Prevention of Nozzle Wear in Abrasive Water Suspension Jets

Transcript of Prevention of Nozzle Wear in Abrasive Water Suspension Jets

ets. Itosity. Thein the

therasiveg andating145

l filmage

from a

s. We, fromthe oilthed. The

Umang Anande-mail: [email protected]

Joseph [email protected]

The Johns Hopkins University,Department of Mechanical Engineering,

Baltimore, MD 21218

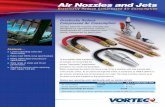

Prevention of Nozzle Wear inAbrasive Water Suspension Jets(AWSJ) Using Porous LubricatedNozzlesThis paper introduces a novel method for preventing nozzle wear in abrasive water jconsists of using a porous nozzle, surrounded by a reservoir containing high-visclubricant, which is exposed to the same driving pressure as the flow in the nozzlepressure difference across the porous medium, generated due to the high-speed flownozzle, continuously forces lubricant through it. The resulting thin oil film forming onwalls of the nozzle protects the walls from the impact and shear caused by the abparticles. The porous nozzles were manufactured using Electric Discharge Machininexamined with Scanning Electron Microscopy. Two test facilities were used for evaluthe porous lubricated nozzles. The first was a two-dimensional facility, supporting amm wide nozzle with windows on both sides, which enabled visualization of the oiand measurements of the liquid and abrasive-particle velocities using Particle ImVelocimetry. The measured slip velocities were also compared to computed valuessimple numerical model involving one-way coupling. The second facility used a 200mmaxisymmetric nozzle to determine the extent of nozzle wear under different conditionfound that the presence of an oil film substantially reduced the extent of nozzle wear111 percent of the diameter, when the nozzle was not lubricated, to 4 percent, whenviscosity was 1800 mm2/s and its flow rate was 2.4 percent of the water flow (oversame period). The wear increased as the lubricant flow rate and viscosity decreasepresence of the oil film also improved the coherence of the jet.@DOI: 10.1115/1.1491977#

pd

i

n

e

t

m

i

t

ets

sengf

r

n-

ity,e the

ion,

o a

sndflowia-bletheir

ayeven

tionper

1 IntroductionAbrasive water jets, namely water jets containing abrasive

ticles, have a considerable niche in the material processing intry. Like laser cutting instruments they are accurate, easily maged and cause very little loss of material. However, abrasivecutting does not involve high temperatures, which is characterto laser cutting, and as a result they are suitable for practicallymaterial. Furthermore, the instrumentation required for high-spjets is simpler and much cheaper. Consequently, jet cutting caimplemented in a broad range of industries, ranging from smmachine shops and quarries, to large sheet metal, compositceramic processing in the car and aircraft industries.

The most troublesome difficulty associated with high-speslurry jets, which presently limits their usefulness, is wear ofnozzle walls~Conn @1#, Dubensky et al.@2#!. Since the jet speedranges between 100–500 m/sec, and the particle size can bhigh as 40 percent of the nozzle diameter, it does not take londestroy a nozzle. Consequently, in current systems nozzlesbe replaced frequently, sometimes every 10–20 minutes~Duben-sky et al.@2#, Kovacevic and Evizi@3#, Mort @4#!. The wear of thenozzle walls also leads to the jet becoming incoherent, whcauses an increase in the kerf width on the workpiece, detertion of surface quality and loss of cutting accuracy. Hence, wof the nozzle requires constant maintenance and inspection, wleads to machine down-time and increases the process cPresent attempts to solve this problem include:~a! Pure water isinjected through an orifice and the abrasive particles are thenat low pressure through a side tube. The water entrains theticles as both travel through a mixing tube~or ‘‘focusing tube’’!whose diameter is typically three times larger than that of

Contributed by the Tribology Division for publication in the ASME JOURNAL OFTRIBOLOGY. Manuscript received by the Tribology Division October 2, 2001 revismanuscript received April 16, 2002. Associate Editor: L. San Andre´s.

168 Õ Vol. 125, JANUARY 2003 Copyright ©

ar-us-

an-jet

sticanyeed

bealls or

edhe

e asg to

ust

ichora-earhichosts.

fedpar-

he

orifice ~Hashish et al.@5#, Hashish@6#, Momber and Kovacevic@7#!. This approach is typically referred to as Abrasive Water J~AWJ!, as opposed to abrasive water suspension jets~AWSJ! thatinvolve injection of premixed slurry through the nozzle. Becauof the wear problem, essentially all the commercial jet cuttisystems are based on this principle;~b! Use of nozzles made overy hard materials, such as diamond and boron carbide~Duben-sky et al. @2#, Hollinger and Mannheimer@8#, Miller @9#!; ~c!Keeping the particles softer than the nozzle walls~Dubensky et al.@2#, Mort @4#!; ~d! Attempts to modify the flow structure in ordeto keep the particles away from the wall~Horii et al. @10#, Okitaet al.@11#!. All the presently available means have major deficiecies. In AWJ~seeding downstream of the jet! the particles are notaccelerated to levels that are close to that of the liquid velocand, hence, requiring substantially higher pressures to achievsame cutting effect~Hashish et al.@5#, Hashish@6#, Momber andKovacevic@7#!. The process also causes considerable expansscattering and unsteadiness~Hollinger and Mannheimer@8#!. Fur-thermore, even in AWJ systems, wear of the mixing tube is alsserious problem~Hashish@12#, Nanduri et al.@13#!. Modificationto the jet flow structure by introducing secondary swirling flownear the nozzle walls is useful only in relatively slow flows asmall particles. It also causes jet expansion and secondaryphenomena that limit the capability to control the process. Dmond nozzles are expensive and difficult to form into desirashapes. Using particles softer than the nozzle walls reducescutting effectiveness.

