PROFESSIONAL COURSE IN ENGLISH€¦ · environment: gauge absolute vacuum The most commonly used...

Transcript of PROFESSIONAL COURSE IN ENGLISH€¦ · environment: gauge absolute vacuum The most commonly used...

2020

Research Associate, Candidate of Engineering Sciences

Belinskaya Nataliya Segeevna

PROFESSIONAL COURSE IN ENGLISH

“PROCESS TECHNOLOGY. EQUIPMENT AND SYSTEMS”

Unit 7. Instruments

Process Technology. Equipment and Systems

Outline

1. Basic instruments

2. Temperature measurement

3. Pressure measurement

4. Fluid flow measurement

5. Level measurement

6. Basic elements of a control loop

2

Process Technology. Equipment and Systems

Introduction

Automatic control is the foundation for efficient continuous flowprocesses. At one time, operators controlled processes manually. Thistype of process was “valve intensive”; it required the technician to openand close valves in piping lineups manually. Modern advances ininstrumentation have made it possible for industrial manufacturers toautomate their processes.

To a process operator, this means that an instrument or computer can

control the opening, closing, and positioning of valves;

start and stop equipment;

measure process variables;

respond automatically.

This automation enables a single process technician to monitor andcontrol large, complex process networks from a single control center.

3

Process Technology. Equipment and Systems

Basic instruments

gauges

transmitters

controllers

transducers

4

primary elements and sensors

computers

control valves, and other finalcontrol elements.

Figure 1. Basic process instruments

Process Technology. Equipment and Systems

Temperature measurement

Process technicians are required to closely monitor thetemperatures of process streams. When heat energy isapplied to an area, molecular activity increases, and energy istransferred from molecule to molecule. As this processoccurs, pressure and temperature increase in an enclosedenvironment, materials expand, and density changes.

Temperature is defined as the degreeof hotness or coldness of an object or environment.

Two commonly used scales are

Fahrenheit

Celsius

5

Process Technology. Equipment and Systems

Temperature measurement

The most common temperature-measuring devicesused in the chemical processing industry arethermoelectric.

Thermoelectric temperature-measuring devicescome in two types:

resistive temperature detectors (RTDs)

thermocouples

6

Process Technology. Equipment and Systems

Temperature measurement

Both RTDs and thermocouples are held in a thermowell, a chamberinstalled in vessels or piping.

An RTD is a thermoelectrictemperature-measuring devicecomposed of a small platinum or nickel wire encased in a rugged metal tube.

The electrical resistance in the wire is influenced by changes in temperature.

Temperature changes in an RTD are sensed by an electronic circuit and directed to a temperature indicator.

7

Figure 2. An RTD and a thermocouple

Process Technology. Equipment and Systems

Temperature measurement

Thermocouples are composed of two different types of metal.

A thermocouple is designed to convert heat into electricity.

When heat is applied to the connected ends of a thermocouple, a low-level current is generated.

The higher the temperature, the greater the current generated.

Electric current is detected easily bythe associated electronic circuit and is converted to a corresponding temperature scale.

8

Figure 2. An RTD and a thermocouple

Process Technology. Equipment and Systems

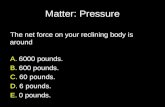

Pressure measurement

Pressure is an important variable that must be carefullymonitored and controlled in an industrial environment.

Pressure is often defined as force per unit area – that is, theamount of force exerted by fluid on the equipment in whichit is contained.

Pressure is measured in

pounds per square inch (psi) in the Englishsystem,

kilograms per square meter (kg/m2) in the metric system,

newtons (N) per square meter, or pascals(Pa) in the System of International Units.

9

Process Technology. Equipment and Systems

Pressure measurement

Two of the most common types of pressure are

atmospheric

hydrostatic

Atmospheric pressure is the force exerted on theearth by the weight of the gases that surround it.

Hydrostatic pressure is the pressure exerted on acontained liquid and is determined by the depth ofthe liquid.

10

Process Technology. Equipment and Systems

Pressure measurement

There are three commonly used pressure scales in the manufacturingenvironment:

gauge

absolute

vacuum

The most commonly used pressure scale is the gauge scale, on whichvalues are expressed in pounds per square inch gauge (psig). The gaugescale starts with atmospheric pressure (14.7 psi) as zero and moves upthe pressure scale.

The absolute pressure scale starts with a perfect vacuum as zero. Valuesare expressed in pounds per square inch absolute (psia). The absolutescale takes into account atmospheric pressure.

Vacuum gauges are designed to operate at less than atmosphericpressure. Vacuum gauges express pressure in inches of mercury (Hg).Vacuum is considered to be anything below atmospheric pressure.

11

Process Technology. Equipment and Systems

Pressure measurement

A manometer is a device that can be used to measure pressure orvacuum. It operates under the hydrostatic pressure principle that acolumn of water of a given volume always exerts a specific force. Theliquid level of the water indicates the pressure.

