Product Data Sheet: Roxar High Pressure Plugs

Transcript of Product Data Sheet: Roxar High Pressure Plugs

Product Data SheetRXPS-002275, Rev B

July 2020

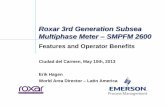

Roxar High Pressure Plugs

Mechanical Plugs (left) and Hydraulic Plugs (right)

Emerson offers a complete range of plugs to be used for both the traditional 2-inch Roxar MechanicalAccess Fitting System as well as the 2-inch Roxar Hydraulic Access Fitting System. The plugs are used toprovide sealing for the access fitting system and to support corrosion and erosion probes, weight losscoupon holders, and injection/sampling quills that are introduced in the process.

IntroductionThere are two main types of plugs available, depending on the device to be installed in the access fitting: hollow plugs and solidplugs. The hollow and solid plugs main purpose is to pressure seal the access fitting system and to support the intrusive monitoringprobe, coupon holder, or injection/sampling quill.

■ The hollow plug assembly is a retrievable carrier for monitoring devices such as linear polarization probes, electrical resistanceprobes, sand probes, hydrogen probes, galvanic probes and other probes or sensors requiring a cable connection.

■ The solid plug assembly is a retrievable carrier for passive monitoring devices such as coupon holders, sacrificial probes andinjection/sampling quills.

A common challenge for high velocity applications is the strength of the device (coupon or probe) with respect to static anddynamic stress in relation to operating conditions (flow velocity, density and viscosity). As an alternative design for bothmechanical and hydraulic plugs, Emerson offers a unique reinforced plug design with increased performance for high velocityapplications.

Mechanical plugs

The mechanical hollow and solid plugs are design with threads for easy mating with the mechanical access fitting. The threads onmechanical plugs may be film coated to reduce the risk of galling.

Figure 1: Solid Mechanical Plug

A. Solid Roxar Mechanical Plug with threadsB. Coupon holder

Roxar High Pressure Plugs July 2020

2 www.Emerson.com/Roxar

Figure 2: Hollow Mechanical Plug

A. Hollow Roxar Mechanical Plug with threadsB. Probe

Hydraulic plug

The hydraulic hollow and solid plugs are of a unique design with no external threads. The design eliminates galling, which is acommon problem with traditional threaded plugs. The hollow and solid plugs are held in place by the support of the locking pins.

Figure 3: Solid Hydraulic Plug

A. Solid Roxar Hydraulic plugB. Coupon holder

July 2020 Roxar High Pressure Plugs

www.Emerson.com/Roxar 3

Figure 4: Hollow Hydraulic Plug

A. Hollow Roxar Hydraulic plugB. Probe

Roxar High Pressure Plugs July 2020

4 www.Emerson.com/Roxar

Model code numbering system

Product description for plugs

Code Product description option

TPLUG Plug

Design type

Code Design type options

H Hydraulic

M Mechanical

Plug type

Code Plug type

11 Solid plug (suitable for hydrotest); Metallic nut – same material as plug body

21 Hollow plug(suitable for hydrotest); Metallic sealing plug – same material as plug body

31 Reinforced plug (suitable for hydrotest); Metallic sealing plug – same material as plug body

Material plug body

Code Material plug body

316B(1) Stainless steel ASTM A479 UNS S31603 (316L), bar, NACE MR0175

318B(1) Duplex ASTM A479 UNS S31803 (316L), bar, NACE MR0175

625B(1) Inconel® ASTM B446 UNS N06625, bar, NACE MR0175

760B(1) Super duplex ASTM A479 UNS S32760, bar, NACE MR0175

825B(1) Incolloy ASTM B425 UNS N08825, bar, NACE MR0175

(1) Requires special tests and certificates options MC or MT.

July 2020 Roxar High Pressure Plugs

www.Emerson.com/Roxar 5

Operating mode and condition for plugs

Code Operating mode and conditions

00 O-ring not applicable; PTFE primary packing

01(1) (2) Standard Viton® o-ring (-4 °F (-20 °C) to 392 °F (200 °C)) PTFE primary packing

02 (1)(2) Rapid gas decompression FR 25/90 o-ring (-41 °F (-41 °C) to 392 °F (200 °C)) PTFE primary packing

03 (1)(2) Rapid gas decompression and/or 100% Methanol Elast-O-Lion® 101 o-ring (-20 °F (-29 °C) to 320 °F (160 °C))PTFE primary packing

(1) Not available with design type option H, Hydraulic.(2) Not available with plug type options 10, 20, 21, 30, 31.