Thus, a solution to the wear problem must still be found. It menable us to increase the jet speed, and reduce its diameterfurther ~present sizes range between 100–500mm!, allowingmuch higher precision, deeper cutting, and wider implementain problematic materials including ceramics. The present paintroduces such a solution.

ed

2003 by ASME Transactions of the ASME

a

iei

h

ne

o

a

c

a

c

ria

tw

ure-

erer’swas

bri-cen-ri-m

outm.ereeri-

tingck-

ri-andan-due

ds-outre

terting

sAs

up-ss

2 The Lubricated Porous NozzleThe proposed solution to solve the wear problem is sketche

Fig. 1 ~Katz @14#!. The nozzle is made of a porous material andsurrounded with a reservoir containing a high viscosity lubricthat is exposed to the same pressure that drives the flow innozzle. The lubricant is forced continuously through the poromedium as a result of the pressure difference created due tohigh-speed flow in the nozzle. The lubricant injection rate, whis controlled by the pressure difference, the nozzle geom~thickness!, permeability of the porous medium and lubricant vcosity, is designed to create a thin layer~film!, with a typicalthickness of 5mm, on the walls of the nozzle. This film of higviscosity fluid protects the walls of the nozzle from the shear aimpact of the abrasive particles. Since the lubricant is constareplenished, sites where particles ‘‘gouge’’ the film are repairpreventing damage to the solid walls. Provided that the prolubricant ~viscosity!, film thickness and nozzle geometry~flowrate through the porous medium! are selected, this approach prvides a reliable but yet very simple method to prevent nozwear. Due to the differences in viscosity between the lubricantthe water~can be as high as 4000:1!, the oil consumption is mini-mal, typically about 1 percent of the water flow rate.

The idea of using a porous nozzle has been introduced beby Tan and Davidson@15# and Tan@16–18#. They used a fluidizedsand bed as a source of the abrasive slurry as well as a sourthe water forced through the porous nozzles to lubricate them,the nozzle was exposed to the same slurry on both sides. Texperiments were performed at low pressures of 1–2 MPa, i.elow velocities, and as a result did not address the wear probunder relevant conditions. As demonstrated in this paper, wdoes not have sufficiently high viscosity to prevent wear. In falubricants with viscosities that were three orders of magnituhigher than that of water were essential. Furthermore, the forof liquid containing particles through the porous medium wouquickly clog it due to the high-pressure difference acrossnozzle.

3 Experimental SetupThe experiments were performed using the supply system

lubricant and abrasive particles illustrated in Fig. 2. The filte~1-micron! tap water was pressurized using a 7.5 kW, positdisplacement pump with maximum pressure of 69 MPa and mmum flow rate of 9.531025 m3/s. We typically operated at pressures of up to 34.5 MPa. A regulating valve at the exit frompump was used to control the flow rate, which was measured

Fig. 1 A Sketch illustrating the principles of the method forpreventing nozzle wear

Journal of Tribology

d inisnttheusthe

chtry

s-

ndtlyd,

per

-zlend

fore

e ofi.e.,heir., atlemter

ct,deingldthe

ofedvexi-

-heith

a turbine flow meter~Hoffer Flow Controls Model HO!. Based onthe manufacturer’s specifications and calibration, the measment uncertainty was less than 1 percent. A pressure gauge~PSI-TRONIX Model PG5000! attached in the main line monitored thpressure upstream of the nozzle. Based on the manufactuspecifications and calibration, the measurement uncertaintyless than 1 percent.

The water also pressurized the chambers containing the lucant and abrasive slurry. The slurry chamber contained a contrated mixture of slurry particles and water. During the expements part of the water was injected into this chamber frobelow, which entrained some of the particles, then flowedfrom the top of the chamber, and mixed with the main streaInjection from below was necessary since the particles wheavier than water and tended to settle. A perforated hemisphcal cap was placed at the inlet of the slurry chamber. The resulsmall jets mixed the slurry in the chamber, and prevented bloage of the inlet when the chamber was loaded with particles.

A small loosely fitted piston separated the water from the lubcant in the oil chamber. This piston ensured that the lubricantthe water would not mix and form an emulsion. There is substtial evidence that the permeability of porous media is reducedto the transport of emulsions through them~McAuliffe @19#, Sooand Radke@20,21#!. The oil line upstream of the nozzle containea 2-micron filter to remove any dirt from the lubricant. The preence of this element was critical. Experiments performed withthis filter resulted in the clogging of the porous medium. Figu3~a! shows Scanning Electron Microscope~SEM! images of theclogged porous surface resulting from experiments with no filand the same surface with embedded dirt after the surface coawas removed. Figure 3~b! shows a SEM image of the porousurface recorded after the experiments with the filter installed.is evident, the nozzle surface remained free from blockage.

We constructed two types of nozzles and the housings to sport them: A two-dimensional nozzle made of porous stainle

Fig. 2 Schematic of the system supplying slurry particles andlubricant to the test chamber

JANUARY 2003, Vol. 125 Õ 169

idt

thef

nar-as oiling,in

ar-thtioniquid

is-eyeru-

theus

in-bothces,ssedrousthe

ntireanddi-

ies

istededduely

gn

steel with windows on both sides was used to visualize the fland the oil film and to measure the liquid and abrasive-partvelocities in the nozzle. An axisymmetric nozzle was used totermine the extent of nozzle wear and investigate the effeclubricant properties and flow rate.

Fig. 3 SEM images of „a… the clogged porous surface when afilter was not used, showing a coating of dirt on the surface anddirt inside the pores, and „b… the porous surface recorded afterthe experiments with a filter installed, free from blockage

170 Õ Vol. 125, JANUARY 2003

owclee-of

3.1 The Two-Dimensional Nozzle Housing. The interior ofthe two-dimensional nozzle housing is shown in Fig. 4 andnozzle is illustrated in Fig. 5~a! and ~b!. The nozzle consisted otwo 1.57 mm thick, symmetric~mirror image! inserts/sectionsmade of porous, 316-stainless steel. The slurry flowed in therow gap between these two sections and the grooves servedreservoirs. The two porous sections were inserted in a houswith a matched slot and openings for oil and slurry, as shownFig. 5~a!. The nozzle geometry consisted of a 4.83 mm long quter ellipse followed by a 1.52 mm long straight portion wismooth transition between them. The length of the straight secwas chosen to accelerate the abrasive particles to nearly the lvelocity near the nozzle exit~analysis follows!. The porous sec-tions were manufactured in our laboratory using Electric Dcharge Machining~EDM!. The shape of the oil reservoir and thnozzle geometry determined the thickness of the porous laseparating the nozzle from the oil reservoir, which in turn inflenced the oil injection rate into the nozzle.

