Precast reinforced concrete pipe culvert Specification

Transcript of Precast reinforced concrete pipe culvert Specification

ICS 93.080.10

Reference number

DRS 265: 2021

© RSB 2021

RWANDA STANDARD

DRS

265

Second edition

2021-mm-dd

Precast reinforced concrete pipe culvert — Specification

DRS 265: 2021

©RSB 2021 - All rights reserved ii

In order to match with technological development and to keep continuous progress in industries, standards are subject to periodic review. Users shall ascertain that they are in possession of the latest edition

© RSB 2021

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without prior written permission from RSB.

Requests for permission to reproduce this document should be addressed to:

Rwanda Standards Board

P.O Box 7099 Kigali-Rwanda

KK 15 Rd, 49

Tel. +250 788303492

Toll Free: 3250

E-mail: [email protected]

Website: www.rsb.gov.rw

ePortal: www.portal.rsb.gov.rw

DRS 265: 2021

iii ©RSB 2021 - All rights reserved

Contents Page

1 Scope ............................................................................................................................................. 1

2 Normative references ................................................................................................................... 1

3 Terms and definitions .................................................................................................................. 1

4 Materials ........................................................................................................................................ 3

5 Design ............................................................................................................................................ 4

6 Manufacture .................................................................................................................................. 6

7 Physical properties ...................................................................................................................... 7

8 Inspection .................................................................................................................................... 12

9 Rejection ..................................................................................................................................... 12

10 Marking ........................................................................................................................................ 12

Annex A (normative) Methods of testing the resistance to proof load ............................................. 14

Annex B (normative) Method of testing ultimate load ........................................................................ 17

Annex C (normative) ............................................................................................................................... 18

DRS 265: 2021

©RSB 2021 - All rights reserved iv

Foreword

Rwanda Standards are prepared by Technical Committees and approved by Rwanda Standards Board (RSB) Board of Directors in accordance with the procedures of RSB, in compliance with Annex 3 of the WTO/TBT agreement on the preparation, adoption and application of standards.

The main task of technical committees is to prepare national standards. Final Draft Rwanda Standards adopted by Technical committees are ratified by members of RSB Board of Directors for publication and gazettment as Rwanda Standards.

RS 265 was prepared by Technical Committee RSB/TC 009, Building materials and civil engineering.

In the preparation of this standard, reference was made to the following standards:

1) ASTM C76M – 20, Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe

2) IS 458: 2021, Precast concrete pipes (with and without reinforcement) – Specification

3) SANS 677: 2020, Concrete non-pressure pipes

4) ASTM C497 – 20: Standard Test Methods for Concrete Pipe, Manhole Sections, or Tile

5) ASTM C822 – 20: Standard Terminology Relating to Concrete Pipe and Related Products

The assistance derived from the above source is hereby acknowledged with thanks.

This second edition cancels and replaces the first edition (RS 265: 2015) of which has been technically revised.

Committee membership

The following organizations were represented on the Technical Committee on Building materials and civil engineering (RSB/TC 009) in the preparation of this standard.

B. J Construction Ltd

Bridge to Prosperity

City of Kigali

Green Pact Africa

MASS Design

NPD Ltd

Rwanda Housing Authority (RHA)

DRS 265: 2021

v ©RSB 2021 - All rights reserved

Rwanda Inspectorate, Competition and Consumer Protection Authority (RICA)

University of Rwanda/College of Science and Technology (UR-CST)

Rwanda Standards Board (RSB) – Secretariat

DRS 265: 2021

1 ©RSB 2021 - All rights reserved

Precast reinforced concrete pipe culvert — Specification

1 Scope

This Draft Rwanda Standard specifies the requirements and test methods for precast reinforced concrete pipe, which is cylindrical in shape and intended to be used for the conveyance of storm water, and for the construction of culverts (SC) and other intended mainly for sewer and irrigation purposes (SI).

