1081 180 270 43.2 84.1

59113-1350-00 496 1650 446 1474 521 1378 555 1321 617 1206 180 270 47.1 91.9

59113-1400-00 502 1700 456 1492 532 1394 567 1337 629 1221 200 278 47.7 100.3

59113-1500-00 549 1800 472 1627 556 1523 594 1461 662 1334 200 278 51.3 106.9

59113-1600-00 569 2000 499 1685 586 1577 625 1513 697 1382 240 298 52.8 119.8

59113-1800-00 633 2200 520 1869 618 1752 662 1682 742 1537 240 298 57.6 133.6

59113-2000-00 708 2400 565 2085 674 1957 724 1880 814 1718 280 317 63.3 169.4

59113-2200-00 787 2600 592 2312 714 2173 769 2089 870 1909 280 317 69.3 184.0

SERIES 59 ROLL DIAMETER 178 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

3 ROLL INLINE CARRY & IMPACT

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

30114-0750-00 282 1000 320 853 362 794 381 759 415 686 140 221 23.4 47.7

30114-0800-00 298 1050 333 899 377 837 398 801 434 724 150 228 24.6 49.9

30114-0900-00 335 1150 345 1006 395 938 419 899 460 814 150 228 27.0 54.5

30114-1000-00 362 1250 364 1083 418 1012 443 970 488 879 165 237 29.4 63.0

30114-1050-00 387 1300 372 1155 430 1080 458 1036 506 939 165 237 31.5 66.7

30114-1200-00 440 1450 401 1308 468 1225 499 1176 554 1067 180 248 34.8 76.3

30114-1350-00 492 1650 419 1458 494 1367 529 1313 591 1193 180 248 39.0 85.0

30114-1400-00 498 1700 429 1475 505 1384 540 1329 603 1207 200 256 39.3 95.2

30114-1500-00 545 1800 445 1610 528 1512 567 1453 636 1321 200 256 42.3 101.5

30114-1600-00 565 2000 472 1668 558 1567 599 1505 670 1369 240 276 44.4 119.0

30114-1800-00 629 2200 494 1852 590 1742 636 1674 716 1523 240 276 49.2 130.7

SERIES 30 ROLL DIAMETER 159 IMPACT BEARING SIZE 6307CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

50114-0750-00 286 1000 347 870 389 804 408 767 441 699 140 243 27.3 53.9

50114-0800-00 300 1050 359 910 403 843 423 804 458 733 150 250 27.6 56.2

50114-0900-00 339 1150 372 1022 423 949 445 907 486 827 150 250 30.9 61.4

50114-1000-00 366 1250 390 1100 445 1023 470 978 514 892 165 259 33.9 70.6

50114-1050-00 391 1300 399 1172 458 1091 484 1044 532 953 165 259 36.0 74.6

50114-1200-00 444 1450 428 1325 495 1236 525 1184 580 1081 180 270 39.6 84.3

50114-1350-00 496 1650 446 1474 521 1378 555 1321 617 1206 180 270 44.7 94.0

50114-1400-00 502 1700 456 1492 532 1394 567 1337 629 1221 200 278 45.0 104.2

50114-1500-00 549 1800 472 1627 556 1523 594 1461 662 1334 200 278 48.3 110.9

50114-1600-00 569 2000 499 1685 586 1577 625 1513 697 1382 240 298 50.7 126.8

50114-1800-00 633 2200 520 1869 618 1752 662 1682 742 1537 240 298 54.6 140.6

50114-2000-00 708 2400 565 2085 674 1957 724 1880 814 1718 280 317 62.1 180.4

50114-2200-00 787 2600 592 2312 714 2173 769 2089 870 1909 280 317 68.1 196.3

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307IMPACT

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

60113-1000-00 366 1250 390 1100 445 1023 470 978 514 892 165 259 37.8 76.4

60113-1050-00 391 1300 399 1172 458 1091 484 1044 532 953 165 259 39.6 79.9

60113-1200-00 444 1450 428 1325 495 1236 525 1184 580 1081 180 270 43.8 90.1

60113-1350-00 496 1650 446 1474 521 1378 555 1321 617 1206 180 270 47.7 98.2

60113-1400-00 502 1700 456 1492 532 1394 567 1337 629 1221 200 278 48.3 106.9

60113-1500-00 549 1800 472 1627 556 1523 594 1461 662 1334 200 278 51.9 114.1

60113-1600-00 569 2000 499 1685 586 1577 625 1513 697 1382 240 298 53.4 127.3

60113-1800-00 633 2200 520 1869 618 1752 662 1682 742 1537 240 298 58.2 139.0

60113-2000-00 708 2400 565 2085 674 1957 724 1880 814 1718 280 317 63.9 174.2

60113-2200-00 787 2600 592 2312 714 2173 769 2089 870 1909 280 317 69.9 189.4

60113-2400-00 848 2800 653 2488 784 2340 844 2250 953 2056 350 357 74.7 253.0

60113-2500-00 873 2900 662 2560 797 2408 859 2315 971 2116 350 357 76.5 260.3

SERIES 60 ROLL DIAMETER 178 IMPACT BEARING SIZE 6309

55 x 55 x 5EA

65 x 65 x 5EA

75 x 75 x 6EA

90 x 90 x 6EA

100 x 100 x 8EA

125 x 125 x 8EA

150 x 150 x 10EA

59 & 60

ANGLE SERIES

Nominated E and F dimensions are based on standard base angle sizes. These dimensions will vary with a in base angel size as tabulated below.