As shown in Fig. 4, the oil entered the oil reservoirs throughoil ports ~Fig. 5~a!! and flowed into the nozzle through the porolayer. The slurry entered through the upper port. The porousserts were covered with metal shims of matched shapes onsides, to prevent leakage of oil and water between the surfaand were then inserted inside the main body. They were preon both sides by sapphire windows. The gap between the poinserts varied for each nozzle set due to their compression bywindows. The actual gap~nozzle width! for the present nozzlewas measured to be 0.145 mm. One window covered the eporous section and the other covered only the converginghigh-speed sections of the nozzle. This arrangement allowedrect observations of the flow, film layer and particle trajectorinside the nozzle.

3.2 The Axisymmetric Nozzle Housing. Figure 6~a! showsthe components of the axisymmetric nozzle setup and Fig. 6~b!shows a cross-section of the porous nozzle. The nozzle consof a short converging section of quarter-circular shape followby a straight section. We were forced to use a shorter nozzleto limitations in the ability to manufacture the nozzle precisewithout smearing the porosity of the interior walls. This desi

Fig. 4 Components of the two-dimensional nozzle housing

Transactions of the ASME

Journal of Tribo

Fig. 5 „a… The shape of the porous inserts and the slot in which they were inserted in thetwo-dimensional housing, and „b… geometry of the two-dimensional nozzle. All dimensions arein mm.

theort.sed

ma-to

also allowed us to vary the outside diameter of the nozzles, whdetermined the thickness of the porous medium separatingnozzle from the oil reservoir. Hence, by changing the thicknesscould vary the oil flow rate~details follow!. The oil enteredthrough the oil port and collected in the reservoir surroundingporous nozzle~Fig. 6~a!!. It then flowed through the porous me

logy

ichthewe

the-

dium due to the pressure difference, to create a thin film onnozzle walls. The abrasive slurry entered through the upper pTwo sets of copper shims, on both sides of the nozzle were uas seals.

The nozzles were made of porous, 316 stainless steel andchined using EDM. The EDM machining parameters required

Fig. 6 „a… Components of the axisymmetric nozzle housing, and „b… cross-section of the porous axisymmetric nozzle. Alldimensions are in mm.

JANUARY 2003, Vol. 125 Õ 171

ydp

eAe

alsohe

10.

oidaserthedes-sult,

n-was

theave-

en-de-

theper

on.e.,andwerebe-

se-nd auter

dedre-s

ld a

maintain the porosity have been established and verified by obvations using SEM. Figures 7 and 8 show SEM images of theand cut section of the porous nozzle, respectively. The qualitthe surface varied substantially, depending on the method usemanufacturing the porous material, and the EDM machiningrameters, such as energy level, spark frequency and cutting spWe experimented with different materials and machining paraeters in order to maintain a uniform pore distribution and prevthe ‘‘smearing’’ of the pores on the surface of the nozzle.illustrated in Fig. 9, decreasing the cutting speed and energy l

Fig. 7 SEM micrograph of the top of the axisymmetric nozzle

Fig. 8 SEM micrograph of the cut section of the axisymmetricnozzle

172 Õ Vol. 125, JANUARY 2003

ser-topoffora-eed.m-ntsvelimproved the surface quality. The machining parameters wereadjusted for preventing oil flow in the undesired regions of tnozzle.

4 Velocity MeasurementsA schematic of the data acquisition setup is shown in Fig.

Due to the high velocities in the nozzle~.150 m/s! the exposuretime had to be very short, in the order of nanoseconds, to avblurred images. Consequently, we used a dual head Nd-YAG lwith pulse duration of 5 ns as a light source. However, due tolaser coherence, direct illumination of the nozzle generated unired interference patterns that obscured the image. As a rewhen we needed uniform background illumination~for PIV appli-cations!, a glass container with an emulsion of oil and water cotaining fluorescent dye-Pyromethene 597 dissolved in the oil,inserted between the laser and the window. The laser exciteddye and caused bright fluorescence at a broad range of wlengths. This method effectively created a 5 nsflash of uniformillumination. The two independent laser heads enabled us to gerate 15-pulse pairs/sec with an essentially unlimited in-pairlay, as low as 100 ns. Particle Image Velocimetry~PIV! was usedfor measuring the velocity of the particles and the liquid insidenozzle. The images were recorded using a 12 bit, 4 framessecond, 204832048 pixels digital camera~SMD-4M4!. All theobservations were performed using a long working distance~50.8mm! microscope objective with a resolution of 1.75mm, manu-factured by Infinity Photo-Optical Company. The magnificatiwas 0.695mm per pixel. We recorded silhouette photographs, ithe camera faced the light source and as a result the oil filmthe particles appeared as shadows. The camera and the lasersynchronized. The time separation between pulses, varyingtween 150 ns at the end of the nozzle to 1.5ms at the top of thenozzle, was too short for relying on the laser electronics. Conquently, the exact timing was measured using a photodiode a500 MHz, 1GS/s oscilloscope, and then recorded by the compusing a GPIB board.

Sample images of the straight section of the nozzle recorusing the fluorescent bulb with and without oil injection are psented in Fig. 11. In Fig. 11~b! the oil layer creates dark patternwith a bright background. Figure 11~c!, obtained by subtractingFig. 11~b! from Fig. 11~a!, clearly shows the formation of the oilayers on the two walls. The oil used in these experiments ha

Fig. 9 Effect of EDM machining parameters on the porous sur-face. SEM image: Top to bottom—improvements by decreasingthe cutting speed and energy level.