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

RS EAS 18-1, Cement ─ Part 1: Composition, specification and conformity criteria for common cements

RS 373, Aggregates for concrete — Specification

RS ISO 6935-1, Steel for the reinforcement of concrete — Part 1: Plain bars

RS ISO 6935-2, Steel for the reinforcement of concrete —Part 2: Ribbed bars

RS ISO 6935-3, Steel for the reinforcement of concrete─ Part 3: Welded fabric

RS ISO 1920-3, Testing of concrete — Part 3: Marking and curing test specimens

RS ISO 1920-4, Testing of concrete — Part 4: Strength of hardened concrete

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply

3.1

admixture

material other than water, aggregates, cement and fibre reinforcing used as an ingredient of concrete and added to the batch immediately before or during its mixture

3.2

cage

assembled unit of steel reinforcement consisting of circumferential and longitudinal bars or wires

©RSB 2021 - All rights reserved 2

3.3

circular reinforcement

circular-shaped line of reinforcement

3.4

circumferential reinforcement

reinforcement that is approximately perpendicular to the longitudinal axis of the concrete pipe, box, or structure

3.5

culvert

pipeline intended to convey water under a highway, railroad, canal, or similar facility

3.6

D-load

supporting strength of a pipe loaded under three-edge-bearing test expressed in Newton per linear metre per millimetre of inside diameter or horizontal span

3.7

elliptical reinforcement

line of reinforcement in the approximate shape of an ellipse

3.8

line of reinforcement

circumferential reinforcement comprised of one or more layers

3.9

longitudinal reinforcement

reinforcement, in a concrete pipe, running parallel to the intended flow

3.10

reinforcement

steel in the form of continuous wire, welded wire fabric, or bars embedded in concrete in such a manner that the above referenced concrete and steel act together to resist stresses

DRS 265: 2021

3 ©RSB 2021 - All rights reserved

3.11

pipe

tube or elongated hollow concrete structure intended to transmit flow between locations

3.12

ultimate load

maximum load that the pipe can withstand

3.13

proof load

load that an acceptable culvert withstands without the development of cracks of width such that the feeler gauge can enter to a depth of 2 mm or more over a continuous length of at least 300 mm

3.14

splice (reinforcement)

junction of two sections of parallel reinforcement intended to provide continuity and to transfer forces between the two sections

4 Materials

4.1 General

4.1.1 Pipes shall be of concrete. Materials for the concrete shall be so selected as to achieve maximum density and minimum porosity. Pipes that are intended to be resistant to chemical attack shall have an acceptably low content of material insoluble in hydrochloric acid.

4.1.2 Reinforced concrete shall consist of cement, mineral aggregates, water and admixtures, if any, in which steel has been embedded in such a manner that the steel and concrete act together.

4.2 Cement

Cement used in the manufacture of the pipes shall comply with requirements for cement compositions given in RS EAS 18-1.

4.3 Aggregate

4.3.1 Aggregate shall consist of natural sand, crushed or uncrushed gravel, crushed stone or crushed rock, or a combination of any of these aggregates.

4.3.2 Aggregates used for the manufacture of reinforced concrete pipes shall conform to

©RSB 2021 - All rights reserved 4

RS 373. The maximum size of aggregate should not exceed one third thickness of the pipe or 20 mm, whichever is smaller for pipes above 250 mm internal diameter. But for pipes of internal diameter 80 mm to 250 mm the maximum size of aggregate should be 10 mm.

NOTE It is preferable to have the size and grading of aggregates conforming to RS 373. It is also preferable that

materials finer than 75 micron sieve is restricted to 3.0 % by mass.

4.4 Steel reinforcement

Steel used for reinforcement shall be free from oil, grease, loose scale and loose or heavy rust. The steel shall comply with the requirements of RS ISO 6935-1, RS ISO 6935-3and RS ISO 6935-3, as appropriate.

4.5 Water

Water used in the mixing of the concrete shall be clean and acceptably free from impurities that could impair the strength or durability (or both) of the concrete.

4.6 Admixtures

Admixtures in the concrete may be permitted and shall comply with the requirements of the respective standards

4.7 Concrete

4.7.1 Concrete shall have a compressive strength not less than 35 N/mm2 at 28 days.

4.7.2 Compressive strength tests shall be conducted on cubes or cylinders as specified in RS ISO 1920-3 and be tested accordance with the requirements of RS ISO 1920-4.