E

140

150

165

180

200

240

-

F

221

228

237

248

256

276

-

E

140

150

165

180

200

240

280

F

233

240

249

260

268

288

307

E

140

150

165

180

200

240

280

F

243

250

259

270

278

298

317

55 x 55 x 5EA

65 x 65 x 5EA

75 x 75 x 6EA

90 x 90 x 6EA

100 x 100 x 8EA

125 x 125 x 8EA

150 x 150 x 10EA

30 IMPACT 45 IMPACT 50 IMPACT

ANGLE SERIESCODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

C D C D C D C D R.P TOTAL

45114-0750-00 286 1000 338 876 381 814 400 778 435 713 140 233 24.0 50.9

45114-0800-00 300 1050 350 916 395 852 415 815 452 746 150 240 24.6 53.2

45114-0900-00 339 1150 363 1029 414 959 437 918 479 841 150 240 27.3 57.8

45114-1000-00 366 1250 381 1106 437 1032 462 989 507 906 165 249 29.4 66.7

45114-1050-00 391 1300 390 1178 449 1101 476 1055 525 966 165 249 31.3 70.1

45114-1200-00 444 1450 419 1331 487 1245 518 1195 573 1094 180 260 34.8 79.8

45114-1350-00 496 1650 437 1481 513 1388 548 1332 610 1220 180 260 39.3 88.6

45114-1400-00 502 1700 447 1498 524 1404 559 1348 622 1234 200 268 39.6 98.8

45114-1500-00 549 1800 463 1633 547 1532 586 1472 656 1348 200 268 42.3 105.2

45114-1600-00 569 2000 490 1691 577 1587 617 1524 690 1396 240 288 44.4 120.8

45114-1800-00 633 2200 511 1875 609 1762 654 1693 735 1550 240 288 48.0 134.3

45114-2000-00 708 2400 556 2091 666 1967 716 1891 807 1731 280 307 54.6 172.9

45114-2200-00 787 2600 583 2319 705 2183 761 2099 863 1922 280 307 60.0 188.2

SERIES 45 ROLL DIAMETER 159 BEARING SIZE 6307IMPACT

PAGE 5 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

25116-0750-00 280 1000 431 1199 475 1159 499 1161 537 1092 140 213 10.5 55.4

25116-0800-00 296 1050 444 1245 490 1203 515 1203 556 1131 150 220 10.8 57.6

25116-0900-00 333 1150 453 1333 508 1304 530 1284 575 1206 150 220 11.7 60.6

25116-1000-00 360 1250 475 1430 536 1395 561 1372 610 1285 165 229 12.6 71.5

25116-1050-00 385 1300 480 1483 538 1429 569 1422 621 1331 165 229 13.2 75.2

25116-1200-00 438 1450 509 1635 576 1573 611 1562 669 1459 180 240 14.7 89.4

25116-1350-00 490 1650 527 1785 602 1716 641 1699 706 1584 180 240 16.2 96.7

25116-1400-00 496 1700 540 1821 623 1766 658 1732 732 1628 200 248 16.2 103.9

25116-1500-00 543 1800 549 1918 636 1860 673 1822 751 1713 200 248 17.7 111.6

25116-1600-00 563 2000 533 2013 676 1950 716 1908 801 1789 240 268 18.0 130.4

25116-1800-00 627 2200 608 2217 708 2124 759 2093 845 1944 240 268 19.8 140.1

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

30116-0750-00 283 1000 431 1199 475 1159 499 1161 537 1092 140 226 16.8 61.7

30116-0800-00 299 1050 444 1245 490 1203 515 1203 556 1131 150 233 17.4 64.2

30116-0900-00 336 1150 453 1333 508 1304 530 1284 575 1206 150 233 18.9 67.8

30116-1000-00 363 1250 475 1430 536 1395 561 1372 610 1285 165 242 20.1 80.5

30116-1050-00 388 1300 480 1483 538 1429 569 1422 621 1331 165 242 21.3 83.3

30116-1200-00 441 1450 509 1635 576 1573 611 1562 669 1459 180 253 23.7 98.4

30116-1350-00 493 1650 527 1785 602 1716 641 1699 706 1584 180 253 25.8 106.3

30116-1400-00 499 1700 540 1821 623 1766 658 1732 732 1628 200 261 26.1 113.5

30116-1500-00 546 1800 549 1918 636 1860 673 1822 751 1713 200 261 28.2 122.1

30116-1600-00 566 2000 533 2013 676 1950 716 1908 801 1789 240 281 29.1 141.2

30116-1800-00 630 2200 608 2217 708 2124 759 2093 845 1944 240 281 31.8 152.1

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

3 ROLL INLINE PLAIN P/A TRAINER

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

35116-0750-00 286 1000 446 1227 490 1185 513 1166 551 1117 140 238 17.1 68.8

35116-0800-00 300 1050 458 1267 509 1241 534 1220 568 1151 150 245 17.7 71.3

35116-0900-00 339 1150 468 1361 523 1330 550 1306 596 1245 150 245 19.5 75.4

35116-1000-00 366 1250 489 1457 551 1421 581 1394 631 1324 165 254 20.7 87.0

35116-1050-00 391 1300 494 1510 558 1472 589 1444 634 1356 165 254 21.9 89.8

35116-1200-00 444 1450 524 1663 591 1598 625 1567 683 1484 180 265 24.3 105.3

35116-1350-00 496 1650 541 1813 617 1742 655 1704 720 1610 180 265 26.4 113.6

35116-1400-00 502 1700 555 1849 638 1792 678 1753 746 1652 200 273 26.7 120.9

35116-1500-00 549 1800 564 1946 651 1886 693 1844 765 1738 200 273 28.8 129.9

35116-1600-00 569 2000 598 2041 691 1975 736 1929 813 1814 240 293 29.7 147.1

35116-1800-00 633 2200 623 2245 723 2150 773 2098 859 1969 240 293 32.4 161.4

35116-2000-00 708 2400 661 2423 775 2338 829 2280 924 2136 280 312 35.7 190.0

35116-2200-00 787 2600 684 2632 804 2510 863 2455 965 2298 280 312 39.0 208.2

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

40116-0750-00 283 1000 446 1227 490 1185 513 1166 551 1117 140 251 20.7 72.1

40116-0800-00 299 1050 458 1267 509 1241 534 1220 568 1151 150 258 21.3 74.9

40116-0900-00 336 1150 468 1361 523 1330 550 1306 596 1245 150 258 23.4 79.3

40116-1000-00 363 1250 489 1457 551 1421 581 1394 631 1324 165 267 24.9 90.9

40116-1050-00 388 1300 494 1510 558 1472 589 1444 634 1356 165 267 26.1 94.0

40116-1200-00 441 1450 524 1663 591 1598 625 1567 683 1484 180 278 28.8 109.8

40116-1350-00 493 1650 541 1813 617 1742 655 1704 720 1610 180 278 31.5 118.7

40116-1400-00 499 1700 555 1849 638 1792 678 1753 746 1652 200 286 31.8 126.0

40116-1500-00 546 1800 564 1946 651 1886 693 1844 765 1738 200 286 34.2 135.3

40116-1600-00 566 2000 598 2041 691 1975 736 1929 813 1814 240 306 35.4 152.8

40116-1800-00 630 2200 623 2245 723 2150 773 2098 859 1969 240 306 38.7 167.4

40116-2000-00 546 2400 661 2423 775 2338 829 2280 924 2136 280 325 42.3 199.9

40116-2200-00 566 2600 684 2632 804 2510 863 2455 965 2298 280 325 46.5 215.4

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

45116-0750-00 284 1000 446 1227 490 1185 513 1166 551 1117 140 238 17.4 71.8

45116-0800-00 298 1050 458 1267 509 1241 534 1220 568 1151 150 245 18.0 74.3

45116-0900-00 337 1150 468 1361 523 1330 550 1306 596 1245 150 245 19.8 79.0

45116-1000-00 364 1250 489 1457 551 1421 581 1394 631 1324 165 254 21.0 90.9

45116-1050-00 389 1300 494 1510 558 1472 589 1444 634 1356 165 254 22.2 94.0

45116-1200-00 442 1450 524 1663 591 1598 625 1567 683 1484 180 265 24.3 109.8