Transactions of the ASME

Journal of Tribology

Fig. 10 Schematic of the setup for data acquisition

ent,ures

ofm-ter.vevenat

d

ingnts

wurerticleare

the

ig.re-xpo-en-tionto-

edtion

et.the

vity,the

, theyinuldthee

uto-f thethe

uid

Fig. 11 „a… The nozzle with water only, „b… with water and oil,and „c… the oil layers on the walls of the nozzle. The flow wasfrom top to bottom. The section shown is 4.42 ËxË5.84 mmand 0.145 mm wide. For definition of x , see Fig. 5 „b….

viscosity of 1800 mm2/s ~at 25°C!. In spite of this high viscosity,the high shear rates in the nozzle caused considerable entrainmas can be observed from the protrusions and eddy-like structin Fig. 11~b! and~c!. However, the typical flow rate of lubricant inthe two-dimensional facility was still very low, below 1 percentthe flow rate of water. Note that the characteristic Reynolds nuber of this flow was 22,000, based on the nozzle exit diameWithout oil, transition to a turbulent boundary layer would habeen triggered immediately due to the wall roughness, and ewith the oil, the eddy-like structures indicate that the flow wasleast transitional.

The same type of ‘‘fluorescent bulb’’ illumination was usewhile observing the motion of the abrasive~slurry! particles andthe ~almost! neutrally buoyant tracer particles used for measurthe liquid velocity. As mentioned before, velocity measuremewere performed using PIV~Adrian @22#! using software and pro-cedures developed in our laboratory~e.g., Roth and Katz@23#,Sinha and Katz@24#!. This method is based on seeding the flowith microscopic tracer particles and recording double exposimages on the same or on separate frames. The measured padisplacements and the known time delay between exposuresused for determining the velocity. In the present experiments,tracers were 4mm diameter~Std. dev.–1.5mm! spherical nylonparticles that had a specific gravity of 1.14. As shown in F12~a! and ~b! and Fig. 13, the double-exposure images werecorded on the same frame due to the short delay between esures~,1 ms!. The images were enhanced using an in-househancement program based on the histogram equalizaalgorithm, and the velocity was calculated using an aucorrelation code~Roth and Katz@23#!.

In order to protect the sapphire windows from being damagdue to the impact of the abrasive particles during the visualizaexperiments in the two-dimensional nozzle, we used 20–45mmCelestite~Strontium Sulphate, a naturally occurring mineral! asslurry particles instead of the typical industry standard of GarnCelestite has a Mohs Hardness of 3–3.5, much lower thanGarnet’s 7–7.5, but both have almost the same specific gra3.95 versus 4.0, respectively. The Celestite particles also hadsame characteristic shape as the Garnet particles, and, hencehad similar hydrodynamic behavior. Due to the large differencesize between the liquid tracers and the slurry particles, they coeasily be distinguished. The large particles were removed fromimage before calculating the liquid velocity. The velocity of thslurry particles was measured separately, also using acorrelation analysis, but also subtraction of enhanced edges oparticles. Sample images of the slurry and tracer particles innozzle are presented in Fig. 14~a!–~c!.

Figure 15 shows the measured centerline velocity of the liq

JANUARY 2003, Vol. 125 Õ 173

e

n

e

cy

d

o

tive/s,

tedity

s-de

alsoise

ed a

inlift

and its standard deviation for a pressure upstream of the nozz14.48 MPa, with and without lubrication. As can be observinjection of oil caused virtually no change in the centerline liquvelocity. Note that the centerline liquid velocity estimated usithe Bernoulli equation would be 170.2 m/s. For each sectionthe nozzle, we used 24 instantaneous realizations to calculataverage velocity. From Dong et al.@25# and Roth et al.@26# thesub-pixel accuracy in velocity measurement using auto-correlaanalysis was about 0.3 pixels~the standard deviation betweemeasured and exact results was 0.2 pixels!, and depended mostlyon the number of particles per window. Since the typical partidisplacement for the PIV images was 30 pixels, the uncertaintliquid velocity measurements was about 1 percent. This numwas reduced further after averaging. The uncertainty in theplacement of individual large particles could be maintained asimilar level provided they were larger~>20 pixels, according toSridhar and Katz@27#!. These conditions were satisfied in thpresent measurements.

Using a sample of 103 slurry particles, Fig. 16 shows the msured slip velocity of slurry particles, i.e.,vW l2vW p ~the averageliquid velocity minus the slurry particle velocity!, in the last 1.93mm of the nozzle and illustrates the decrease in slip velocity al

Fig. 12 „a… The nozzle with water and tracer particles, and „b…enhanced double exposure image of the tracers. The flow wasfrom top to bottom. For location, see Fig. 11.

174 Õ Vol. 125, JANUARY 2003

le ofd,idgofthe

tionn

lein

beris-

t a

e

ea-

ng

the straight section of the nozzle. Near the nozzle exit, the relavelocity decreased to negligible levels, for example to 1.88 mi.e., 1.2 percent of the local liquid velocity, atx55.94 mm.

5 Numerical Analysis of Particle SlipIn order to compare the measured slip velocity to expec

levels, we performed a simple numerical analysis of the velocof spherical particles using Eq.~1! that accounted for inertia, vir-tual mass, pressure gradients and drag forces~Maxey and Riley@28#, Sridhar and Katz@27,29#!. Since the pressure gradients asociated with the nozzle geometry were five orders of magnituhigher than the buoyancy forces, we neglected the latter. Weneglected the lift forces, as we were interested in the streamwmotion. Based on the assumption of spherical particles we usvirtual mass coefficient of 0.5.