5 Design

5.1 General

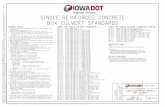

5.1.1 The reinforcement shall extend throughout the length of the pipe and shall be so designed that it may be readily placed and maintained to designed shape and in the proper position within the pipe mould during the manufacturing process(see figure 1).

5.1.2 The circumferential and longitudinal reinforcement shall be adequate to satisfy the requirements specified in 4.1.

5.1.3 For non-welded cages spiral reinforcement of the same diameter shall be closely spaced at the end of the pipe for a length of 150 mm to minimize damage during handling. The spacing of such end spirals shall not exceed 50 mm or half the pitch whichever is less.

DRS 265: 2021

5 ©RSB 2021 - All rights reserved

Figure1 — Triple cage reinforcement

5.1.4 The pitch shall also be not less than the maximum size of aggregate plus the diameter of the reinforcement bar used.

5.2 Reinforcement

5.2.1 Circumferential Reinforcement

5.2.1.1 A line of circumferential reinforcement for any given total area may be composed of two layers for pipe with wall thicknesses of less than 180 mm or three layers for pipe with wall thicknesses of 180 mm or greater. The layers shall not be separated by more than the thickness of one longitudinal plus 6 mm. The multiple layers shall be fastened together to form a single cage. All other specification requirements such as laps, welds, and tolerances of placement in the wall of the pipe, etc., shall apply to this method of fabricating a line of reinforcement.

5.2.1.2 Where one line of circular reinforcement is used, it shall be placed from 35 to 50 % of the wall thickness from the inner surface of the pipe, except that for wall thicknesses less than 63 mm, the protective cover of the concrete over the circumferential reinforcement in the wall of the pipe shall be 19 mm.

5.2.1.3 In pipe having two lines of circular reinforcement, each line shall be so placed that the protective covering of concrete over the circumferential reinforcement in the wall of the pipe shall be 25 mm.

5.2.1.4 In pipe having elliptical reinforcement with wall thicknesses 63 mm or greater, the reinforcement in the wall of the pipe shall be so placed that the protective covering of concrete over the circumferential reinforcement shall be 25 mm from the inner surface of the pipe at the vertical diameter and 25 mm from the

©RSB 2021 - All rights reserved 6

outer surface of the pipe at the horizontal diameter. In pipe having elliptical reinforcement with wall thicknesses less than 63 mm, the protective covering of the concrete shall be 19 mm at the vertical and horizontal diameters.

5.2.1.5 The spacing centre to centre of circumferential reinforcement in a cage shall not exceed 100 mm for pipe up to and including pipe having a 100 mm wall thickness nor exceed the wall thickness for larger pipe, and shall in no case exceed 150 mm.

5.2.1.6 The continuity of the circumferential reinforcing steel shall not be destroyed during the manufacture of the pipe, except that when agreed upon by the owner, lift eyes or holes may be provided in each pipe for the purpose of handling.

5.2.1.7 If splices are not welded, the reinforcement shall be lapped not less than 20 diameters for deformed bars and deformed cold-worked wire, and 40 diameters for plain bars and cold-drawn wire. In addition, where lapped cages of welded-wire fabric are used without welding, the lap shall contain a longitudinal wire. When splices are welded and are not lapped to the minimum requirements above, pull tests of representative specimens shall develop at least 50 % of the minimum specified ultimate strength of the steel, and there shall be a minimum lap of 50 mm. For butt-welded splices in bars or wire, permitted only with helically wound cages, pull tests of representative specimens shall develop at least 75 % of the minimum specified ultimate strength of the steel.

5.2.2 Longitudinal reinforcement

Each line of circumferential reinforcement shall be assembled into a cage that shall contain sufficient longitudinal bars or members, to maintain the reinforcement in shape and in position within the form to comply with permissible variations in 5.2.1. The exposure of the ends of longitudinal, stirrups, or spacers that have been used to position the cages during the placement of the concrete shall not be a cause for rejection.

6 Manufacture

6.1 General

The method of manufacture shall be such that the forms and dimensions of the finished pipe are accurate within the limits specified in this standard. The surfaces and edges of the pipes shall be well defined and true, and their ends shall be square with the longitudinal axis.