45116-1350-00 494 1650 541 1813 617 1742 655 1704 720 1610 180 265 26.7 118.4

45116-1400-00 500 1700 555 1849 638 1792 678 1753 746 1652 200 273 27.0 126.0

45116-1500-00 547 1800 564 1946 651 1886 693 1844 765 1738 200 273 29.1 132.9

45116-1600-00 567 2000 598 2041 691 1975 736 1929 813 1814 240 293 30.0 150.4

45116-1800-00 631 2200 623 2245 723 2150 773 2098 859 1969 240 293 32.7 164.7

45116-2000-00 706 2400 661 2423 775 2338 829 2280 924 2136 280 312 36.0 193.9

45116-2200-00 785 2600 684 2632 804 2510 863 2455 965 2298 280 312 39.6 208.8

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

50116-0750-00 284 1000 446 1227 490 1185 513 1166 551 1117 140 251 30.3 84.7

50116-0800-00 298 1050 458 1267 509 1241 534 1220 568 1151 150 258 31.5 87.8

50116-0900-00 337 1150 468 1361 523 1330 550 1306 596 1245 150 258 34.2 93.7

50116-1000-00 364 1250 489 1457 551 1421 581 1394 631 1324 165 267 36.3 106.2

50116-1050-00 389 1300 494 1510 558 1472 589 1444 634 1356 165 267 38.4 110.2

50116-1200-00 442 1450 524 1663 591 1598 625 1567 683 1484 180 278 42.3 127.5

50116-1350-00 494 1650 541 1813 617 1742 655 1704 720 1610 180 278 46.2 138.2

50116-1400-00 500 1700 555 1849 638 1792 678 1753 746 1652 200 286 46.8 145.8

50116-1500-00 547 1800 564 1946 651 1886 693 1844 765 1738 200 286 50.4 154.2

50116-1600-00 567 2000 598 2041 691 1975 736 1929 813 1814 240 306 51.9 172.3

50116-1800-00 631 2200 623 2245 723 2150 773 2098 859 1969 240 306 56.7 189.0

50116-2000-00 706 2400 661 2423 775 2338 829 2280 924 2136 280 325 62.7 220.3

50116-2200-00 785 2600 684 2632 804 2510 863 2455 965 2298 280 325 68.7 237.9

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 6

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

54116-0750-00 286 1000 446 1227 490 1185 513 1166 551 1117 140 238 18.3 74.5

54116-0800-00 300 1050 458 1267 509 1241 534 1220 568 1151 150 245 18.9 77.3

54116-0900-00 339 1150 468 1361 523 1330 550 1306 596 1245 150 245 20.7 82.0

54116-1000-00 366 1250 489 1457 551 1421 581 1394 631 1324 165 254 21.9 93.9

54116-1050-00 391 1300 494 1510 558 1472 589 1444 634 1356 165 254 22.8 97.0

54116-1200-00 444 1450 524 1663 591 1598 625 1567 683 1484 180 265 25.2 113.1

54116-1350-00 496 1650 541 1813 617 1742 655 1704 720 1610 180 265 27.6 122.0

54116-1400-00 502 1700 555 1849 638 1792 678 1753 746 1652 200 273 27.6 129.6

54116-1500-00 549 1800 564 1946 651 1886 693 1844 765 1738 200 273 29.7 136.8

54116-1600-00 569 2000 598 2041 691 1975 736 1929 813 1814 240 293 30.6 154.3

54116-1800-00 633 2200 623 2245 723 2150 773 2098 859 1969 240 293 33.6 168.9

54116-2000-00 708 2400 661 2423 775 2338 829 2280 924 2136 280 312 36.9 198.4

54116-2200-00 787 2600 684 2632 804 2510 863 2455 965 2298 280 312 40.2 213.6

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

55116-1200-00 444 1450 524 1663 591 1598 625 1567 683 1484 180 265 25.8 119.1

55116-1350-00 496 1650 541 1813 617 1742 655 1704 720 1610 180 265 28.2 128.6

55116-1400-00 502 1700 555 1849 638 1792 678 1753 746 1652 200 273 28.5 136.2

55116-1500-00 549 1800 564 1946 651 1886 693 1844 765 1738 200 273 30.3 143.7

55116-1600-00 569 2000 598 2041 691 1975 736 1929 813 1814 240 293 31.2 161.5

55116-1800-00 633 2200 623 2245 723 2150 773 2098 859 1969 240 293 34.2 177.0

55116-2000-00 708 2400 661 2423 775 2338 829 2280 924 2136 280 312 37.2 207.1

55116-2200-00 787 2600 684 2632 804 2510 863 2455 965 2298 280 312 40.8 223.2

55116-2400-00 848 2800 745 2808 880 2703 944 2633 1056 2430 350 352 43.5 306.9

55116-2500-00 873 2900 761 2917 897 2788 964 2715 1080 2504 350 352 44.7 314.6

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

3 ROLL INLINE PLAIN P/A TRAINER

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

60116-1000-00 366 1250 489 1457 551 1421 581 1394 631 1324 165 267 37.8 114.3

60116-1050-00 391 1300 494 1510 558 1472 589 1444 634 1356 165 267 39.6 118.6

60116-1200-00 444 1450 524 1663 591 1598 625 1567 683 1484 180 278 43.8 137.1

60116-1350-00 496 1650 541 1813 617 1742 655 1704 720 1610 180 278 47.7 148.1

60116-1400-00 502 1700 555 1849 638 1792 678 1753 746 1652 200 286 48.3 156.0

60116-1500-00 549 1800 564 1946 651 1886 693 1844 765 1738 200 286 51.9 165.3

60116-1600-00 569 2000 598 2041 691 1975 736 1929 813 1814 240 306 53.4 183.7

60116-1800-00 633 2200 623 2245 723 2150 773 2098 859 1969 240 306 58.2 198.6

60116-2000-00 708 2400 661 2423 775 2338 829 2280 924 2136 280 325 63.9 233.5

60116-2200-00 787 2600 684 2632 804 2510 863 2455 965 2298 280 325 69.9 252.3

60116-2400-00 848 2800 745 2808 880 2703 944 2633 1056 2430 350 365 74.7 337.8

60116-2500-00 873 2900 761 2917 897 2788 964 2715 1080 2504 350 365 76.5 346.4

SERIES 60 ROLL DIAMETER 178 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

CODE NUMBER A B 20 ° 30 ° 35 ° 45 ° E F MASS Kgs.

J M J M J M J M R.P TOTAL

59116-0750-00 286 1000 446 1227 490 1185 513 1166 551 1117 140 251 31.2 87.4

59116-0800-00 300 1050 458 1267 509 1241 534 1220 568 1151 150 258 32.1 90.5

59116-0900-00 339 1150 468 1361 523 1330 550 1306 596 1245 150 258 35.1 96.4

59116-1000-00 366 1250 489 1457 551 1421 581 1394 631 1324 165 267 37.2 109.2

59116-1050-00 391 1300 494 1510 558 1472 589 1444 634 1356 165 267 39.0 113.2

59116-1200-00 444 1450 524 1663 591 1598 625 1567 683 1484 180 278 43.2 131.1

59116-1350-00 496 1650 541 1813 617 1742 655 1704 720 1610 180 278 47.1 141.8

59116-1400-00 502 1700 555 1849 638 1792 678 1753 746 1652 200 286 47.7 149.4

59116-1500-00 549 1800 564 1946 651 1886 693 1844 765 1738 200 286 51.3 158.1

59116-1600-00 569 2000 598 2041 691 1975 736 1929 813 1814 240 306 52.8 176.2

59116-1800-00 633 2200 623 2245 723 2150 773 2098 859 1969 240 306 57.6 193.2

59116-2000-00 708 2400 661 2423 775 2338 829 2280 924 2136 280 325 63.3 228.7

59116-2200-00 787 2600 684 2632 804 2510 863 2455 965 2298 280 325 69.3 246.9

SERIES 59 ROLL DIAMETER 178 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

Note: “RP” is an abbreviation for Rotating Parts. “00” – Insert required Troughing Angle: 20˚, 30˚, 35˚ or 45˚.