DF rP

dnW p

dt1

1

2r lS dnp

d t2

dnW l

dt D G523

4r l unW p2nW l u~nW p2nW l !Cd

2¹pD (1)

here,v is the velocity,Cd is the drag coefficient,r andm are thedensity and viscosity, respectively,p is the pressure,D is the di-ameter of the particle and the subscriptsp and 1 refer to theparticle and liquid, respectively. The drag coefficient, presentedEq. ~2!, was based on an empirical expression available in Cet al. @30# for Re,33105 ~the present range was less than 103!

Cd524

[email protected] Re0.687#1

0.42

~114.253104 Re21.16!(2)

Fig. 13 The converging section of the nozzle with enhanceddouble exposure image of the tracers. The flow was from top tobottom. The section shown is 0.84 ËxË2.26 mm. For definitionof x , see Fig. 5 „b….

Transactions of the ASME

0

d

v

t

r

heired

les

m-thetent

terr, ascles

where Re5r l unW l2nW PuD

m

We also assumed a steady liquid flow, i.e.,

]nW l

]t5nW l

]nW l

]x52

1

r l

]p

]x

The numerical analysis was performed for several particleameters assuming one-way coupling, i.e., neglecting the effecthe particle motion on the liquid flow~although the particle sizecompared to the nozzle diameter made the validity of this assution doubtful!. We also assumed that the particle traveled alothe centerline of the nozzle. A 10th order polynomial was fitted tothe measured centerline liquid velocity with oil injection and thcurve was used as an input to the numerical calculations.Adams–Bashforth, third order scheme was used to march forwin time and we used time steps of 0.05ms. By varying the timesteps and repeating the calculations we verified that a step ofms was short enough not to have an effect on the results.

Figure 17~a! compares the 10th order curve fit to the measureliquid velocity with the computed velocity of a 25mm slurryparticle. Figure 17~b! shows the computed slip velocities for seeral particle diameters. At the entrance to the straight sectioncomputed slip velocity of a 25mm slurry particle~;23 m/s!, washigher by 50 percent than the measured value~;15 m/s!. Near theexit the measured slip velocities~;2–4 m/s! were substantiallylower than the computed values~;13 m/s!. However, if the com-parison had been performed using the results for a 35mm slurryparticle, the discrepancy would have increased to 90 percent400 percent at the entrance and exit from the straight secrespectively. This discrepancy could have been a result of sevfactors, such as the fact that the real slurry particles were far f

Fig. 14 „a–c… show three samples of double exposure imagesof the nozzle with water and oil along with slurry „large darkobjects … and tracer particles „small dark objects …. The flow wasfrom top to bottom. For location, see Fig. 11.

Journal of Tribology

di-t of

mp-ng

isAnard

.05

-the

andion,eralom

being spherical, i.e., they had larger drag coefficients and tvirtual mass coefficient was different than 0.5. Also, the assumone-way coupling was doubtful due to the size of the particcompared to the width of the nozzle. Analysis~results not shown!performed to identify the required drag that would match the coputed slip velocities to the experimental values indicated thatCd would have to be tripled. Such drag coefficients are consiswith the published data on non-spherical particles~Clift et al.@30#, Haider and Levenspiel@31#!.

Most of the slurry particles appeared to be moving in the cenof the nozzle as the sample images in Fig. 14 show. Howeveshown at the left side of Fig. 18, in some cases the slurry parti

Fig. 15 The centerline liquid velocity in the two-dimensionalnozzle measured using PIV, with and without injection of oil.The velocities were obtained using 135 Ã24 measurements foreach case. Every 5 th data point, representing an average of 24measurements, is shown for clarity. The error bars representthe standard deviation values at these points. For dimensions,see Fig. 5 „b….

Fig. 16 Measured slip velocity of the slurry particles withnominal diameter of 20–45 mm close to the exit from the nozzle„4.42ËxË6.35 mm … and the linear least squares fit to the data.The standard deviation for all the values is 5.2 m Õs. For defini-tion of x , see Fig. 5 „b….

JANUARY 2003, Vol. 125 Õ 175

t

e

i

aak-

gouged the oil layer. We found that in such cases, the oil laquickly ~subsequent image! replenished itself and maintained iintegrity.

6 Wear Tests Using the Axisymmetric NozzleGarnet particles with nominal size of 25mm were used as abra

sive for all the wear experiments. The slurry concentration insthe slurry chamber was 4.4431023 g/cm3. In all the presentcases, the upstream pressure was 14.48 MPa~same liquid veloc-ity! and the run-time was 1 hour and 45 min. Oils with thrdifferent viscosities, 460 mm2/s, 1800 mm2/s, and 4000 mm2/s ~at25°C! were used as lubricants. Figure 19 shows the time requto empty the 125 cm3 oil reservoir as a function of viscosity. Alsoshown is the flow rate of oil relative to that of water,R ~oil flowrate ratio!. As is evident, the time required to empty the chambvaried linearly with viscosity, in agreement with the Darcy’s La

Fig. 17 „a… The 10th order curve fit to the measured liquid ve-locity and the computed velocity of a 25 mm spherical slurryparticle based on Eq. „1…; and „b… the computed slip velocitiesat the centerline of the nozzle for several diameters of slurryparticles. For dimensions, see Fig. 5 „b….

176 Õ Vol. 125, JANUARY 2003

yers

-ide

e

red

erw

~Eq. ~3!!. Accordingly, the relative oil flow rate curve exhibitedhyperbolic behavior. Note that these results included slight leage of oil around the porous nozzle.

According to Darcy’s law

nW o521

moK•¹P (3)

Here,vo andmo are the oil velocity and viscosity, respectively,K isthe permeability tensor of the porous medium, and¹P is thepressure gradient within the porous medium.

Fig. 18 Slurry particles impinging the nozzle walls. The flowwas from top to bottom. The section shown is 4.42 mm ËxË5.03 mm. For definition of x , see Fig. 5 „b….