6.2 Concrete mixing and placing

6.2.1 The aggregates shall be sized, graded, proportioned, and mixed with such proportions of cementitious materials,water and admixtures, if any, to produce a homogeneous concrete mixture of such quality that the pipe shall conform to the test and design requirements of this specification. All concrete shall have a water cementitious materials ratio not exceeding 0.53 by weight. Cementitious materials shall be as specified in 4.2 and the produced concrete shall as specified in 4.7.1

6.2.2 Concrete shall be mixed in a mechanical mixer, mixing shall be continued until there is a uniform

distribution of the materials and the mass is uniform in colour and consistency, but in no case shall the mixing be done for less than 2 min.

6.2.3 Concrete shall be placed before setting has commenced. It should be ensured that the concrete is not dropped freely so as to cause segregation. The concrete shall be consolidated by spinning, vibrating, spinning combined with vibrations, or other appropriate mechanical means.

DRS 265: 2021

7 ©RSB 2021 - All rights reserved

6.3 Curing

Pipe shall be subjected to any one of the methods of curing described in 6.3.1 to 6.3.2 or to any other method or combination of methods approved by the owner that shall give satisfactory results. The pipe shall be cured for a sufficient length of time so that the specified D-load is obtained so that the concrete develops the specified compressive strength at 28 days. Exposed surfaces shall be protected from low humidity until the concrete has reached sufficient maturity for lifting and storage.

6.3.1 Steam curing

Pipe shall be placed in a curing chamber, free of outside drafts, and cured in a moist atmosphere maintained by the injection of live steam for such time and such temperature as needed to enable the pipe to meet the strength requirements. At no time shall the ambient temperature exceed 71 °C. The curing chamber shall be so constructed as to allow full circulation around the inside and outside of the pipe.

6.3.2 Water curing

6.3.2.1 Concrete pipe may be water-cured by covering with water saturated material or by a system of perforated pipes, mechanical sprinklers, porous hose, or by any other approved method that keeps the pipe moist during the specified curing period.

6.3.2.2 The manufacturer may, at his/her option, combine the methods described in 6.3.1 to 6.3.2 provided that the required concrete compressive strength is attained.

6.3.2.3 A sealing membrane may be applied and should be left intact until the required strength requirements are met. All surfaces shall be kept moist prior to the application of the compounds and shall be damp when the compound is applied.

7 Physical properties

7.1 Internal and wall thickness dimensions

7.1.1 Permissible deviations

Any variation in the wall thickness of the pipe shall not exceed the appropriate value given in column 3 of table 1.

7.1.2 Internal diameter

7.1.2.1 The actual internal diameter of a pipe shall not differ from the stated internal diameter by more than the appropriate tolerance given in column 2 of table 1.

7.1.2.2 Pipe sections that are intended to be jointed to each other shall be furnished with the same internal diameter alternative.

©RSB 2021 - All rights reserved 8

7.1.3 Wall thickness

The wall thickness shall not vary more than shown in the design or specified wall by more than the appropriate tolerance given in column 3 of table 1. Wall thickness more than required in the design is not cause for rejection. Pipe having localized variations in wall thickness exceeding those specified above shall be accepted if the three-edge-bearing strength and minimum steel cover requirements are met.

7.1.4 Length of two opposite sides

Variations in the laying length of two opposite sides of the pipe shall not be more than 6 mm for all sizes through 600 mm internal diameter, and not more than 10 mm/m of internal diameter for all sizes larger with a maximum of 16 mm in any length of pipe through 2 100 mm internal diameter, and a maximum of 19 mm for 2250 mm internal diameter or larger.

7.1.5 Length of pipe

The underrun in length of a section of pipe shall not be more than 10 mm/m with a maximum of 13 mm in the case of of an SC type pipe and 0,5% in the case of an SI type pipe .

7.1.6 Ogee (interlocking) ends

The length of an ogee joint shall not exceed 50% of the wall thickness and shall be at least (𝐷

100+ 7)𝑚𝑚

where

D is the nominal internal diameter of the pipe (in millimetres).