PAGE 7 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

Note: “RP” is an abbreviation for Rotating Parts.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

SINGLE ROLL FLAT CARRY & IMPACT

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

25155-0750 846 1000 60 158 8.6 17.9

25155-0800 896 1050 60 158 9.1 18.8

25155-0900 996 1150 60 158 10.0 20.5

25155-1000 1096 1250 60 158 10.9 23.8

25155-1050 1146 1300 60 158 11.4 24.8

25155-1200 1296 1450 60 158 12.8 27.6

25155-1350 1496 1650 60 158 14.6 33.7

25155-1400 1546 1700 60 158 15.1 34.7

25155-1500 1646 1800 60 158 16.0 36.8

25155-1600 1846 2000 60 158 17.8 40.8

25155-1800 2046 2200 60 158 19.6 48.3

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

30155-0750 849 1000 60 171 13.8 23.1

30155-0800 899 1050 60 171 14.5 24.2

30155-0900 999 1150 60 171 16.0 27.9

30155-1000 1099 1250 60 171 17.4 30.4

30155-1050 1149 1300 60 171 18.2 31.6

30155-1200 1299 1450 60 171 20.4 35.2

30155-1350 1499 1650 60 171 23.3 42.4

30155-1400 1549 1700 60 171 24.0 43.7

30155-1500 1649 1800 60 171 25.5 46.3

30155-1600 1849 2000 60 171 28.4 54.5

30155-1800 2049 2200 60 171 31.3 60.0

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

40155-0750 852 1000 60 184 16.6 28.0

40155-0800 902 1050 60 184 17.5 29.3

40155-0900 1002 1150 60 184 19.2 33.6

40155-1000 1102 1250 60 184 20.9 36.4

40155-1050 1152 1300 60 184 21.8 37.8

40155-1200 1302 1450 60 184 24.3 44.3

40155-1350 1502 1650 60 184 27.8 50.3

40155-1400 1552 1700 60 184 28.6 51.8

40155-1500 1652 1800 60 184 30.3 59.9

40155-1600 1852 2000 60 184 33.8 66.5

40155-1800 2052 2200 60 184 37.2 73.1

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

35155-0750 852 1000 60 171 14.0 25.4

35155-0800 902 1050 60 171 14.7 26.6

35155-0900 1002 1150 60 171 16.2 30.6

35155-1000 1102 1250 60 171 17.6 33.2

35155-1050 1152 1300 60 171 18.4 34.5

35155-1200 1302 1450 60 171 20.6 40.5

35155-1350 1502 1650 60 171 23.5 46.0

35155-1400 1552 1700 60 171 24.2 47.4

35155-1500 1652 1800 60 171 25.6 55.2

35155-1600 1852 2000 60 171 28.6 61.3

35155-1800 2052 2200 60 171 31.5 67.4

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

45155-0750 850 1000 60 171 14.1 26.9

45155-0800 900 1050 60 171 14.8 28.2

45155-0900 1000 1150 60 171 16.3 30.8

45155-1000 1100 1250 60 171 17.7 35.2

45155-1050 1150 1300 60 171 18.5 36.6

45155-1200 1300 1450 60 171 20.7 40.7

45155-1350 1500 1650 60 171 23.6 48.9

45155-1400 1550 1700 60 171 24.3 50.4

45155-1500 1650 1800 60 171 25.8 53.3

45155-1600 1850 2000 60 171 28.7 61.5

45155-1800 2050 2200 60 171 31.6 67.6

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

50155-0750 850 1000 60 184 24.5 36.0

50155-0800 900 1050 60 184 25.8 37.7

50155-0900 1000 1150 60 184 28.3 42.8

50155-1000 1100 1250 60 184 30.9 46.5

50155-1050 1150 1300 60 184 32.2 48.3

50155-1200 1300 1450 60 184 36.0 56.0

50155-1350 1500 1650 60 184 41.1 64.6

50155-1400 1550 1700 60 184 42.3 65.6

50155-1500 1650 1800 60 184 44.9 69.4

50155-1600 1850 2000 60 184 49.9 82.7

50155-1800 2050 2200 60 184 55.1 91.0

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 8

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

55155-1000 1102 1250 60 171 18.2 39.4

55155-1050 1152 1300 60 171 18.9 45.7

55155-1200 1302 1450 60 171 21.1 50.9

55155-1350 1502 1650 60 171 24.0 57.7

55155-1400 1552 1700 60 171 24.8 59.5

55155-1500 1652 1800 60 171 26.2 62.9

55155-1600 1852 2000 60 171 29.1 75.3

55155-1800 2052 2200 60 171 32.1 82.8

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

54155-0750 852 1000 60 171 14.4 27.3

54155-0800 902 1050 60 171 15.1 30.1

54155-0900 1002 1150 60 171 16.5 32.9

54155-1000 1102 1250 60 171 18.0 35.6

54155-1050 1152 1300 60 171 18.7 39.1

54155-1200 1302 1450 60 171 20.9 43.5

54155-1350 1502 1650 60 171 23.8 51.2

54155-1400 1552 1700 60 171 24.6 52.7

54155-1500 1652 1800 60 171 26.0 55.8

54155-1600 1852 2000 60 171 28.9 68.1

54155-1800 2052 2200 60 171 31.8 74.9

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts.

Note: “RP” is an abbreviation for Rotating Parts.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

SINGLE ROLL FLAT CARRY & IMPACT

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

60155-1000 1102 1250 60 184 31.3 57.1

60155-1050 1152 1300 60 184 32.6 59.3

60155-1200 1302 1450 60 184 36.4 66.1

60155-1350 1502 1650 60 184 41.5 75.2

60155-1400 1552 1700 60 184 42.8 77.5

60155-1500 1652 1800 60 184 45.3 82.0

60155-1600 1852 2000 60 184 50.4 96.6

60155-1800 2052 2200 60 184 55.5 106.2

SERIES 60 ROLL DIAMETER 178 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

59155-0750 852 1000 60 184 24.7 40.7

59155-0800 902 1050 60 184 26.0 42.7

59155-0900 1002 1150 60 184 28.6 46.7

59155-1000 1102 1250 60 184 31.1 52.2

59155-1050 1152 1300 60 184 32.4 54.2

59155-1200 1302 1450 60 184 36.2 65.8

59155-1350 1502 1650 60 184 41.3 74.8

59155-1400 1552 1700 60 184 42.5 77.1

59155-1500 1652 1800 60 184 45.1 81.6

59155-1600 1852 2000 60 184 50.1 96.2

59155-1800 2052 2200 60 184 55.2 105.9

SERIES 59 ROLL DIAMETER 178 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