Transactions of the ASME

w

et of

,

nt,atub-

facetric,

t thesur-toe to

ithally

4.icaleshby

Integrating Eq.~3! for a cylindrical annular flow in a mediumwith uniform properties, the oil flow rate,Qo , is given by

Qo52pKLDP

mo lnS r o

r iD (4)

whereDP is the pressure drop across the nozzle,L is the height ofthe nozzle, andr o andr i are the external and internal radii of thaxisymmetric nozzle, respectively. To examine the effect of vcosity on the wear at similar oil flow rates, we used nozzlesthree different external diameters, 5.08 mm, 3.81 mm, and 2mm, keeping the internal diameter the same~about 200mm!.However, being inversely proportional to ln(ro /ri), the flow rateincreased only by 27 percent when the external diameterhalved.

A series of images of the nozzle exit, prior to and after twenone runs~five minutes each! are presented in Fig. 20–21. Asreference case, Fig. 20 shows SEM images of the nozzletaken before and after a test with a non-lubricated nozzleR50). The nozzle exit diameter increased from an initial size202 mm to 426 mm based on the diameter of a circle with aequivalent area, i.e., a change of 111 percent. Figure 21 shsample images of the nozzle exit taken before and after expments with oil injection but at different conditions. For the nozzin Fig. 21~a!, mo51800 mm2/s andR50.024. The nozzle exitdiameter changed from an initial size of 202mm to 210mm, i.e.an increase of 4 percent. For the nozzle shown in Fig. 21~b!, theoil flow rate ratio was reduced toR50.014, and consequently, thdiameter changed from an initial size of 210mm to 232mm, i.e.an increase of 10.5 percent. Figure 21~c! shows sample images fo

Fig. 19 Time taken to empty the 125 cm 3 reservoir for threedifferent oils

Fig. 20 The reference case: SEM images of the nozzle exitrecorded „a… before and „b… after 105 minutes of test using abra-sive slurry but without any oil injection

Journal of Tribology

eis-of.54

as

ty-aexit(ofnowseri-le

r

mo5460 mm2/s and R50.041 ~for a lower viscosity oil!. Thenozzle exit diameter changed from 208mm to 248mm, i.e., anincrease of 19.5 percent. The uncertainty in the measuremenwear results was less than 1 percent.

Figures 22~a! and ~b! show SEM images of the cut sectionsafter the experiment, of the nozzles shown in Fig. 20~111 percentwear! and Fig. 21~a! ~4 percent wear!, respectively. Figures 23~a!and ~b! show the top of the same nozzles after the experimerespectively. Comparing them with Figs. 7 and 8, it is evident thbesides being larger, the nozzle with 111 percent wear had sstantial wear grooves and ridges, and the interior porous surwas smeared. The wear of this nozzle was also quite asymmeboth in the interior walls and on the top~Fig. 23~a!!. Conversely,the images of the nozzle with 4 percent wear demonstrate thawear was essentially symmetric and very small. The porousface on the internal wall of this nozzle remained quite similarthat of a new nozzle, although some wear could be seen closthe entrance of the nozzle.

Table 1 summarizes the different experiments conducted waxisymmetric nozzles. The results are also presented graphicas a function of the oil flow rate ratio and viscosity in Fig. 2Each point represents the overall wear after twenty-one identruns, each lasting five minutes, and each performed with a frload of slurry and lubricant. The slurry load was prepared

Fig. 21 SEM images of the nozzle exit recorded before andafter 105 minutes of test with „a… oil viscosity moÄ1800 mm2Õs, and flow rate ratio RÄ0.024; „b… moÄ1800 mm2Õs, RÄ0.014; and „c… moÄ460 mm2Õs, RÄ0.041.

JANUARY 2003, Vol. 125 Õ 177

re-of

tomhe.44n.llsthentvis-sed.rThisoil,

ountiningtialina-rom

Fig. 22 SEM images of the cut section of the nozzles recordedafter 105 minutes of test: „a… using abrasive slurry but withoutoil injection „nozzle of Fig. 20 …, and „b… using abrasive slurryand injection of oil with moÄ1800 mm2Õs and RÄ0.024 „nozzleof Fig. 21 „a…….

Fig. 23 SEM images of the top of the nozzles recorded after105 minutes of test „a… without any oil injection „nozzle of Fig.20…; and „b… moÄ1800 mm2Õs and RÄ0.024 „nozzle of Fig.21„a…….

178 Õ Vol. 125, JANUARY 2003

measuring a fixed quantity of abrasive particles using a high pcision balance and then mixing them with a measured volumewater. During the experiments the small water jets at the botof the chamber helped in maintaining a well-mixed slurry. Taverage particle concentration in the nozzle was 431023 g/cm3 and most likely decreased slightly during each ruIt is evident that the presence of an oil film on the nozzle wahad a substantial impact on the extent of nozzle wear. Bothlubricant flow rate and the viscosity of the oil were importaparameters affecting the extent of the wear. For the same oilcosity, the wear increased as the lubricant injection rate decreaHowever, as the data formo5460 mm2/s suggested, the weaseemed to reach a plateau that depended on the viscosity.trend may be a result of reaching a phase where adding moreinstead of increasing the film thickness just increased the amof oil being entrained into the stream. This issue will be verifiedfuture observations using the two-dimensional nozzle. Lowerthe oil viscosity for the same flow rate ratio caused a substanincrease in the nozzle wear. Unfortunately, the present combtion of nozzle size, permeability and pressures prevented us f

Table 1 A listing of the different experiments conducted onthe axisymmetric nozzles

Fig. 24 The effect of oil viscosity and flow rate on the increasein effective nozzle diameter due to wear. Without oil the wearwas 111 percent. Each point represents the overall wear aftertwenty-one identical runs, each lasting five minutes, and eachperformed with a fresh load of slurry and lubricant.

