Fuzzy logic in control systems: fuzzy logic controller. II ...

Programmble Logic Control

-

Upload

vinay-felix -

Category

Documents

-

view

232 -

download

0

Transcript of Programmble Logic Control

-

7/29/2019 Programmble Logic Control

1/16

1

March 3, 2013

Project Title: PLC BASED

AUTOMATED FILLING SYSTEM

Maharaja Institute of Technology

Project Guide: GURUPRASAD L Asst. Professor

Project Group Members: Rakesh S K, Shruthi A, Vinay K

-

7/29/2019 Programmble Logic Control

2/16

2

Agenda

Project definition/description

Design details

Project completion time lines

Implementation

Results demo,

Report writing,

Project review and closure.

Any risks/difficulties in completion of the project.

Conclusions

-

7/29/2019 Programmble Logic Control

3/16

3

Project Definition/Description

Theme of the project deals with simplified approach to develop an automated

system for filling and capping.

Automated system for filling and capping is operated through Programmable

Logic Control using ladder logic

Containers are confined in position over a conveyor and conveyor is driven

by 24volts DC geared motor.

Containers are sensed by capacitive sensor and issue a command to PLC to

stop the conveyor at predefined position and filling process is started.

Inductive sensor determine the quantity of material filled in the container and

the container is directed for capping process.

Capping process is done by the help of handling device.

-

7/29/2019 Programmble Logic Control

4/16

4

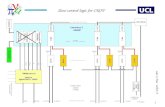

System block diagram

PROGRAMMABLE

LOGIC

CONTROLLER

CONTROL LOGIC

INDUCTIVE SENSOR

HANDLING DEVICE

PHTOELECTRIC SENSOR

CAPACITIVE SENSOR

CONVEYOR

(DC MOTOR)

PNEMATIC CYLINDER

-

7/29/2019 Programmble Logic Control

5/16

5

Block diagram of PLC

Communication

module

Power supplyInput

modules

Output

modules

RAM E-EPROMnetwork

power cord

Machine

C P UProgramming

tool

-

7/29/2019 Programmble Logic Control

6/16

6

Design details

-

7/29/2019 Programmble Logic Control

7/167

Indracontrol L20 PLC

1 xEthernet TCP/IP1 x Profibus

1 x RS232

Processor STM ST40 / 166 MHz

Output voltage 24V DC

retentive memory 64 K Byte

Compact Flash 128 M Byte (3 partitions)

RAM 16MB

Onboard interfaces PROFIBUS DP, Ethernet, RS232Onboard I/O DI8/DO8

Local extension 32 Byte

Special features RTC, Display

Dimensions 120 x 175 x 76mm

Technical Data

Connectivity

User memory 3 MB (1 MB Code / 2 MB Data)

Processing time typ. 150 s / 1000 instructions

Performance

approx. 175 mm

-

7/29/2019 Programmble Logic Control

8/168

Operating voltage 10 36V

Current rating 250mA

Short circuit protected yes

Reverse polarity protected yes

Voltage drop

-

7/29/2019 Programmble Logic Control

9/169

PHOTOELECTRIC SENSOR

Operating voltage 10 36 V

Current rating 250 mA

Short circuit protected yes

Reverse polarity protected yesVoltage drop

-

7/29/2019 Programmble Logic Control

10/1610

Handling device is equipped with 3 axis.

Two linear axis and one rotating axis.

Lifting is done by a double acting Pneumatic

cylinder.

Air presser in pneumatic cylinder is controlledby compressor.

HANDLING DEVICE

-

7/29/2019 Programmble Logic Control

11/1611

Pneumatic cylinders are mechanical devices which uses

the power of compressed gas to produce a force required

for linear motion

Gas forces a piston to move in the desire direction and

piston road transfers the force to the object to be moved

Operation diagram of a

double acting cylinder

PNEUMATIC CYLINDER

-

7/29/2019 Programmble Logic Control

12/1612

RESULTS DEMO

Conveyor

direction

Hopper

Inductive

Sensor

Capacitive

Sensor

Empty

Container

Sequence of movements:Conveyor start

Filling process

Container filled

Container rotted for

capp.

-

7/29/2019 Programmble Logic Control

13/1613

RESULTS DEMO

Animation:

slide leftmove down & vacuum onmove upslide rightmove downvacuum offmove up

Sequence of movements:

-

7/29/2019 Programmble Logic Control

14/1614

PROJECTSELEC.

SYNOPSIS

PREPR.

PROJECT

IMPLEM.PLAN

PHASE1 LEARNING

PLCBASICS

LADERPROGRAMING

PHASE2

COMPN.SURVEY

MODELMAKING

PHASE3

INTERFACING

CODING

FINAL

REPORT

PHASE4

FINALDEMO

FINAL

REPORT

PHASE5

Project review and closure

-

7/29/2019 Programmble Logic Control

15/1615

Risks/Dependencies

Risks:

Learning PLC concepts because its new for us.

Dependencies:

Trine from BOSCH group.

-

7/29/2019 Programmble Logic Control

16/1616

Conclusion