Table 1 — Dimensions in mm

1 2 3 4 5 6 7

Nominal internal

diameter

Tolerances in mm Permissible variation in wall

thickness max. in mm

Spigot and socket and in-the-wall joints

SC type SI type SC type SI type Tolerance on stated internal

diameter of spigot and male

end of in-the-

wall joint

Tolerance on stated internal diameter of

spigot and female end of in-the-wall

joint

300 ± 8 ± 6 10 6 ± 1,5 +1,5

-1,0

375 ± 8 ± 6 10 6 ± 2,0 +2,0

-1,5 450

600 ± 10 ± 8 13 6

± 2,5

+2,5

-2,0

675

750 ± 13 ± 10 13 10

825

900

DRS 265: 2021

9 ©RSB 2021 - All rights reserved

1050 ± 19 ± 11 16 10

1200

1350 ± 3,0 +3,0

-2,5 1500

1800

7.2 Resistance to proof load

When a pipe is tested in accordance with Annex A, it shall be capable of withstanding, without the development of any crack of width exceeding 0.3 mm.

7.3 Ultimate load

The ultimate load (i.e. the maximum load that the pipe can withstand) shall be at least 1.25 times the appropriate proof load given in table 2.

Table 2 — Proof load

Nominal internal

diameter

Load on effective length of pipe kN/m

D-load1

mm 25D 50D 75D 100D

300

375

450

–

–

11.3

15.0

18.8

22.5

22.5

28.1

33.8

30.0

37.5

45.0

525

600

675

13.1

15.0

16.9

26.3

30.0

33.8

39.4

45.0

50.6

52.5

60.0

67.5

750

825

900

18.8

20.6

22.5

37.5

41.3

45.0

56.3

62.0

67.5

75.0

82.5

90.0

1 050

1 200

1 350

26.3

30.0

33.8

52.5

60.0

67.5

78.8

90.0

101.3

105.0

120.0

135.0

1 500

1 800

37.5

45.0

75.0

90.0

112.5

135.0

150.0

180.0

1) The D-load (diameter-crushing load) designation of a pipe is derived from the load, in kilonewtons, that a 1-m length pipe can

withstand (without the development of cracks of width exceeding the value specified in 7.2 divided by the nominal internal

diameter of the pipe, in metres, e.g. if a load of 60 kN /m of its effective length on a pipe of nominal internal diameter 1 200

mm produces cracks of width not exceeding the value specified in 7.2, the D-load designation of the pipe is 50 D.

©RSB 2021 - All rights reserved 10

7.4 Resistance to hydraulic pressure (SI types pipes)

When tested in accordance Annex C, an SI type pipe shall withstand for at least 2 min, an internal hydraulic pressure of 140 kPa without showing any sign of leakage.

7.5 Finish of pipes

All surfaces and edges of a pipe shall be acceptably free from imperfections that could impair the serviceability of the pipe. Craze cracks of a superficial nature and hair cracks of depth not exceeding one-third of the wall thickness shall be permissible.

NOTE Unless otherwise required, a pipe may have lifting holes (to facilitate handling and laying).

7.6 Joints

The joints shall be of such design and the ends of the concrete pipe sections so formed that when the sections are laid together they will make a continuous line of pipe with a smooth interior free from appreciable irregularities in the flow line.

7.7 Test specimens

The specified number of pipe required for the tests shall be furnished without charge by the manufacturer and shall be selected at random by the owner, and shall be pipe that would not otherwise be rejected under this specification. The selection shall be made at the point or points designated by the owner when placing the order.

7.7.1 Compression testing of cylinders

At least five test cylinders from a group (one day’s production) of pipe sections shall be prepared for testing.

7.7.2 Acceptability on the basis of cylinder test results

7.5.2.1 When the compressive strengths of all cylinders tested for a group are equal to or greater than the required concrete strength, the compressive strength of concrete in the group of pipe sections shall be accepted.

7.5.2.2 When the average compressive strength of all cylinders tested is equal to or greater than the required concrete strength, and not more than 10 % of the cylinders tested have a compressive strength less than the required concrete strength, and no cylinder tested has a compressive strength less than 80 % of the required concrete strength, then the group shall be accepted.

