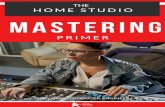

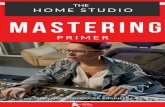

Process Mastering : A Sure Way to Invigorate Your Improvement Efforts

description

Transcript of Process Mastering : A Sure Way to Invigorate Your Improvement Efforts

Process Mastering:A Sure Way to Invigorate Your Improvement Efforts

Presented by Ray W. Wilson

Definitions Process Mastering: A discipline which focuses on

reducing process variation and increasing process knowledge through experts, linking customers and suppliers. In this case the experts are the people who do the work in the process everyday.

Process Master: The documented, current best known way to do a job or run a process. A cookbook for doing the process - putting the best known way down on paper or on line.

Best Known Way: The safest, easiest, simplest current way to get results that satisfy customer needs – the road map for everyone to follow until a better method is chosen.

Step One – Select Team Leader

The Team Leader: Assembles the team Sets agendas Leads team meetings

Coordinates paperwork

Trains new workers using process master

Monitors the process to be sure master is followed

Is the process owner

Done by the Process Mastering team sponsor

Step Two – Define the Process

• What is the name of the process?

• Where does the process start and stop?

• What inputs and suppliers are part of the process?

• What is the process output?

• Are there naturally occurring boundaries?

• Smaller is normally better because processes are always more complicated than they look. An ideally sized process could have up to 9 major steps with fewer than 5 sub-steps each

Set process boundaries

Step Three – Select a Team

• Team members should have: Process know-

how, tricks of the trade

Process theory, safety information

• Approximately five process workers

• Team members should: Keep rest of workers

informed Get input from other

workers • All shifts need to be

included• May include suppliers

and customers

Sponsor and team leader select team

Step Four – Establish Team Norms

• Decided by the team and sponsor• Every team member gets a copy• Everyone is expected to follow, challenge and add

to the list as necessary• Examples:

Everyone participates Honesty No put-downs No beepers or cell phones

Team chooses standard, rules, or pattern for their individual and group behavior

Step Five – Flowchart the Process

• Use a top-down flow chart with major steps at the top and sub-steps underneath

• Capture the best known methods

• Start step name with an action verb

• Number flow chart steps for later identification

• Identify key steps with asterisks

• Capture new, untried ideas on a Parking Lot List for later trial

Decide on the best sequence of job steps

Step Six – List Customers Needs and How the Process Fills Those Needs

(Do this for External and Internal Customers)

• List the vital few customers or customer classes

• List and choose two to five most important customer needs

• List process actions (steps) which affect how the customer needs are met

• Evaluate how strongly the process actions affect the customers’ needs

Step Seven - List What is ControlledList two to five critical conditions or control

points watched in the process • Write how the critical conditions or control

points can be monitored for effectiveness• Evaluate how important the measurement is to

the critical condition or control point

Step Eight - List Needs From Suppliers• List the vital few suppliers or classes of

suppliers• List what is wanted or needed most from

suppliers• List how the process uses the suppliers’

deliveries• Evaluate how important the supplier inputs are

to the process

Step Nine – List Tools, Equipment and Supplies. . . that are necessary to do the job. (Those that are necessary but may be removed

from the work area)• Ex. A volt meter, grease gun, or gas mask, NOT

a desk or light fixtures • List supplies that may be used up during the

process• Note if inspection, calibration or maintenance is

required before use

Step Ten - Capture Key Steps -Identification

1. Has the step caused errors in the past?

2. Is the step complicated?

3. Does the step have a safety issue?

4. Has the step been found important to internal or external customers? (Check the A Charts)

5. Is a control point associated with the step?

Mark key steps on flow chart with asterisks

Identify key process steps on the flow chart

Step Ten - Capture Key Steps (cont.) - Worksheet• Transfer flowchart step number and name to

worksheet• Reach consensus and document the best

known way to do the step• Capture “tricks of the trade”• Identify consequences of doing the step wrong

including safety issues• List or identify at least one measurement for

the process• Discuss possible exceptions to the best known

way

Step Eleven - Try Out Process Master• Train those not on the team• Follow process master to check for errors and

omissions• Have a novice work through the process to see

if it makes sense• Collect exceptions that may be added to the

process master

Step Twelve - Review and Modify Process Master

• Are any steps, tricks, or safety concerns missing, wrong or unclear?

• Should any exceptions be included in the master?

• Did the novice follow through the process master to find anything that doesn’t make sense?

Discuss how it went

Step Thirteen - Sign Off and Take Responsibility• Update the Process Master and get documents

put into final form• Have everyone including the sponsor sign the

finished document• Monitor the use and the process

measurement(s)• Begin improving to make the process better

Some Benefits From Process Mastering

Stable predictable processes

Trained workforce Communication cleaner

and friendlier Management support

(Workers are empowered) Less reliance on

inspection Data used to manage and

make decisions Fewer workers injured on

the job

Happier, more fulfilled workers. More pride and joy in work.

Lower employee turnover

Fewer breakdowns Organization learns

more rapidly Support for revised ISO

9000 More profit, less waste

Additional information:Ray Wilson, P.E. served on the executive

management team of Countrymark Cooperative, Inc. for 10 years and led the company's Customer Focused Quality improvement effort. He is co-author of Process Mastering - How to Establish and Document the Best Known Way to Do a Job. His firm, Ray Wilson & Associates, specializes in organizational and operational improvement.

Email: [email protected] Page: www.rwwilson.com