45156-0600 685 850 60 174 16.9 26.9

45156-0650 735 900 60 174 18.4 28.9

45156-0750 835 1000 60 174 20.4 33.2

45156-0800 885 1050 60 174 21.9 35.2

45156-0900 985 1150 60 174 23.9 38.4

45156-1000 1085 1250 60 174 26.4 42.0

45156-1050 1135 1300 60 174 27.8 45.9

45156-1200 1285 1450 60 174 31.3 51.4

45156-1350 1485 1650 60 174 36.3 61.6

45156-1400 1535 1700 60 174 37.3 63.4

45156-1500 1635 1800 60 174 39.8 67.3

45156-1600 1835 2000 60 174 44.7 77.5

45156-1800 2035 2200 60 174 49.2 85.2

SERIES 45 ROLL DIAMETER 159 BEARING SIZE 6307CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

50156-0600 685 850 60 184 19.1 29.1

50156-0650 735 900 60 184 20.1 31.3

50156-0750 835 1000 60 184 23.0 35.9

50156-0800 885 1050 60 184 24.8 38.1

50156-0900 985 1150 60 184 27.0 41.5

50156-1000 1085 1250 60 184 29.9 47.4

50156-1050 1135 1300 60 184 31.6 49.7

50156-1200 1285 1450 60 184 35.5 55.6

50156-1350 1485 1650 60 184 41.2 66.6

50156-1400 1535 1700 60 184 42.4 68.4

50156-1500 1635 1800 60 184 45.2 72.7

50156-1600 1835 2000 60 184 50.9 83.7

50156-1800 2035 2200 60 184 56.0 91.9

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

25161-0750 846 1000 60 25 8.7 15.5

25161-0800 896 1050 60 25 9.1 16.2

25161-0900 996 1150 60 25 10.0 18.9

25161-1000 1096 1250 60 25 10.9 20.5

25161-1050 1146 1300 60 25 11.4 21.3

25161-1200 1296 1450 60 25 12.8 23.6

25161-1350 1496 1650 60 25 14.6 29.0

25161-1400 1546 1700 60 25 15.1 29.8

25161-1500 1646 1800 60 25 16.0 31.6

25161-1600 1846 2000 60 25 17.8 35.1

25161-1800 2046 2200 60 25 19.7 41.5

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

30161-0750 849 1000 60 38 13.8 20.6

30161-0800 899 1050 60 38 14.6 21.6

30161-0900 999 1150 60 38 16.0 24.9

30161-1000 1099 1250 60 38 17.5 27.1

30161-1050 1149 1300 60 38 18.2 28.1

30161-1200 1299 1450 60 38 20.4 31.4

30161-1350 1499 1650 60 38 23.3 37.7

30161-1400 1549 1700 60 38 24.0 38.8

30161-1500 1649 1800 60 38 25.5 41.1

30161-1600 1849 2000 60 38 28.4 45.7

30161-1800 2049 2200 60 38 31.3 53.2

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts.

PAGE 9 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

SINGLE ROLL PLAIN & DISC FLAT RETURN

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

40161-0750 852 1000 60 51 16.6 25.0

40161-0800 902 1050 60 51 17.5 27.5

40161-0900 1002 1150 60 51 19.2 30.0

40161-1000 1102 1250 60 51 20.9 32.6

40161-1050 1152 1300 60 51 21.8 33.8

40161-1200 1302 1450 60 51 24.3 39.5

40161-1350 1502 1650 60 51 27.8 44.9

40161-1400 1552 1700 60 51 28.6 46.2

40161-1500 1652 1800 60 51 30.4 48.9

40161-1600 1852 2000 60 51 33.8 57.2

40161-1800 2052 2200 60 51 37.2 62.8

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

35161-0750 852 1000 60 38 14.0 22.4

35161-0800 902 1050 60 38 14.8 23.5

35161-0900 1002 1150 60 38 16.2 27.0

35161-1000 1102 1250 60 38 17.7 29.3

35161-1050 1152 1300 60 38 18.4 30.4

35161-1200 1302 1450 60 38 20.6 33.9

35161-1350 1502 1650 60 38 23.5 40.6

35161-1400 1552 1700 60 38 24.2 41.8

35161-1500 1652 1800 60 38 25.7 44.2

35161-1600 1852 2000 60 38 28.6 52.0

35161-1800 2052 2200 60 38 31.5 57.1

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

45161-0750 850 1000 60 38 14.1 25.1

45161-0800 900 1050 60 38 14.8 26.3

45161-0900 1000 1150 60 38 16.3 28.7

45161-1000 1100 1250 60 38 17.8 31.1

45161-1050 1150 1300 60 38 18.5 32.3

45161-1200 1300 1450 60 38 20.7 36.0

45161-1350 1500 1650 60 38 23.6 40.8

45161-1400 1550 1700 60 38 24.3 44.5

45161-1500 1650 1800 60 38 25.8 47.0

45161-1600 1850 2000 60 38 28.7 52.2

45161-1800 2050 2200 60 38 31.6 60.8

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

50161-0750 850 1000 60 51 24.5 35.5

50161-0800 900 1050 60 51 25.8 37.2

50161-0900 1000 1150 60 51 28.3 40.7

50161-1000 1100 1250 60 51 30.9 44.2

50161-1050 1150 1300 60 51 32.2 46.0

50161-1200 1300 1450 60 51 36.0 51.3

50161-1350 1500 1650 60 51 41.1 60.6

50161-1400 1550 1700 60 51 42.4 62.5

50161-1500 1650 1800 60 51 44.9 66.1

50161-1600 1850 2000 60 51 50.0 73.5

50161-1800 2050 2200 60 51 55.1 84.2

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts.

Note: “RP” is an abbreviation for Rotating Parts.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 10

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

55161-1000 1102 1250 60 38 18.2 37.5

55161-1050 1152 1300 60 38 19.0 38.9

55161-1200 1302 1450 60 38 21.2 43.3

55161-1350 1502 1650 60 38 24.1 49.1

55161-1400 1552 1700 60 38 24.8 50.6

55161-1500 1652 1800 60 38 26.3 53.5

55161-1600 1852 2000 60 38 29.2 61.7

55161-1800 2052 2200 60 38 32.1 67.8

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

54161-0750 852 1000 60 38 14.4 26.8

54161-0800 902 1050 60 38 15.1 28.1

54161-0900 1002 1150 60 38 16.6 30.7

54161-1000 1102 1250 60 38 18.0 33.2

54161-1050 1152 1300 60 38 18.7 34.5

54161-1200 1302 1450 60 38 20.9 38.4

54161-1350 1502 1650 60 38 23.9 43.5

54161-1400 1552 1700 60 38 24.6 44.8

54161-1500 1652 1800 60 38 26.0 50.2

54161-1600 1852 2000 60 38 29.0 55.7

54161-1800 2052 2200 60 38 31.9 61.2

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts.