7.7.3 Compression testing of cores

7.5.3.1 The compressive strength of the concrete in the pipe shall be determined by making crushing tests of cores cut from the pipe.

7.5.3.2 A core drill shall be used for securing cylindrical core specimens from the wall of the pipe; a shot drill or a diamond drill shall be used.

DRS 265: 2021

11 ©RSB 2021 - All rights reserved

7.5.3.3 A core specimen for the determination of compressive strength shall have a diameter at least three times the maximum size of the coarse aggregate used in the concrete. If cores are cut from the wall of the pipe and tested, the length to diameter ratio shall lie between one and two after the curved surfaces have been removed from the cut core.

7.7.4 Number of cores

One core shall be taken from a pipe section selected at random from each day’s production run of a single concrete strength.

7.7.5 Acceptability on the basis of core test results

7.5.5.1 When the compressive strengths of cores tested for a group of pipe sections is equal to or greater than the required concrete strength, the compressive strength of the concrete for the group is acceptable. Concrete represented by core tests shall be considered acceptable if:

a) the average of three cores is equal to at least 85 % of the required strength, and

b) no single core is less than 75 % of the required strength.

7.5.5.2 If the compressive strength of the core tested is less than the required concrete strength, the pipe section from which that core was taken may be recored. If the compressive strength of the recore is equal to or greater than the required concrete compressive strength, the compressive strength of the concrete for the group is acceptable.

7.5.5.3 If the compressive strength of the recore is less than the required concrete strength, the pipe section from which the core was taken shall be rejected. Two pipe sections from the remainder of the group shall be selected at random and one core shall be taken from each pipe section. If the compressive strength of both cores is equal to or greater than the required concrete compressive strength, the concrete compressive strength of the remainder of the group shall be acceptable. If the compressive strength of either of the two cores tested is less than the required concrete compressive strength, then the remainder of the group shall be either rejected or, at the option of the manufacturer, each pipe section of the remainder shall be cored and accepted individually, and any of the pipe sections that have a core with less than the required concrete compressive strength shall be rejected.

7.7.6 Plugging core holes

7.5.6.1 Core holes shall be plugged and sealed by the manufacturer in a manner such that the pipe section shall meet all of the requirements of this specification.

7.5.6.2 Pipe sections so plugged and sealed shall be considered satisfactory for use.

7.7.7 Absorption

An absorption test shall be performed for each mix design for each production process. The absorption of a sample from the wall of the pipe shall not exceed 9 % of the dry mass. Each sample shall have a minimum mass of 1.0 kg, shall be free of visible cracks, and shall represent the full wall thickness of the pipe. When the initial absorption sample from a pipe fails to conform to this specification, the absorption test shall be made on another sample from the same pipe and the results of the retest shall be substituted for the original test results.

©RSB 2021 - All rights reserved 12

7.7.8 Retests of pipe

When not more than 20 % of the concrete specimens fail to pass the requirements of this specification, the manufacturer may cull the project stock and may eliminate whatever quantity of pipe desired and shall mark those pipes so that they shall not be shipped. The required tests shall be made on the balance of the order and the pipe shall be accepted if they conform to the requirements of this specification.

7.7.9 Repairs

Pipe may be repaired, if necessary, because of imperfections in manufacture or damage during handling and shall be acceptable if, in the opinion of the owner, the repaired pipe conforms to the requirements of this specification.

8 Inspection

The quality of materials, the process of manufacture, and the finished pipe shall be subject to inspection and approval by the client.

9 Rejection

Pipe shall be subject to rejection on account of failure to conform to any of the specification requirements. Individual sections of pipe may be rejected because of any of the following:

a) fractures or cracks passing through the wall, except for a single end crack that does not exceed the depth of the joint;

b) defects that indicate proportioning, mixing, and molding not in compliance with 6.2 or surface defects indicating honey combed or open texture that would adversely affect the function of the pipe;

c) damaged or cracked ends where such damage would prevent making a satisfactory joint; and

d) any continuous crack having a surface width of 0.3 mm or more and extending for a length of 300 mm or more, regardless of position in the wall of the pipe, for pipe not installed or under load.