Product specific options

Code Product specific options

C0 No coating

C4(1) PTFE coating on mechanical plug threads

(1) Not available with design type option H, Hydraulic.

Factory option for plugs

Code Factory options

Z Standard product

Certificates, tests, calibrations, and services for plugs

Code Certificates, tests, calibrations and services (optional)

D1 Dye penetrant test for plug body

PM Positive material identification for plug body (without C content)

PC(1) Positive material identification for plug body (with C content)

PD(2)(3) PED statement of conformity

MC Material inspection certificate 3.1 (supplier lot traceability per EN 10204)

MT Material inspection certificate 3.2 (supplier lot traceability per EN 10204)

MN(4) Material requirements according to NORSOK M-630

M2(5) Material specification type 2

(1) Not available wth Material Plug Body options 625B, 825B.(2) Only available with material options 318B.(3) Not available with design type option M and Plug type option 11, and operating mode and conditions option 00.(4) Not available with material plug body option 825B.(5) Not available with special tests and certificate options MT, MN.

Roxar High Pressure Plugs July 2020

6 www.Emerson.com/Roxar

Spare partsThe parts presented in this section are available as spare parts for the high pressure mechanical and hydraulic plugs.

Model Description

ROX000264646(1) O-RING 34.52X3.53, material Viton 75

ROX000264659 Bolt DIN916 M5 X 5, material A4

ROX000278520(1) Primary packing, material PTFE, 25 % glass filled, certificate-EN 10204 type 3.1

ROX000278530(1) Probe packing

PTFE .25 %, glass filled

ROX000278558 Bolt DIN916 M5 X 5, material UNS S31803

ROX000278560 O-ring 34.52 X 3.53, material FR 25/90

ROX000278561 O-ring 34.52 X 3.53, material Elast-O-Lion 101

ROX000283685 Sealing plug for hollow plugs – 316L6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS S01, NACE-yes, material UNS S31603 A79

ROX000283686 Sealing plug for hollow plugs – DUP6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31803 A79

ROX000283687 Pipe plug for hollow and solid plugs – 316L6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31603 A79

ROX000283688 Pipe plug for hollow and solid plugs – DUP6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31803 A79

ROX000283690 Solid plug nut – 316L6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS S01, NACE=yes, material UNS S31603 A479

ROX000283693 Solid plug nut – DUP6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31803 A479

ROX000283694 Hollow plug nut – 316L6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS S01, NACE=yes, material UNS S31603 A479

ROX000283695 Hollow plug nut – DUP6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31803 A479

ROX000283700 Sealing plug for reinforced plugs – 316L6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS S01, material UNS S31603 A479

ROX000283701 Sealing plug for reinforced plugs – DUP6C

Certificates: EN 10204 type 3.1, MDS-NORSOK MDS D47, NACE-yes, material UNS S31803 A479

ROX000292116(1) Wear ring for hydraulic plugs

PTFE .15% glass and 5% MO-AS

ROX000341542 O-ring 34.52 X 3.53

material FKM xplor v9t22

ROX000333747 O-ring 34.52 X 3.53

material PTFE .50

(1) Fast track items are also available for expedited shipment under the fast track program, with terms and conditions subject to a pricing premium.

July 2020 Roxar High Pressure Plugs

www.Emerson.com/Roxar 7

RXPS-002275Rev. B

July 2020

Emerson Automation SolutionsRoxar Norway:Gamle Forusveien 174031 StavangerEurope: + 47 51 81 8800Russian/CIS: + 7 495 504 3405 www.Emerson.com/[email protected]

Emerson Automation SolutionsNorth America: + 1 281 879 2300Latin America:Mexico: + 52 55 5809 5300Argentina: + 54 11 4809 2700Brazil: + 55 15 3413 8000Chile: + 56 2 2928 4800Peru: + 51 15190130

Emerson Automation SolutionsAsia Pacific: + 60 3 5624 2888Australia: + 1 300 55 3051Middle East: + 971 4811 8100

©2020 Roxar AS. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Roxar is a trademark ofRoxar ASA. All other marks are property of their respective owners.

Roxar supplies this publication for informational purposes only. While every effort has been made toensure accuracy, this publication is not intended to make performance claims or processrecommendations. Roxar does not warrant, guarantee, or assume any legal liability for the accuracy,completeness, timeliness, reliability, or usefulness of any information, product, or process describedherein. All sales are governed by our terms and conditions, which are available on request. Wereserve the right to modify or improve the designs or specifications of our products at any timewithout notice. For actual product information and recommendations, please contact your localRoxar representative.

Roxar products are protected by patents. See http://www.emerson.com/en-us/automation/brands/roxar-home/roxar-patents for details.