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

SINGLE ROLL PLAIN & DISC FLAT RETURN

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

60161-1000 1102 1250 60 51 31.4 50.6

60161-1050 1152 1300 60 51 32.6 52.6

60161-1200 1302 1450 60 51 36.5 58.6

60161-1350 1502 1650 60 51 41.6 66.6

60161-1400 1552 1700 60 51 42.8 68.6

60161-1500 1652 1800 60 51 45.4 72.6

60161-1600 1852 2000 60 51 50.5 83.6

60161-1800 2052 2200 60 51 55.3 97.7

SERIES 60 ROLL DIAMETER 178 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F MASS Kgs

R.P. TOTAL

59161-0750 852 1000 60 51 24.7 37.2

59161-0800 902 1050 60 51 26.0 39.0

59161-0900 1002 1150 60 51 28.6 42.7

59161-1000 1102 1250 60 51 31.1 46.4

59161-1050 1152 1300 60 51 32.4 48.2

59161-1200 1302 1450 60 51 36.2 55.9

59161-1350 1502 1650 60 51 41.3 63.6

59161-1400 1552 1700 60 51 42.5 68.3

59161-1500 1652 1800 60 51 45.1 72.3

59161-1600 1852 2000 60 51 50.2 82.6

59161-1800 2052 2200 60 51 55.2 90.9

SERIES 59 ROLL DIAMETER 178 BEARING SIZE 6308

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F G H MASS Kgs

R.P. TOTAL

45162-0600 685 850 60 38 153 675 14.2 23.7

45162-0650 735 900 60 38 153 725 14.8 24.7

45162-0750 835 1000 60 38 153 825 16.6 27.5

45162-0800 885 1050 60 38 153 875 17.1 28.5

45162-0900 985 1150 60 38 153 975 18.9 31.3

45162-1000 1085 1250 60 38 153 1075 20.7 34.1

45162-1050 1135 1300 60 38 153 1125 21.3 35.1

45162-1200 1285 1450 60 38 153 1275 23.7 38.9

45162-1350 1485 1650 60 38 153 1425 26.6 43.8

45162-1400 1535 1700 60 38 153 1475 27.2 44.8

45162-1500 1635 1800 60 38 204 1575 29.6 50.9

45162-1600 1835 2000 60 38 204 1675 32.6 56.0

45162-1800 2035 2200 60 38 204 1875 35.5 61.2

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307DISC

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B E F G H MASS Kgs

R.P. TOTAL

50162-0600 685 850 60 51 153 675 16.5 26.0

50162-0650 735 900 60 51 153 725 17.1 27.1

50162-0750 835 1000 60 51 153 825 19.2 30.1

50162-0800 885 1050 60 51 153 875 19.8 31.2

50162-0900 985 1150 60 51 153 975 21.9 34.3

50162-1000 1085 1250 60 51 153 1075 24.1 37.3

50162-1050 1135 1300 60 51 153 1125 24.5 38.4

50162-1200 1285 1450 60 51 153 1275 27.2 42.5

50162-1350 1485 1650 60 51 153 1425 30.4 47.6

50162-1400 1535 1700 60 51 153 1475 31.0 51.1

50162-1500 1635 1800 60 51 204 1575 34.1 55.3

50162-1600 1835 2000 60 51 204 1675 37.3 60.8

50162-1800 2035 2200 60 51 204 1875 40.5 66.2

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307DISC

PAGE 11 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

25163-0750 846 1000 248 1080 60 34 8.7 52.5

25163-0800 896 1050 248 1130 60 34 9.1 54.0

25163-0900 996 1150 248 1230 60 34 10.0 58.3

25163-1000 1096 1250 248 1330 60 34 10.9 61.5

25163-1050 1146 1300 248 1380 60 34 11.4 63.0

25163-1200 1296 1450 255 1530 60 34 12.8 68.8

25163-1350 1496 1650 277 1730 60 34 14.6 90.7

25163-1400 1546 1700 277 1780 60 34 15.1 92.7

25163-1500 1646 1800 298 1880 60 34 16.0 108.6

25163-1600 1846 2000 298 2080 60 34 17.8 117.7

25163-1800 2046 2200 318 2280 60 34 19.7 140.4

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

30163-0750 849 1000 248 1080 60 46 13.8 57.6

30163-0800 899 1050 248 1130 60 46 14.6 59.5

30163-0900 999 1150 248 1230 60 46 16.0 64.3

30163-1000 1099 1250 248 1330 60 46 17.5 68.1

30163-1050 1149 1300 248 1380 60 46 18.2 69.8

30163-1200 1299 1450 255 1530 60 46 20.4 76.6

30163-1350 1499 1650 277 1730 60 46 23.3 99.4

30163-1400 1549 1700 277 1780 60 46 24.0 101.7

30163-1500 1649 1800 298 1880 60 46 25.5 118.1

30163-1600 1849 2000 298 2080 60 46 28.4 128.3

30163-1800 2049 2200 318 2280 60 46 31.3 152.1

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

SINGLE ROLL PLAIN P/A RETURN TRAINER

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

35163-0750 852 1000 260 1080 60 46 14.0 62.4

35163-0800 902 1050 260 1130 60 46 14.8 64.2

35163-0900 1002 1150 260 1230 60 46 16.2 69.3

35163-1000 1102 1250 260 1330 60 46 17.7 73.2

35163-1050 1152 1300 260 1380 60 46 18.4 75.1

35163-1200 1302 1450 267 1530 60 46 20.6 82.0

35163-1350 1502 1650 289 1730 60 46 23.5 105.7

35163-1400 1552 1700 289 1780 60 46 24.2 108.1

35163-1500 1652 1800 310 1880 60 46 25.7 125.3

35163-1600 1852 2000 310 2080 60 46 28.6 138.7

35163-1800 2052 2200 330 2280 60 46 31.5 160.2

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

40163-0750 852 1000 260 1080 60 59 16.6 65.0

40163-0800 902 1050 260 1130 60 59 17.5 68.2