10 Marking

10.1 The following information shall appear in legible and durable marking on each pipe in a position such that it cannot be covered by a joint:

a) the manufacturer's name or trade name or trade mark;

b) the nominal internal diameter;

c) the D-load designation;

d) the date of manufacture; and

DRS 265: 2021

13 ©RSB 2021 - All rights reserved

e) the word “TOP” or “BOTTOM”, or both, in the appropriate position(s) if elliptically placed reinforcement is used.

10.2 Markings shall be indented on the pipe section or painted thereon with waterproof paint.

©RSB 2021 - All rights reserved 14

Annex A (normative)

Methods of testing the resistance to proof load

A.1 Apparatus

A.1.1 Bearers

Two unyielding bearers of width 150 mm and having (on the inner surfaces) rubber packing pieces of width 150 mm and of thickness 25 mm (see figure 2). Alternatively, three unyielding bearers (with rubber packing pieces of thickness 25 mm) of the shape and positioned as shown in figure 3. In both cases, the length of the bearers and of the packing is at least equal to the effective length of the pipe to be tested where, in the case of a spigot and socket pipe, then effective length is, for the purpose of the test, the length of the plain cylindrical portion of the pipe. The hardness of the rubber is 55 IRHD ± 5 IRHD.

A.1.2 Gauge

A gauge made from a steel leaf, of thickness 0.25 mm and of width 10 mm and tapered (1 in 4) to a rounded end of width 2 mm (measured at a line scribed at right angles to its longitudinal axis at a position 2 mm from the tapered end (see figure A.3).

A.2 Procedure

A.2.1 Place the pipe under test between, and with its longitudinal axis parallel to, the bearers.

A.2.2 So apply an increasing load to one bearer that the load is applied uniformly over the whole effective length of the pipe at a rate not exceeding 150 N/m of effective length per second.

A.2.3 Continue until the appropriate proof load (based on the effective length of the pipe) is reached.

A.2.4 Then, without removing or increasing the load, use the gauge to determine the width of any cracks in the pipe. Deem the pipe to have failed the test if any crack is so wide that the point of the gauge can, without being forced, penetrate to a depth of 2 mm at close intervals over a distance of 300 mm or more.

Figure A.1 — Two-bearer proof load test arrangement

DRS 265: 2021

15 ©RSB 2021 - All rights reserved

Figure A.2 — Three-bearer proof load test arrangement

Figure A.3 — Geometric relationships of cracks

©RSB 2021 - All rights reserved 16

Figure A.4 — Crack measuring gauge

DRS 265: 2021

17 ©RSB 2021 - All rights reserved

Annex B (normative)

Method of testing ultimate load

Immediately after checking the pipe for cracks (if any) in the test given in Annex A, increase the load (at the rate used in that test) until the pipe fails or until a load of at least 1.25 times the appropriate proof load (see 7.3) is reached, whichever occurs first.

©RSB 2021 - All rights reserved 18

Annex C (normative)

Hydraulic test (SI Type pipes)

C.1 Preparation of test specimen

Test the pipe in the air-dry condition or after it has been soaked in water, but ensure that the surfaces of the pipe are dry when the pipe is tested.

NOTE If a pipe fails when tested in the air-dry condition, it may be soaked in water and the retested.

C.2 Procedure

a) Use machined test heads having dimensions and profiles such that they match the ends of the pipe under test and are capable of sealing, or use any other suitable method of sealing the ends of the pipe.

b) Connect the pipe (through the closure at one end) to a suitable source of hydraulic pressure. Fill the pipe with water and ensure that all the air has been removed from the pipe.

c) Apply pressure at a rate not exceeding 70 kPa/5 s, until a test pressure of 140 kPa has been reached.

d) Maintain this test pressure for 2 min and then examine the pipe for signs of leakage.

NOTE Regard as leakage any drops forming on the surface and subsequently running or falling away from the point of

formation.

DRS 265: 2021

19 ©RSB 2021 - All rights reserved

Bibliography

RS 265: 2015, Precast reinforced concrete pipe culvert — Specification

DRS 265: 2021

Price based on 18 pages

©RSB 2021 - All rights reserved