Transactions of the ASME

r

drn

nl

h

r

te

aa

t

c

uir

l

e

o

et

t

mayise

tionand

eingedtheci-to

port

et

rd

e

n

foro.

er-Jet9–

ofet

,

J.,re-–

or-on-ter

a-

w-

es

m aut-51.

s

rg-

n

ble

te

increasing the flow rate ratio of themo54000 mm2/s oil beyond 1percent. The trends, however, suggest that a 4 percent wear couldbe achieved atR;1.5 percent, and that atR52.5 percent the weamay be reduced to below 2 percent. These statements are astage only speculations.

We had also observed that as long as oil injection occurrethe nozzle, the jet stream from the exit of the nozzle was coheand well defined. Once the oil injection stopped, the jet broke idroplets and spread immediately at the exit of the nozzle. Teffect could be attributed to the smoothening of the jet wallsthe presence of the oil layer.

7 ConclusionsThis paper introduces a novel solution for preventing noz

wear in Abrasive Water Suspension Jets~AWSJ! used for jet cut-ting. The nozzle was made of porous material and was surrounby a reservoir containing a high viscosity lubricant. The lubricareservoir was exposed to the same pressure that drove the flothe nozzle. The pressure difference created due to the high-sflow in the nozzle, continuously forced the lubricant through tporous medium, resulting in the formation of a thin film of higviscosity fluid on the interior walls of the nozzle. This lubricafilm protected the walls of the nozzle from the abrasive particand substantially reduced the extent of nozzle wear.

A facility with a two-dimensional nozzle with windows on botsides was used for observations of the lubricant film and for msuring the velocity of liquid and slurry particles in the nozzle.spite of the high oil viscosity, the high shear rates in the nozcaused considerable entrainment. However, the typical flowratio of lubricant in the two-dimensional nozzle was still belowpercent. When the particles gouged the oil layer, it immediareplenished itself and maintained its integrity. The velocity msurements showed that the centerline liquid velocity was notfected significantly by the injection of oil. The measured slip vlocity decreased along the straight section of the nozzle. In fnear the exit the measured slip velocity decreased to less thpercent of the local liquid velocity, i.e., to a negligible level. Thmeasured velocities of the slurry particles relative to that ofliquid, i.e. the slip velocities, were also compared to the compuvalues from a simple numerical model that assumed one-waypling and spherical particles. The measured slip velocities andcomputed values showed discrepancies, which may be attribto the difference between the assumed and actual drag and vmass coefficients~the slurry particles were far from being sphecal!. Assuming one-way coupling when the particle size w14–31 percent of the nozzle diameter was also questionabbest.

Tests were also conducted using axisymmetric nozzles to dmine the extent of nozzle wear and investigate the effects ofbricant viscosity and flow rate. It was found that the presenceoil substantially reduced the wear of the nozzle walls, from 1percent of the diameter to 4 percent, our best result to-date,the same period. For this case the oil flow rate ratio was onlypercent. The wear increased as the lubricant flow rate and visity decreased. However, the tests indicated that increasing thflow rate beyond a certain level had a diminishing effect onwear. Thus, increasing the viscosity promised to be a betterproach for future improvements. The presence of the oil film aimproved the coherence of the jet.

This paper clearly demonstrates that the porous lubricanozzles can substantially reduce the extent of nozzle wear of asive water suspension jets. Once several issues associatedcommercializing this technology are resolved, it may expanduse and applications of high-speed abrasive waterjet cutters.ing able to accelerate the particles to nearly the liquid velocwith minimal damage to the nozzle, even when the nozzle is mof plain stainless steel, is a substantial improvement over opresently used techniques. Compared to the present commeabrasive water jet~AWJ! cutters, the smaller jet diameter and th

Journal of Tribology

t this

inentto

hisby

zle

dedntw inpeedheht

es,

ea-Inzleate1elya-af-e-ct,n 2ehetedou-theted

rtuali-ase at

ter-lu-of

11ver

2.4cos-

oilheap-lso

tedbra-with

theBe-ityadeherrciale

lower pressure required to achieve the same cutting effect,result in cost savings, higher cutting efficiency and more preccutting. A more durable nozzle may also enable further reducin nozzle diameter, hence, even greater cutting precision,higher particle speeds that may lead to deeper cutting.

AcknowledgmentsWe are grateful to Andy Conn, first for introducing us to th

problem of nozzle wear, and then for his continued advice durthe course of this project. Yury Ronzhes and Steve King providengineering support. Seed funding that enabled us to buypump and some of the equipment was provided by National Sence Foundation under Grant No. 9320153. We would likethank Jet Edge Corp., USA for providing graduate student supfor one year.

References@1# Conn, A. F., 1991, ‘‘A Review of the 10th International Symposium of J

Cutting Technology,’’ International Journal of Water Jet Technology,1~3!, pp.135–149.

@2# Dubensky, E., Groves, K., Gulau, A., Howard, K., and Mort, G., 1992, ‘‘HaCeramics for Long Life Abrasive Water Jet Nozzles,’’Proceedings of the 11thInternational Conference on Jet Cutting Technology, St. Andrews, Scotland,Sept. 8–10.

@3# Kovacevic, R., and Evizi, M., 1990, ‘‘Nozzle Wear Detection in AbrasivWaterjet Cutting Systems,’’ Mater. Eval.,48, pp. 348–353.

@4# Mort, G. A., 1991, ‘‘Long Life Abrasive Water Jet Nozzles and Their Effect oAWJ Cutting,’’ Proceedings of the 6th American Water Jet Conference, Hous-ton, Texas, August 24–27, pp. 315–344.

@5# Hashish, M. A., Kirby, M. J., and Pao Y. H., 1987, ‘‘Method and ApparatusForming a High Velocity Liquid Abrasive Jet,’’ United States Patent N4,648,215.

@6# Hashish, M., 1990, ‘‘Abrasive-Fluidjet Machinery Systems: Entrainment Vsus Direct Pumping,’’Proceedings of the 10th International Symposium onCutting Technology, Amsterdam, The Netherlands, Oct. 31–Nov. 2, pp. 9114.

@7# Momber, A. W., and Kovacevic, R., 1998,Principles of Abrasive Water JetMachining, Springer-Verlag, New York.