40163-0900 1002 1150 260 1230 60 59 19.2 72.3

40163-1000 1102 1250 260 1330 60 59 20.9 76.5

40163-1050 1152 1300 260 1380 60 59 21.8 78.5

40163-1200 1302 1450 267 1530 60 59 24.3 87.6

40163-1350 1502 1650 289 1730 60 59 27.8 110.0

40163-1400 1552 1700 289 1780 60 59 28.6 112.5

40163-1500 1652 1800 310 1880 60 59 30.4 130.0

40163-1600 1852 2000 310 2080 60 59 33.8 143.9

40163-1800 2052 2200 330 2280 60 59 37.2 165.9

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

45163-0750 850 1000 260 1080 60 46 14.1 65.1

45163-0800 900 1050 260 1130 60 46 14.8 67.0

45163-0900 1000 1150 260 1230 60 46 16.3 71.0

45163-1000 1100 1250 260 1330 60 46 17.8 75.0

45163-1050 1150 1300 260 1380 60 46 18.5 77.0

45163-1200 1300 1450 267 1530 60 46 20.7 84.1

45163-1350 1500 1650 289 1730 60 46 23.6 105.9

45163-1400 1550 1700 289 1780 60 46 24.3 110.8

45163-1500 1650 1800 310 1880 60 46 25.8 128.1

45163-1600 1850 2000 310 2080 60 46 28.7 138.9

45163-1800 2050 2200 330 2280 60 46 31.6 163.9

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

Note: “RP” is an abbreviation for Rotating Parts

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

50163-0750 850 1000 260 1080 60 59 24.5 75.5

50163-0800 900 1050 260 1130 60 59 25.8 77.9

50163-0900 1000 1150 260 1230 60 59 28.3 83.0

50163-1000 1100 1250 260 1330 60 59 30.9 88.1

50163-1050 1150 1300 260 1380 60 59 32.2 90.7

50163-1200 1300 1450 267 1530 60 59 36.0 99.4

50163-1350 1500 1650 289 1730 60 59 41.1 125.7

50163-1400 1550 1700 289 1780 60 59 42.4 128.8

50163-1500 1650 1800 310 1880 60 59 44.9 147.2

50163-1600 1850 2000 310 2080 60 59 50.0 160.2

50163-1800 2050 2200 330 2280 60 59 55.1 187.3

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

Note: “RP” is an abbreviation for Rotating Parts.

IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST. PAGE 12

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office

SINGLE ROLL PLAIN P/A RETURN TRAINER

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

54163-0750 852 1000 260 1080 60 46 14.4 66.8

54163-0800 902 1050 260 1130 60 46 15.1 68.8

54163-0900 1002 1150 260 1230 60 46 16.6 73.0

54163-1000 1102 1250 260 1330 60 46 18.0 77.1

54163-1050 1152 1300 260 1380 60 46 18.7 79.2

54163-1200 1302 1450 267 1530 60 46 20.9 86.5

54163-1350 1502 1650 289 1730 60 46 23.9 108.6

54163-1400 1552 1700 289 1780 60 46 24.6 111.0

54163-1500 1652 1800 310 1880 60 46 26.0 131.3

54163-1600 1852 2000 310 2080 60 46 29.0 142.4

54163-1800 2052 2200 330 2280 60 46 31.9 164.3

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

55163-1000 1102 1250 260 1330 60 46 18.2 81.4

55163-1050 1152 1300 260 1380 60 46 19.0 83.6

55163-1200 1302 1450 267 1530 60 46 21.2 91.4

55163-1350 1502 1650 289 1730 60 46 24.1 114.2

55163-1400 1552 1700 289 1780 60 46 24.8 116.9

55163-1500 1652 1800 310 1880 60 46 26.3 134.6

55163-1600 1852 2000 310 2080 60 46 29.2 148.4

55163-1800 2052 2200 330 2280 60 46 32.1 170.9

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

Note: “RP” is an abbreviation for Rotating Parts.

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

59163-0750 852 1000 260 1080 60 59 24.7 77.2

59163-0800 902 1050 260 1130 60 59 26.0 79.7

59163-0900 1002 1150 260 1230 60 59 28.6 85.0

59163-1000 1102 1250 260 1330 60 59 31.1 90.3

59163-1050 1152 1300 260 1380 60 59 32.4 92.9

59163-1200 1302 1450 267 1530 60 59 36.2 104.0

59163-1350 1502 1650 289 1730 60 59 41.3 128.7

59163-1400 1552 1700 289 1780 60 59 42.5 134.6

59163-1500 1652 1800 310 1880 60 59 45.1 153.4

59163-1600 1852 2000 310 2080 60 59 50.2 169.3

59163-1800 2052 2200 330 2280 60 59 55.2 194.0

SERIES 59 ROLL DIAMETER 178 BEARING SIZE 6308

CODE NUMBER A B C D E F MASS Kgs

R.P. TOTAL

60163-1000 1102 1250 260 1330 60 59 31.4 94.5

60163-1050 1152 1300 260 1380 60 59 32.6 97.3

60163-1200 1302 1450 267 1530 60 59 36.5 106.7

60163-1350 1502 1650 289 1730 60 59 41.6 131.7

60163-1400 1552 1700 289 1780 60 59 42.8 134.9

60163-1500 1652 1800 310 1880 60 59 45.4 153.7

60163-1600 1852 2000 310 2080 60 59 50.5 169.7

60163-1800 2052 2200 330 2280 60 59 55.3 200.8

SERIES 60 ROLL DIAMETER 178 BEARING SIZE 6309

Note: “RP” is an abbreviation for Rotating Parts.

PAGE 13 IN THE INTEREST OF PRODUCT DEVELOPMENT, PROK GROUP RESERVES THE RIGHT TO CHANGE CRITICAL DATA AT ANY TIME WITHOUT PRIOR NOTICE. DIMENSIONS SHOWN ARE NOMINAL ONLY. CERTIFIED DRAWINGS ARE AVAILABLE ON REQUEST.

