Program Able Logic Control

-

Upload

samara-simha-reddy -

Category

Documents

-

view

225 -

download

0

Transcript of Program Able Logic Control

-

8/3/2019 Program Able Logic Control

1/24

Submitted to:Prof. Dr. A. WILLIAMSON(Dean & H.O.D. Elec. & Comm.)

Submitted by:Rounak TripathiVII Sem(Electronics & Comm. Engg.)

http://powerpointpresentationon.blogspot.com

-

8/3/2019 Program Able Logic Control

2/24

Hindustan Zinc Limited (HZL) was incorporated from the MetalCorporation of India on 10 January 1966 as a PSU.

But, today it is a subsidiary of the Sterlite Opportunities andVentures Ltd. (SOVL)- Vedanta Resources which took it over in2002.

Worlds 2nd largest and Indias largest producer of Zinc and Lead.

(LME registered) Among top 25 companies declared as Hewitt Best Employers inAsia09

Revenues ofRs 8,017 Crore and PBDIT of Rs 5,392 Crore (for FY2010)

Current metal production capacity is 964,000 tonnes per annum

(879,000 tonnes of zinc and 85,000 tonnes of lead).

-

8/3/2019 Program Able Logic Control

3/24

1. Rampura AguchaMine

2. Sindesar Khurd Mine3. Rajpura Dariba Mine

4. Zawar Mine

1. Chanderiya SmeltingComplex

2. Dariba Smelting Complex3. Rajpura Smelting Complex

4. Vizag Smelting Complex

1. Gadag Wind2. Samana Wind3. Chanderiya Wind4. Zawar Wind

Total reserves and resource base of 298.6 million tonnes. Estimated ore production capacity of Rampura Agucha Mines : 6 million

tonnes. Targeted capacity to be worlds largest producer :1,064,000 tonnes.

-

8/3/2019 Program Able Logic Control

4/24

-

8/3/2019 Program Able Logic Control

5/24

-

8/3/2019 Program Able Logic Control

6/24

What is PLC

This training introduces the basic hardware and software componentsof a Programmable Controller (PLC). It details the architecture andbasic instruction set common to all PLCs. Basic programmingtechniques and logic designs are covered. This training describes theoperating features of the PLC, the advantages of the PLC over hard-

wired control systems, practical applications, troubleshooting andmaintenance of PLCs.

-

8/3/2019 Program Able Logic Control

7/24

PLC Origin

- Developed to replace relays in the late 1960s - Costs dropped and became popular by 1980s - Now used in many industrial designs

-

8/3/2019 Program Able Logic Control

8/24

Advantages ofPLCs

Less wiring. Wiring between devices and relay contacts are done in the PLC

program. Easier and faster to make changes.

Trouble shooting aids make programming easier and reduce downtime. Reliable components make these likely to operate for years before

failure.

INTRODUCTION TO PLCS

-

8/3/2019 Program Able Logic Control

9/24

Leading Brands OfPLC

AMERICAN 1. Allen Bradley2. Gould Modicon3. Texas Instruments4. General Electric5. Westinghouse

6. Cutter Hammer7. Square D

EUROPEAN 1. Siemens2. Klockner & Mouller3. Festo4. Telemechanique

-

8/3/2019 Program Able Logic Control

10/24

Areas of Application

Manufacturing / Machining

Food / Beverage

Metals

Power

Mining

Petrochemical / Chemical

-

8/3/2019 Program Able Logic Control

11/24

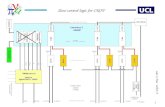

Major Components of a Common PLC

PROCESSOR

POWERSUPPLY

I M

N OP DU UT LE

O M

U OT DP UU LT E

PROGRAMMINGDEVICE

FromSENSORS

Pushbuttons,contacts,

limit switches,etc.

ToOUTPUT

Solenoids,

contactors,alarms

etc.

-

8/3/2019 Program Able Logic Control

12/24

Processor

The processor module contains the PLCs microprocessor, its supportingcircuitry, and its memory system.

The main function of the microprocessor is to analyze data coming fromfield sensors through input modules, make decisions based on the usersdefined control program and return signal back through output modules to

the field devices. Field sensors: switches, flow, level, pressure, temp.transmitters, etc. Field output devices: motors, valves, solenoids, lamps, oraudible devices.

The memory system in the processor module has two parts: a systemmemoryand an application memory.

-

8/3/2019 Program Able Logic Control

13/24

I/O Module

The I/O interface section of a PLC connects it to external field devices.

The main purpose of the I/O interface is to condition the various signalsreceived from or sent to the external input and output devices.

Input modules converts signals from discrete or analog input devices tologic levels acceptable to PLCs processor.

Output modules converts signal from the processor to levels capable ofdriving the connected discrete or analog output devices.

-

8/3/2019 Program Able Logic Control

14/24

PLC

INPUTS

OUTPUTS

MOTOR

LAMP

CONTACTOR

PUSHBUTTONS

-

8/3/2019 Program Able Logic Control

15/24

L1 L2

P. BSWITCH

INPUT MODULE

WIRING DIAGRAM

LADDERPROGRAM

I:2

0

I= Input

Moduleslot # in rack

ModuleTerminal #

Allen-Bradley 1746-1A16

AddressI:2.0/0

-

8/3/2019 Program Able Logic Control

16/24

N.O

C

L2 L1

L1L2

OUTPUT MODULEWIRING

MOTOR

CONTACTOR

O:4

0CONTACTOR

LADDER PROGRAM

L1 L2

FIELD WIRING

SOLENOID

VALVES LAMP BUZZE

R

-

8/3/2019 Program Able Logic Control

17/24

While the PLC is running, the scanning process includes the following fourphases, which are repeated continuously as individual cycles of operation:

PHASE 2

ProgramExecution

PHASE 3

Diagnostics/

CommPHASE 4

OutputScan

PHASE 1

Read InputsScan

-

8/3/2019 Program Able Logic Control

18/24

PLC Communications

Programmable Controllers and Networks

Dedicated Network System of Different Manufacturers

-

8/3/2019 Program Able Logic Control

19/24

Selectinga PLC

Criteria

Number of logical inputs and outputs. Memory Number of special I/O modules

Scan Time Communications Software

-

8/3/2019 Program Able Logic Control

20/24

Examples ofPLC Programming Software:

1. Allen-Bradley Rockwell Software RSLogix5002. Modicon - Modsoft3. Omron - Syswin4. GE-Fanuc Series 6 LogicMaster65. Square D- PowerLogic6. Texas Instruments Simatic

6. Telemecanique Modicon TSX Micro

-

8/3/2019 Program Able Logic Control

21/24

PROGRAMMING

Normally Open(NO)

Normally Closed(NC)

Power flows through these contacts when they are closed. Thenormally open (NO) is true when the input or output status bitcontrolling the contact is 1. The normally closed (NC) is truewhen the input or output status bit controlling the contact is 0.

-

8/3/2019 Program Able Logic Control

22/24

AND OPERATION

Each rung or network on a ladder program representsa logic operation. In the rung above, both inputs A and Bmust be true (1) in order for the output C to be true (1).

Rung

A B C

-

8/3/2019 Program Able Logic Control

23/24

OR OPERATION

In the rung above, it can be seen that either input A orBis be true (1), or both are true, then the output C is true (1).

Rung

A

B

C

-

8/3/2019 Program Able Logic Control

24/24

THANK YOU

Presented by:-Rounak TripathiVII sem ECE(B)

Any questions ?