@8# Hollinger, R. H., and Mannheimer, R. J., 1991, ‘‘Rheological Investigationthe Abrasive Suspension Jet,’’Proceedings of the 6th American Water JConference, Houston, Texas, August 24–27, pp. 515–528.

@9# Miller, D. S., 2001, ‘‘Micro Abrasive Waterjet Cutting,’’Proceedings of the11th American Water Jet Conference, Minneapolis, Minnesota, August 18–21pp. 59–69.

@10# Horii, K., Matsumae, Y., Cheng, X., Takei, M., Hashimoto, B., and Kim, T.1990, ‘‘Developments of a New Mixing Nozzle Assembly for High PressuAbrasive Water Jet Applications,’’Proceedings of the 10th International Symposium on Jet Cutting Technology, Amsterdam, The Netherlands, Oct. 31Nov. 2, pp. 193–206.

@11# Okita, Y., Nakamura, K., Nishimoto, K., and Yanasaka, N., 2000, ‘‘Perfmance of Abrasive Water Suspension Jet Nozzles With a Single Annular Cduit,’’ Proceedings of the 6th Pacific Rim International Conference on WaJet Technology, Sydney, Australia, October 9–11, pp. 111–114.

@12# Hashish, M., 1994, ‘‘Observations of Wear of Abrasive-Waterjet Nozzle Mterials,’’ ASME J. Tribol.,116, pp. 439–444.

@13# Nanduri, M., Taggart, D. G., Kim, T. J., Ness, E., Haney, C. N., and Bartkoiak, C., 1996, ‘‘Wear Patterns in Abrasive Waterjet Nozzles,’’Proceedings ofthe 13th International Symposium on Jetting Technology, Sardinia, Italy, Oc-tober 29–31, pp. 27–45.

@14# Katz, J., 1999, ‘‘Lubricated High Speed Fluid Cutting Jet,’’ United StatPatent No. 5,921,846.

@15# Tan, R. B. H., and Davidson, J. F., 1990, ‘‘Cutting by Sand-Water Jets FroFluidised Bed,’’Proceedings of the 10th International Symposium on Jet Cting Technology, Amsterdam, The Netherlands, Oct. 31–Nov. 2, pp. 235–2

@16# Tan, R. B. H., 1991, ‘‘Fluidised Abrasive Jets,’’Proceedings of the First AsianConference on Recent Advances in Jetting Technology, Singapore, May 7–8,pp. 100–107.

@17# Tan, R. B. H., 1995, ‘‘A Model for Liquid-Particle Jet Flow in a PorouRe-Entrant Nozzle,’’ International Journal of Water Jet Technology,2~2!, pp.97–102.

@18# Tan, R. B. H., 1998, ‘‘Discharge of particle-liquid jets through porous conveing nozzles,’’ International Journal of Water Jet Technology,3~1!, pp. 13–19.

@19# McAuliffe, C. D., 1973, ‘‘Oil-in-Water Emulsions and Their Flow Properties iPorous Media,’’ J. Pet. Technol.,25, pp. 727–733.

@20# Soo, H., and Radke, C. J., 1984, ‘‘The Flow Mechanism of Dilute, StaEmulsions in Porous Media,’’ Ind. Eng. Chem. Fundam.,23, pp. 342–347.

@21# Soo, H., and Radke, C. J., 1986, ‘‘A Filtration Model for the Flow of DiluStable, Emulsions in Porous Media—I. Theory,’’ Chem. Eng. Sci.,41~2!, pp.263–272.

JANUARY 2003, Vol. 125 Õ 179

b

od

l

les

id

ure

ity

@22# Adrian, R. J., 1991, ‘‘Particle-Imaging Techniques for Experimental Fluid Mchanics,’’ Annu. Rev. Fluid Mech.,23, pp. 261–304.

@23# Roth, G. I., and Katz, J., 2001, ‘‘Five Techniques for Increasing the SpeedAccuracy of PIV Interrogation,’’ Meas. Sci. Technol.,12~3!, pp. 238–245.

@24# Sinha, M., and Katz, J., 2000, ‘‘Quantitative Visualization of The Flow inCentrifugal Pump with Diffuser Vanes, Part A: On Flow Structure and Turlence; Part B: Addressing Passage Averaged and LES Modeling Issues inbomachinery Flows,’’ ASME J. Fluids Eng.,122, pp. 97–116.

@25# Dong, R., Chu, S., and Katz, J., 1992, ‘‘Quantitative Visualization of the FlWithin the Volute of a Centrifugal Pump, Part A: Technique,’’ ASME J. FluiEng.,114, pp. 390–395.

@26# Roth, G., Mascenik, D. T., and Katz, J., 1999, ‘‘Measurements of The F

180 Õ Vol. 125, JANUARY 2003

e-

and

Au-Tur-

ws

ow

Structure And Turbulence Within A Ship Bow Wave,’’ Phys. Fluids,11~11!, pp.3512–3523.

@27# Sridhar, G., and Katz, J., 1995, ‘‘Drag and Lift Forces on Microscopic BubbEntrained by a Vortex,’’ Phys. Fluids,7~2!, pp. 389–399.

@28# Maxey, M. R., and Riley, J. J., 1983, ‘‘Equation of Motion for a Small RigSphere in a Nonuniform Flow,’’ Phys. Fluids,26~4!, pp. 883–889.

@29# Sridhar, G., and Katz, J., 1999, ‘‘Effect of Entrained Bubbles on the Structof Vortex Rings,’’ J. Fluid Mech.,397, pp. 171–202.

@30# Clift, R., Grace, J. R., and Weber, M. E., 1978,Bubbles, Drops and Particles,Academic Press, New York.

@31# Haider, A., and Levenspiel, O., 1989, ‘‘Drag Coefficient and Terminal Velocof Spherical and Nonspherical Particles,’’ Powder Technol.,58~1!, pp. 63–70.

Transactions of the ASME