2 ROLL PLAIN & DISC VEE RETURN

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

25169-1200-00 648 1450 51 1332 215 42 1308 283 31 1274 354 60 13.6 33.4

25169-1350-00 724 1650 49 1483 231 37 1457 308 24 1421 388 60 15.0 41.8

25169-1400-00 741 1700 48 1517 233 36 1491 312 21 1454 394 60 15.4 42.6

25169-1500-00 792 1800 48 1619 248 36 1591 332 21 1552 420 60 16.4 48.4

25169-1600-00 842 2000 44 1718 265 27 1690 358 7 1649 454 60 17.2 60.8

25169-1800-00 939 2200 44 1912 274 26 1881 376 5 1836 481 60 19.0 66.4

25169-2000-00 1044 2400 44 2121 301 27 2088 411 6 2039 526 60 21.0 84.3

25169-2200-00 1144 2600 44 2320 309 27 2285 429 5 2232 553 60 22.8 90.8

25169-2400-00 1244 2800 44 2519 318 26 2482 446 4 2425 580 60 24.6 97.2

25169-2500-00 1303 2900 44 2637 342 28 2598 475 6 2539 613 60 25.6 125.6

SERIES 25 ROLL DIAMETER 127 BEARING SIZE 6305

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

35169-1600-00 848 2000 69 1743 265 53 1699 358 34 1656 454 60 28.0 67.7

35169-1800-00 945 2200 69 1936 274 52 1890 376 32 1843 481 60 30.8 86.8

35169-2000-00 1050 2400 70 2146 301 53 2097 411 33 2046 527 60 33.8 103.8

35169-2200-00 1150 2600 69 2345 309 53 2294 429 32 2239 554 60 36.8 111.6

35169-2400-00 1248 2800 69 2540 318 52 2487 446 30 2429 580 60 39.6 119.3

35169-2500-00 1309 2900 70 2662 342 54 2607 475 33 2547 613 60 41.4 153.2

35169-2600-00 1348 3000 69 2739 346 52 2684 484 29 2622 626 60 42.6 157.7

35169-2800-00 1448 3200 69 2939 354 51 2881 502 28 2815 653 60 45.4 167.3

35169-3000-00 1550 3400 69 3142 363 51 3082 519 28 3012 680 60 48.4 177.2

SERIES 35 ROLL DIAMETER 152 BEARING SIZE 6306

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

30169-1200-00 651 1450 63 1333 215 55 1307 283 43 1270 354 60 21.8 43.0

30169-1350-00 727 1650 61 1484 231 50 1456 308 36 1417 388 60 24.0 50.8

30169-1400-00 744 1700 61 1518 233 49 1490 312 34 1450 394 60 24.6 51.8

30169-1500-00 795 1800 61 1620 248 49 1590 332 33 1548 420 60 26.0 58.0

30169-1600-00 845 2000 56 1719 265 40 1689 358 20 1645 454 60 27.6 71.2

30169-1800-00 942 2200 56 1912 274 39 1880 376 18 1832 481 60 30.4 80.0

30169-2000-00 1047 2400 56 2121 301 40 2086 411 18 2035 526 60 33.4 96.9

30169-2200-00 1147 2600 56 2320 309 39 2283 429 17 2228 553 60 36.4 104.4

30169-2400-00 1247 2800 56 2519 318 39 2480 446 16 2422 580 60 39.2 112.0

30169-2500-00 1306 2900 57 2637 342 40 2597 475 18 2536 613 60 41.0 140.8

SERIES 30 ROLL DIAMETER 152 BEARING SIZE 6305

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

40169-1600-00 848 2000 82 1741 265 66 1695 358 46 1649 454 60 33.2 72.9

40169-1800-00 945 2200 82 1934 274 65 1886 376 45 1837 481 60 36.4 92.6

40169-2000-00 1050 2400 83 2143 301 66 2093 411 45 2039 527 60 40.0 110.0

40169-2200-00 1150 2600 82 2343 309 65 2290 429 45 2233 554 60 43.4 118.4

40169-2400-00 1248 2800 82 2538 318 65 2483 446 43 2422 580 60 46.8 130.3

40169-2500-00 1309 2900 83 2659 342 67 2603 475 45 2540 613 60 49.0 160.8

40169-2600-00 1348 3000 82 2737 346 64 2680 484 42 2615 626 60 50.2 165.5

40169-2800-00 1448 3200 82 2936 354 64 2877 502 41 2808 653 60 53.8 175.5

40169-3000-00 1550 3400 82 3140 363 64 3077 519 41 3005 680 60 57.2 186.0

SERIES 40 ROLL DIAMETER 178 BEARING SIZE 6306

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

45169-1600-00 846 2000 69 1741 265 53 1697 358 34 1654 454 60 28.2 73.1

45169-1800-00 943 2200 69 1934 274 52 1888 376 32 1842 481 60 31.0 90.0

45169-2000-00 1048 2400 69 2144 301 53 2095 411 32 2044 527 60 34.0 107.2

45169-2200-00 1148 2600 69 2343 309 52 2292 429 31 2240 554 60 37.0 115.4

45169-2400-00 1246 2800 69 2538 318 52 2485 446 30 2427 580 60 39.8 123.3

45169-2500-00 1307 2900 70 2660 342 54 2605 475 32 2545 613 60 41.6 153.6

45169-2600-00 1346 3000 69 2737 346 51 2682 484 29 2620 626 60 42.8 158.1

45169-2800-00 1446 3200 69 2937 354 51 2879 502 28 2813 653 60 45.6 167.7

45169-3000-00 1548 3400 69 3140 363 51 3080 519 28 3010 680 60 48.6 182.4

SERIES 45 ROLL DIAMETER 152 BEARING SIZE 6307

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

50169-1600-00 846 2000 82 1739 265 66 1693 358 46 1647 454 60 48.8 93.7

50169-1800-00 943 2200 82 1932 274 65 1884 376 44 1835 481 60 53.8 112.8

50169-2000-00 1048 2400 82 2141 301 61 2097 411 45 2038 527 60 59.2 132.4

50169-2200-00 1148 2600 82 2341 309 65 2288 429 44 2231 554 60 64.2 142.6

50169-2400-00 1246 2800 82 2536 318 65 2481 446 42 2420 580 60 69.2 152.9

50169-2500-00 1307 2900 83 2657 342 66 2601 475 45 2538 613 60 72.4 184.4

50169-2600-00 1346 3000 82 2735 346 64 2678 484 42 2613 626 60 74.4 189.7

50169-2800-00 1446 3200 82 2934 354 64 2875 502 41 2806 653 60 79.4 206.1

50169-3000-00 1548 3400 82 3138 363 64 3075 519 40 3003 680 60 84.6 218.4

SERIES 50 ROLL DIAMETER 178 BEARING SIZE 6307

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

54169-1600-00 848 2000 69 1743 265 53 1699 358 34 1656 454 60 28.6 76.5

54169-1800-00 945 2200 69 1936 274 52 1890 376 32 1843 481 60 31.4 93.8

54169-2000-00 1050 2400 70 2146 301 53 2097 411 33 2046 527 60 34.6 111.4

54169-2200-00 1150 2600 69 2345 309 53 2294 429 32 2239 554 60 37.4 119.8

54169-2400-00 1248 2800 69 2540 318 52 2487 446 30 2429 580 60 40.4 128.1

54169-2500-00 1309 2900 70 2662 342 54 2607 475 33 2547 613 60 42.0 158.6

54169-2600-00 1348 3000 69 2739 346 52 2684 484 29 2622 626 60 43.2 163.1

54169-2800-00 1448 3200 69 2939 354 51 2881 502 28 2815 653 60 46.2 172.9

54169-3000-00 1550 3400 69 3142 363 51 3082 519 28 3012 680 60 49.2 183.2

SERIES 54 ROLL DIAMETER 152 BEARING SIZE 6308

CODE NUMBER A B 5° 10° 15° E MASS Kgs.

C D F C D F C D F R.P TOTAL

55169-1600-00 848 2000 69 1743 265 53 1699 358 34 1656 454 60 29.0 83.3

55169-1800-00 945 2200 69 1936 274 52 1890 376 32 1843 481 60 31.8 101.2

55169-2000-00 1050 2400 70 2146 301 53 2097 411 33 2046 527 60 35.0 119.6

55169-2200-00 1150 2600 69 2345 309 53 2294 429 32 2239 554 60 37.8 128.6

55169-2400-00 1248 2800 69 2540 318 52 2487 446 30 2429 580 60 40.8 137.5

55169-2500-00 1309 2900 70 2662 342 54 2607 475 33 2547 613 60 42.6 168.4

55169-2600-00 1348 3000 69 2739 346 52 2684 484 29 2622 626 60 43.6 173.3

55169-2800-00 1448 3200 69 2939 354 51 2881 502 28 2815 653 60 46.6 183.9

55169-3000-00 1550 3400 69 3142 363 51 3082 519 28 3012 680 60 49.6 194.6

SERIES 55 ROLL DIAMETER 152 BEARING SIZE 6309

To ensure correct product selection or to enable PROK to select the correct product, please complete & submit the sheet on page 24 to your nearest PROK office