There are three basic types of manometer:

U-tube manometer measurespressure in units of inches of water.

On a well manometer, read the scale directly.

The scale of an inclined manometer is also read directly, but the scale is “expanded” to make it easier to read small changes.

12

Process Technology. Equipment and Systems

Fluid flow measurement

Fluids flow through a series of pipes, valves, pumps, and vessels.Knowing and controlling the flow rate of a particular processstream are critical to the operation of the unit.

Continuous chemical reactions require precise measurements toensure that all of the reactants (raw materials) are combined in theproper proportions to form the final products.

Feed rates and product rates must be accurately controlled for economic reasons.

Process flow measurements can be taken by any kind of flow meter, but flow control most often requires a flow transmitter.

13

Process Technology. Equipment and Systems

Fluid flow measurement

Certain types of flow meters, such as orifice plate meters andventuri meters, use differential pressure to measure flowrate.Fluid flow through a pipe can be related to pressure differences inside the pipe when flow-restrictivedevices, such as orifice plates, venturi tubes, or flow nozzles, are installed. When the fluid flow encounters a restriction in a pipe, the pressure increases in front of the restriction.

Fluid velocity through the restriction increases. The pressure on the other side of the restriction drops.

14

Figure 3. Flow transmitter and primary elements

Fluid flow measurement

Flow meters

positive displacement meters (nutating disc and oval gear)

rotameter

turbine flow meter

magnetic flow meters

ultrasonic flow meters

vortex flow meters

thermal flow meters

the coriolis meter

15

Figure 4. Nutating Disc Meter

Figure 5. Oval Gear Meter

Process Technology. Equipment and Systems

Fluid flow measurement

16

Figure 6. Rotameter

Figure 7. Turbine flow meter

Process Technology. Equipment and Systems

Level measurement

Process technicians use fixed reference points, typically vessel taps, onwhich to base level measurements. The lowermost tap represents zerolevel, and the uppermost tap is 100%. Correct level readings and controlhelp make modern processing possible and profitable.

Level measurements can be

continuous (levels monitored continuously)

single point.

In single-point measurements, readings are taken from as single point orfrom multiple points on a vessel. Single-point measurements are used toturn on or turn off the equipment (valves, pumps, compressors, motors,alarms) and to detect high and low process levels.

Level-measurement devices can also be classified

direct

indirect

17

Process Technology. Equipment and Systems

Level measurement

Direct level-measurement instruments

Direct instrumentation is in physical contact with the surfaceof the fluid. Direct level-measurement equipment maycalculate the product surface level from a specific point ofreference.

Direct instruments include

sight glasses

floats

displacers

probes

18

Process Technology. Equipment and Systems

Level measurement

A sight glass is a transparent tube with graduated markings (agauge) mounted on the side of a tank.

In a float and tape device, a float rests on the surface of thefluid, and the tape moves up and down, depending on the level.

Displacers are buoyancy devices, or weights, that can be linkedto a transmitter to control flow.

Conductivity probes are high- and low-level alarms. They useelectricity to complete the lower leg circuit. If liquid reaches thehigher leg, the circuit is broken. This type of system, which isdesigned to keep the level between the high and lowconductivity probes, typically is used for nonflammablematerial.

Capacitance probes are radiation devices or load cells.

19

Process Technology. Equipment and Systems

Level measurement

20

Figure 8. Sight glass Figure 9. Level control by displacer

Process Technology. Equipment and Systems

Level measurement

Indirect Level Measurement

Indirect instrumentation incorporates pressure changesthat respond proportionally to level changes.

Differential pressure cells convert pressure differences toa level indication.

They measure the hydrostatic pressure difference between two points on a pressurized vessel.

21

Process Technology. Equipment and Systems

Basic elements of a control loop

The key component of automatic control is

the control loop

the group of instruments that work together tocontrol a process.

Process plants contain many control loops that are used to maintain pressure, temperature, flow, level, and composition.

22

Process Technology. Equipment and Systems

Basic elements of a control loop

The basic elements of a control loop are:

1. Measurement device – primary elements and sensors.

2. Transmitter – a device designed to convert a measurement intoa signal. This signal will be transmitted to another instrument.

3. Controller – a device designed to compare a signal with a setpoint and transmit a signal to a final control element.

4. Transducer – a device designed to convert an air signal to anelectric signal to a pneumatic signal.

5. Final control element – that part of a control loop (for example,control valve, damper, or governor for speed control) that actuallymakes the change to the process. The final control element isgoverned by a controller.

23

Process Technology. Equipment and Systems

Revision

1. Describe manual and automatic control.

2. List basic types of instruments found in the processing industry.

3. Describe a thermocouple and explain how it is used.

4. What is a rotameter used for?

5. List the basic elements of a control loop.

24